Preparation method for improving quality factor of lithium molybdate microwave dielectric ceramic

A technology of microwave dielectric ceramics and quality factor, which is applied in the field of ceramic compositions, can solve the problems such as inability to eliminate the uneven distribution of raw materials, difficult to obtain the purity target phase, affecting the performance of ceramic materials, etc., so as to improve the microwave dielectric performance, Improve the quality factor and avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

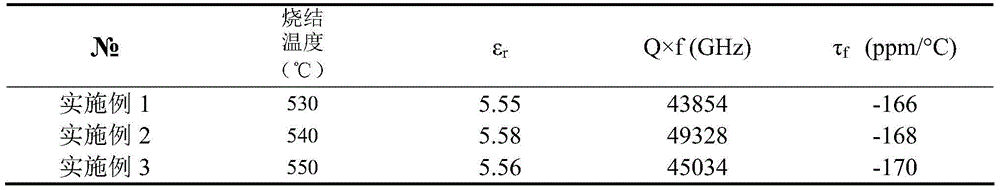

Examples

Embodiment Construction

[0020] The present invention adopts the analytically pure raw material (NH 4 ) 6 Mo 7 o 24 4H 2 O and LiOH·H 2 O preparation of microwave dielectric ceramics, the specific implementation is as follows.

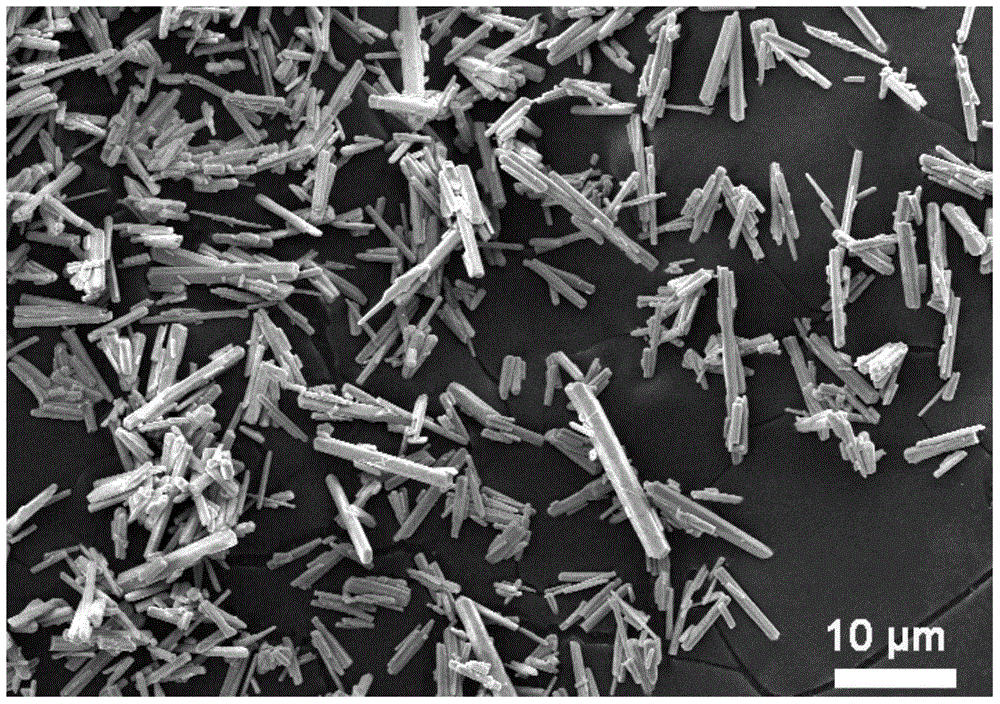

[0021] Raw materials (NH 4 ) 6 Mo 7 o 24 4H 2 O and LiOH·H 2 O mole ratio (NH 4 ) 6 Mo 7 o 24 4H 2 O: LiOH·H 2 O=1:14 Weigh the ingredients. Put the mixed powder into a beaker, add deionized water and magnetically stir for 30 minutes to fully dissolve the powder to obtain a clear solution, transfer the obtained solution to a mortar, put the mortar into a constant temperature heating mantle, heat, and make the solution The temperature was controlled at 60°C. When all the water in the mortar has evaporated, stop heating, and a white powder is obtained on the inner wall of the mortar. Add absolute alcohol into the mortar as a dispersant, the weight ratio of powder and absolute alcohol is 1:2, grind for 15 minutes, and dry the powder to obtain a powder with unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com