Lithium molybdate nano-rod electronic packaging material

An electronic packaging material and nanorod technology, which is applied in the field of lithium molybdate nanorod electronic packaging materials, can solve the problems of difficulty in meeting the performance requirements of electronic packaging materials, large thermal expansion coefficient, poor aging resistance, etc. Low energy consumption, low thermal expansion coefficient and good insulation

Active Publication Date: 2015-12-23

ANHUI UNIVERSITY OF TECHNOLOGY

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Although inorganic non-metallic electronic packaging materials have the characteristics of high strength, small thermal expansion coefficient, and good aging resistance, they have the disadvantages of difficult processing and high preparation temperature.

Polymer electronic packaging materials have the characteristics of easy processing, good insulation, and low preparation temperature, but they also have disadvantages such as large thermal expansion coefficient and poor aging resistance.

Therefore, it is difficult for a single material to meet the performance requirements of electronic packaging materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

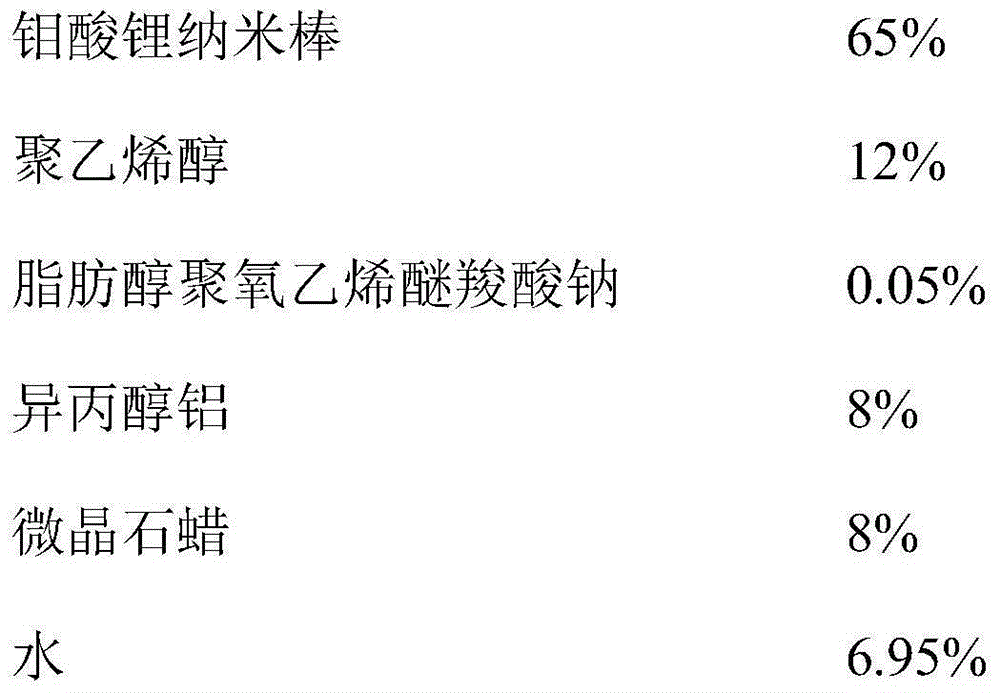

Embodiment 1

[0020] The mass percentage composition of the lithium molybdate nanorod electronic packaging material is determined as follows:

[0021]

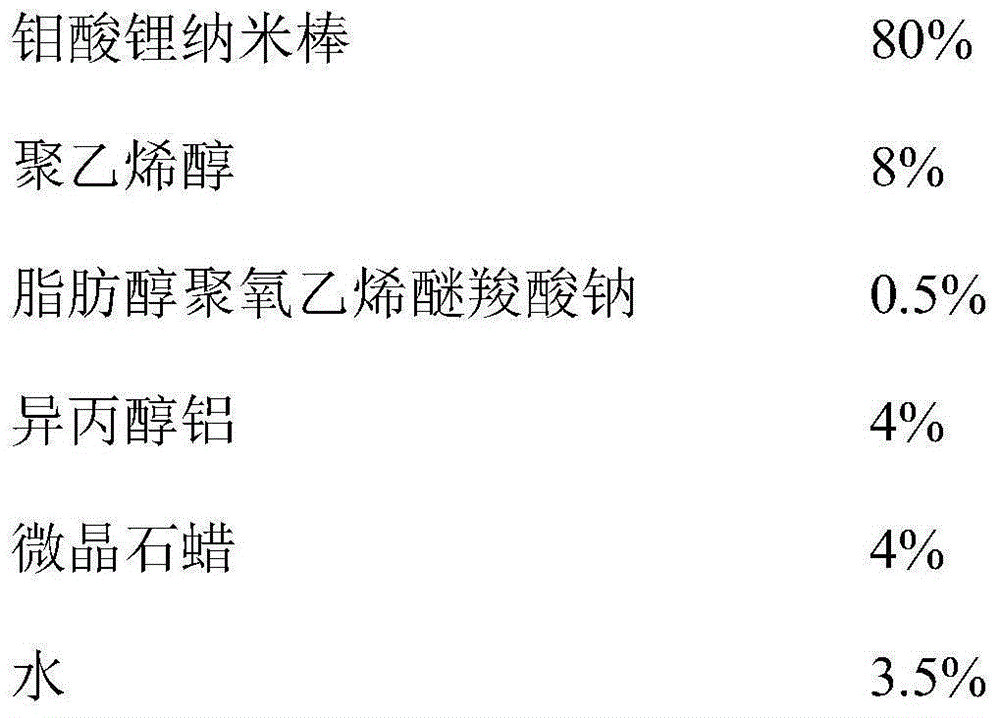

Embodiment 2

[0023] The mass percentage composition of the lithium molybdate nanorod electronic packaging material is determined as follows:

[0024]

Embodiment 3

[0026] The mass percentage composition of the lithium molybdate nanorod electronic packaging material is determined as follows:

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

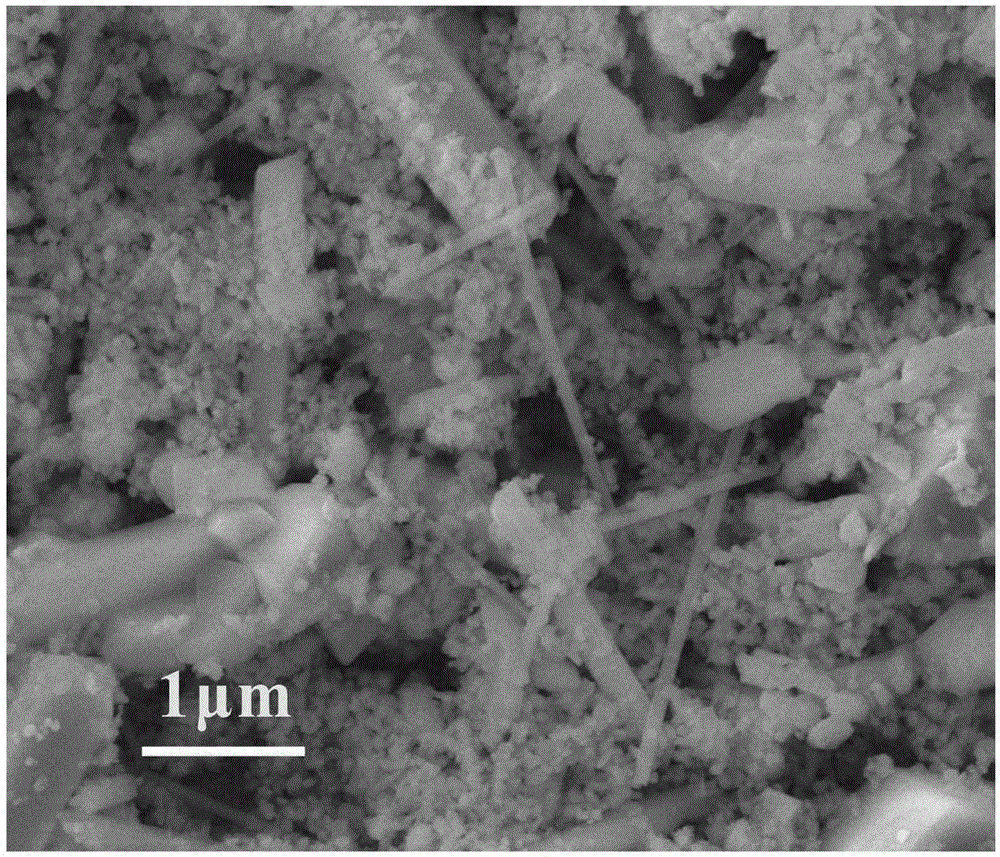

The invention discloses a lithium molybdate nano-rod electronic packaging material, and belongs to the technical field of electronic packaging materials. The lithium molybdate nano-rod electronic packaging material comprises, by mass, 65-80% of lithium molybdate nano-rods, 8-12% of polyvinyl alcohol, 0.05-0.5% of sodium fatty alcohol polyoxyethylene ether carboxylate, 4-8% of aluminum isopropoxide, 4-8% of microcrystalline paraffin and 3-7% of water, the diameter of the lithium molybdate nano-rods is 50-100nm, and the length of the lithium molybdate nano-rods is 1-3[mu]m. The lithium molybdate nano-rod electronic packaging material has the characteristics of good insulation property, excellent ageing and corrosion resistance, high heat conduction coefficient, small heat expansion coefficient, good workability, simple preparation process and low preparation temperature, and has good application prospect in the field of electronic packaging materials.

Description

technical field [0001] The invention belongs to the technical field of electronic packaging materials, and particularly relates to a lithium molybdate nanorod electronic packaging material. Background technique [0002] With the miniaturization, multi-function and high performance of electronic devices, the requirements for electronic packaging materials are getting higher and higher. As an ideal electronic packaging material, it is required to have the characteristics of small thermal expansion coefficient, high thermal conductivity, good insulation, excellent aging resistance and corrosion resistance, and easy processing. Improve the lifespan of electronic equipment and enhance the ability to adapt to the environment. [0003] The national invention patent "Ceramic Powder for Electronic Components Packaging Materials and Its Production Method" (National Invention Patent No.: ZL201210396718.8) contains barium oxide, boron oxide, silicon oxide, aluminum oxide, zinc oxide, z...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L29/04C08L91/06C08L71/02C08K3/24C08K5/057

Inventor 裴立宅林楠吴胜华蔡征宇

Owner ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com