Production method of acid flavoring liquor

A production method and technology for seasoning wine, applied in the field of liquor blending, can solve the problems of low added value of feed, affecting the taste quality of liquor, and failing to make full use of it, and achieve long aftertaste, obvious blending effect and less off-flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

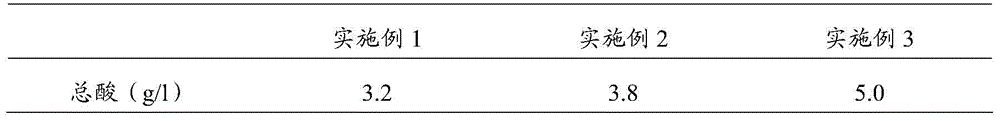

Embodiment 1

[0042]1.1 In a certain amount of water, add 10g of glucose and 100g of distiller’s grains, mix well, sterilize at 0.01MPa for 20 minutes, add wine tail to adjust the alcohol concentration of the medium to 5% (the total volume of water and wine tail is 1L), inoculate with acetic acid bacteria , cultivated for 24 hours to obtain acetic acid bacteria liquid.

[0043] 1.2 Spread out 400kg of liquor after leaving the cellar and let it cool down to 30-35°C, add 320g of distiller’s koji and 1.2kg of the acetic acid bacteria liquid obtained in 1.1, then sprinkle 12kg of wine tails, turn it into the cellar, step on it tightly, and seal it After 20 days of fermentation, the cellar is opened to obtain fermented grains of distilled grains.

[0044] 1.3 Add 400kg of original basic wine into the bottom pot of the retort pot, evenly and loosely spread a layer of 40cm1.2 fermented wine grains obtained in 1.2 on the retort, then introduce steam with a pressure of 0.03MPa, and detect steam laye...

Embodiment 2

[0046] 2.1 Spread out 400kg of white wine grains after leaving the cellar to cool to 30-35°C, add 400g of distiller’s koji and 1.6kg of the acetic acid bacteria solution obtained in Example 1, then sprinkle 20kg of wine tails, and then turn it into the cellar and step on it tightly. After sealing and fermenting for 20 days, the cellar is opened to obtain fermented grains with discarded grains.

[0047] 2.1 Add 400kg of the original base wine into the bottom pot of the retort pot, evenly and loosely spread a layer of 40cm2.1 fermented wine grains obtained in the retort on the retort, and then introduce steam with a pressure of 0.03MPa, and detect the steam layer by layer On the top of the retort, the speed of the wine flowing in each retort is less than 10 kg per minute, and the temperature of the flowing wine is lower than 30°C. After distillation, the resulting liquor is stored for four months to obtain sour seasoning wine.

Embodiment 3

[0049] 3.1 Spread out 400kg of white wine grains after leaving the cellar and let it cool to 30-35°C, add 480g of distiller's yeast and 2.0kg of the acetic acid bacteria solution obtained in Example 1, then sprinkle 20kg of wine tails, turn it into the cellar and step on it tightly. After sealing and fermenting for 20 days, the cellar is opened to obtain fermented grains with discarded grains.

[0050] 3.2 Add 400kg of the original base wine into the bottom pot of the retort pot, evenly and loosely spread a layer of 40cm3.1 fermented wine grains obtained in the retort on the retort, and then introduce steam with a pressure of 0.03MPa, and detect the steam layer by layer On the top of the retort, the speed of the wine flowing in each retort is less than 10 kg per minute, and the temperature of the flowing wine is lower than 30°C. After distillation, the resulting liquor is stored for four months to obtain sour seasoning wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com