High-purity strontium-calcium-europium nitride solid solution powder and preparation method thereof

A technology of pure strontium calcium europium and nitride, which is applied in the field of high-purity strontium calcium europium nitride solid solution powder and its preparation, can solve the problems of low purity and waste of nitrogen, and achieve the effect of high purity of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

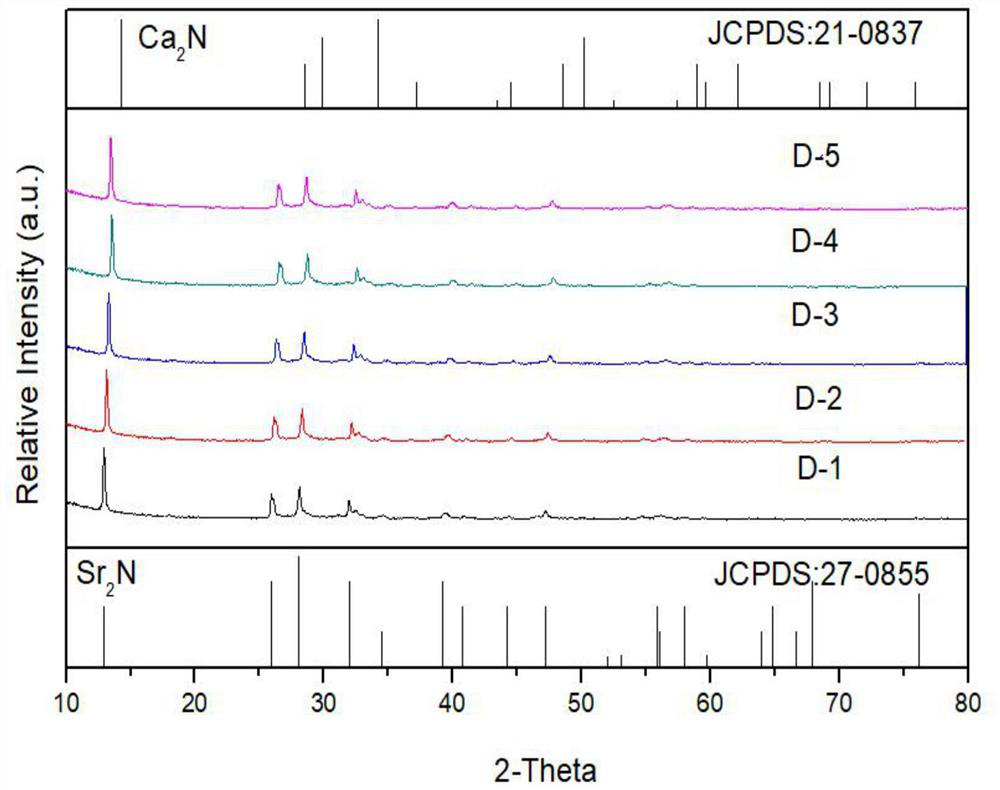

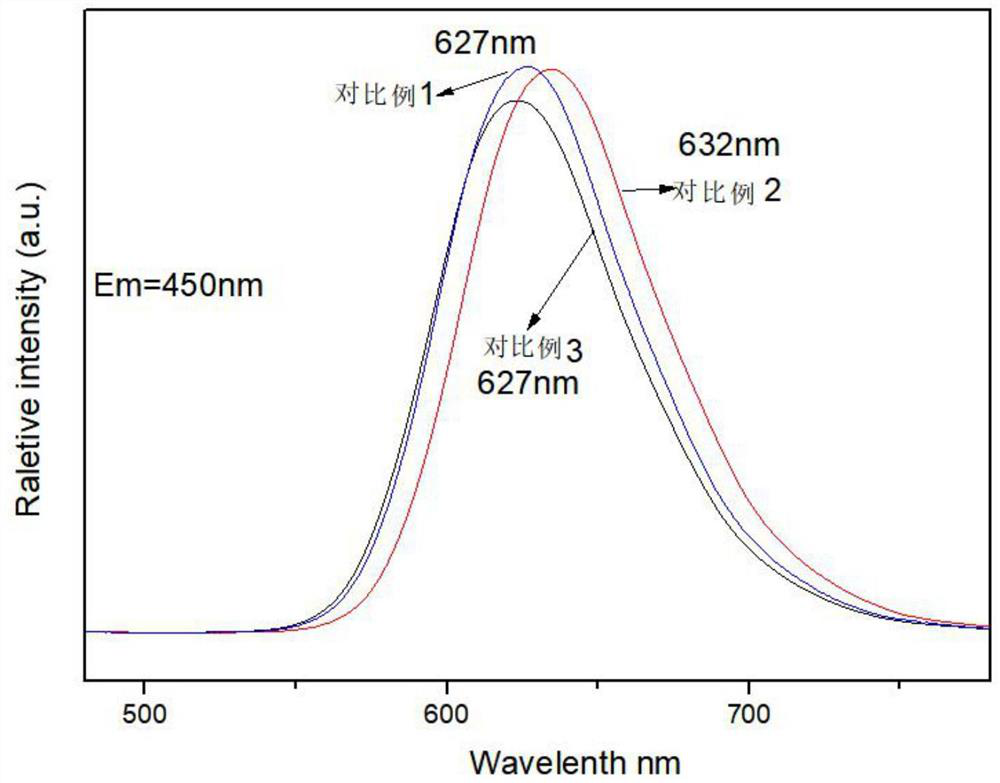

[0032] Embodiment 1: (Sr 0.992 Eu 0.008 )2N

[0033] Weigh 819.7g of calcium metal and 1.25g of europium metal, wash the furnace with argon three times in a vacuum melting furnace, flush with argon to 80KPa, heat to 800°C to melt into a slurry state, pour and cool to obtain an alloy ingot. After cleaning the surface of the alloy ingot, put it into a hydrogen breaker furnace, heat it to 220°C for three times to activate and feed in hydrogen, then heat it to 400°C for 4 hours, then heat it to 600°C to remove the hydrogen, and the vacuum degree is less than 40pa ( instrument display), cool to below 150°C, start feeding nitrogen gas to 0.4MPa, then gradually raise the temperature to 580°C and maintain the gas pressure at 0.5MPa for 4 hours, if the pressure gauge shows no lower within 5 minutes, the reaction is over. Then cool to room temperature, put the material in a stainless steel tank, move it into a glove box with water and oxygen content less than 1ppm, grind it in a pulve...

Embodiment 2

[0034] Embodiment 2: (Sr 0.8 Ca 0.185 Eu 0.015 ) 2 N

[0035]Weigh 83.2g of calcium metal, 786.5g of strontium metal, and 25.57g of europium metal, wash the furnace with argon three times in a vacuum melting furnace, flush with argon to 80KPa, heat to 830°C to melt into a slurry state, pour and cool to obtain an alloy ingot. Clean the surface of the alloy ingot and put it into a hydrogen breaker furnace, heat it to 220°C for three times to activate and feed in hydrogen gas, then heat it to 400°C for 4 hours, then heat it to 600°C to remove the hydrogen gas, and the vacuum degree is less than 40pa (the instrument shows ), cool down to below 150°C, start feeding nitrogen gas to 0.4MPa, then gradually raise the temperature to 580°C and maintain the gas pressure at 0.5MPa for 4 hours, the pressure gauge will not show within 5min, and the reaction is over. Then cool to room temperature, fill the material with a stainless steel tank, move it into a glove box with water and oxyge...

Embodiment 3

[0036] Embodiment 3: (Sr 0.75 Ca 0.235 Eu 0.015 ) 2 N

[0037] Weigh 295.7g of calcium metal, 543.9g of strontium metal, and 31.44g of europium metal, wash the furnace with argon three times in a vacuum melting furnace, flush with argon to 80KPa, heat to 850°C to melt into a slurry state, pour and cool to obtain an alloy ingot. Clean the surface of the alloy ingot and put it into a hydrogen breaker furnace, heat it to 220°C for three times to activate and feed in hydrogen gas, then heat it to 400°C for 4 hours, then heat it to 600°C to remove the hydrogen gas, and the vacuum degree is less than 40pa (the instrument shows ), cool down to below 150°C, start feeding nitrogen gas to 0.4MPa, then gradually raise the temperature to 580°C and maintain the gas pressure at 0.5MPa for 4 hours, the pressure gauge will not show within 5min, and the reaction is over. Then cool to room temperature, fill the material with a stainless steel tank, move it into a glove box with water and ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com