A kind of recycling method of stainless steel pickling waste sulfuric acid solution

A technology of waste sulfuric acid and stainless steel, applied in separation methods, chemical instruments and methods, metallurgical wastewater treatment, etc., can solve the problems of high equipment cost investment, large equipment footprint, and low energy consumption in operation, so as to save treatment costs, The effect of small footprint and high acid recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

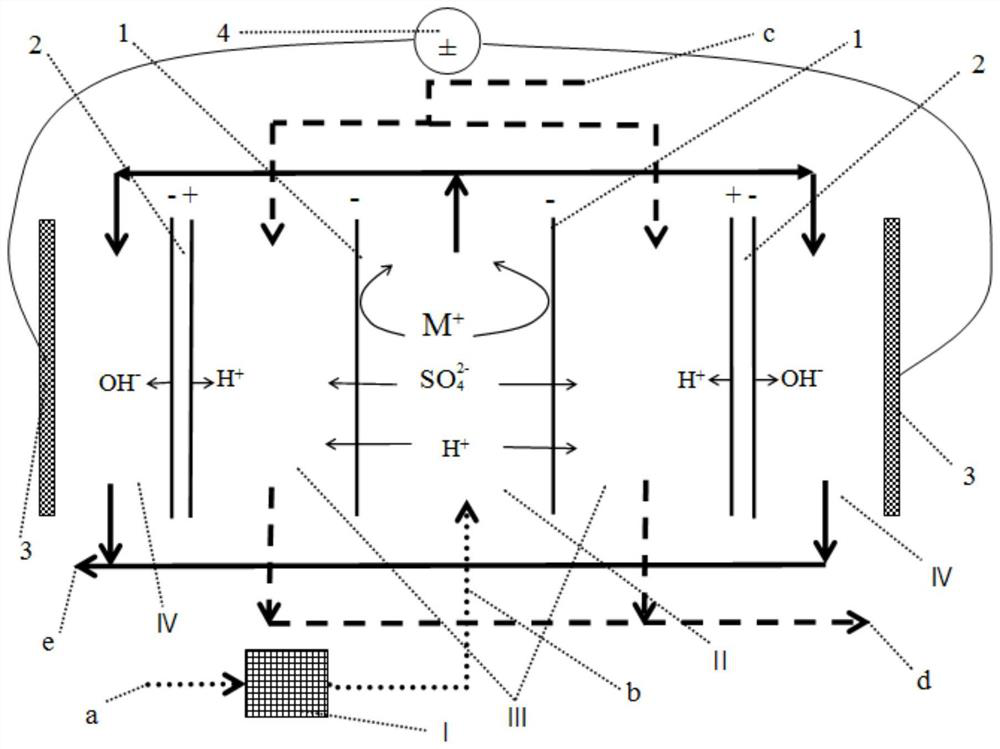

[0020] Reference attached figure 1 , The present invention provides a method for recycling stainless steel pickling waste sulfuric acid solution, which specifically includes the following steps:

[0021] 1. The sulfuric acid content is 5.1% and the iron content is 2.2%. The stainless steel pickling waste sulfuric acid a is filtered through a 1-micron-level precision filter I to obtain a pretreatment solution b.

[0022] 2. The volume ratio of pretreatment liquid b and tap water c is 1:0.7, and the feed flow rate of pretreatment liquid b is 400L / h. The feeding conditions enter into the periodic reverse pulse power diffusion dialysis-electrodialyzer for acid and metal salts. separation and recycling. Further description: the pretreatment liquid b enters the waste acid chamber II, the tap water c enters the recovery acid chamber III, and the process parameters of the periodic reverse pulse power supply 4 are set as voltage 10V~15V, output pulse frequency 10Hz, positive and negat...

Embodiment 2

[0025] The sulfuric acid content is 5.1% and the iron content is 2.2% stainless steel pickling waste sulfuric acid a as the raw material; the volume ratio of the pretreatment solution b and the tap water c is 1:1, the feed flow rate of the pretreatment solution b is 500L / h, and the cycle The output pulse frequency of the reverse pulse power supply 4 is 50 Hz, and other steps are the same as those in the first embodiment of the specific implementation. Finally, a recovered acid d with an acid content of 5.5% and a metal salt content of 0.05% and a raffinate e with an acid content of 0.5% were obtained.

Embodiment 3

[0027] The stainless steel pickling waste sulfuric acid a with a sulfuric acid content of 24.8% and an iron content of 2.0% is used as the raw material; the feed flow rate of the pretreatment solution b is 300L / h, and the process parameters of the periodic reverse pulse power supply 4 are the voltage of 15V ~ 20V, The frequency of the output pulse wave is 30 Hz, and other steps are the same as those in Embodiment 1 of the specific embodiment. Finally, a recovered acid d with an acid content of 29.8% and a metal salt content of 0.11% and a raffinate e with an acid content of 0.5% were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com