Patents

Literature

30results about How to "Small ionic radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-doped garnet type LLZO lithium ion conductor and preparation method thereof

ActiveCN106025348AImprove ionic conductivityImprove electrochemical stabilitySecondary cellsElectrolyte immobilisation/gelificationMetallic lithiumAll solid state

The invention provides a boron-doped garnet type cubic phase structural LLZO lithium ion conductor. The structural expression formula of the boron-doped garnet type cubic phase structural LLZO lithium ion conductor is Li7La(3-x)BxZr2O12, wherein the x is 0.2 to 0.6. The boron-doped garnet type cubic phase structural LLZO lithium ion conductor has relatively high ionic conductivity and has good electrochemical stability on metallic lithium, can be used as a solid electrolyte of an all-solid-state lithium battery or a lithium ion battery, and can also be used as the solid electrolyte of a metallic lithium-air or metallic lithium-sulphur battery.

Owner:SHANGHAI JIAO TONG UNIV

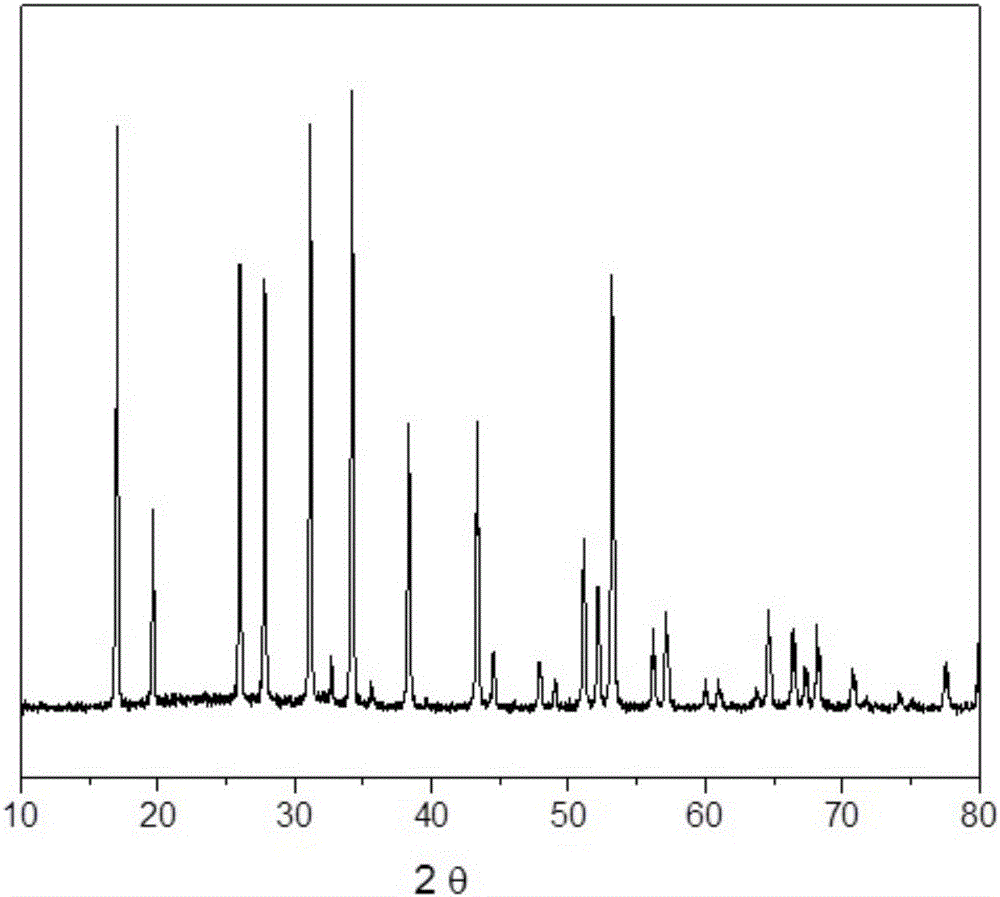

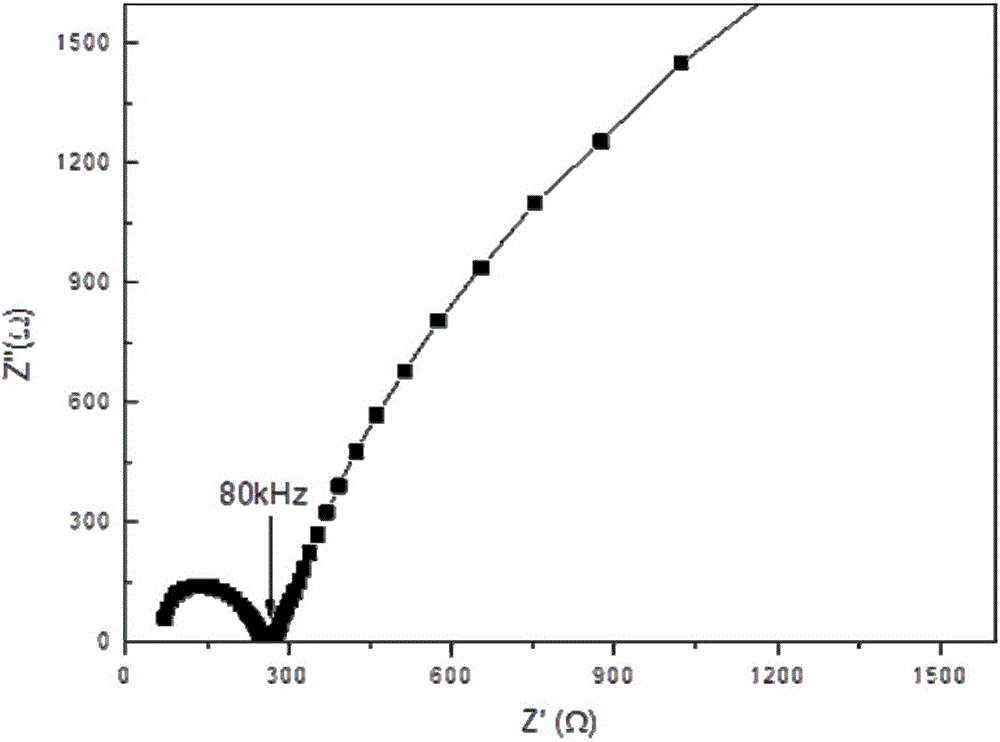

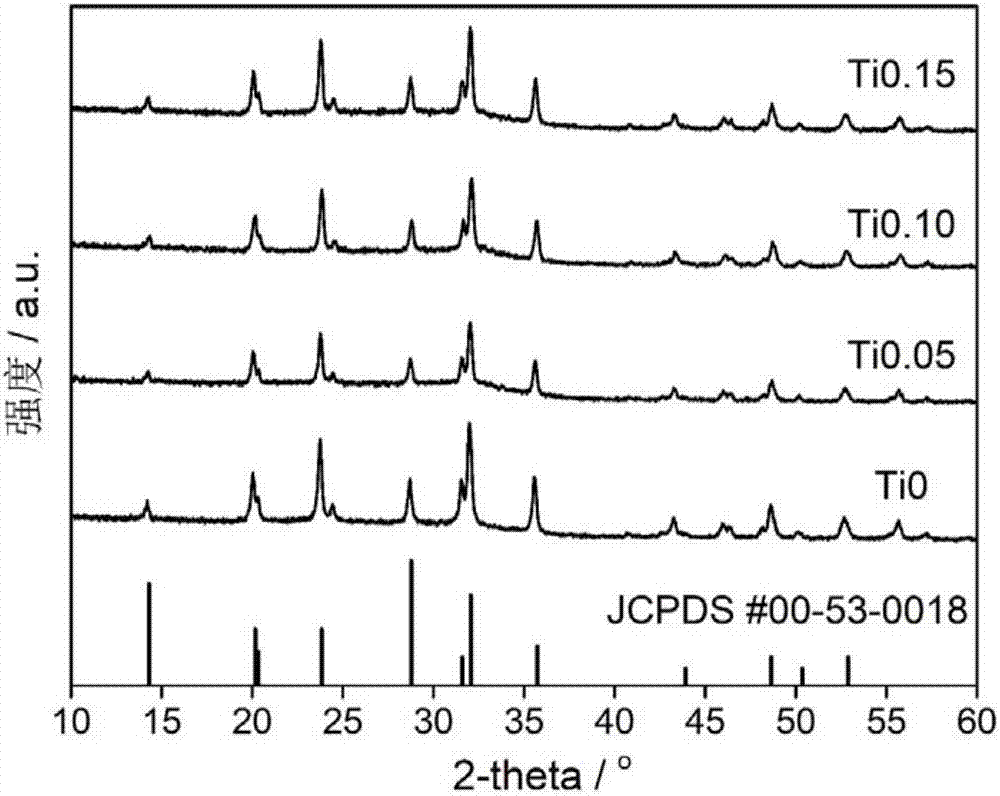

Sodium vanadium phosphate composite electrode material as well as preparation method and application thereof

InactiveCN107425190AElectrochemically activeHigh discharge specific capacityCell electrodesSecondary cellsSodium-ion batteryPromotion effect

The invention relates to a sodium vanadium phosphate composite electrode material as well as a preparation method and application thereof. The sodium vanadium phosphate composite electrode material is a Na3TixV[2-x](PO4)3 / C composite electrode material with a core-shell structure. According to the preparation method, an organic reducing agent and a carbon source are selected, the carbon source can be thermally decomposed into amorphous carbon in the heat treatment process, the formed core refers to Na3TixV[2-x](PO4)3 / C particles, and the shell is a core-shell structure of the amorphous carbon. The unique nano-particle core-shell structure is capable of shortening the sodium ion transport path, improving the ionic conductivity of the material and improving the electronic conductivity through an in-situ coating carbon material, and has a huge promotion effect of improving the electrochemical performance of the Na3TixV[2-x](PO4)3 / C composite electrode material. The composite electrode material disclosed by the invention is widely applied to the technical field of energy storage material and secondary sodium-ion batteries. The invention belongs to the field of electrode materials.

Owner:UNIV OF SCI & TECH BEIJING

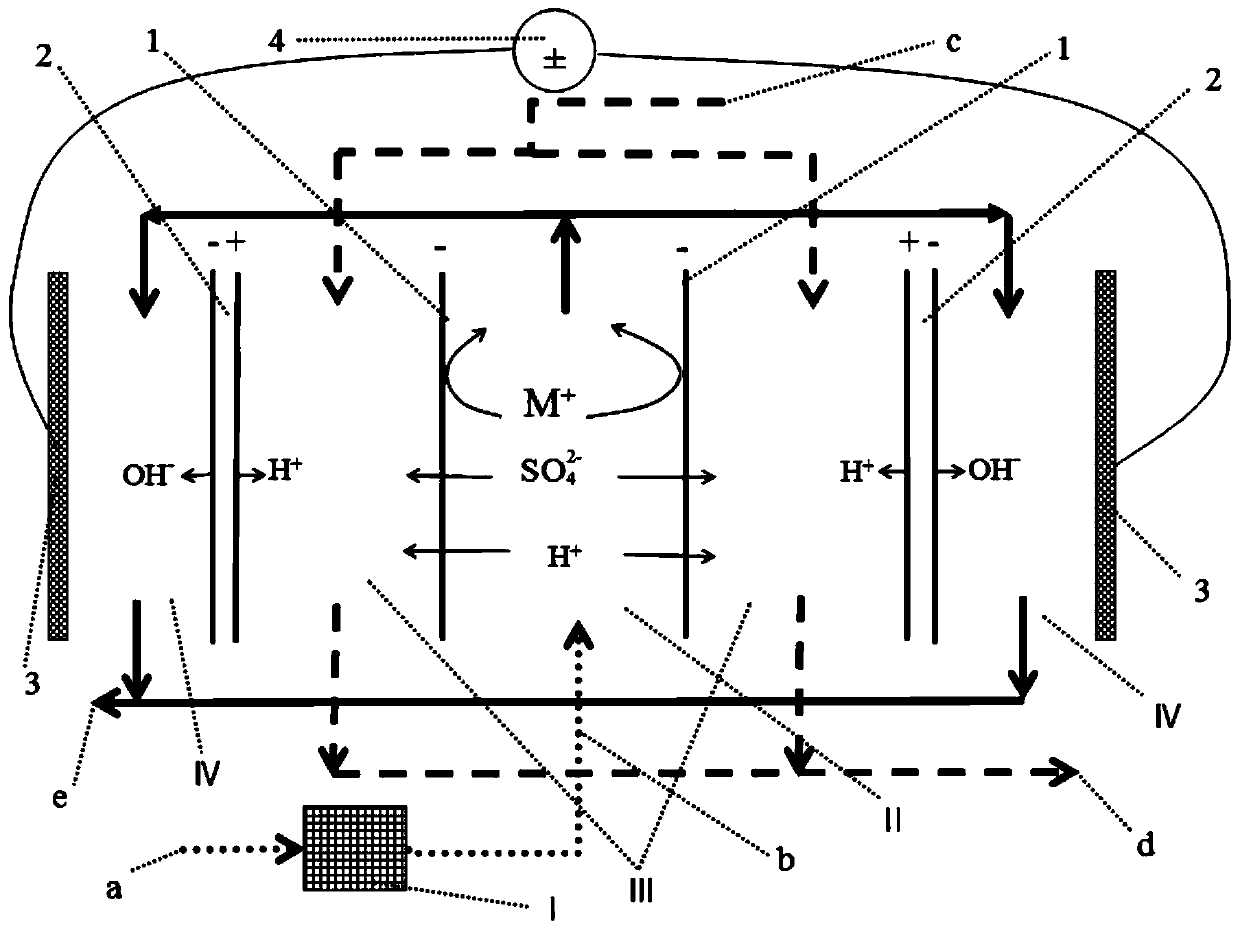

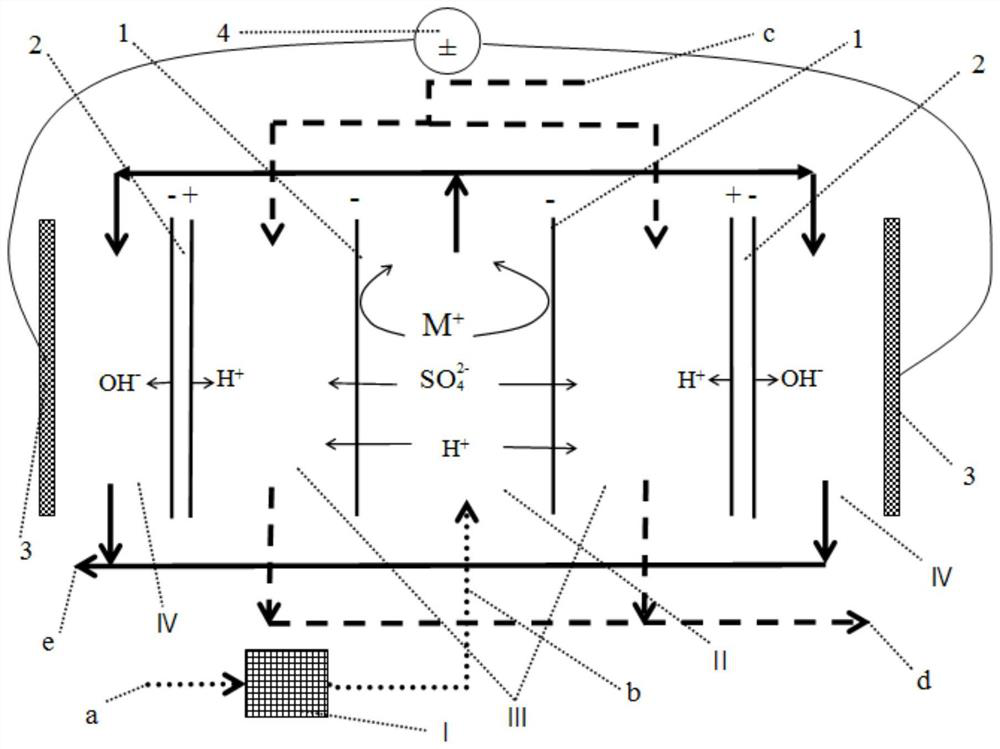

Method for recovering stainless steel acid pickling waste sulfuric acid solution

ActiveCN110835150ASmall ionic radiusLess positive chargeWater contaminantsDispersed particle separationIron sulfateSodium phosphates

The invention discloses a method for recovering a stainless steel acid pickling waste sulfuric acid solution. The method includes steps: pretreating the waste sulfuric acid, and finely removing fine impurities by using a 1-micron-size filter to obtain a pretreated solution; (2) separating and recovering sulfuric acid and a metal salt solution from the pretreated solution by utilizing a periodic reverse pulsed power supply diffusion dialysis-electrodialyzer to obtain recovered acid and residual liquid, respectively; (3) returning the recovered acid to a production line of a workshop for reuse,and after adding a proper amount of sodium phosphate and an alkali agent into the residual liquid to remove heavy metal impurities such as chromium, oxidizing the residual liquid to prepare polyferricsulfate which is a water treatment agent. The periodic reverse pulsed power supply diffusion dialysis-electrodialyzer is utilized for efficient separation of acid from metal ions. The method is low in cost, resources can be fully recovered, and economic and environment protection benefits are good.

Owner:3R ENVIRONMENTAL TECH CO LTD

Paraffin hydrofining catalyst and preparation method thereof

PendingCN111097489AGood dispersionIncrease profitMolecular sieve catalystsPetroleum wax refiningMolecular sievePtru catalyst

The invention discloses a paraffin hydrofining catalyst and a preparation method thereof. A carrier of the paraffin hydrofining catalyst comprises aluminum oxide, layered clay and a Y-type molecular sieve; nickel and molybdenum are taken as active metal components; taking the mass of the paraffin hydrofining catalyst as a reference, the paraffin hydrofining catalyst comprises 2.0%-35.0% of molybdenum oxide, and 0.5%-20.0% of nickel oxide; the dispersity of the active metal components is as follows: IMo / IAl is 0.15-0.30, and INi / IAl is 0.07-0.15. The paraffin hydrofining catalyst is high in active metal utilization rate, high in active metal dispersity and high in activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

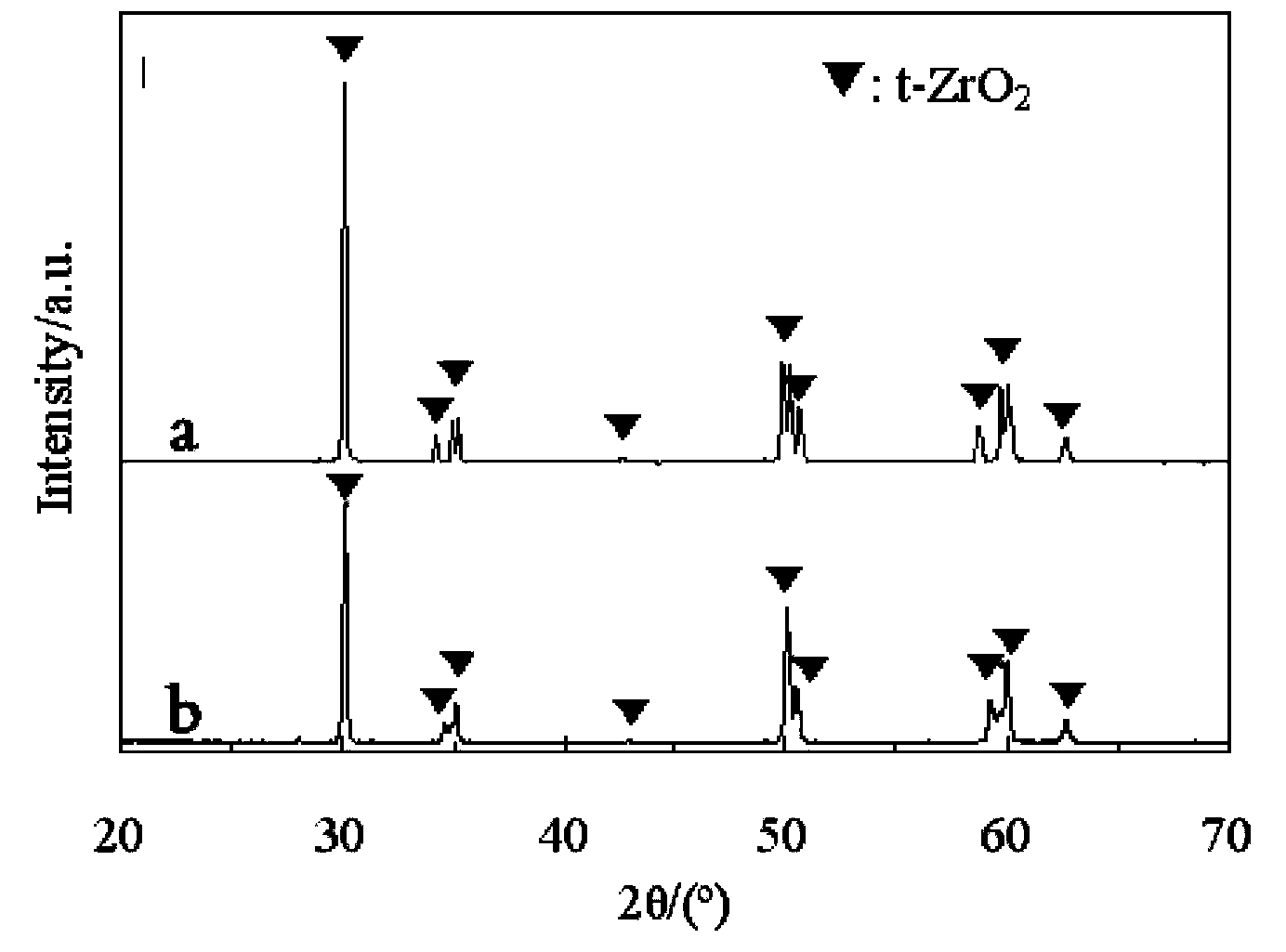

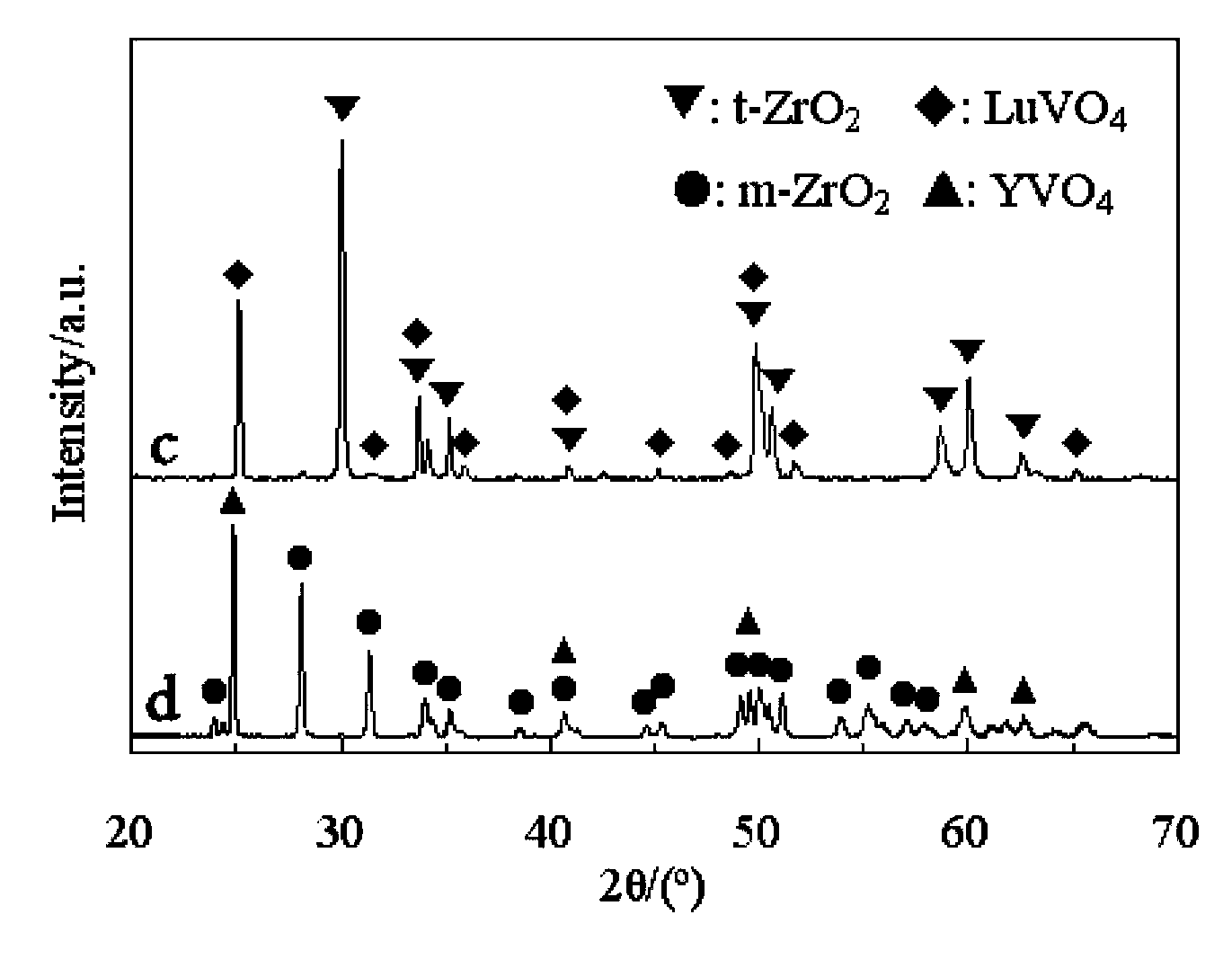

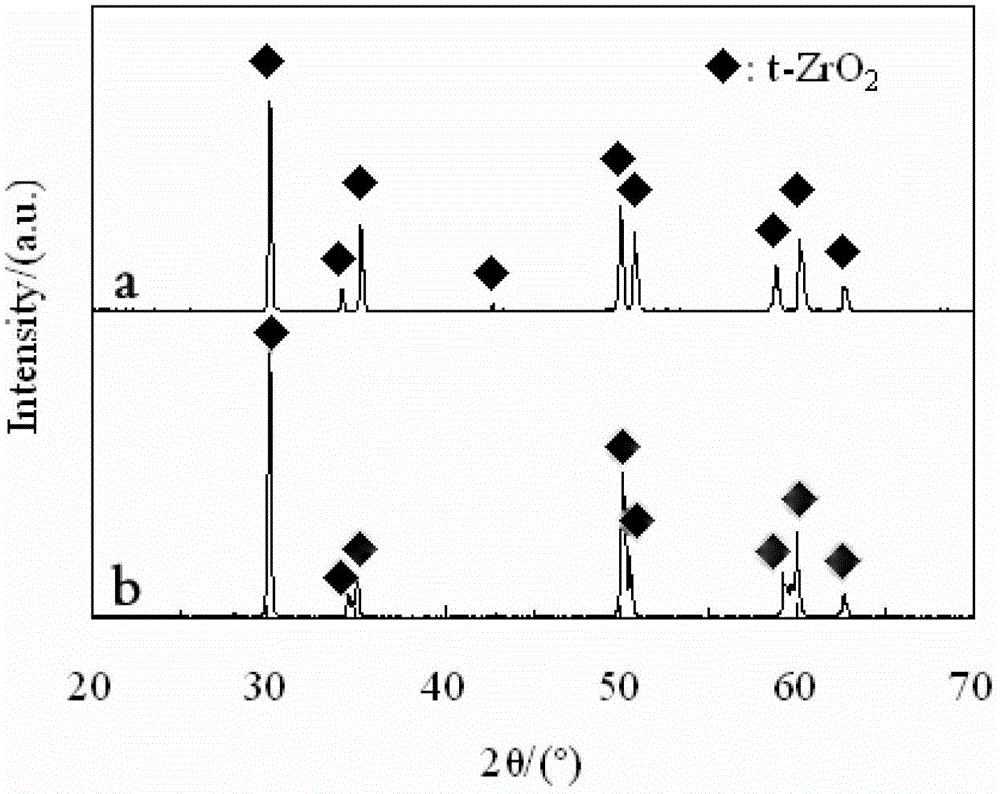

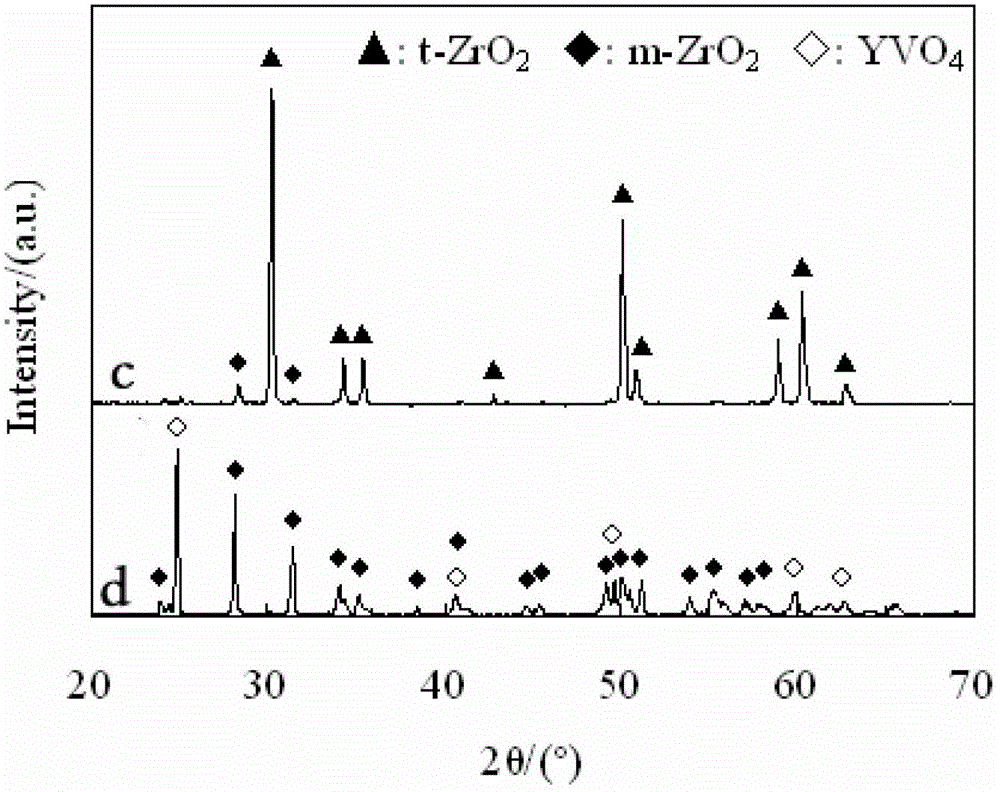

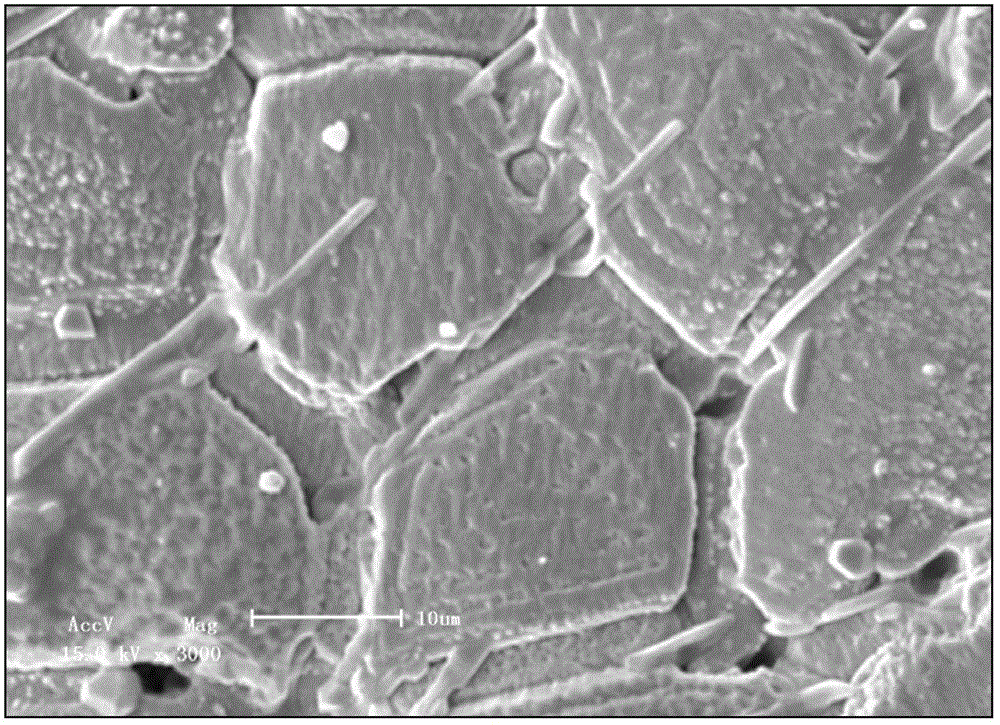

Multi-component stable thermal-corrosion-resistant zirconia coat material

ActiveCN103224391AExcellent molten salt corrosion performanceMolten Salt Corrosion Life ImprovementCorrosion resistantMolten glass

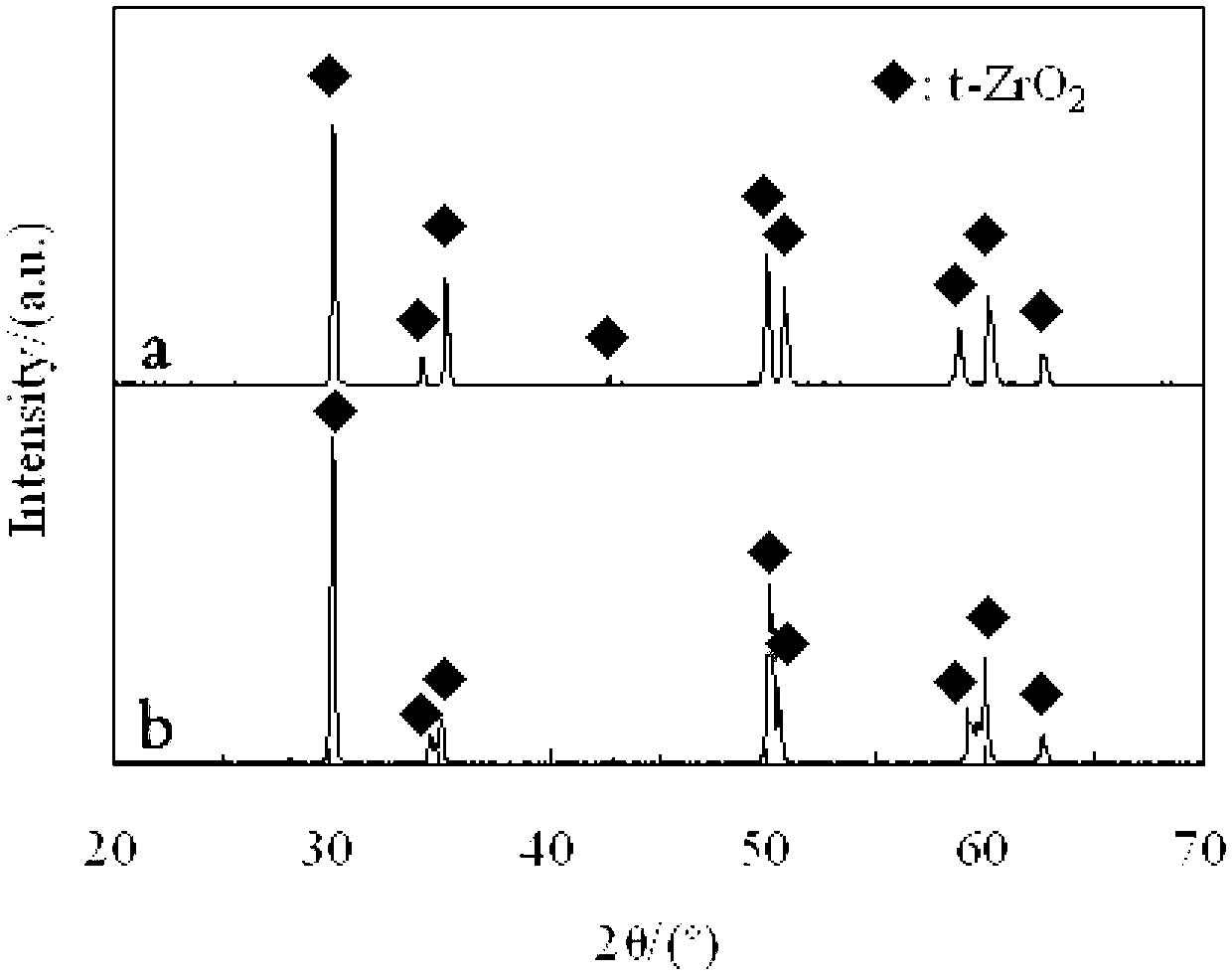

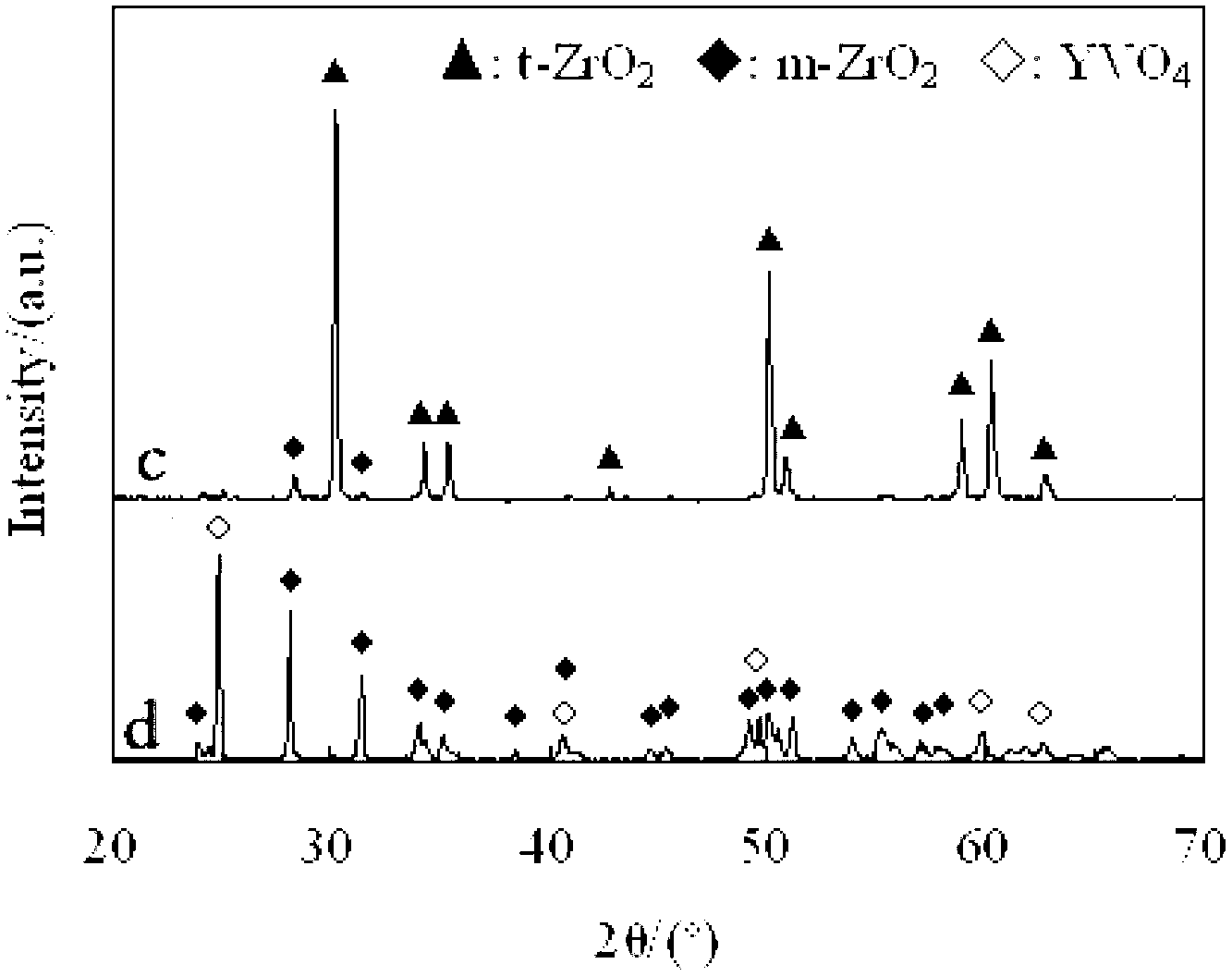

The invention provides a multi-component stable thermal-corrosion-resistant zirconia coat material. The coat material is obtained through mixing a main agent with a stabilizer and carrying out ball milling, the main agent is ZrO2, the stabilizer is a mixture of Ta2O5, In2O3, Al2O3 and TiO2, the molar ratio of Ta2O5: In2O3: Al2O3: TiO2: ZrO2 in the multi-component stable thermal-corrosion-resistant zirconia coat material is x:x:x:x:(100-4x), and x is not greater than 4 and not lower than 2. Tetragonal phase ZrO2 is finally obtained through adopting Ta2O5, In2O3, Al2O3 and TiO2 as the stabilizer to stabilize ZrO2 in the invention. The multi-component stable thermal-corrosion-resistant zirconia coat material has an excellent Na2SO4-V2O5 molten salt corrosion resistance, and an excellent calcium magnesium aluminosilicate molten glass corrosion resistance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Color changing method of artificial sapphire crystal

The invention discloses a color changing method of an artificial sapphire crystal. According to the method disclosed by the invention, coloring ions are dispersed into the artificial sapphire crystal through a relatively low temprature heat treatment technology, so that the color and the transparency of the sapphire crystal are improved. When the sapphire crystal treated by the method disclosed by the invention, colorless sapphire crystals can be changed into crystals with a plurality of colors, the color and luster are uniform and the transparency is better; According to the method, the treatment process is simple and equipment is simple, and the pollution to the environment is avoided. The ornamental value and the market economic value of sapphires treated by the method can be greatly improved.

Owner:HEBEI UNIV OF TECH

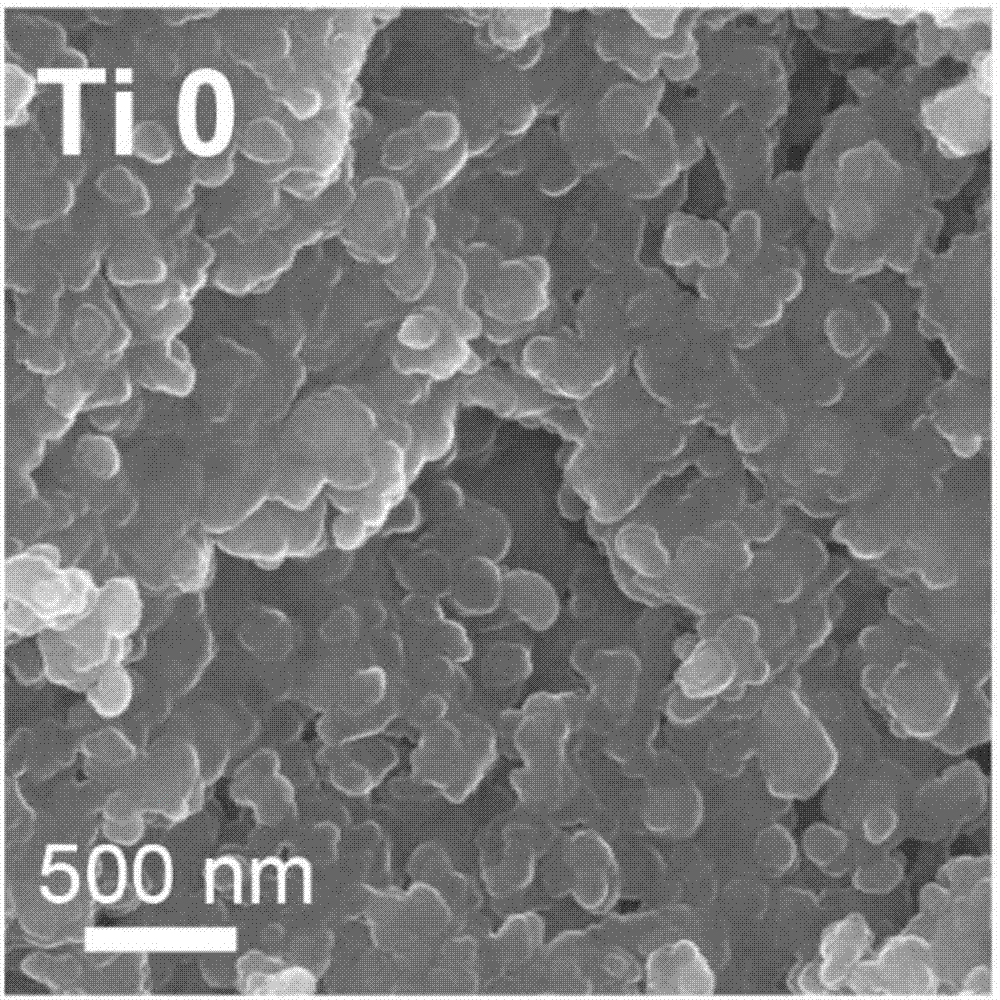

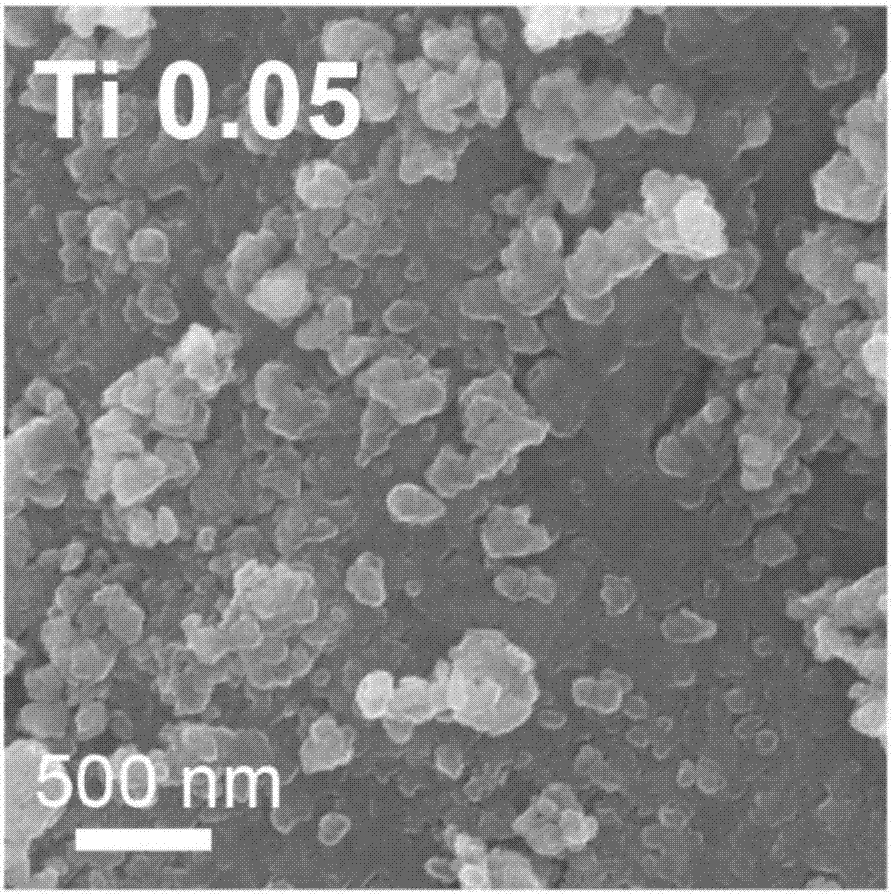

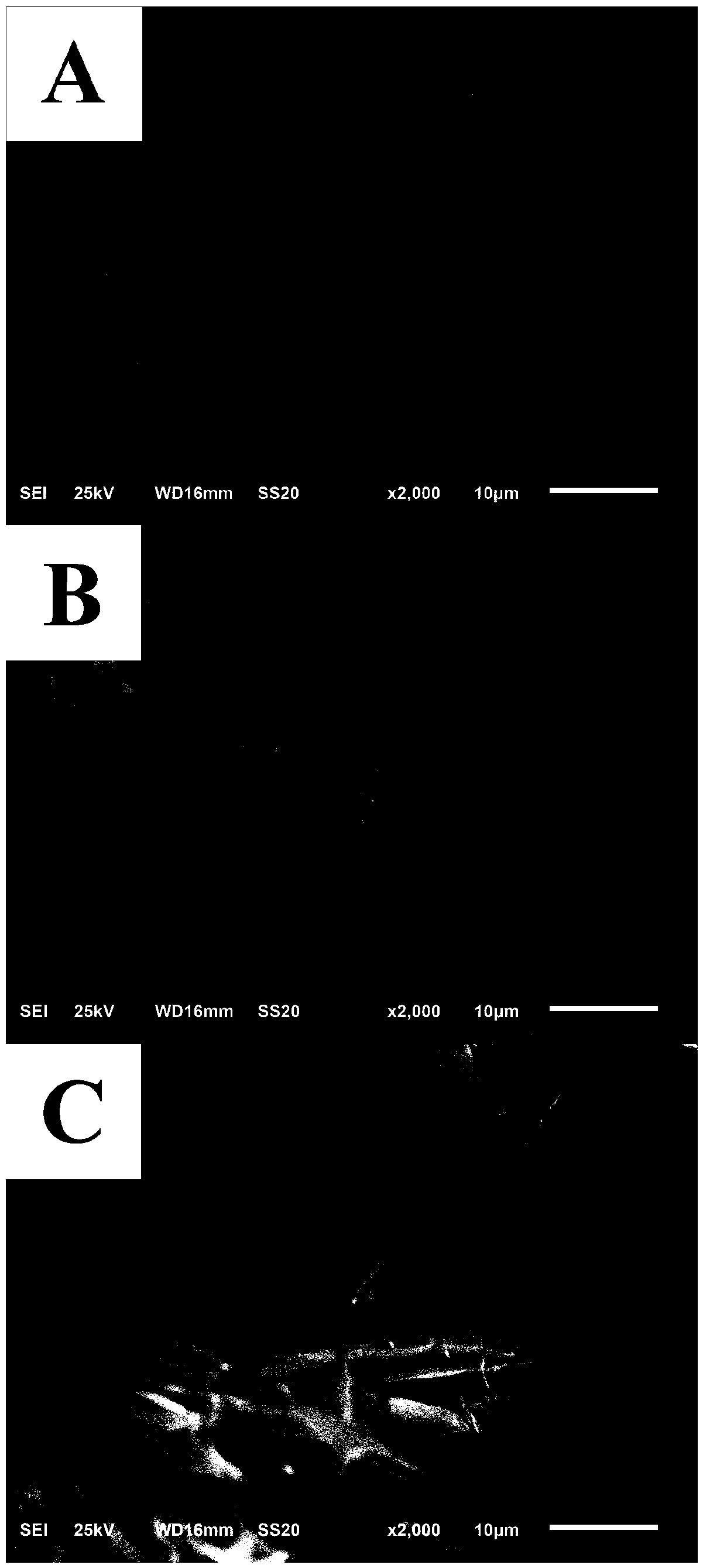

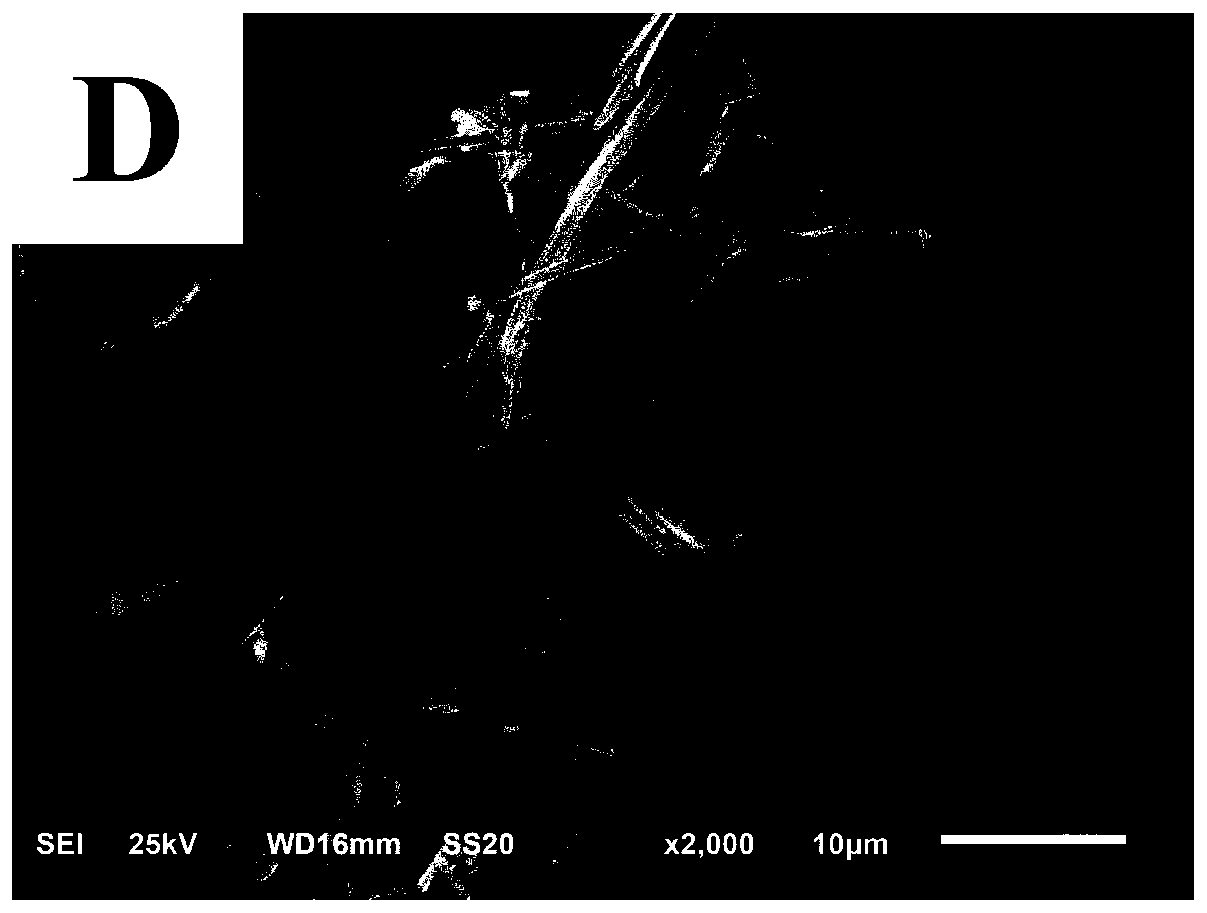

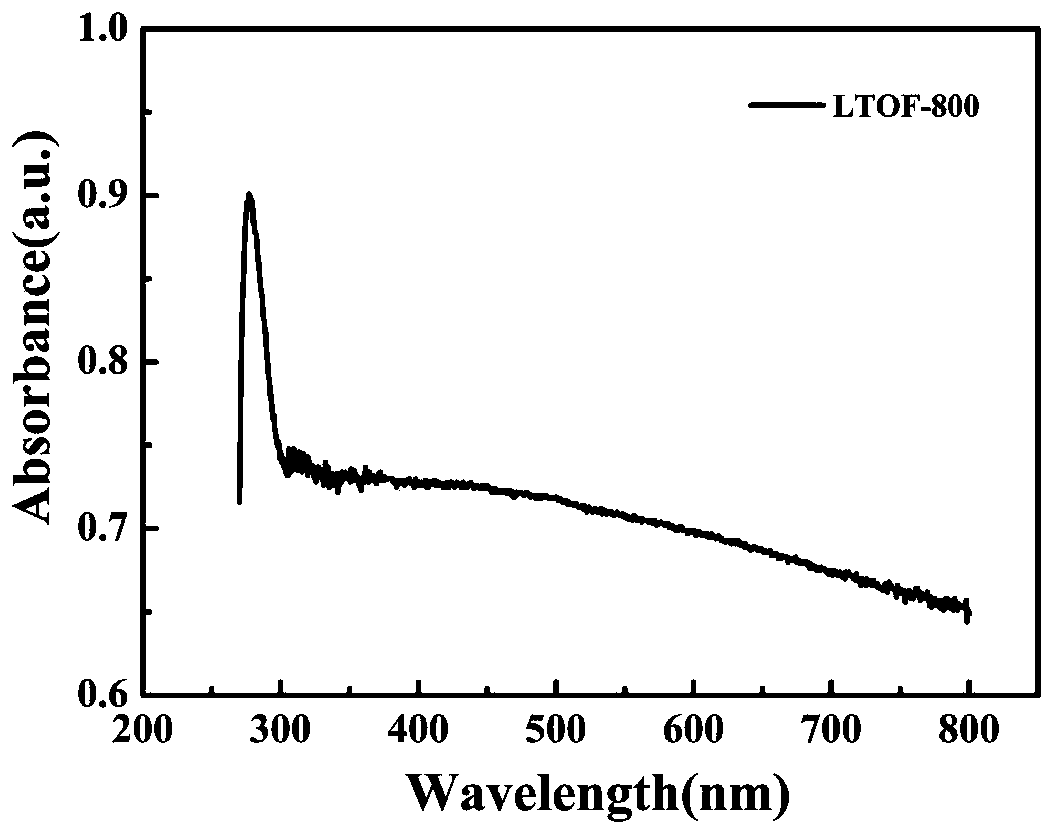

Preparation method and application of self-cleaning electrochemical sensor under visible light

ActiveCN110568031AGood for detectionGood effectMaterial electrochemical variablesUltraviolet lightsHydroquinone Compound

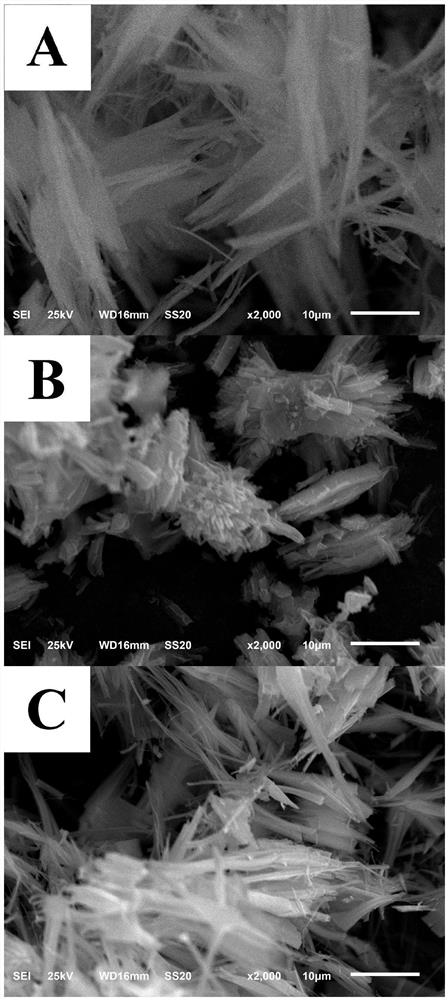

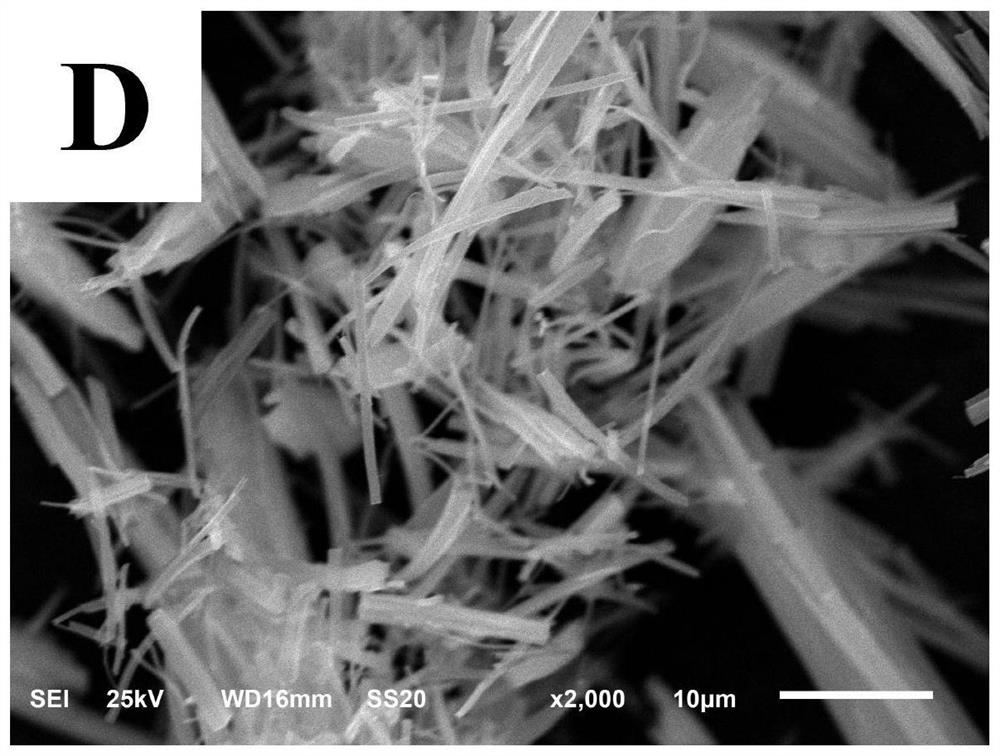

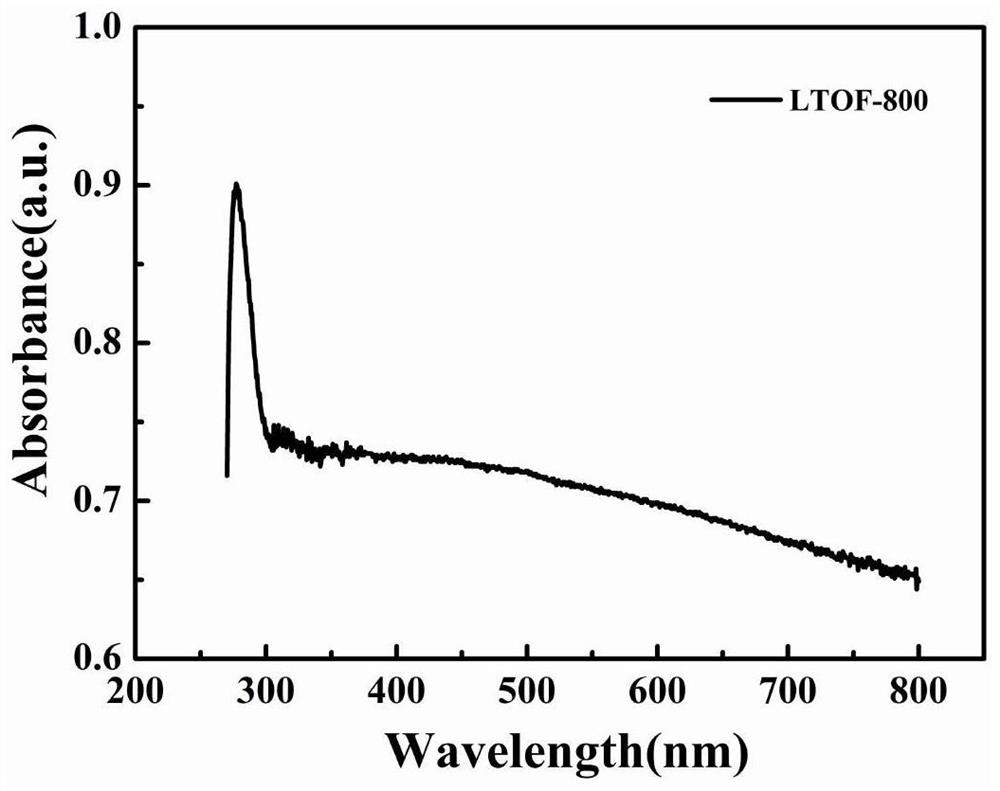

The invention belongs to the technical field of preparation of electrochemical sensors, and specifically discloses an electrochemical sensor with self-cleaning ability. The electrochemical sensor comprises an electrode core and a novel composite material based on MTOF (M refers to a doped metal element), and the composite material is attached to the surface of the electrode core. The preparation method of the sensor is simple, time-saving, low in cost and environmentally friendly. In particular, the residue of polymers and detected substance contained in the sensor and attached to the surfaceof the electrode core after detection can be oxidized under ultraviolet light and visible light conditions, thereby realizing the regeneration and self-cleaning effects of electrochemical sensor undervisible light. An electrochemical sensing platform regenerated under visible light not only reduces the tedious process of electrode polishing and modification, but also saves the cost of modifying materials, and the descaling regeneration of the electrode prolongs the service life of the electrode. The sensor is applied to the simultaneous detection of environmental pollutants, that is, hydroquinone and catechol, the operation is simple and convenient, the selectivity is good, the sensitivity is high, and the detection limit is low.

Owner:HUBEI UNIV FOR NATITIES

Dry pressing forming method of Nixing pottery

InactiveCN107825566AImprove liquidityReduce frictionCeramic shaping apparatusEmulsionVolumetric Mass Density

The invention discloses a dry pressing forming method of Nixing pottery. The dry pressing forming method of the Nixing pottery includes the following steps that (1) east clay and west clay are mixed and crushed to 80-120 meshes, so that clay powder is obtained; (2) 0.02-0.05% by weight of sodium tartrate and 0.01-0.02% of silicone emulsion are added into the argil powder, water is added until thewater content is 5-10%, and a preform body is obtained after uniform mixing; and (3) the preform body is injected into a metal mold cavity and pressed for 10-30 s at the front pressure of 15-25 MPa, and a formed green body is obtained. The small amount of sodium tartrate and silicone emulsion are added into the traditional Nixing pottery clay, the fluidity of the preform body is greatly increased,friction force among clay particles and between the clay and a mold wall is reduced, and therefore the formed green body with uniform density is obtained. As the density of the formed green body is uniform, deformation and cracking are greatly reduced in the subsequent firing process, and the yield is improved.

Owner:QINZHOU UNIV

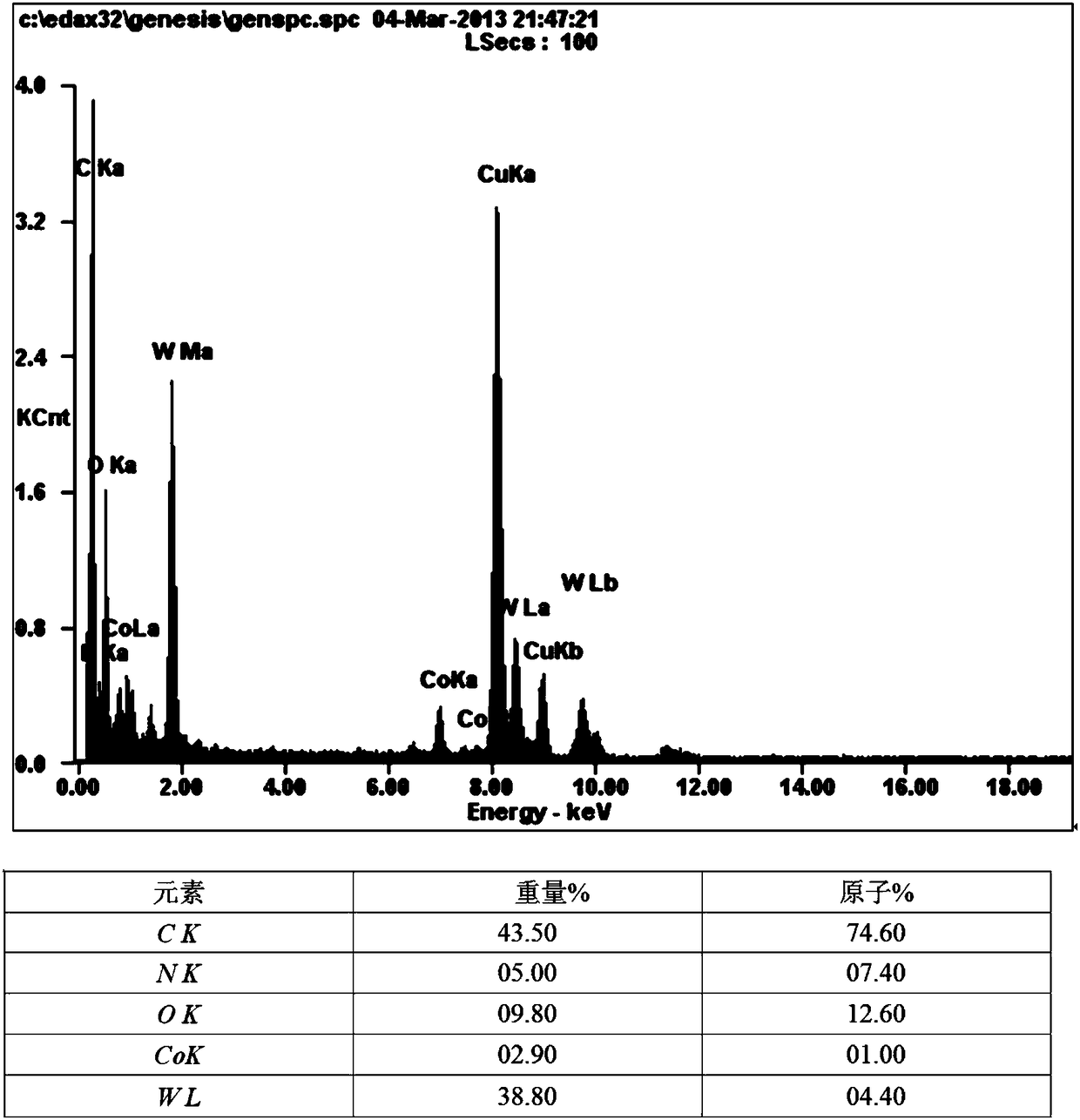

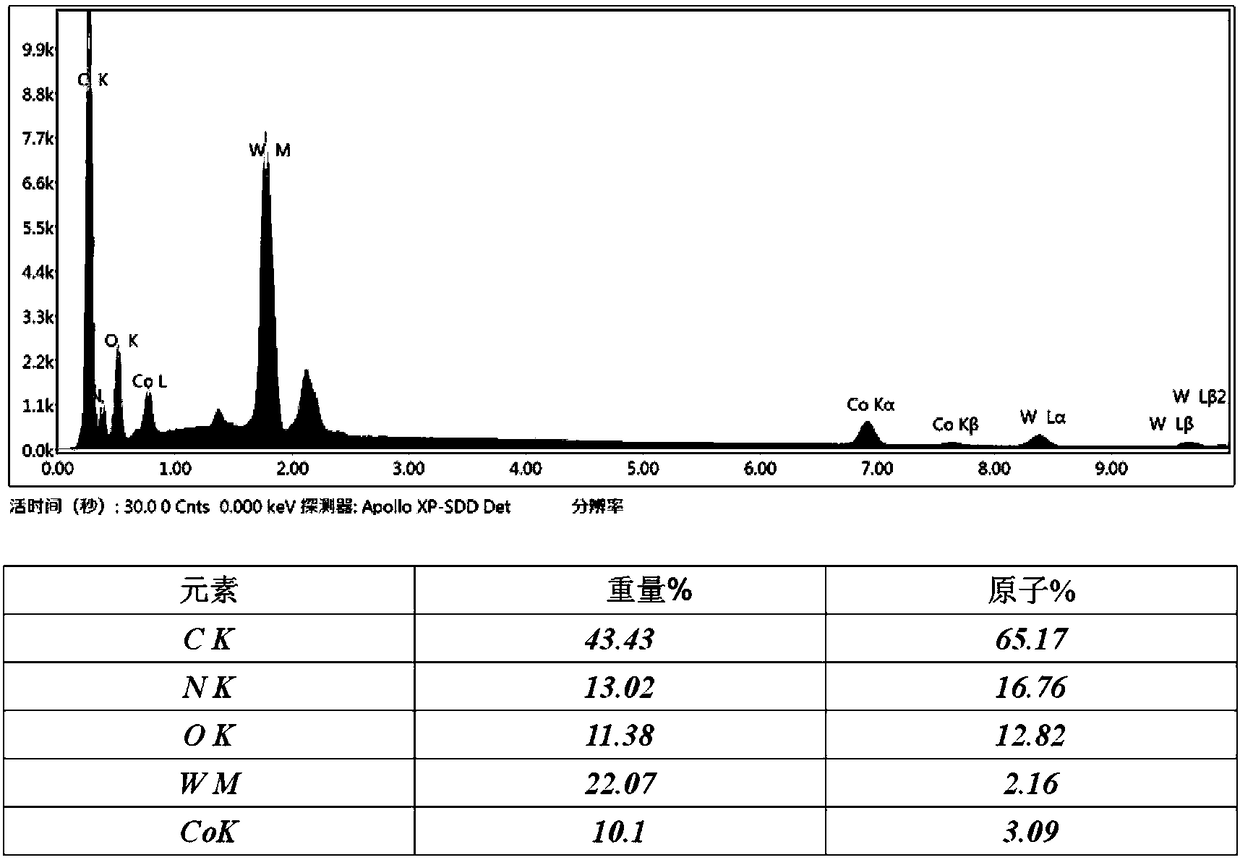

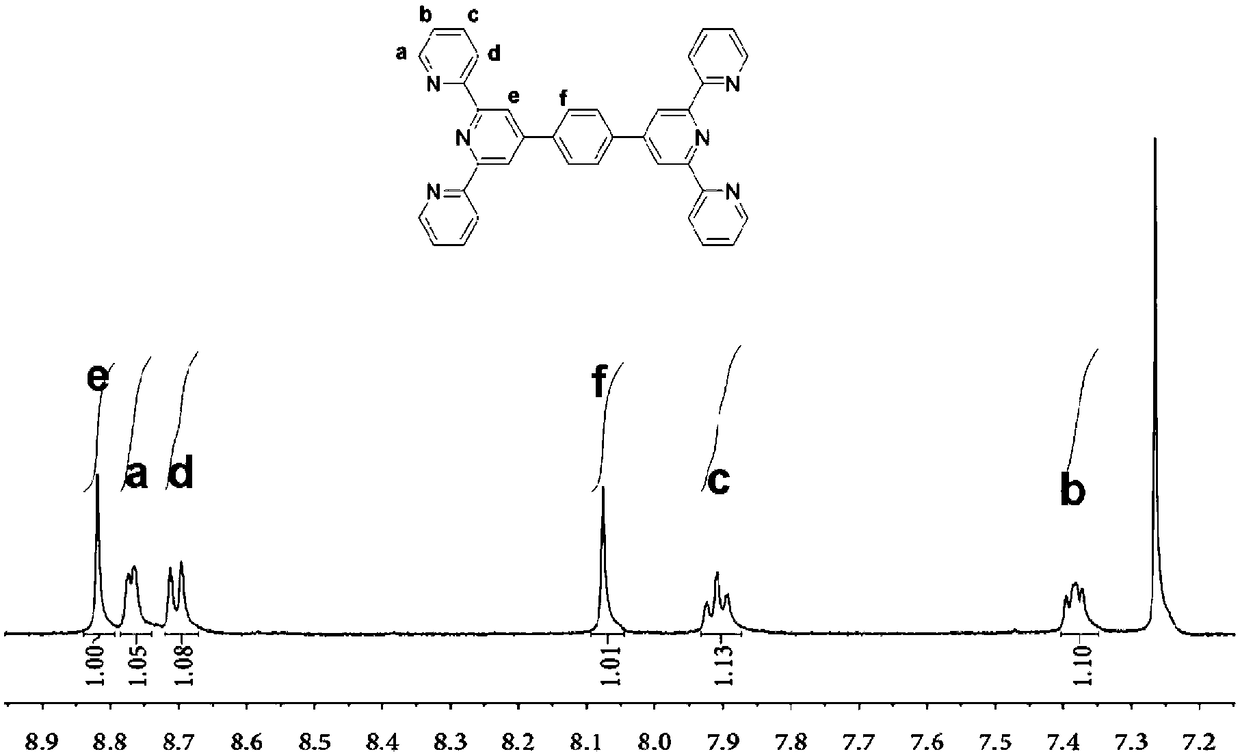

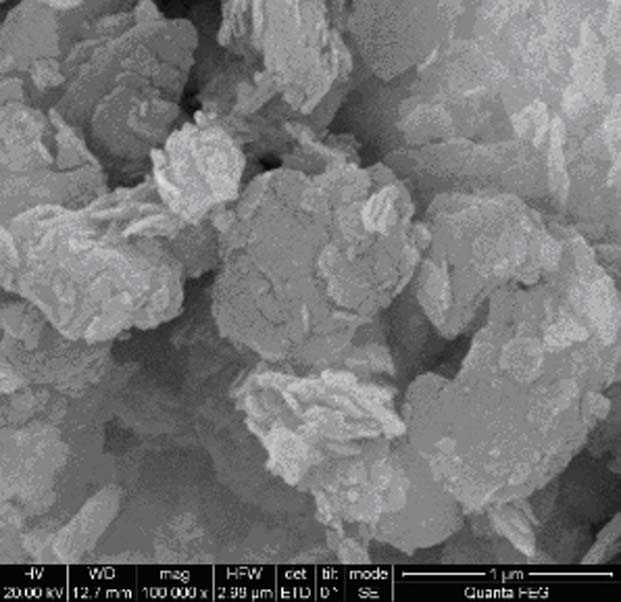

Bis-terpyridine based bi-metal polymer and preparation method thereof

ActiveCN108456311AHigh degree of polymerizationSmall sizeOrganic-compounds/hydrides/coordination-complexes catalystsTerpyridineSelf-assembly

The invention discloses a bis-terpyridine based bi-metal polymer and a preparation method thereof. A bis-terpyridine based metal complex is obtained through a self-assembly reaction of a transition metal salt and a bis-terpyridine ligand compound, the bis-terpyridine based metal complex reacts with excessive WO4<2-> solution, so as to obtain the bis-terpyridine based bi-metal polymer with high stability and high catalytic activity, and the polymer has wide application prospects in the field of catalysis.

Owner:CENT SOUTH UNIV

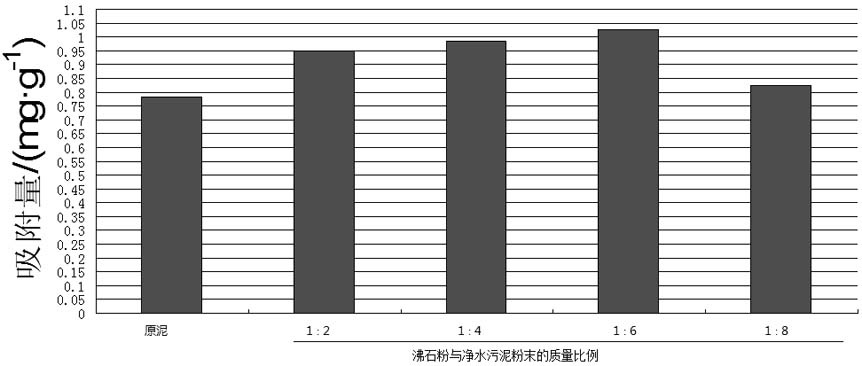

Sodium pyrophosphate modified water purification sludge/zeolite composite adsorbent and preparation method and application thereof

PendingCN112844304AHigh removal rateIncrease the areaOther chemical processesAluminium silicatesAmmoniacal nitrogenNitrogen removal

The invention discloses a sodium pyrophosphate modified water purification sludge / zeolite composite adsorbent and a preparation method and application thereof. The preparation method of the sodium pyrophosphate modified water purification sludge / zeolite composite adsorbent comprises the following steps of mixing water purification sludge powder with zeolite powder, then adding the mixture into a sodium pyrophosphate solution for dipping, then putting the mixture into a drying oven for drying, and then adding water to form a sludge mixture, and granulating and calcining the sludge mixture to obtain the sodium pyrophosphate modified water purification sludge / zeolite composite adsorbent. The adsorbent is used for adsorption treatment of ammonia-nitrogen wastewater, and the ammonia-nitrogen removal rate is high.

Owner:SUZHOU UNIV OF SCI & TECH

Hydrogenation regeneration method for waste lubricating oil

ActiveCN111978985AImprove stabilityExtended operating cyclePhysical/chemical process catalystsTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a hydrogenation regeneration method for waste lubricating oil. The method comprises the following steps: (1) distilling a pretreated raw material, namely waste lubricating oil;(2) feeding a lubricating oil fraction evaporated in the step (1) into a protective agent reactor for a reaction; and (3) feeding a product obtained after the reaction in the step (2) into a hydrogenation reactor filled with a hydrofining catalyst, and carrying out reacting to obtain lubricating oil base oil. The waste lubricating oil treated by the method can be used for producing standard lubricating oil base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

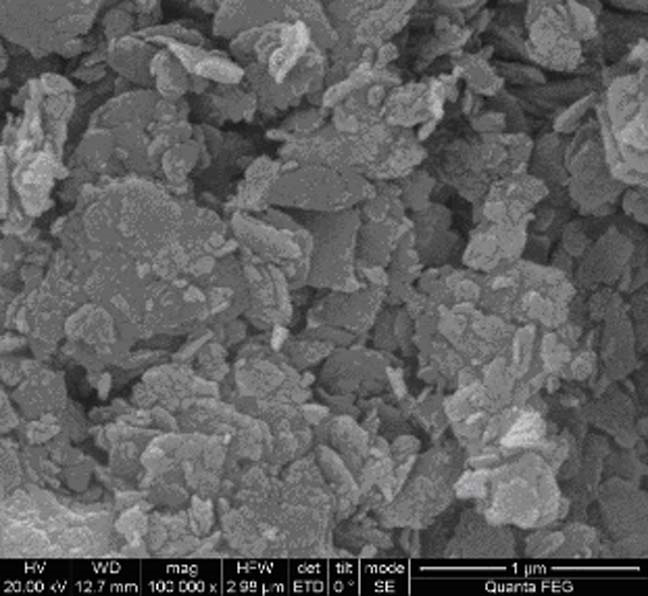

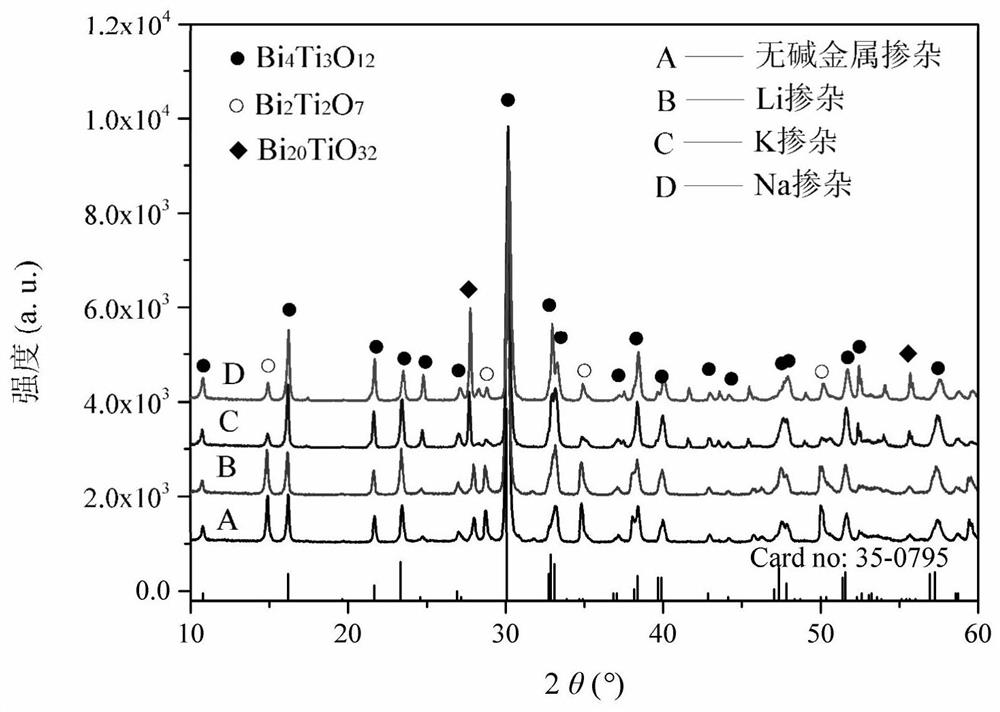

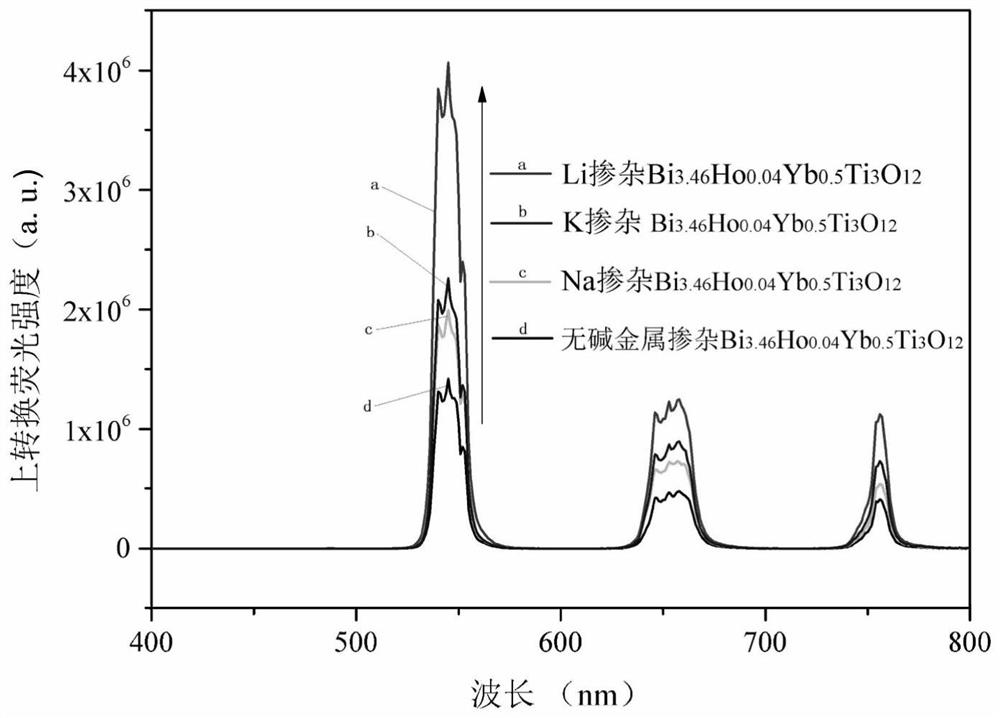

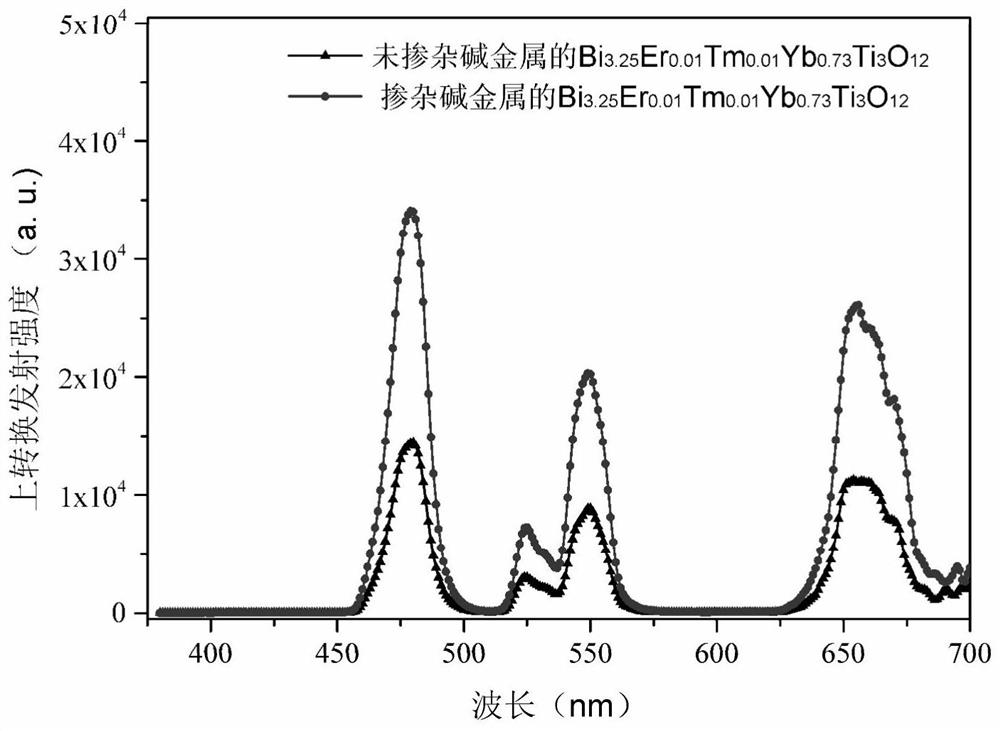

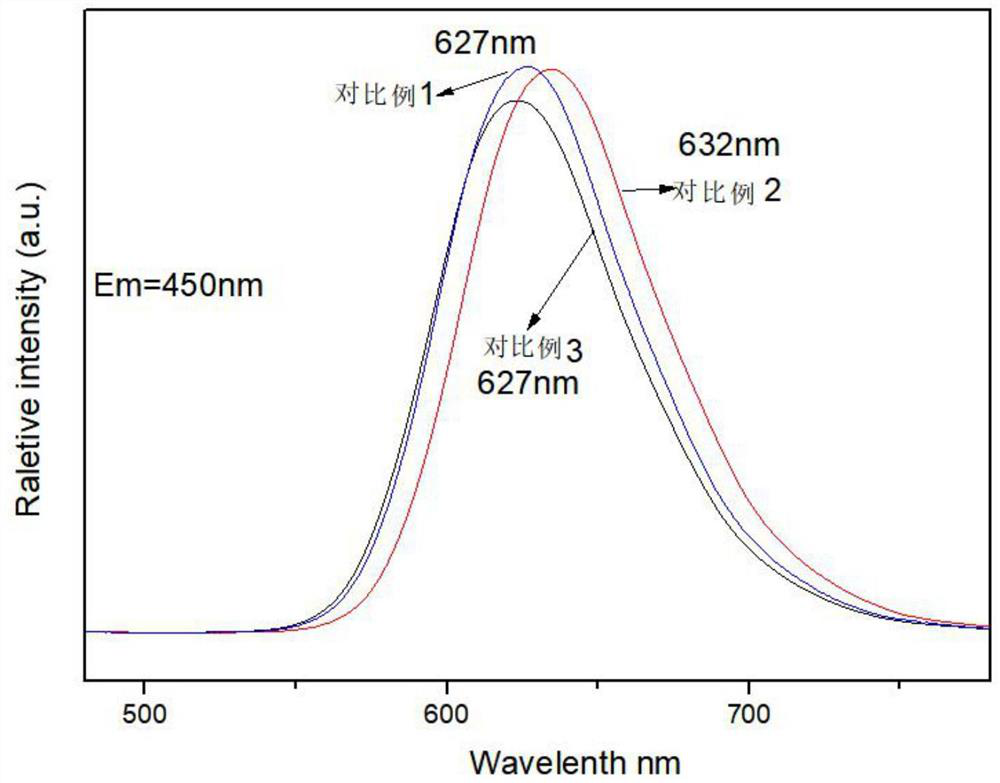

Alkali metal enhanced bismuth titanate-based up-conversion fluorescent material and preparation method thereof

PendingCN112745841ASmall ionic radiusReduce symmetryLuminescent compositionsRare-earth elementChemical solution

The invention relates to an alkali metal enhanced bismuth titanate-based up-conversion fluorescent material and a preparation method thereof. The chemical formula of the material can be recorded as Bi4-xRExTi3O12:yM (x is more than 0 and less than or equal to 0.5, y is more than or equal to 0 and less than or equal to 2.5), wherein RE can be one or more up-conversion rare earth elements of Ho, Er, Tm, Sm and Yb, and M can be one or more alkali metal elements of K, Li and Na. The alkali metal ion doped bismuth titanate material is excited by 980nm infrared light by adopting a chemical solution method, and the emission intensity can be improved by more than two times compared with the emission intensity when the bismuth titanate material is not doped with the alkali metal ions. The phosphor is prepared by adopting a chemical solution method, the technological process is simple, and the operation is convenient. The synthesized phosphor has high luminous efficiency, and has good application prospects in the aspects of up-conversion red lasers, fluorescence labeling, anti-counterfeiting and the like.

Owner:GUANGXI UNIV

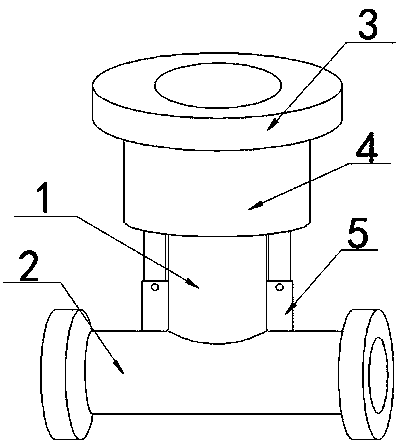

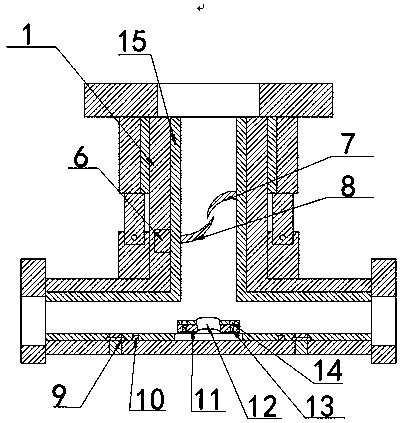

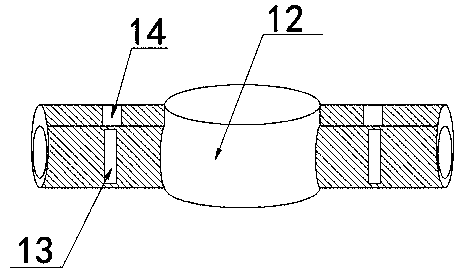

Three-way ceramic valve

InactiveCN108775424AHigh ion electricity priceLarge coordination numberOperating means/releasing devices for valvesMultiple way valvesBonding strengthEngineering

The invention discloses a three-way ceramic valve which comprises a main pipeline, a branch pipeline and an inner pipeline. A movable pipe is arranged on the lower side of a connecting flange. The main pipeline is arranged on the lower side of a movable rod. Telescopic supporting rods are arranged on the left side and the right side of the main pipeline, and the branch pipeline is arranged on thelower side of the main pipeline. The movable pipe and the branch pipeline are connected through the telescopic supporting rods. The main pipeline is internally provided with the inner pipeline. A first motor is arranged in an interlayer between the inner pipeline and the main pipeline. A static blocking cover is arranged in the inner pipeline. A movable blocking cover is arranged on the lower sideof the static blocking cover. A transfer main pipe is arranged in the branch pipeline and directly faces the lower side of the main pipeline. Transfer branch pipes are arranged on the left side and the right side of the transfer main pipe correspondingly. Solenoid valves are arranged in the transfer branch pipes. Solenoid valve controllers are arranged on the upper sides of the solenoid valves. The three-way ceramic valve can replace a metal valve, compared with the metal valve, the deformation of the ceramic valve is small, and the ceramic valve has high bonding strength.

Owner:冠立科技扬州有限公司

Multi-element stable zirconium oxide corrosion-resistant thermal barrier coating material

ActiveCN103130501BMolten Salt Corrosion Life ImprovementHigh viscosityAluminum silicateGlass corrosion

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Paraffin hydrofining catalyst and preparation method thereof

PendingCN111097462AGood dispersionIncrease profitPetroleum wax refiningCatalyst activation/preparationPtru catalystHigh activity

The invention discloses a paraffin hydrofining catalyst and a preparation method thereof. The catalyst is prepared by taking aluminum oxide as a carrier, and nickel and molybdenum as active metal components; taking the mass amount of the catalyst as a reference, the catalyst comprises 2.0%-35.0% of molybdenum oxide, and 0.5%-20.0% of nickel oxide; and the dispersity of the active metal componentsis as follows: IMo / IAl is 0.14-0.30, and INi / IAl is 0.07-0.15. The paraffin hydrofining catalyst is high in active metal utilization rate, high in active metal dispersity and high in activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-PID effect assembly and preparation method and application thereof

PendingCN112820791AImprove performanceLight transmittance has little effectFinal product manufacturePhotovoltaic energy generationWeather resistanceTransmittance

The invention relates to the technical field of photovoltaics, and provides an anti-PID effect assembly. The anti-PID effect assembly comprises a glass substrate and a tin oxide layer arranged on any surface of the glass substrate. The ion radius of tin ions is smaller than that of sodium ions and calcium ions, so that the ion potential energy is higher, the binding capacity with oxygen atoms is higher, the tin ions have an obvious aggregation effect, and a glass network structure can be enhanced and is more compact, and accordingly migration of the sodium ions and the calcium ions is limited, carbonate containing the sodium ions and the calcium ions is not formed on the surface of the glass, the glass is protected from serious erosion, the weather resistance of the glass surface and a glass coating can be obviously improved, and the PID attenuation effect on the upper surface of the glass is effectively reduced. Meanwhile, the tin oxide layer has smaller influence on the light transmittance of the whole glass, so that the obtained assembly is stronger in PID effect resistance, excellent in overall performance and wide in application.

Owner:湖南旗滨光能科技有限公司

A kind of color changing method of artificial sapphire crystal

ActiveCN106637417BReduced surface activationDiffusion helpsDiffusion/dopingChange colorColor changes

The invention discloses a color changing method of an artificial sapphire crystal. According to the method disclosed by the invention, coloring ions are dispersed into the artificial sapphire crystal through a relatively low temprature heat treatment technology, so that the color and the transparency of the sapphire crystal are improved. When the sapphire crystal treated by the method disclosed by the invention, colorless sapphire crystals can be changed into crystals with a plurality of colors, the color and luster are uniform and the transparency is better; According to the method, the treatment process is simple and equipment is simple, and the pollution to the environment is avoided. The ornamental value and the market economic value of sapphires treated by the method can be greatly improved.

Owner:HEBEI UNIV OF TECH

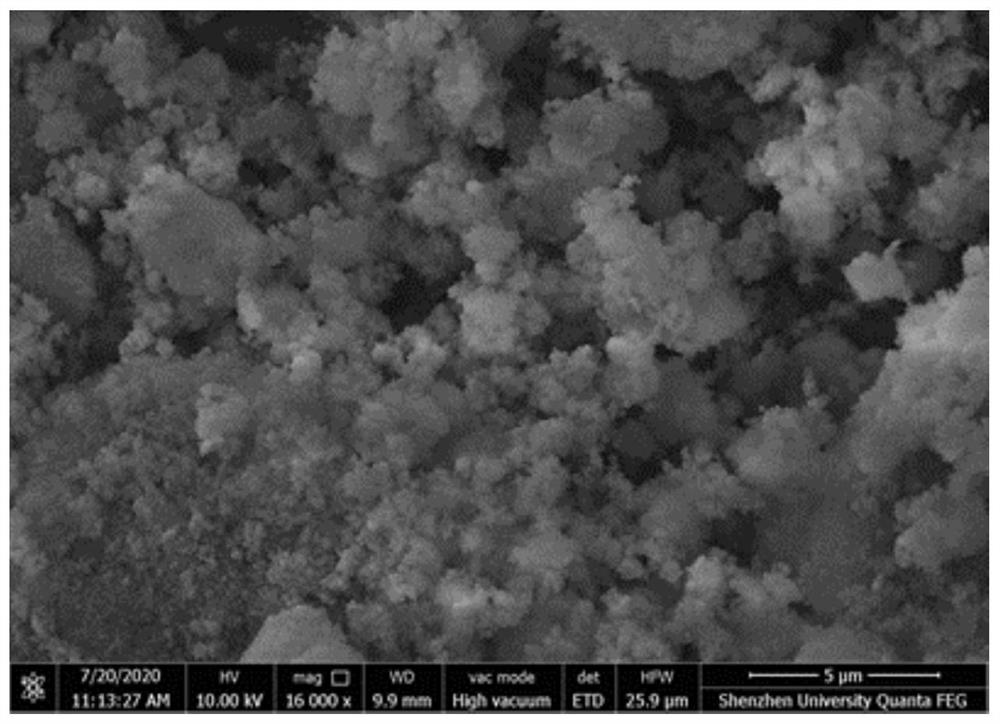

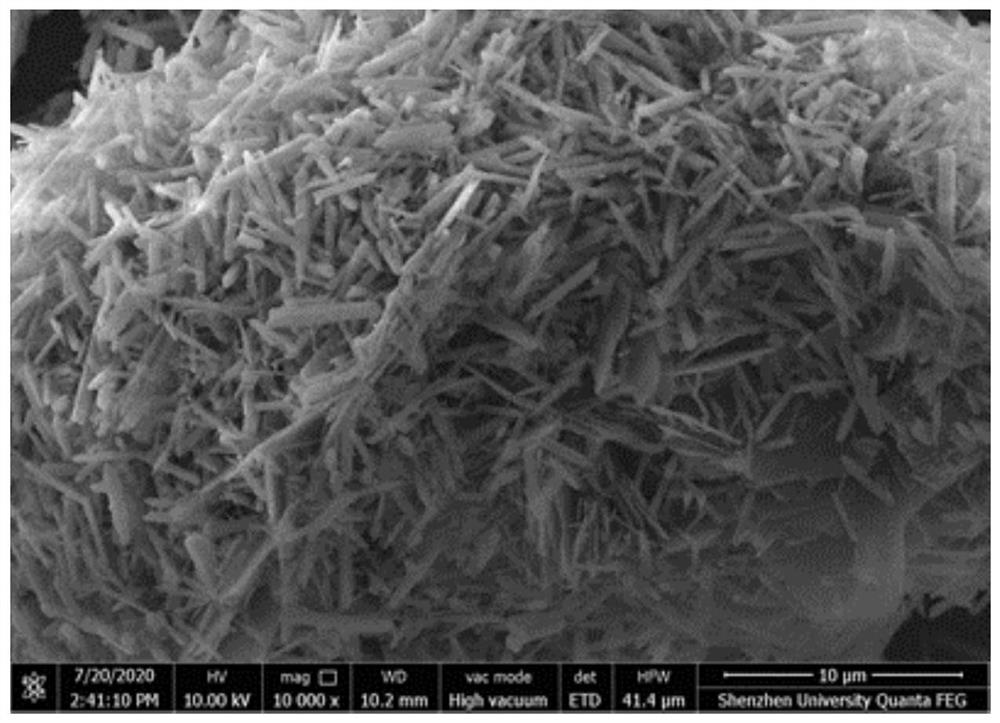

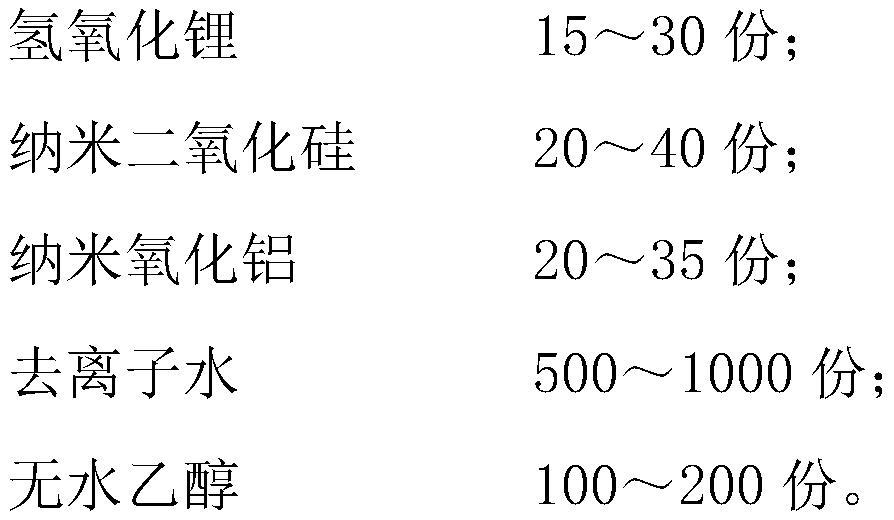

L-A-S-H nanogel precursor for inhibiting alkali-aggregate reaction, preparation method and application thereof

The invention discloses an L-A-S-H nanogel precursor for inhibiting an alkali-aggregate reaction, a preparation method and application thereof. The L-A-S-H nanogel precursor is prepared from the following components in parts by mass: 15 to 30 parts of lithium hydroxide; 20 to 40 parts of nano silicon dioxide; 20 to 35 parts of nano aluminum oxide; 500 to 1000 parts of deionized water; and 100 to 200 parts of absolute ethyl alcohol. According to the invention, a hydrothermal synthesis method is adopted for preparation, so that the preparation method is mature and stable, the reaction process is simple, operation is convenient, energy consumption is low, treatment is easy, and secondary pollution is avoided; and the L-A-S-H nanogel precursor can effectively inhibit concrete alkali-aggregate reaction, can also effectively inhibit development of microcracks in the concrete, can also play a role in repairing the part subjected to the alkali-aggregate reaction, enables the size of the part to be kept stable, and has important significance for improving the durability of the concrete.

Owner:SHENZHEN UNIV

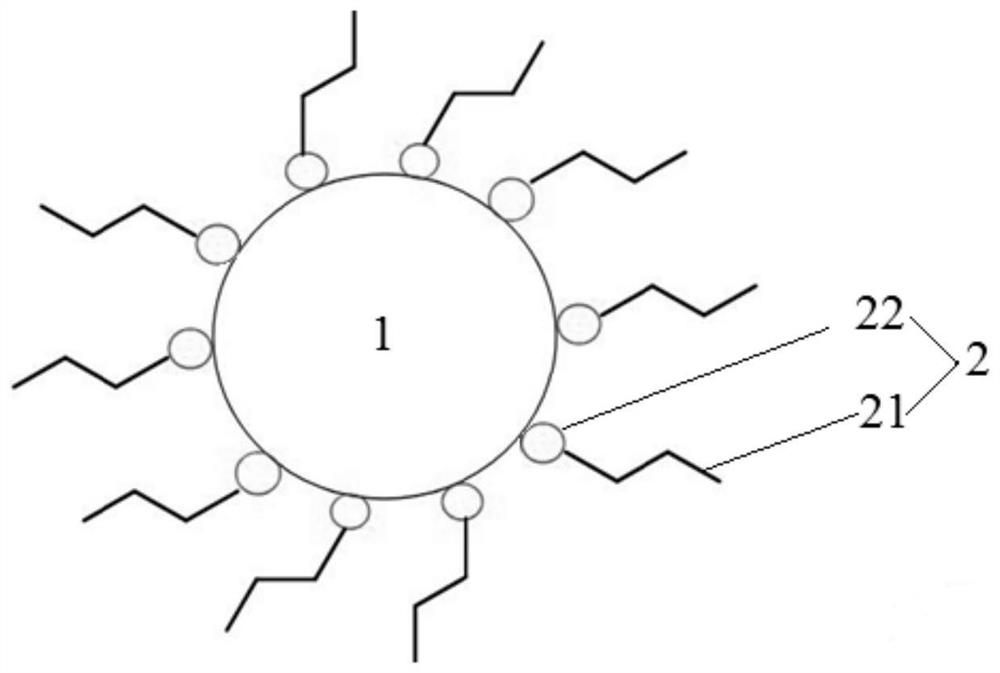

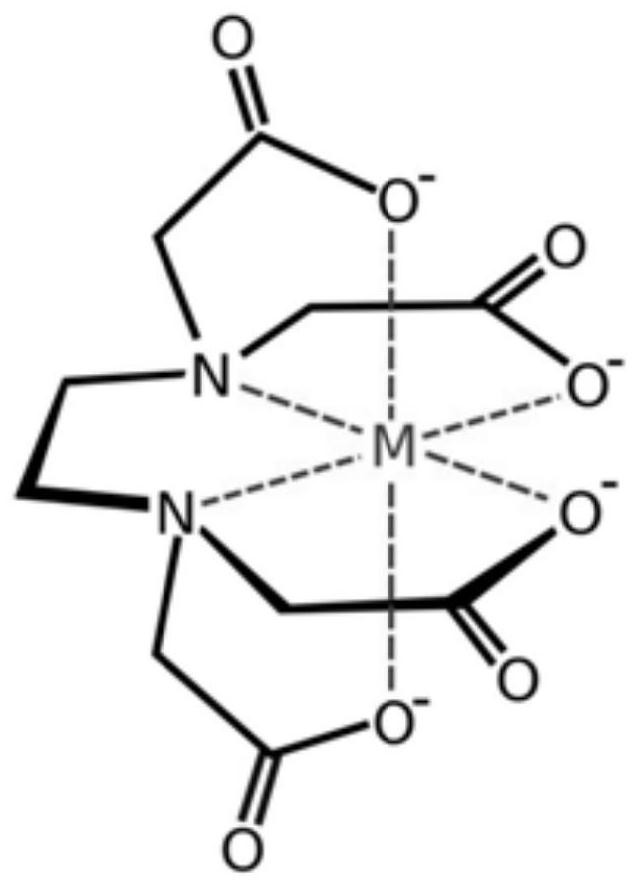

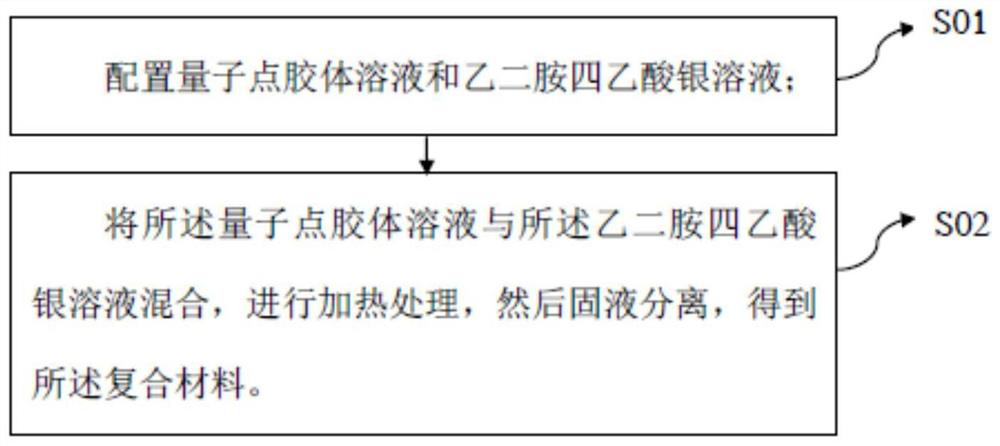

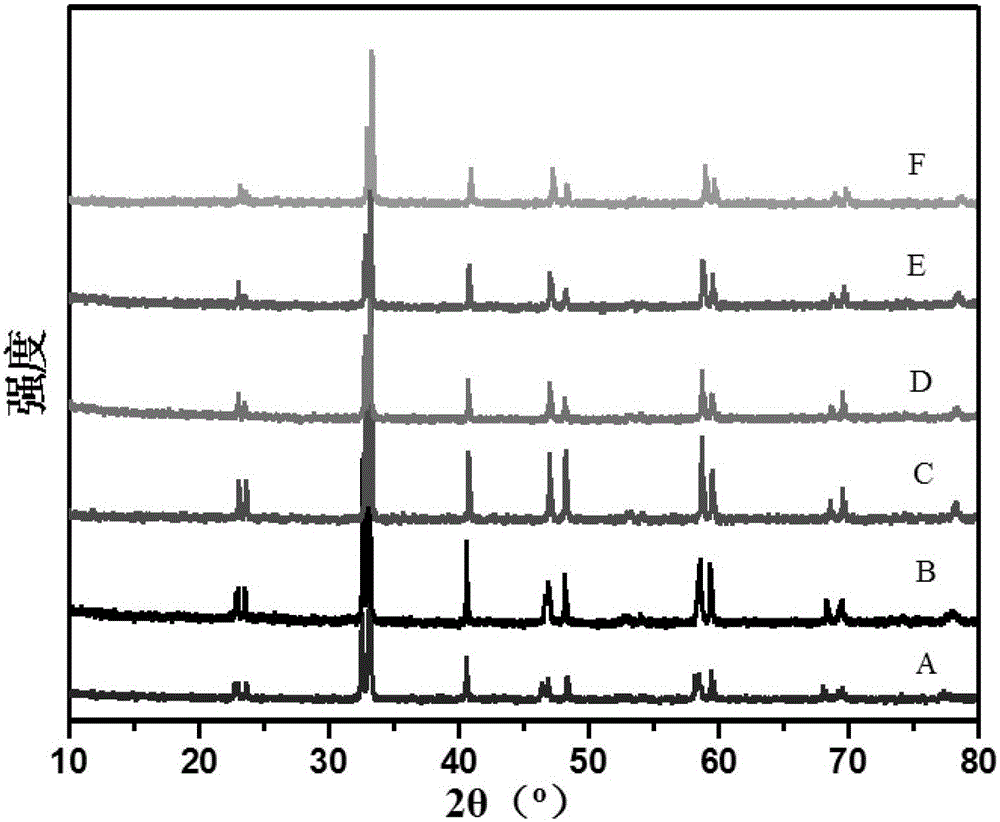

Composite material and its preparation method and quantum dot light-emitting diode

ActiveCN112300781BGood dispersionCapable of donating electronsSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotSilver ion

The invention belongs to the technical field of nanometer materials, and in particular relates to a composite material, a preparation method thereof and a quantum dot light-emitting diode. The composite material includes quantum dots and silver ethylenediamine tetraacetate combined on the surface of the quantum dots; wherein, silver ions in the silver ethylenediamine tetraacetate combine with anions on the surface of the quantum dots. In the composite material, the surface plasmon resonance effect of silver on the surface of the quantum dot can induce local electromagnetic field enhancement, thereby increasing the light output coupling of the quantum dot and the recombination luminescence rate, and the composite material is used for the quantum dot luminescence of the quantum dot light-emitting diode layer, which can effectively improve the luminous efficiency of the device, thereby improving the performance of the device.

Owner:TCL CORPORATION

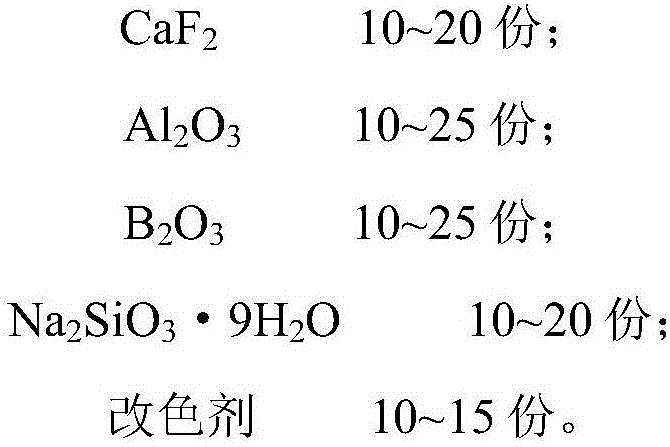

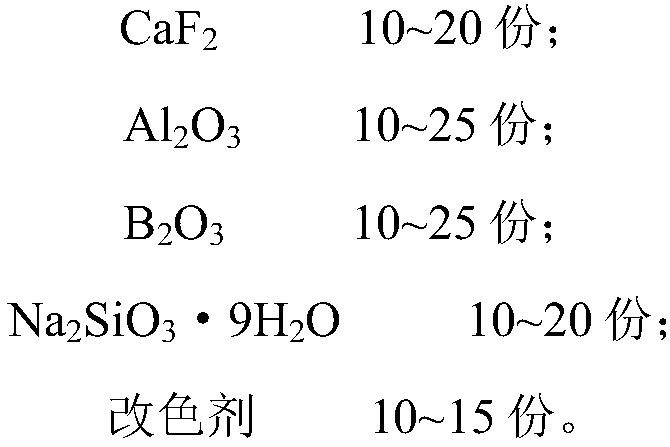

Fluoride-free slag agent

Owner:NANYANG MINGXINSI DIOR TECH

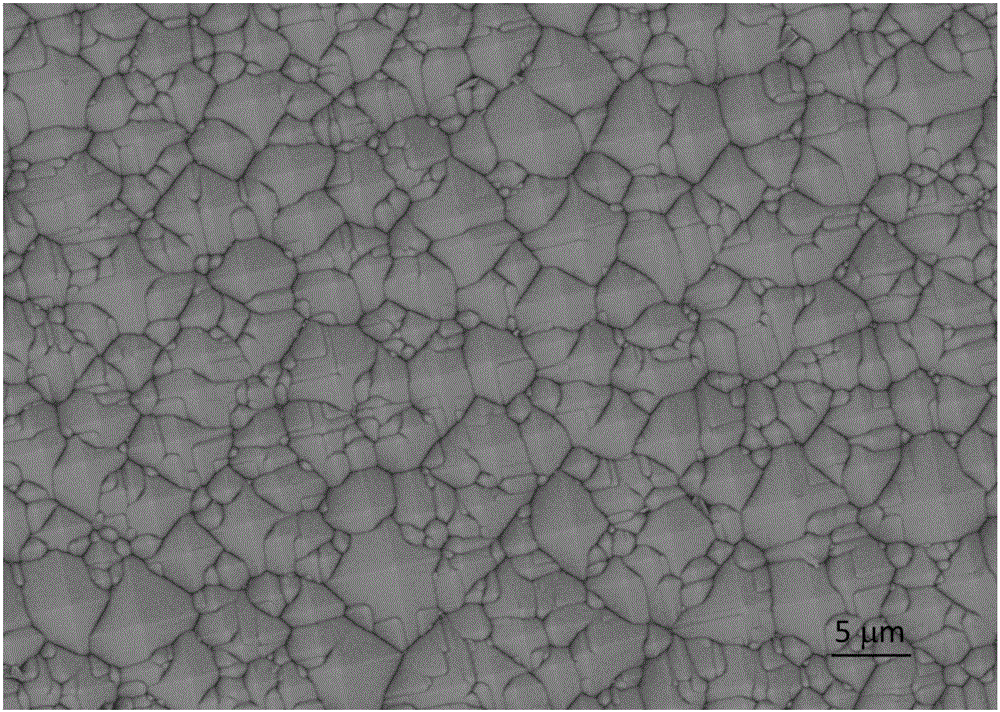

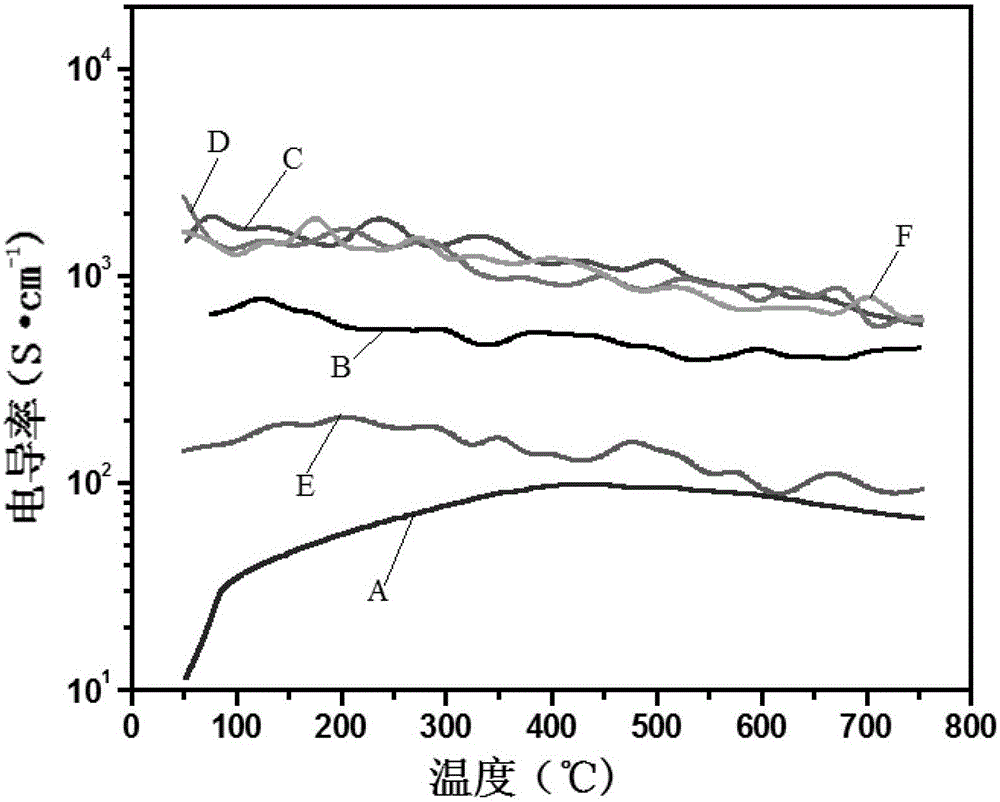

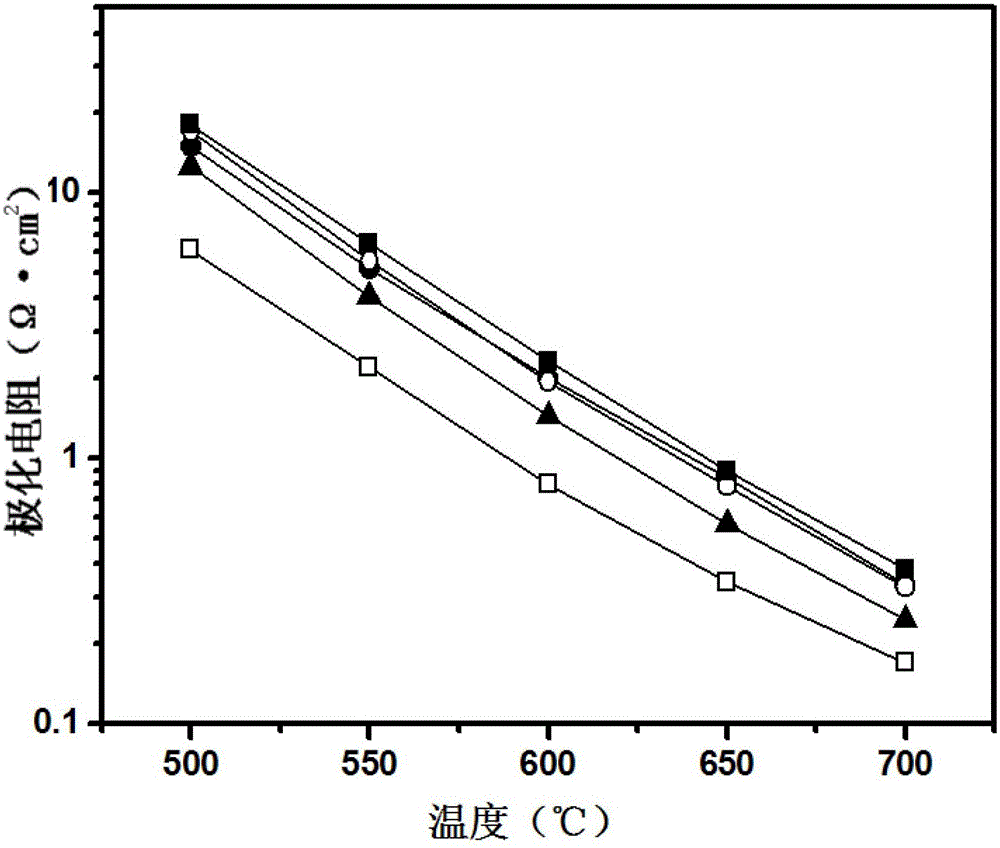

Application of a doped double perovskite structure cathode material for intermediate temperature solid oxide fuel cells

InactiveCN103367767BGood ability to catalyze oxygen reduction reactionHigh crystallinityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsOxygenPerovskite

The invention relates to a cathode material and a preparation method thereof, particularly a moderate-temperature solid oxide fuel battery doped double-perovskit-structure cathode material and a preparation method thereof. The invention aims to solve the problem that the catalytic oxygen reduction reaction capacity of the existing solid oxide fuel battery cathode material La1-xSrxMnO3 acutely reduces under moderate temperature conditions. The moderate-temperature solid oxide fuel battery doped double-perovskit-structure cathode material is an alkaline earth element Sr-doped double-perovskite powder material, and the chemical formula is EuBa1-xSrxCo2O5+delta. The method comprises the following steps: 1. weighing materials according to the chemical formula EuBa1-xSrxCo2O5+delta; 2. grinding to obtain a mixture; and 3. calcining to obtain the alkaline earth element Sr-doped double-perovskite powder material of which the chemical formula is EuBa1-xSrxCo2O5+delta. The invention is mainly used for preparing the moderate-temperature solid oxide fuel battery doped double-perovskit-structure cathode material.

Owner:HEILONGJIANG UNIV

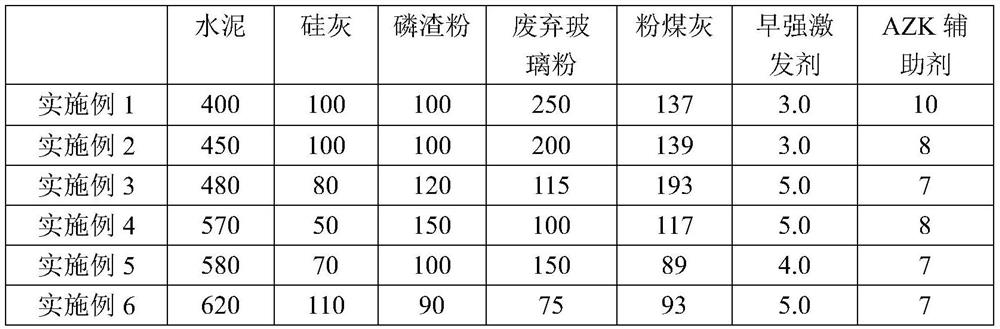

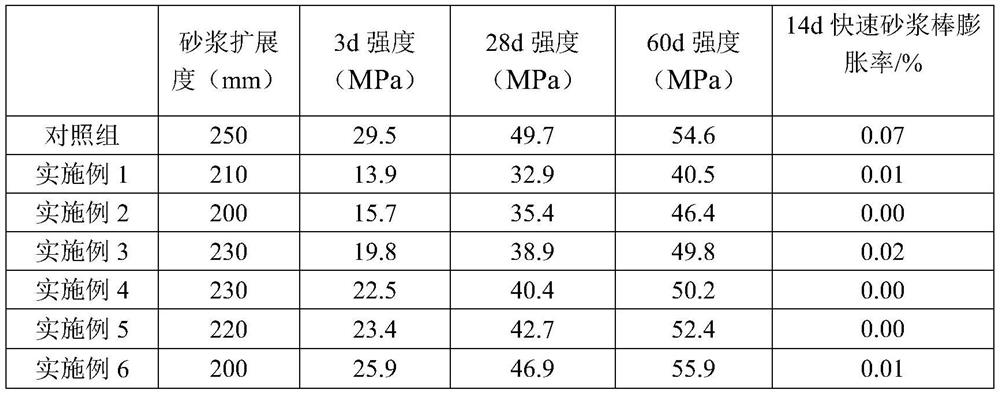

Cementing material for inhibiting metamorphic rock alkali aggregate reaction and preparation method thereof

The invention relates to a cementing material for inhibiting metamorphic rock alkali aggregate reaction and a preparation method thereof. The cementing material comprises the following components: cement, silica fume, phosphorus slag powder, waste glass powder, fly ash, an early strength activator and an AZK auxiliary agent according to a mass ratio of (400-620): (50-100): (90-105): (75-250): (89-193): (3.0-5.0): (7.0-10.0). The cementing material for inhibiting metamorphic rock alkali aggregate reaction is developed through a creative synergistic effect of a cementing material compounding technology, a cementing material secondary hydration process control technology and a cementing material excitation technology, the performance of inhibiting metamorphic rock alkali aggregate reaction is excellent, the comprehensive utilization of industrial wastes such as silica fume, fly ash, phosphorus slag powder and waste glass powder is further enhanced, and the cementing material is green and environment-friendly.

Owner:贵阳中建西部建设有限公司 +1

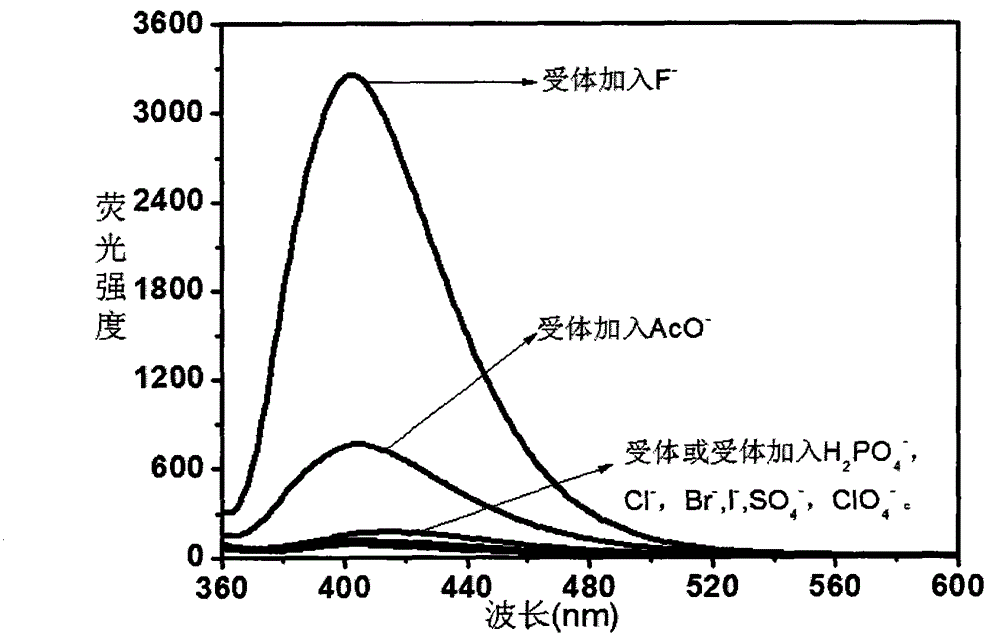

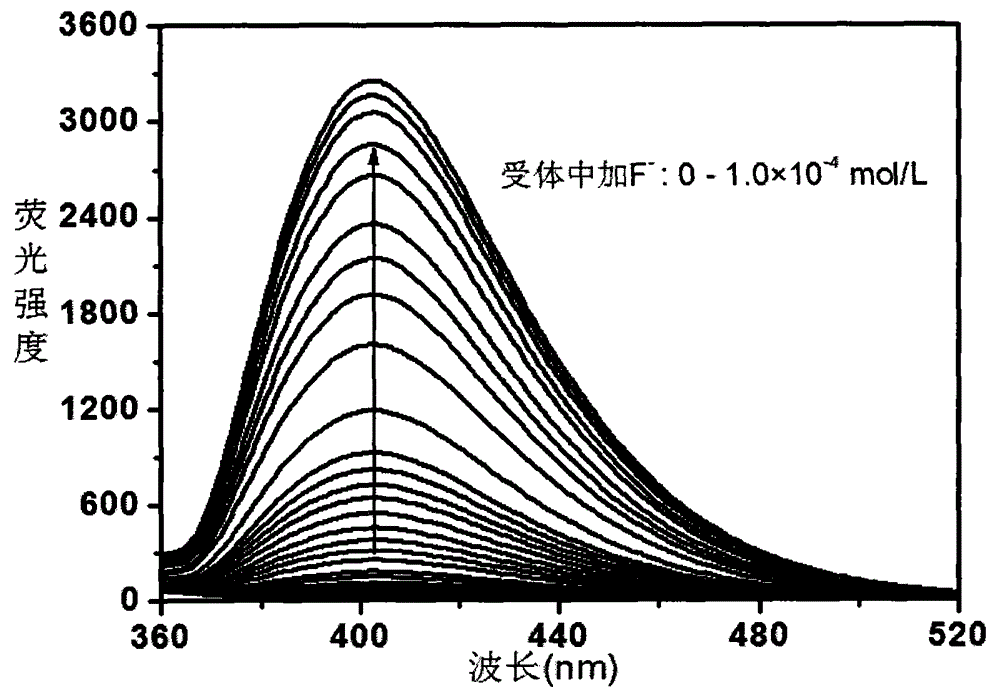

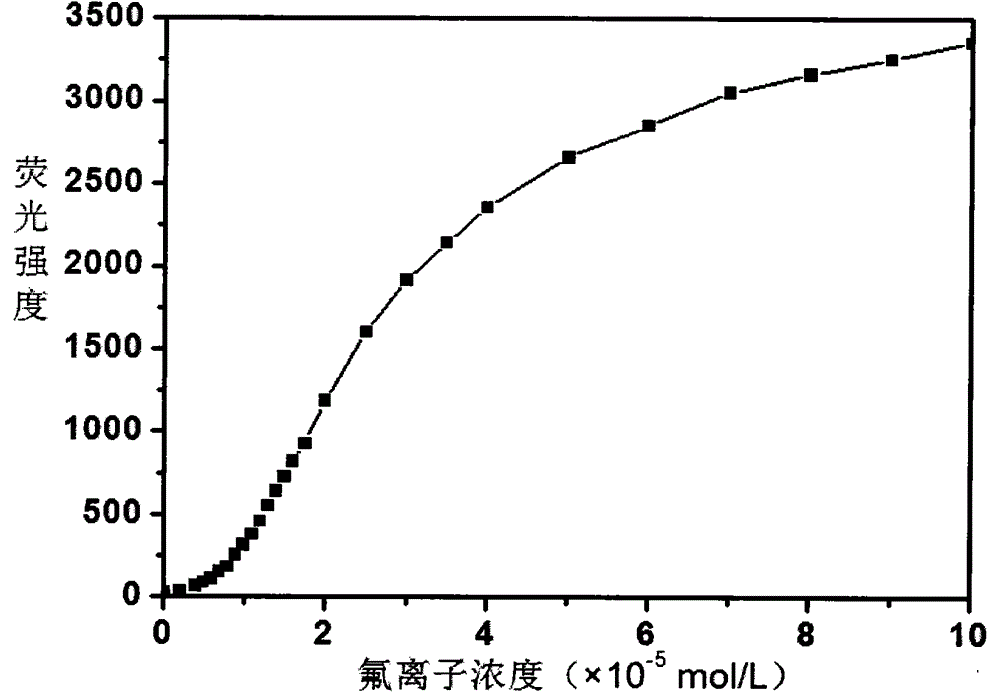

Method for selective fluorescence recognition and colorimetric recognition of fluorine ions by using perimidine onium anion receptor

InactiveCN105651743AReal-time detectionEasy to detectMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceFluorescenceAnalytical chemistry

The present invention provides a method for selective fluorescence recognition and colorimetric recognition of fluorine ions by using a perimidine onium anion receptor. According to the present invention, the fluorescence emission spectrum of the perimidine onium anion receptor is significantly enhanced on the basis of the zero fluorescence after fluorine ions are added to a DMSO solution while the color of the solution is colorless from the yellow color so as to achieve the naked eye recognition; the method has advantages of real-time detection, easy operation, high sensitivity, simple detection equipment, and the like; and the perimidine onium anion receptor can achieve the effective selective recognition of the fluorine ions in the mixed solution of DMSO and water, such that the perimidine onium anion receptor shows the water phase fluorine ion recognition application prospects.

Owner:EAST CHINA NORMAL UNIV

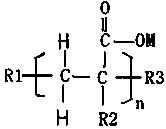

Paraffin hydrofining catalyst and preparation method thereof

InactiveCN111097488AGood dispersionIncrease profitMolecular sieve catalystsPetroleum wax refiningParaffin waxMolecular sieve

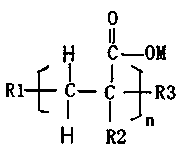

The invention discloses a paraffin hydrofining catalyst and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing pseudo-boehmite and layered clay; (2) mixing aY-type molecular sieve with water, and pulping to obtain a uniformly dispersed slurry; (3) adding the slurry obtained in the step (2) into a mixture obtained in the step (1), mixing, kneading, molding, drying and roasting to obtain a carrier; (4) impregnating the catalyst carrier obtained in the step (3) with a phosphorus-containing solution, and then drying; and (5) impregnating the carrier driedin the step (4) with an active metal solution containing a carboxyl-containing polymer, and then drying and roasting to obtain the paraffin hydrofining catalyst. The paraffin hydrofining catalyst prepared by the method is high in active metal utilization rate, high in active metal dispersity and high in activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of a self-cleaning electrochemical sensor under visible light

ActiveCN110568031BEasy to detectWith self-cleaning abilityMaterial electrochemical variablesUltraviolet lightsEngineering

The invention belongs to the technical field of preparation of electrochemical sensors, and specifically discloses an electrochemical sensor with self-cleaning ability, including an electrode core and a new composite material based on MTOF (M refers to doped metal elements), and the composite material is attached to on the surface of the electrode core. The preparation method of the sensor is simple, time-saving, low-cost, and environmentally friendly, especially the polymer and the residue of the detected substance attached to the surface of the electrode core after detection can be oxidized under the conditions of ultraviolet light and visible light. The regeneration and self-cleaning effect of the electrochemical sensor under visible light can be achieved. The electrochemical sensing platform regenerated under visible light not only reduces the cumbersome procedures of electrode grinding and modification, but also saves the cost of modification materials, and the descaling and regeneration of electrodes prolongs the service life of electrodes. It is used for the simultaneous detection of environmental pollutants hydroquinone and catechol, with simple operation, good selectivity, high sensitivity and low detection limit.

Owner:HUBEI UNIV FOR NATITIES

A method for hydrogenation regeneration of waste lubricating oil

ActiveCN111978985BImprove stabilityExtended operating cyclePhysical/chemical process catalystsTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a method for hydrogenation regeneration of waste lubricating oil. The method comprises the following steps: (1) distilling the pretreated raw material waste lubricating oil; (2) putting the distilled lubricating oil fraction in step (1) into a protective agent reactor for reaction; (3) distilling the step (2) ) The reacted product enters a hydrogenation reactor equipped with a hydrorefining catalyst for reaction to obtain a lubricating oil base oil. The method of the invention treats the waste lubricating oil to produce the lubricating oil base oil meeting the standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-component stable thermal-corrosion-resistant zirconia coat material

ActiveCN103224391BIncreased molten salt corrosion performanceMolten Salt Corrosion Life ImprovementMolten saltGlass corrosion

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Electric ceramic material for recycling existing electric ceramic wastes for reproduction, and production method thereof

The invention relates to a remanufactured electric porcelain material and a manufacturing method thereof by recycling existing electric porcelain waste materials. There is an impurity problem in the reuse of the waste generated in the manufacturing process of electric porcelain products. The present invention weighs 50-73 parts of electric porcelain waste, 15-25 parts of bauxite, 3-17 parts of clay, 1-8 parts of potassium feldspar, 0.5-2 parts of zinc oxide, and 1-1.5 parts of fluorite to form a mixed composition; According to the weight ratio of composition: alumina ball stone: water = 1:1.5:1, the composition, alumina ball stone and water are mixed for ball milling until the balance of the million-hole sieve is less than 0.2%; the raw materials are filtered mud, The mud is practiced and aged for 48 hours, then shaped, dried, glazed, and finally fired at a temperature of 1200-1250°C. The present invention adds zinc oxide and fluorite to the formula for reusing electric porcelain waste to form a low-melting substance with impurities at high temperature, improves sintering performance, and promotes the formation of mullite crystal phase, which not only eliminates the influence of impurities, but also improves Improve the porcelain mechanical strength and hot and cold abrupt change.

Owner:西安杰力特种瓷研制有限责任公司

A kind of recycling method of stainless steel pickling waste sulfuric acid solution

ActiveCN110835150BHigh total acid contentSmall ionic radiusWater contaminantsDispersed particle separationIron sulfateSodium phosphates

The invention discloses a method for recycling stainless steel pickling waste sulfuric acid solution, which specifically comprises the following steps: (1) pretreating stainless steel pickling waste sulfuric acid, and using a filter of 1 micron level to fine filter to remove fine particle impurities to obtain the pretreated treatment fluid. (2) Separation and recovery of sulfuric acid and metal salt solution are performed on the pretreatment solution with periodic reverse pulse power supply diffusion dialysis-electrodialyzer to obtain recovered acid and raffinate respectively. (3) Recover the acid and return it to the production line of the workshop for reuse; add appropriate amount of sodium phosphate and alkaline agent to the raffinate to remove heavy metal impurities such as chromium, and then oxidize to prepare the water treatment agent polyferric sulfate. The method of the invention utilizes a periodic reverse pulse power supply diffusion dialysis-electrodialyzer to realize high-efficiency separation of acid and metal ions. The technical method has low operating costs, fully recycles resources, and has good economic and environmental benefits.

Owner:3R ENVIRONMENTAL TECH CO LTD

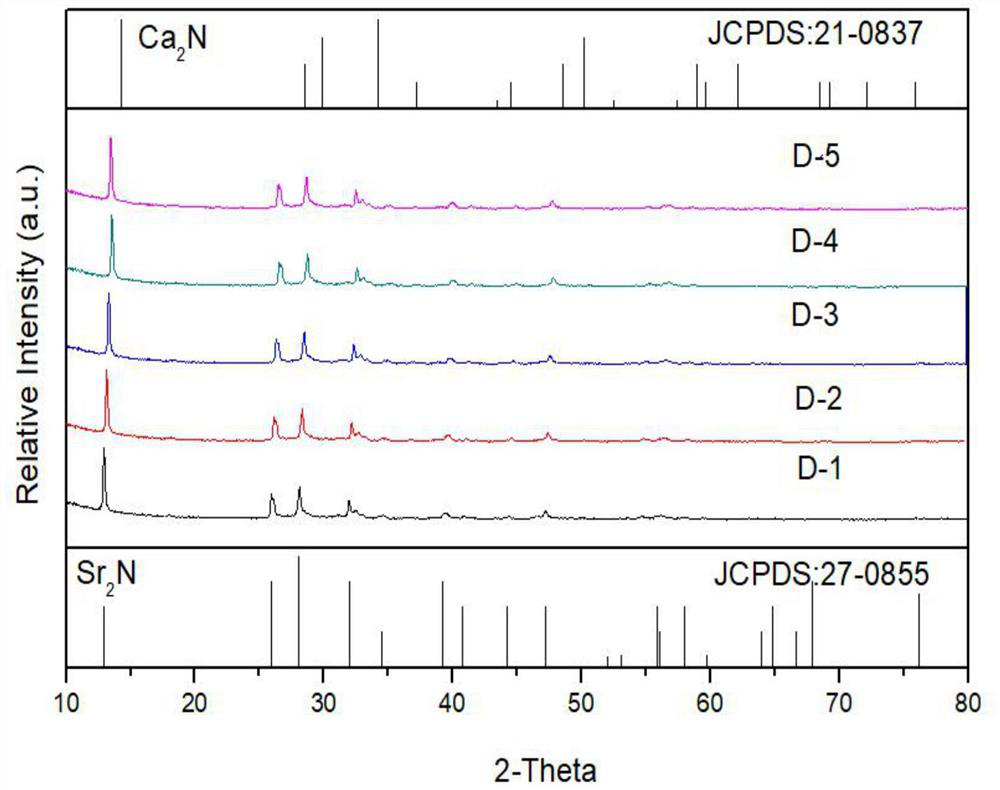

High-purity strontium-calcium-europium nitride solid solution powder and preparation method thereof

PendingCN112441610ASmall ionic radiusAvoid introducingNitrogen compoundsRare earth metal compounds preparation/treatmentStrontiumIngot

The invention discloses high-purity strontium-calcium-europium nitride solid solution powder and a preparation method thereof. The general formula of the high-purity strontium-calcium-europium nitridesolid solution powder is (Sr1-x-yCaxEuy)2N (x is more than or equal to 0 and less than or equal to 0.45, and y is more than or equal to 0.008 and less than or equal to 0.025). The preparation methodcomprises the steps that S1, Ca, Sr and Eu with the purity larger than or equal to 99.99% are weighed and placed in a vacuum smelting furnace, argon is introduced, melting and pouring are conducted atthe temperature of 700-880 DEG C, and an alloy cast ingot is obtained; S2, after the surface of the cast ingot is cleaned, the cast ingot is placed in a hydrogen decrepitation furnace, hydrogen withthe purity larger than or equal to 99.99% is introduced, the cast ingot is heated to 200-400 DEG C, and the cast ingot is broken and dehydrogenated to obtain alloy coarse powder; S3, the temperature is reduced, liquid nitrogen with the purity larger than or equal to 99.99% is introduced, the temperature is increased to 580 DEG C, the pressure ranges from 0.5 Mpa to 0.8 Mpa, heat preservation is conducted for 5 hours, and high-purity strontium-calcium-europium nitride solid solution coarse powder is obtained; and S4, the coarse powder is transferred into a glove box, and the coarse powder is crushed in a crusher coated with a tungsten carbide coating to obtain a powder finished product.

Owner:兰州冉华实德新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com