Lithium ion battery positive electrode material lithium-enriched doped lithium molybdate and preparation method thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex crystal structure and uncertainty, achieve high specific capacity, reduce defects, and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

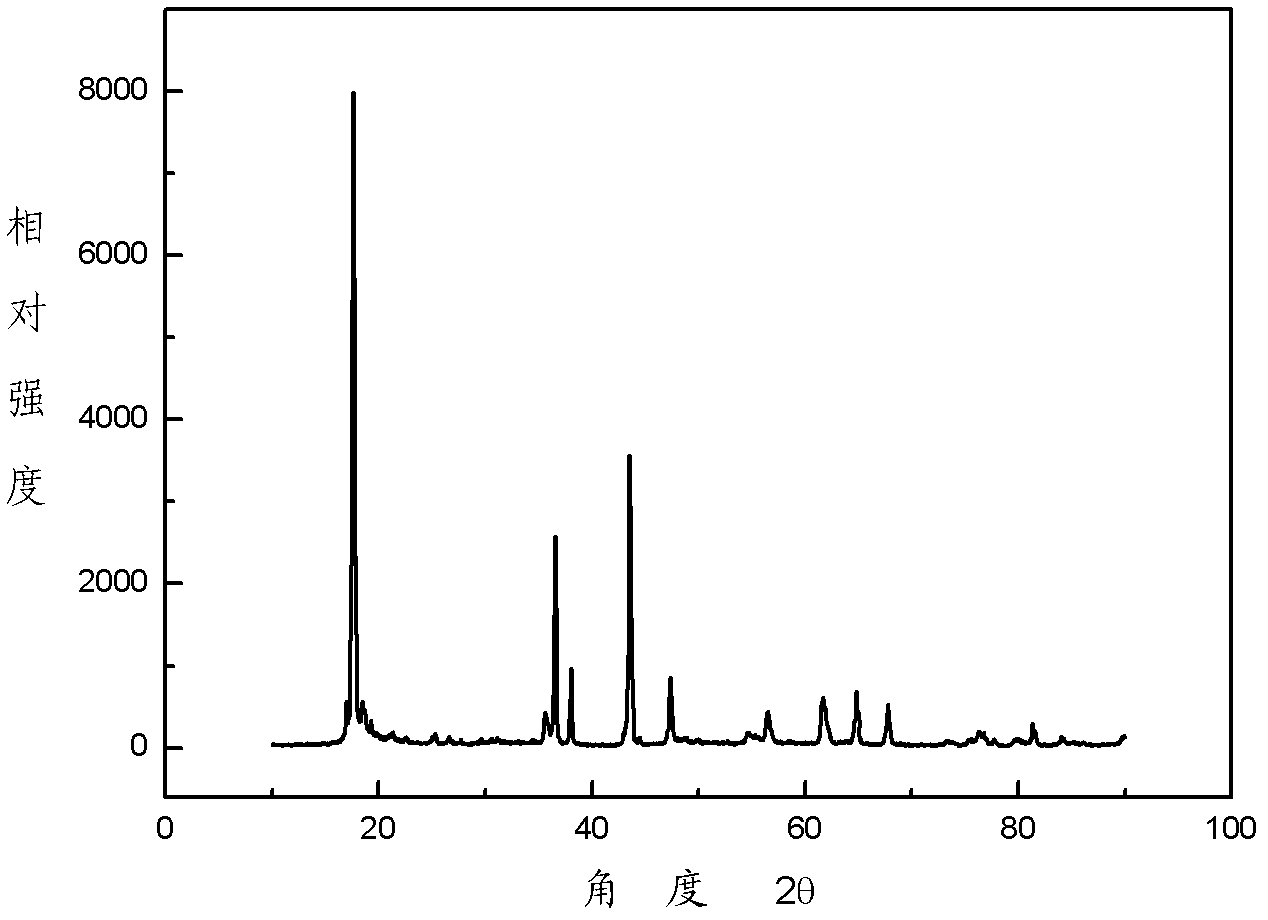

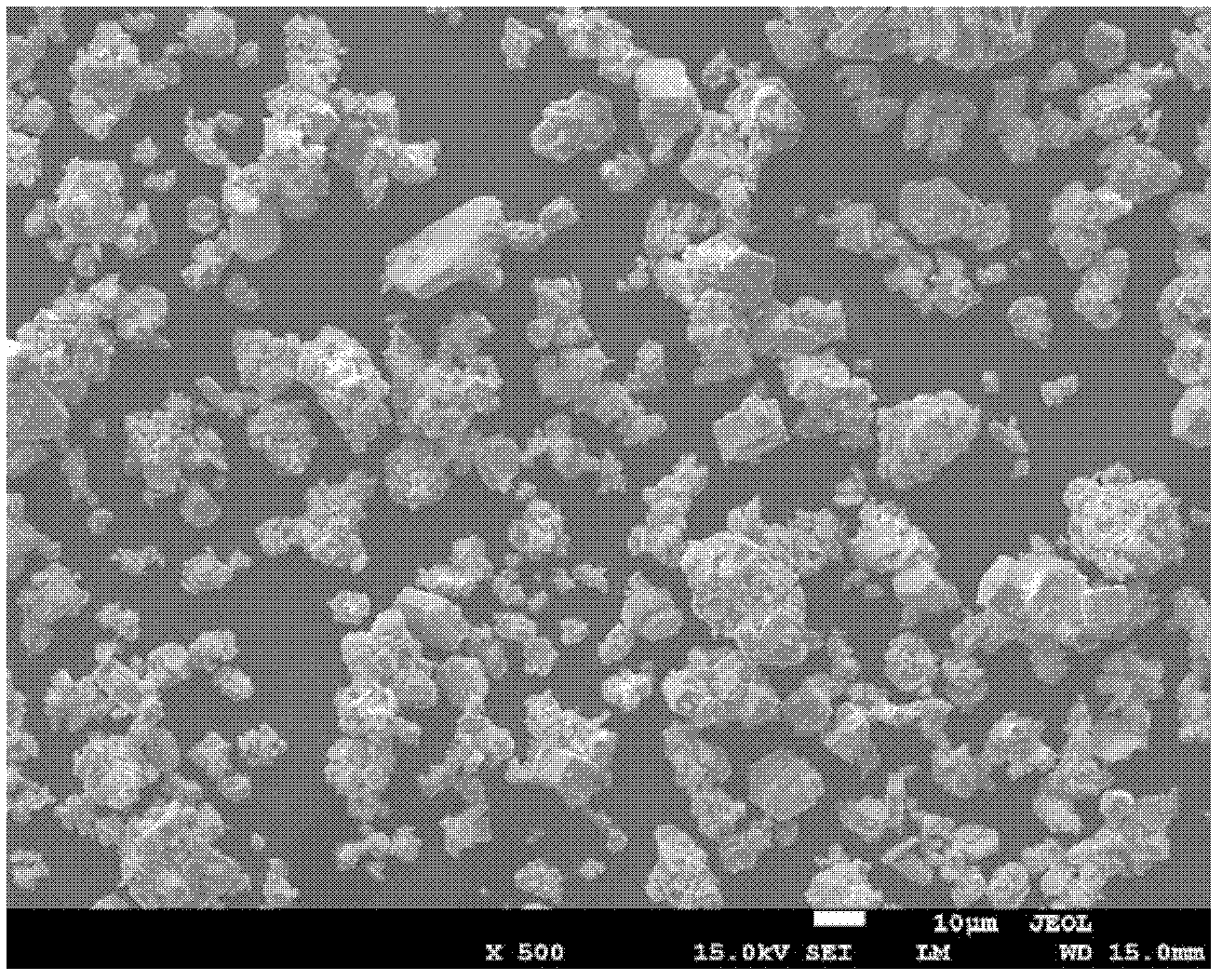

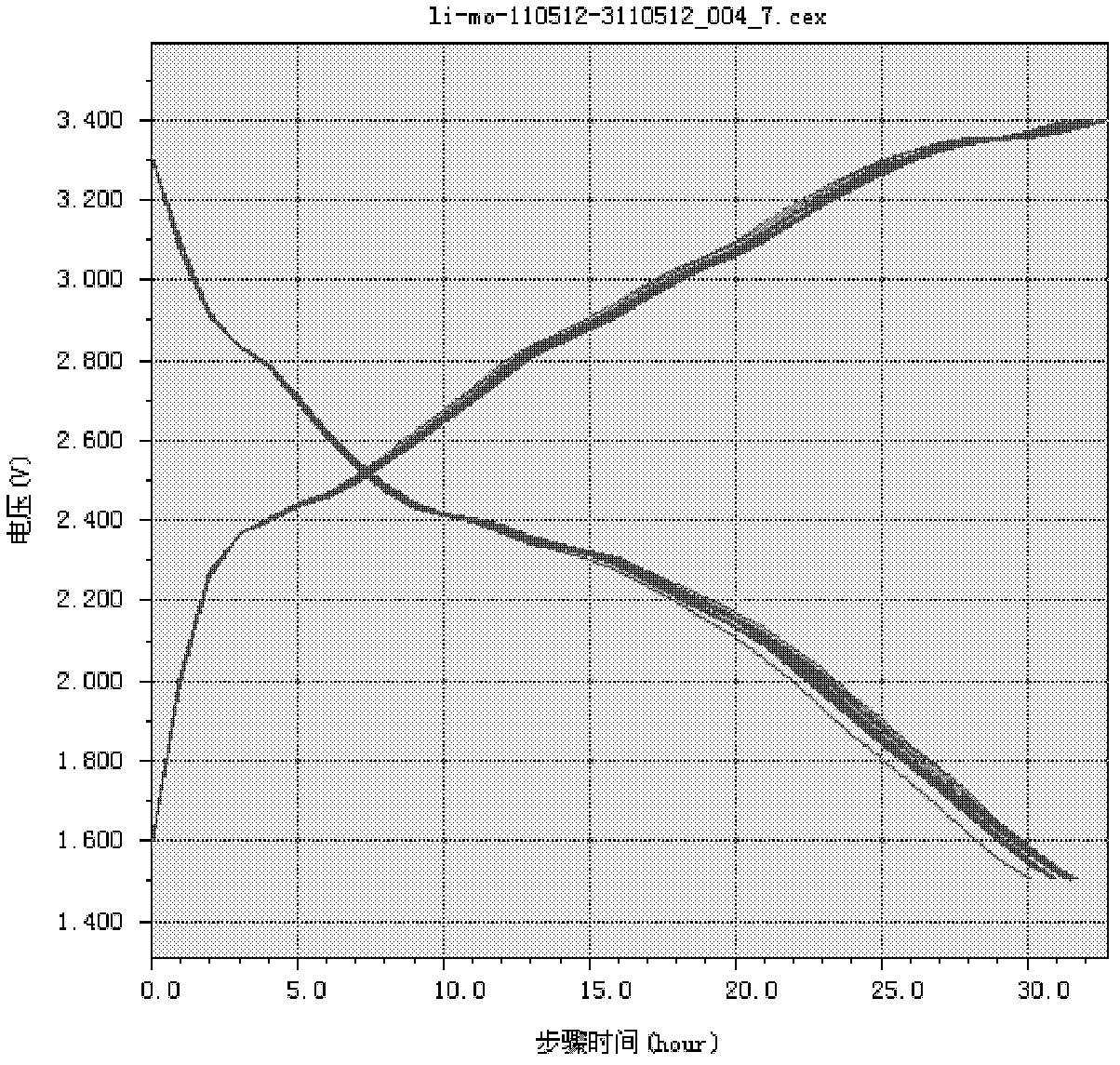

[0021] Example 1 Lithium-rich manganese-doped lithium molybdate Li 2 mn 0.7 Mo 0.3 o 3 (x=0.3) Preparation

[0022] 1, adopt lithium carbonate, molybdenum trioxide, manganese dioxide, active carbon as raw material, the consumption of raw material is Li: Mo: Mn: C=2: 0.3: 0.7: 2 by the molar ratio of raw material, wherein lithium carbonate 14.8 grams, 4.3 grams of molybdenum trioxide, 6.1 grams of manganese dioxide, and 2.4 grams of activated carbon are placed in an agate mortar to grind the raw materials evenly, then the mixture powder is added to 100 g of aqueous solution containing 5 g of polyvinyl alcohol, and stirred for 3 hours to make the mixture Evenly disperse to obtain a mixed solution.

[0023] 2. The temperature of the above mixture was raised to 90° C., stirred and dried for 48 hours to obtain a xerogel.

[0024] 3. Put the above dry gel into an alumina crucible, and heat it in a tubular heating furnace under an argon protective atmosphere. Rapidly raise the ...

Embodiment 2

[0034] Example 2, lithium-rich titanium doped lithium molybdate Li 2 Ti 0.1 Mo 0.9 o 3 (x = 0.9) Preparation

[0035] 1, adopt lithium carbonate, molybdenum trioxide, titanium dioxide, active carbon as raw material, the consumption of raw material is Li: Mo: Ti: C=2: 0.9: 0.1: 2 by the molar ratio of raw material, wherein lithium carbonate 14.8 grams, trioxide 12.96 grams of molybdenum, 0.8 grams of titanium dioxide, and 2.4 grams of activated carbon are placed in an agate mortar to grind the raw materials evenly, then the mixture powder is added to 100 g of aqueous solution containing 6 g of polyvinyl alcohol, stirred for 5 hours, and the mixture is uniformly dispersed to obtain Mixture.

[0036] 2. The temperature of the mixture was raised to 80° C., stirred and dried for 36 hours to obtain a xerogel.

[0037] 3. Put the above dry gel into an alumina crucible, and heat it in a tubular heating furnace under an argon protective atmosphere. Rapidly raise the temperature t...

Embodiment 3

[0040] Embodiment 3, lithium-rich type ruthenium doped lithium molybdate Li 2 Ru 0.4 Mo 0.6 o 3 (x=0.6) Preparation

[0041] 1, adopt lithium carbonate, molybdenum trioxide, ruthenium oxide, active carbon as raw material, the consumption of raw material is Li: Mo: Ru: C=2: 0.6: 0.4: 2 by the mol ratio of the raw material, wherein lithium carbonate 14.8 grams, three 8.63 grams of molybdenum oxide, 5.32 grams of ruthenium dioxide, and 2.4 grams of activated carbon, put the raw materials in an agate mortar and grind them evenly, then add the mixture powder to 100 g of aqueous solution containing 9 g of polyvinyl alcohol, stir for 6 hours, and make the mixture uniform Disperse to obtain a mixed solution.

[0042] 2. The temperature of the above mixture was raised to 85° C., stirred and dried for 24 hours to obtain a xerogel.

[0043] 3. Put the above dry gel into an alumina crucible, and heat it in a tubular heating furnace under an argon protective atmosphere. Rapidly raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com