Preparation method and application of self-cleaning electrochemical sensor under visible light

An electrochemical and sensor technology, which is applied in the field of electrochemical sensor preparation, can solve problems such as unfavorable electrochemical testing, unfavorable formation of network structure, asymmetry of carboxyl salts, etc., so that the use efficiency of electrodes will not be affected and the detection effect will be improved. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a hydroquinone and catechol electrochemical sensor with self-cleaning ability under ultraviolet light or visible light, comprising the following steps in sequence:

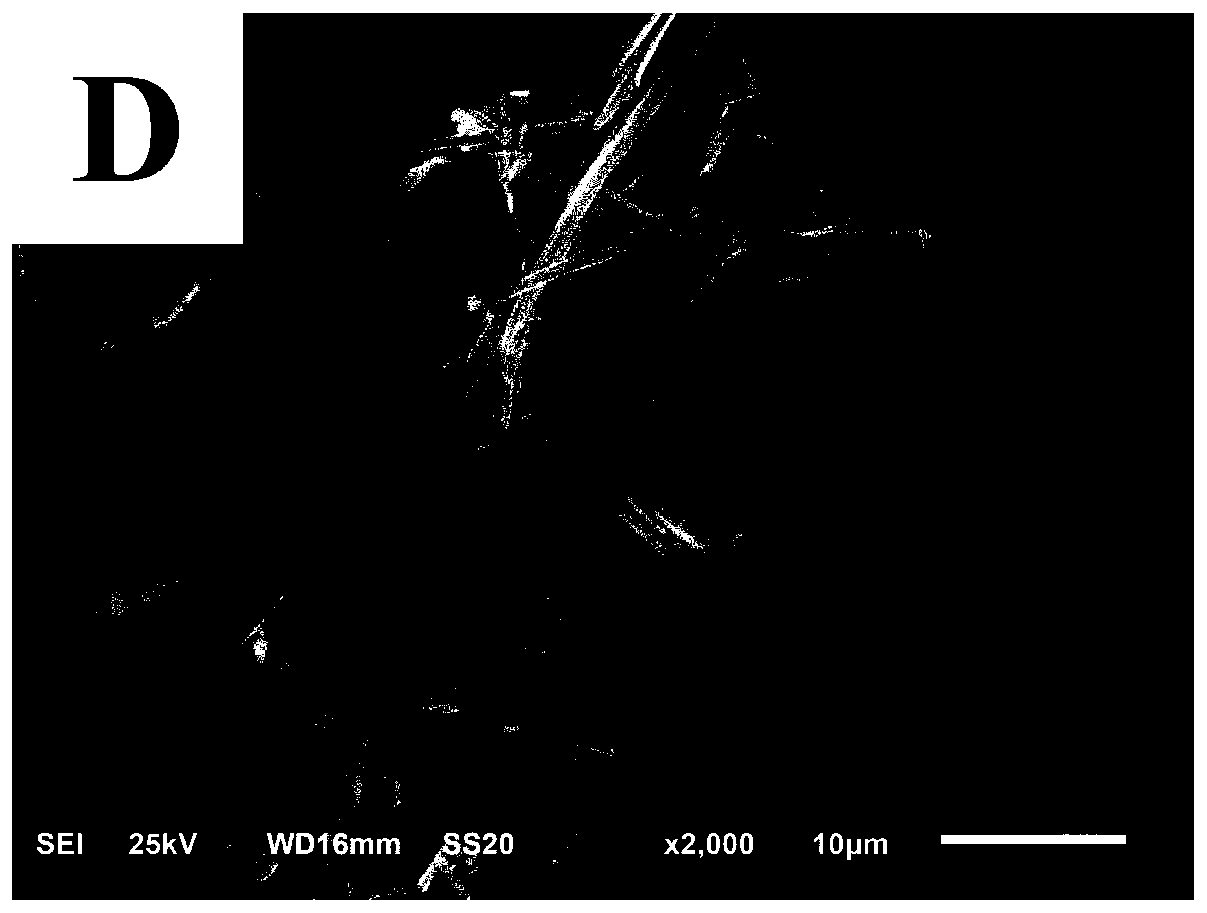

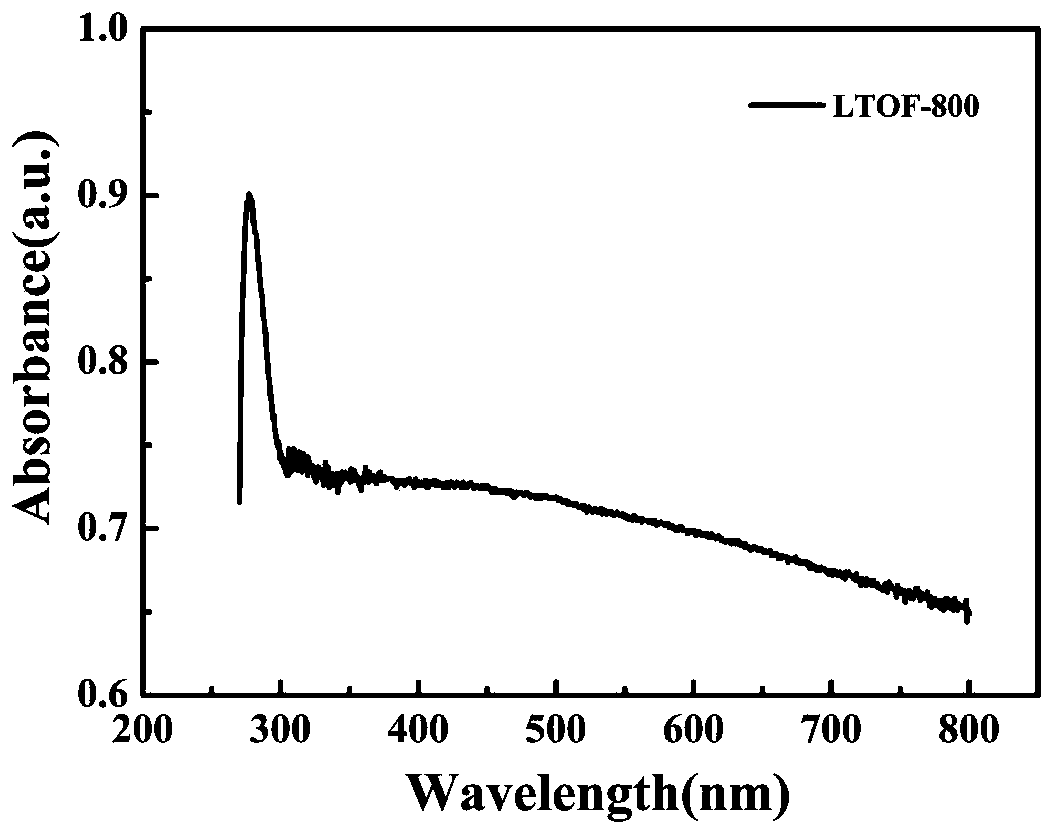

[0053] (1) Mix 0.012g citric acid monohydrate, 0.55g trimesic acid and 0.8g (1.8476mmol) La(NO 3 ) 3 ·6H 2 Add O to 9mL N, N-dimethylformamide (DMF) to dissolve, slowly add 0.5mL (1.467mmol) tetra-n-butyl titanate (TBOT) under magnetic stirring, and heat at a heating rate of 10°C / min. Reaction at 150°C for 48 hours to obtain the La-Ti metal frame material, followed by solvent exchange of the La-Ti metal frame material with chloroform and methanol, and drying at 100°C to obtain the LTOF precursor material;

[0054] (2) Weigh 2g of LTOF precursor material in a crucible, raise the temperature to 800°C at a heating rate of 10°C / min under the protection of nitrogen flow, and keep it warm for 300min, take it out, grind it, and name this new composite material LTOF- 800;

[0055] (3) Tak...

Embodiment 2

[0061] A method for preparing a hydroquinone and catechol electrochemical sensor with self-cleaning ability under ultraviolet light or visible light, comprising the following steps in sequence:

[0062] (1) Mix 0.012g citric acid monohydrate, 0.55g trimesic acid and 0.802g (1.8477mmol) Ce(NO 3 ) 3 ·6H 2 Add O to 9mL N, N-dimethylformamide (DMF) to dissolve, slowly add 0.638mL (1.8703mmol) tetra-n-butyl titanate (TBOT) under magnetic stirring, and heat with hydrothermal heating at a rate of 10°C / min React at 150°C for 48 hours to obtain the Ce-Ti metal frame material, perform solvent exchange on the Ce-Ti metal frame material with chloroform and methanol in sequence, and dry at 100°C to obtain the CTOF precursor material;

[0063] (2) Weigh 2g of CTOF precursor material in a crucible, raise the temperature to 800°C at a heating rate of 10°C / min under the protection of nitrogen flow, and keep it warm for 300min, take it out and grind it, and name this new composite material CT...

Embodiment 3

[0070] A method for preparing a hydroquinone and catechol electrochemical sensor with self-cleaning ability under ultraviolet light or visible light, comprising the following steps in sequence:

[0071] (1) Mix 0.012g citric acid monohydrate, 0.55g trimesic acid, 0.810g (1.848mmol) Nd(NO 3 ) 3 ·6H 2 O, take 9mL of N, N-dimethylformamide (DMF) to dissolve, slowly add 0.644mL (1.888mmol) tetra-n-butyl titanate (TBOT) under magnetic stirring, and heat to React at 150°C for 48 hours to prepare the Nd-Ti metal frame material, perform solvent exchange on the Nd-Ti metal frame material with chloroform and methanol in sequence, and dry at 100°C to obtain the NTOF precursor material;

[0072] (2) Weigh 2g of NTOF precursor material in a crucible, raise the temperature to 800°C at a heating rate of 10°C / min under the protection of nitrogen flow, and keep it warm for 300min, take it out and grind it, and name this new composite material NTOF-800 ;

[0073] (3) Dissolve 10 mg of NTOF-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com