Bis-terpyridine based bi-metal polymer and preparation method thereof

A technology based on terpyridyl and double terpyridine, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of high cost of composite materials, low relative catalytic efficiency, Poor stability and other problems, to achieve the effect of improving catalytic activity, high electricity price, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of double terpyridine ligands:

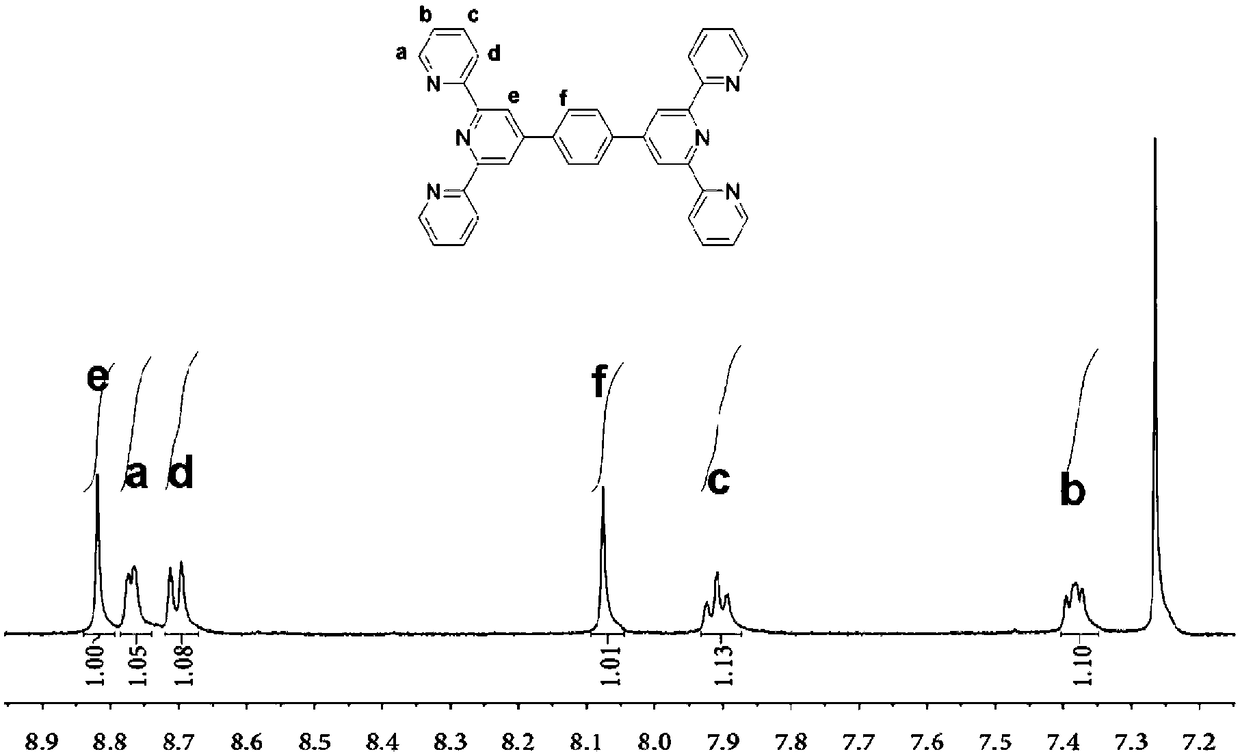

[0046]Add terephthalaldehyde (0.67g, 5mmol), 2-acetylpyridine (2.9g, 24mmol), NaOH (2.4g, 60mmol) into a 250mL single-necked round bottom flask, add 30mL of ethanol, stir at 25°C for 10h, Add 40mL of 25-28% ammonia water, stir and reflux for 20h, then cool to room temperature, add 100mL of methanol to ultrasonically reflux and filter with suction, repeat twice, then reflux and filter with 100mL glacial acetic acid, wash with methanol once more, and vacuum dry at 50°C to obtain 1.6g Product, white solid, yield 60%. Characterization: 1H NMR (CDCl 3 )δ (ppm): 8.818 (s, 4H), 8.770 (d, J = 2.8Hz, 4H), 8.704 (d, J = 6.4Hz, 4H), 8.075 (s, 4H), 7.908 (t, J = 6.2Hz, 4H), 7.382(t, J=5.0Hz, 4H).

[0047] (2) Preparation of double terpyridine cobalt polymer (Polymer-Co):

[0048] Cobalt Chloride (CoCl 2 ) and 1,4-bis(terpyridine)benzene 3 were refluxed and stirred in ethylene glycol at a molar ratio of 1 / 1 for 12 hours, cooled t...

Embodiment 2

[0052] Transmission Electron Microscopy (TEM) projects electron beams onto the sample, and the electrons collide with the atoms in the sample to change their direction, resulting in solid angle scattering and forming a clear image, so the morphology of nanostructures can be observed intuitively. Take a certain amount of flocculent precipitation of bimetallic terpyridine cobalt-tungsten bimetallic polymer nanomaterials, use 5 ml of methanol to ultrasonically disperse, take two drops of methanol dispersion and drop them on the copper grid covered with ultra-thin carbon film dedicated for transmission electron microscopy , tested after drying on a desiccator at 60 degrees Celsius for 20 minutes, it was observed that the synthesized high molecular polymer existed in a fibrous form.

[0053] Scanning electron microscope (SEM) uses a very narrow electron beam to scan the sample, and produces various effects through the interaction between the electron beam and the sample. It can dire...

Embodiment 3

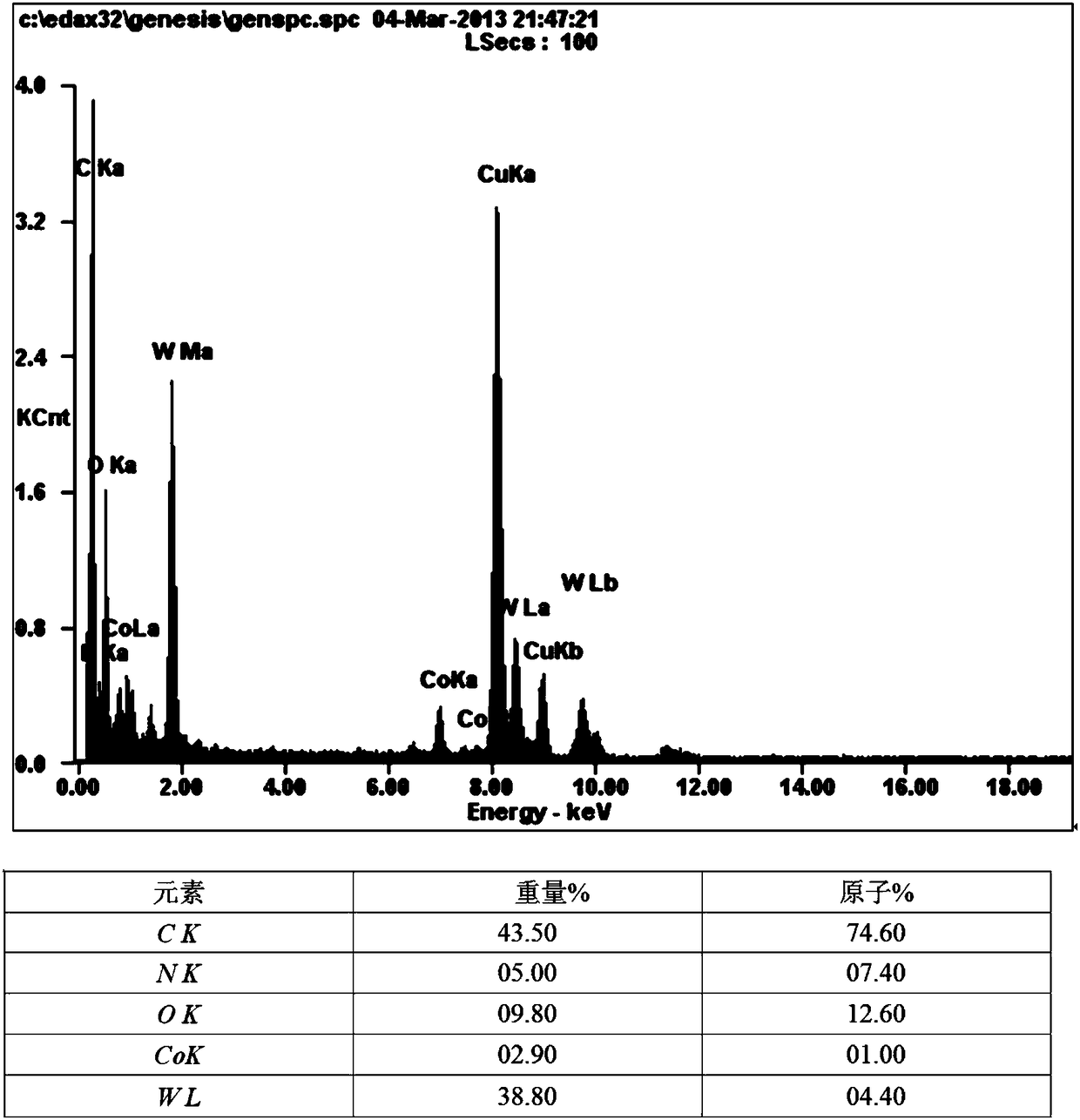

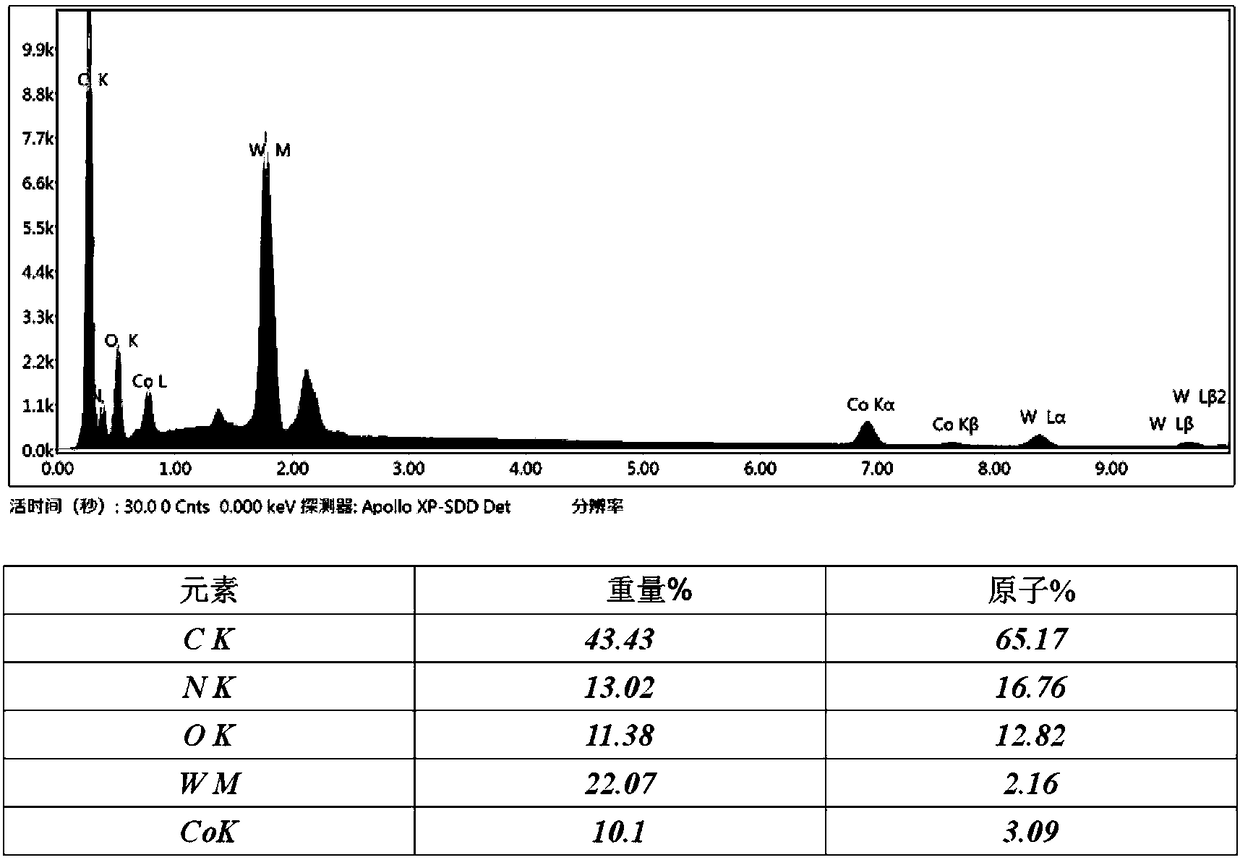

[0055] Energy dispersive X-ray spectroscopy (EDX) is realized by analyzing the characteristic X-ray wavelength and intensity of the elements emitted by the sample. The elements contained in the sample are determined according to the wavelength, and the relative content of the element is determined according to the intensity. According to the EDX diagram, the existence of Co element and W element can be clearly seen, and the analysis of the content can facilitate the follow-up work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com