Preparation method of coated multilayer precursor and application

A precursor and cladding technology, which is applied in the field of the preparation of clad multilayer precursors, can solve the problems of increased battery polarization, less cladding, reduced material rate performance and energy density, etc., so as to improve safety performance. , reduce side reactions, slow down the effect of resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

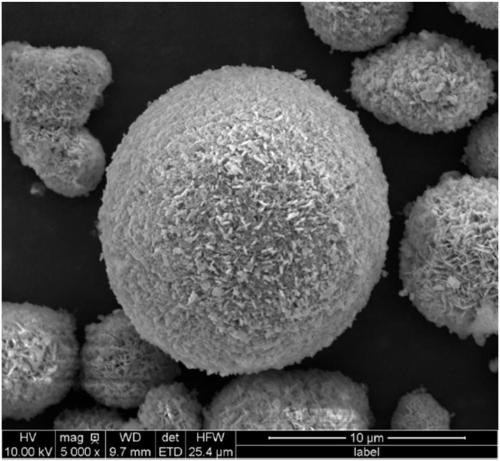

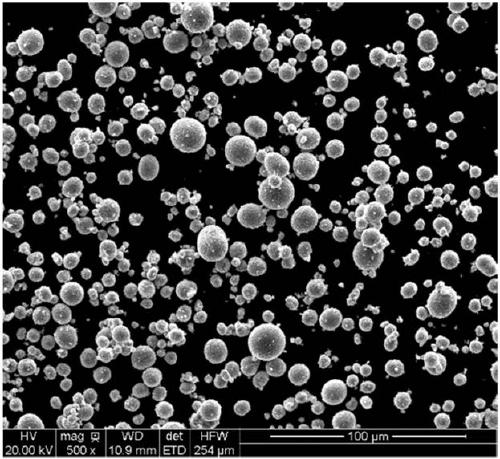

[0104] Example 1 Preparation of ternary cathode material C1

[0105] Prepare a mixed solution according to the molar ratio of Ni, Co, and Mn as 8:1:1, weigh 46.53g, 5.82g, and 5.02g of nickel nitrate hexahydrate, cobalt nitrate hexahydrate, and manganese nitrate tetrahydrate, respectively, and add 100mL of water to dissolve. Prepare 1000mL of a mixed solution of 2mol / L NaOH and 1.5mol / L ammonia water.

[0106] In the reaction kettle protected by argon, add 200mL water, add the mixed solution, 2mol / L NaOH solution and 2mol / L ammonia solution into the reaction kettle at the same time, the final pH of the solution is controlled at 11.5, after the sedimentation is completed, the precipitate Filter and wash, and dry at 80°C to obtain precursor P1, the chemical composition is Ni 0.8 co 0.1 mn 0.1 (HO) 2 .

[0107] Weigh 10g of the above-mentioned P1 precursor, mix according to the molar ratio of lithium salt to precursor 1.05:1, weigh LiOH·H 2 O4.77g was mixed evenly with the ...

Embodiment 2

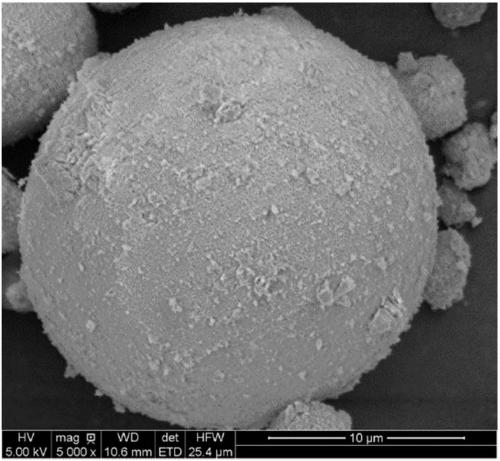

[0108] Example 2 Preparation of Lithium Iron Phosphate Cathode Material C2

[0109] Weigh 40.40 g of ferric nitrate nonahydrate and 13.21 g of diammonium hydrogen phosphate, and add 100 mL of deionized water to dissolve, respectively, to obtain ferric nitrate solution and diammonium hydrogen phosphate solution. Prepare 100mL of 2mol / L ammonia solution.

[0110] Under the protection of argon, add ferric nitrate solution and diammonium hydrogen phosphate solution into the reaction kettle at the same time, and adjust the pH value to about 5 with ammonia solution. Stir at 40°C for 4 hours. After the sedimentation is over, filter and wash the precipitate, and dry it at 80°C to obtain the precursor P2, whose chemical composition is FePO 4 .

[0111] Weigh 10g of the above-mentioned P2 precursor, mix according to the molar ratio of lithium salt to precursor 1.08:1, weigh LiOH·H 2 Mix O3.00g with the precursor evenly, sinter at 450°C for 6 hours, and then sinter at 750°C for 10 hou...

Embodiment 3

[0112] Example 3 Preparation of lithium cobaltate cathode material C3

[0113] Weigh Co 3 o 4 50g, according to the molar ratio of lithium salt to precursor is 1.05, weigh LiOH·H 2 O27.44g with Co 3 o 4 Mix evenly, sinter at 600°C for 6 hours in an oxygen atmosphere, and then sinter at 900°C for 10 hours to obtain a lithium cobalt oxide cathode material, marked as C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com