Preparation method and application of a self-cleaning electrochemical sensor under visible light

An electrochemical and sensor technology, applied in the field of electrochemical sensor preparation, can solve problems such as unfavorable formation of a network structure, unfavorable electrochemical testing, carboxyl salt asymmetry, etc., and achieves good detection effect and efficient use of electrodes. Impact, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a hydroquinone and catechol electrochemical sensor with self-cleaning ability under ultraviolet light or visible light, comprising the following steps in sequence:

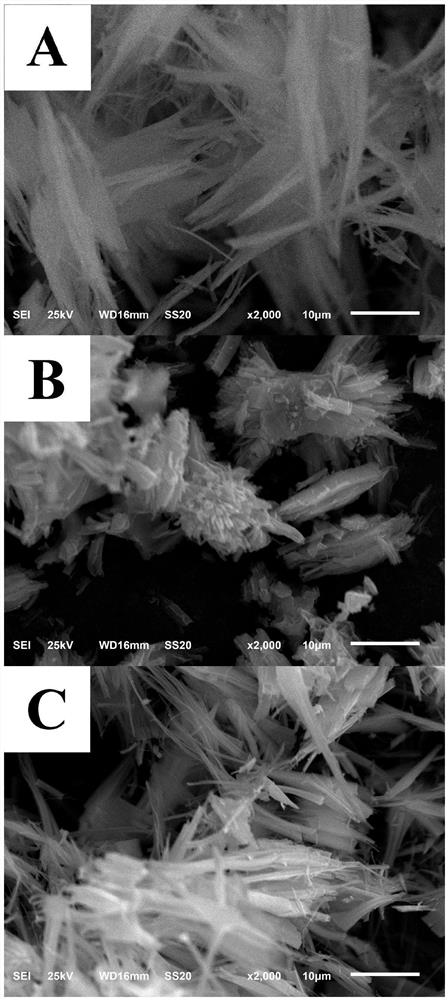

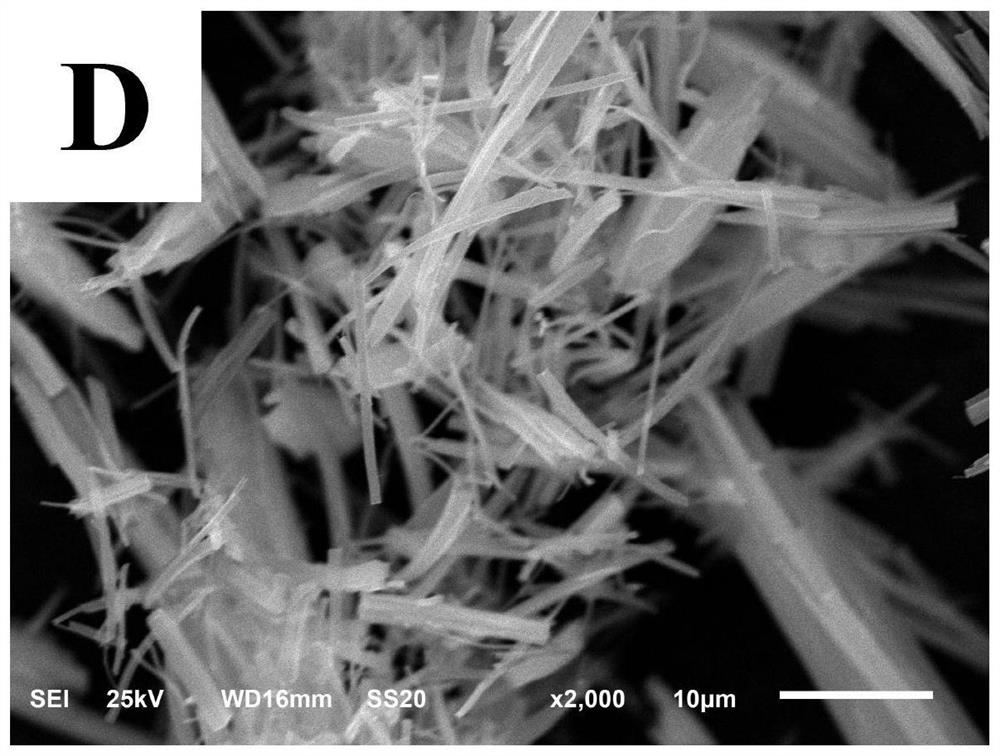

[0053] (1) Mix 0.012g citric acid monohydrate, 0.55g trimesic acid and 0.8g (1.8476mmol) La(NO 3 ) 3 ·6H 2 Add O to 9mL N, N-dimethylformamide (DMF) to dissolve, slowly add 0.5mL (1.467mmol) tetra-n-butyl titanate (TBOT) under magnetic stirring, and heat at a heating rate of 10°C / min. Reaction at 150°C for 48 hours to obtain the La-Ti metal frame material, followed by solvent exchange of the La-Ti metal frame material with chloroform and methanol, and drying at 100°C to obtain the LTOF precursor material;

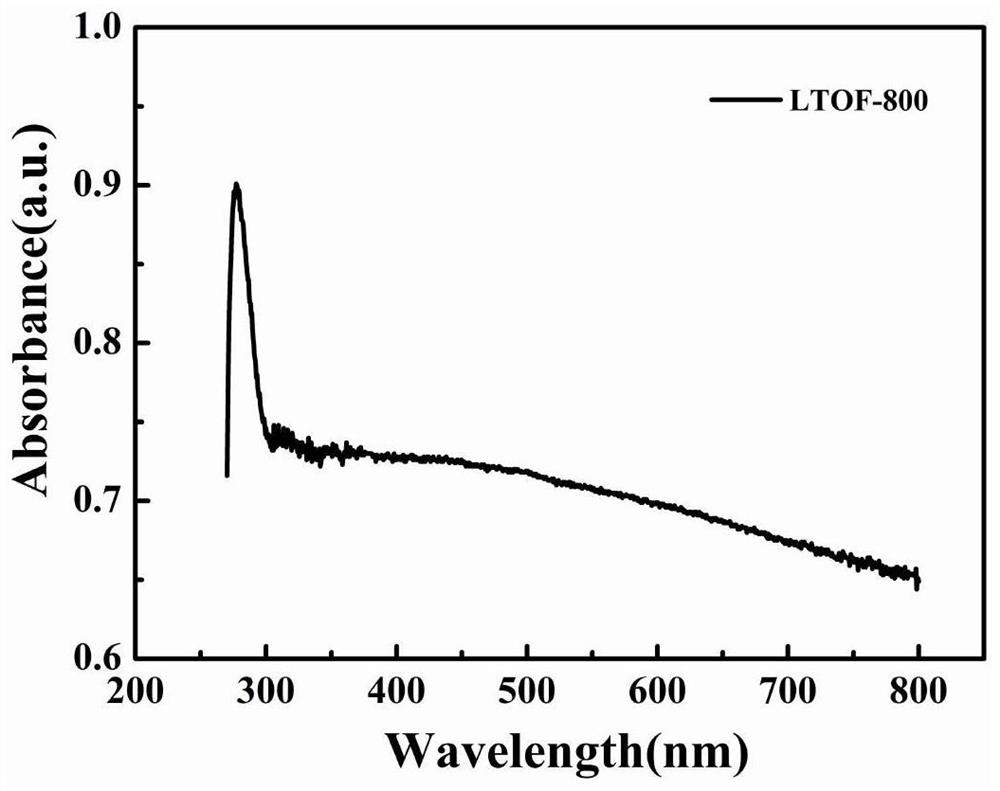

[0054](2) Weigh 2g of LTOF precursor material in a crucible, raise the temperature to 800°C at a heating rate of 10°C / min under the protection of nitrogen flow, and keep it warm for 300min, take it out, grind it, and name this new composite material LTOF- 800;

[0055] (3) Take...

Embodiment 2

[0061] A method for preparing a hydroquinone and catechol electrochemical sensor with self-cleaning ability under ultraviolet light or visible light, comprising the following steps in sequence:

[0062] (1) Mix 0.012g citric acid monohydrate, 0.55g trimesic acid and 0.802g (1.8477mmol) Ce(NO 3 ) 3 ·6H 2 Add O to 9mL N, N-dimethylformamide (DMF) to dissolve, slowly add 0.638mL (1.8703mmol) tetra-n-butyl titanate (TBOT) under magnetic stirring, and heat with hydrothermal heating at a rate of 10°C / min React at 150°C for 48 hours to obtain the Ce-Ti metal frame material, perform solvent exchange on the Ce-Ti metal frame material with chloroform and methanol in sequence, and dry at 100°C to obtain the CTOF precursor material;

[0063] (2) Weigh 2g of CTOF precursor material in a crucible, raise the temperature to 800°C at a heating rate of 10°C / min under the protection of nitrogen flow, and keep it warm for 300min, take it out and grind it, and name this new composite material CT...

Embodiment 3

[0070] A method for preparing a hydroquinone and catechol electrochemical sensor with self-cleaning ability under ultraviolet light or visible light, comprising the following steps in sequence:

[0071] (1) Mix 0.012g citric acid monohydrate, 0.55g trimesic acid, 0.810g (1.848mmol) Nd(NO 3 ) 3 ·6H 2 O, take 9mL of N, N-dimethylformamide (DMF) to dissolve, slowly add 0.644mL (1.888mmol) tetra-n-butyl titanate (TBOT) under magnetic stirring, and heat to React at 150°C for 48 hours to prepare the Nd-Ti metal frame material, perform solvent exchange on the Nd-Ti metal frame material with chloroform and methanol in sequence, and dry at 100°C to obtain the NTOF precursor material;

[0072] (2) Weigh 2g of NTOF precursor material in a crucible, raise the temperature to 800°C at a heating rate of 10°C / min under the protection of nitrogen flow, and keep it warm for 300min, take it out and grind it, and name this new composite material NTOF-800 ;

[0073] (3) Dissolve 10 mg of NTOF-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com