L-A-S-H nanogel precursor for inhibiting alkali-aggregate reaction, preparation method and application thereof

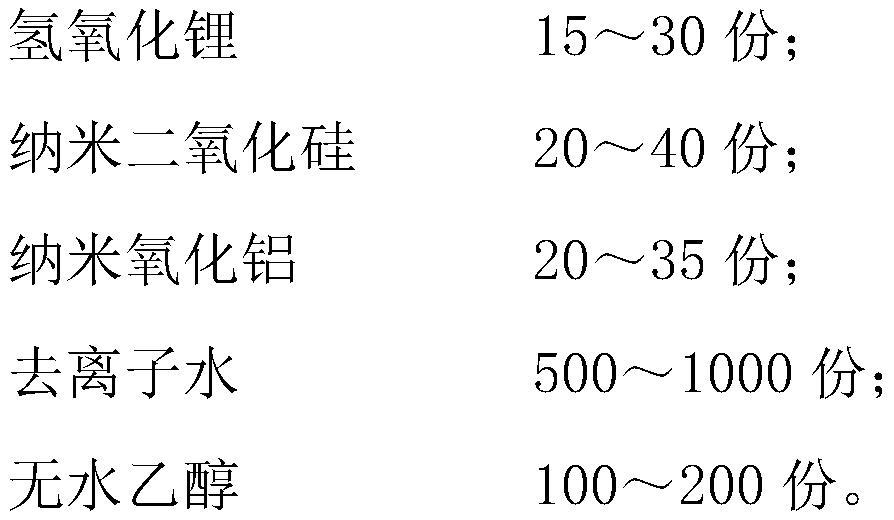

A technology of L-A-S-H and nano gel, which is applied in the research field of inhibiting alkali-aggregate reaction, can solve the problems of affecting the development of slurry strength and insufficient ability to inhibit the expansion of cement slurry, and achieves mature and stable preparation methods, stable dimensions, and no The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Taking water than 0.5, cement and standard sand mass (glue ratio) 1: 3, does not incorporate the lash nanogel precursor, prepared cement mortar; in the control group, the ingredients, the ingredients, such as shown in Table 1, reference The expansion rate test method (JCT313-2009) is expanded to the cement mortar test piece, the test age is 7d, 14d, 28d, and the test results are shown in Table 2; in the control group, refer to ordinary concrete mechanical performance test method The standard GB / T50081-2016, the mechanical properties of cement mortar test parts, the test age is 7d, 14d, 28d, and the test results are shown in Table 3.

Embodiment 2

[0055] Take water as average ratio 0.5, cement and standard sand mass (glue ratio) 1: 3, incorporated in Lash nanogel precursor with 1% percentage of diamonds, preparing cement mortar, ingredients, such as Table 1 The expansion rate test of the cement mortar test piece (JCT313-2009) is used to expand the cement mortar test piece (JCT313-2009), the test age is 7d, 28d, the test results are shown in Table 2; refer to normal concrete mechanical performance test method GB / T50081 -2016, a mechanical properties of cement mortar test pieces, the test age is 7d, 14d, 28d, and the test results are shown in Table 3.

Embodiment 3

[0057] Taking water than 0.5, cement and standard sand mass (glue ratio) 1: 3, incorporates a lash nanogel precursor with a percentage of diarotes of diamonds, preparing cement mortar, ingredients, such as shown in Table 1 The expansion rate test of the cement mortar test piece (JCT313-2009) is used to expand the cement mortar test piece (JCT313-2009), the test age is 7d, 28d, the test results are shown in Table 2; refer to normal concrete mechanical performance test method GB / T50081 -2016, a mechanical properties of cement mortar test pieces, the test age is 7d, 14d, 28d, and the test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com