Zinc oxide voltage-sensitive ceramic and preparation method thereof, as well as zinc oxide voltage-sensitive resistor and preparation method thereof

A technology of varistor ceramics and varistors, applied in varistors, varistor cores, resistance manufacturing, etc., can solve the problem of high sintering temperature varistor voltage threshold, small nonlinear coefficient, small leakage current density, etc. problem, achieve the effect of optimizing grain boundary composition and structure, reducing sintering temperature, and lowering threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The second aspect of the present invention provides the preparation method of the zinc oxide varistor ceramics, the preparation steps comprising:

[0052] Step 1, provide the dried powder according to the following mole percentage, wherein,

[0053] ZnO 94.5 ~98%;

[0054] Bi 2 o 3 0 ~ 1%;

[0055] co 2 o 3 0 ~ 1%;

[0056] V 2 o 5 0 ~ 2%;

[0057] CaF 2 0 ~ 1%;

[0058] Ba(NO 3 ) 2 0 ~ 0.5%;

[0059] Na 2 WO 4 0 ~ 0.5%;

[0060] Li 2 MoO 4 0 ~ 0.5%;

[0061]Step 2, adding lubricant to the dried powder provided in Step 1, and ball milling;

[0062] Step 3, after drying the powder obtained in step 2, pre-burning to obtain powder;

[0063] Step 4, pressing the powder obtained in Step 3 into a green body;

[0064] In step five, the green body obtained in step four is heated to 800-1200° C., kept warm, and cooled to obtain zinc oxide varist...

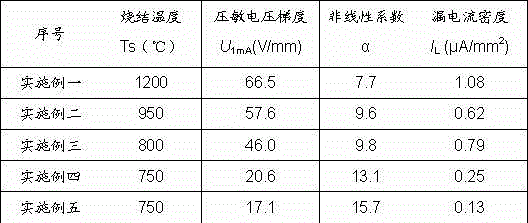

Embodiment 1

[0084] Step 1, provide the dried powder according to the following mole percentage, wherein,

[0085] ZnO 98%;

[0086] Bi 2 o 3 1 %;

[0087] co 2 o 3 1 %;

[0088] In step 2, the dried powder provided in step 1 is milled in a ball mill at a rate of 300 r / min for 24 h with absolute ethanol as a lubricant and zirconia balls as a ball milling medium;

[0089] Step 3, after drying the powder obtained in Step 2, pre-calcine at 600 °C for 2 h to obtain a powder;

[0090] Step 4, pressing the powder obtained in Step 3 under 10 MPa into a disc green body with a diameter of about 10 mm and a thickness of about 1 mm;

[0091] Step 5, heating the green body obtained in Step 4 to 1200°C at a rate of 5°C / min, cooling naturally after a holding time of 4 hours, and obtaining sintered zinc oxide varistor ceramics;

[0092] Step 6: Coarsely grind and finely grind the upper and lower surfaces of the zinc oxide varistor ceramic obtained in step 5, coa...

Embodiment 2

[0094] Step 1, provide the dried powder according to the following mole percentage, wherein,

[0095] ZnO 96%;

[0096] Bi 2 o 3 1 %;

[0097] co 2 o 3 1 %;

[0098] V 2 o 5 2 %;

[0099] In step 2, the dried powder provided in step 1 is milled in a ball mill at a rate of 300 r / min for 24 h with absolute ethanol as a lubricant and zirconia balls as a ball milling medium;

[0100] Step 3, after drying the powder obtained in Step 2, pre-calcine at 600 °C for 2 h to obtain a powder;

[0101] Step 4, pressing the powder obtained in Step 3 under 10 MPa into a disc green body with a diameter of about 10 mm and a thickness of about 1 mm;

[0102] Step five, heating the green body obtained in step four to 950°C at a rate of 5°C / min, cooling naturally after a holding time of 4 hours, and obtaining sintered zinc oxide varistor ceramics;

[0103] Step 6: Roughly and finely grind the upper and lower surfaces of the zinc oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com