High-temperature lithium battery cathode material, preparation method thereof and high-temperature lithium battery

A high-temperature lithium battery and cathode material technology, applied in the field of materials, can solve problems such as insufficient discharge capacity, and achieve the effect of excellent discharge capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a method for preparing a high-temperature lithium battery positive electrode material, which includes the following steps;

[0049] Step S1: preparing lithium molybdate.

[0050] For the preparation of lithium molybdate in step S1, the present invention provides the following two preparation methods.

[0051] Among them, method one includes the following steps:

[0052]Step S11: Weighing the lithium source and the molybdenum source according to the molar ratio of Li:Mo=(2~2.2):1, grinding and mixing to obtain the mixture B;

[0053] Step S12: placing the mixture B obtained in step S11 in an air atmosphere, sintering at a temperature of 450-700° C. for 3-10 hours, and obtaining lithium molybdate after cooling;

[0054] Step S13: placing the lithium molybdate obtained in step S12 under a reducing atmosphere, reducing at a temperature of 700-900° C. for 10-20 hours at a high temperature, and obtaining the lithium molybdate after cooling.

[0055] ...

Embodiment 1

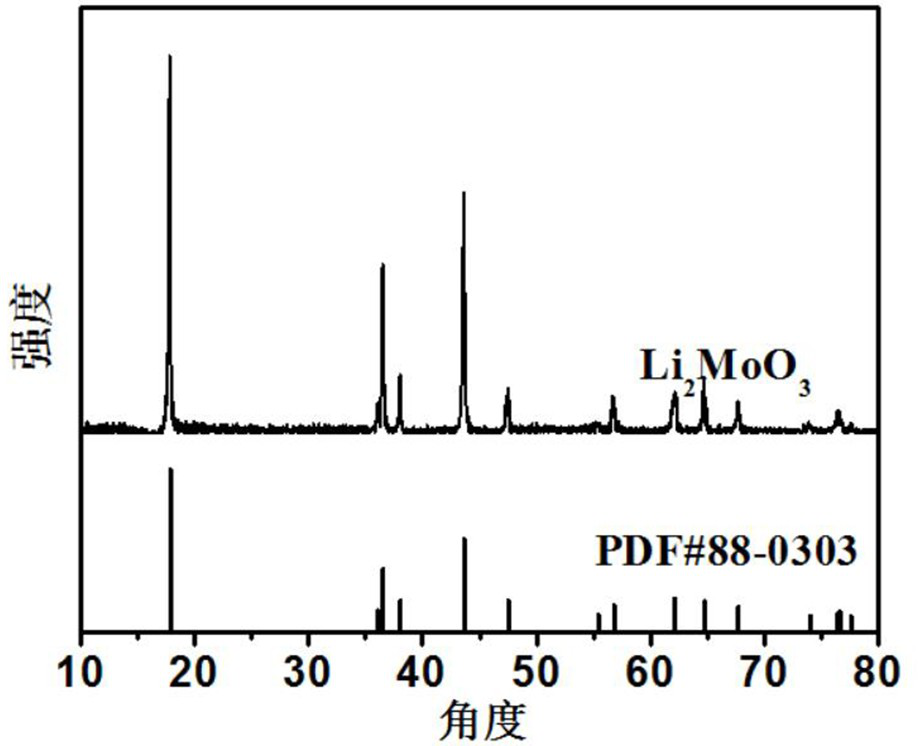

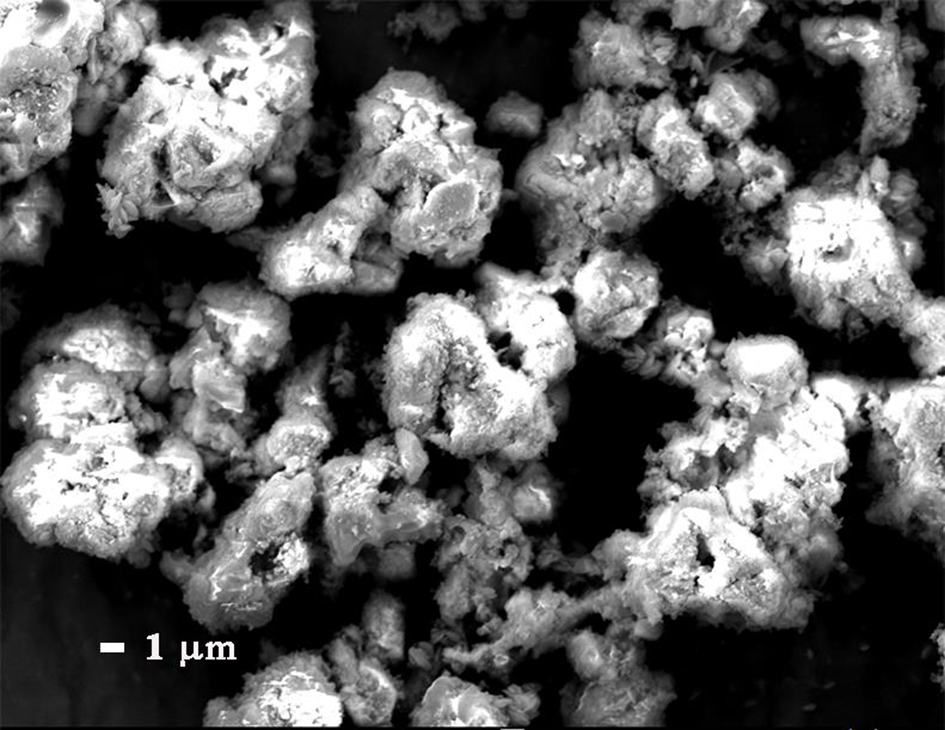

[0073] According to the mol ratio of Li:Mo=2:1, take by weighing 14.8g lithium carbonate and 28.8g molybdenum trioxide with analytical balance, the lithium carbonate and molybdenum trioxide that take are poured in the agate mortar, after fully grinding, pass 150 mesh sieves to obtain mixture B.

[0074] Put the mixture B into a corundum crucible and place it in a muffle furnace for sintering. The sintering atmosphere is air, and the temperature is raised at a heating rate of 5°C / min, and then sintered at 550°C for 5 hours. The sintered product is cooled to room temperature with the furnace. Then take it out to get lithium molybdate.

[0075] Grind the obtained lithium molybdate and pass through a 150-mesh sieve, put it into a crucible and place it in a tube furnace for high-temperature reduction; pass hydrogen-argon mixed gas into the tube furnace (the content of hydrogen is 5%) A reducing atmosphere is formed, and the rate of hydrogen-argon gas mixture is 150mL / min; the tube...

Embodiment 2

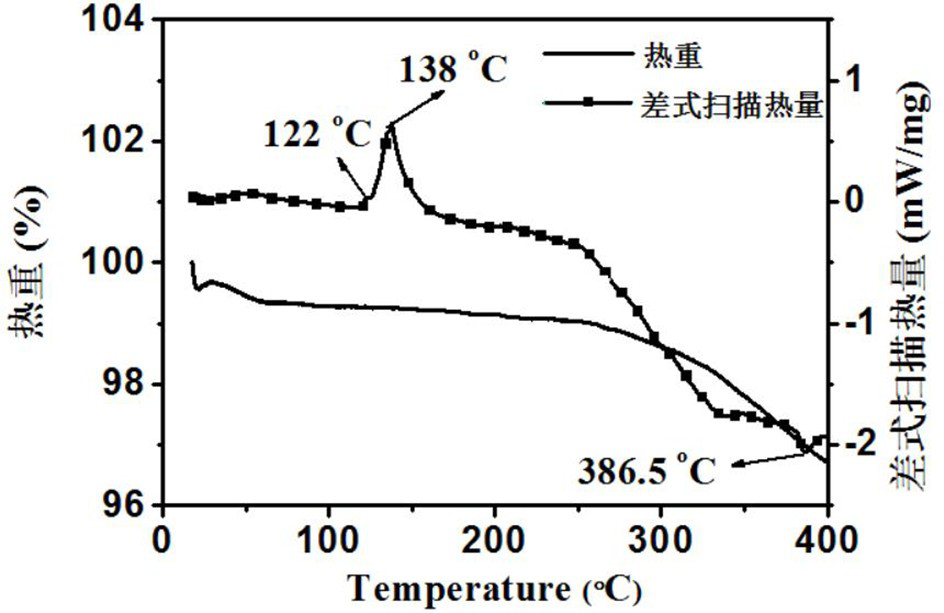

[0079] According to the mol ratio of Li:Mo=2:1, take by weighing 3.0g lithium carbonate and 5.1g molybdenum dioxide with analytical balance, pour the lithium carbonate and molybdenum dioxide that take into agate mortar, after fully grinding, pass 150 mesh sieves to obtain mixture B.

[0080] Put the mixture B into a corundum crucible and place it in a tube furnace. Argon gas is introduced into the tube furnace to form an inert gas atmosphere. The rate of argon gas introduction is 100mL / min; The heating rate is raised to 600°C, and the temperature is kept for sintering for 4 hours; then, the tube furnace continues to heat up to 800°C at a rate of 5°C / min, and the temperature is kept for sintering for 10 hours; the sintered product is cooled to room temperature with the furnace and taken out to obtain molybdenum Lithium Oxide.

[0081] The obtained lithium molybdate is ground and crossed a 200 mesh sieve; the lithium molybdate, 2.0g lithium nitrate and potassium nitrate formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com