Alkali metal enhanced bismuth titanate-based up-conversion fluorescent material and preparation method thereof

A fluorescent material, bismuth titanate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of affecting luminous efficiency, deterioration, easy to absorb moisture, etc., and achieve the effect of good chemical stability, not easy to absorb water, and enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

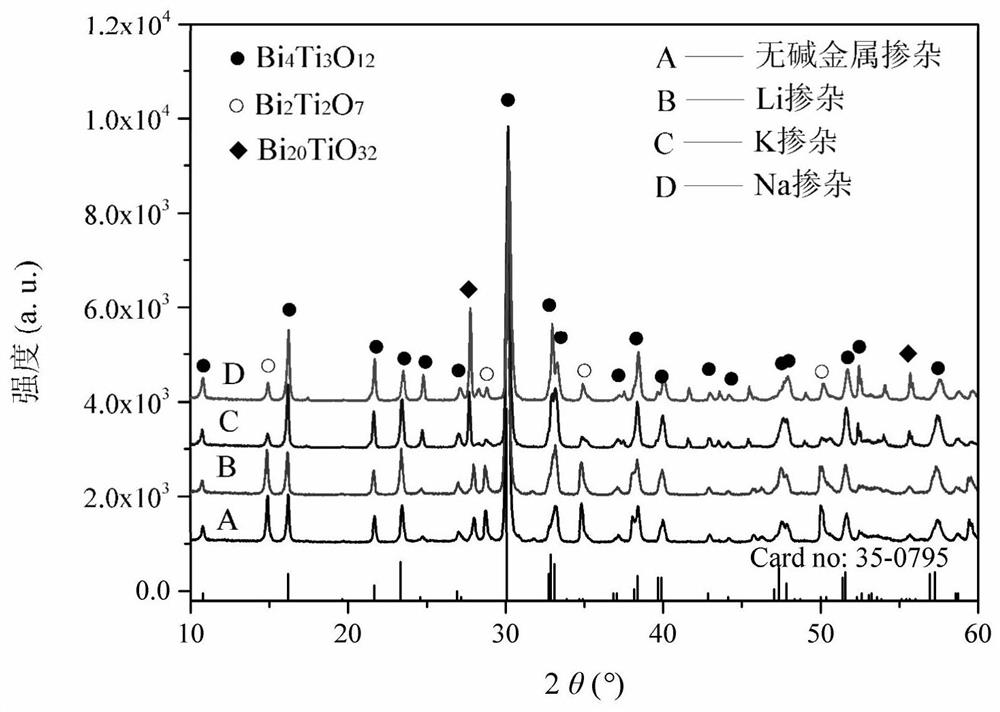

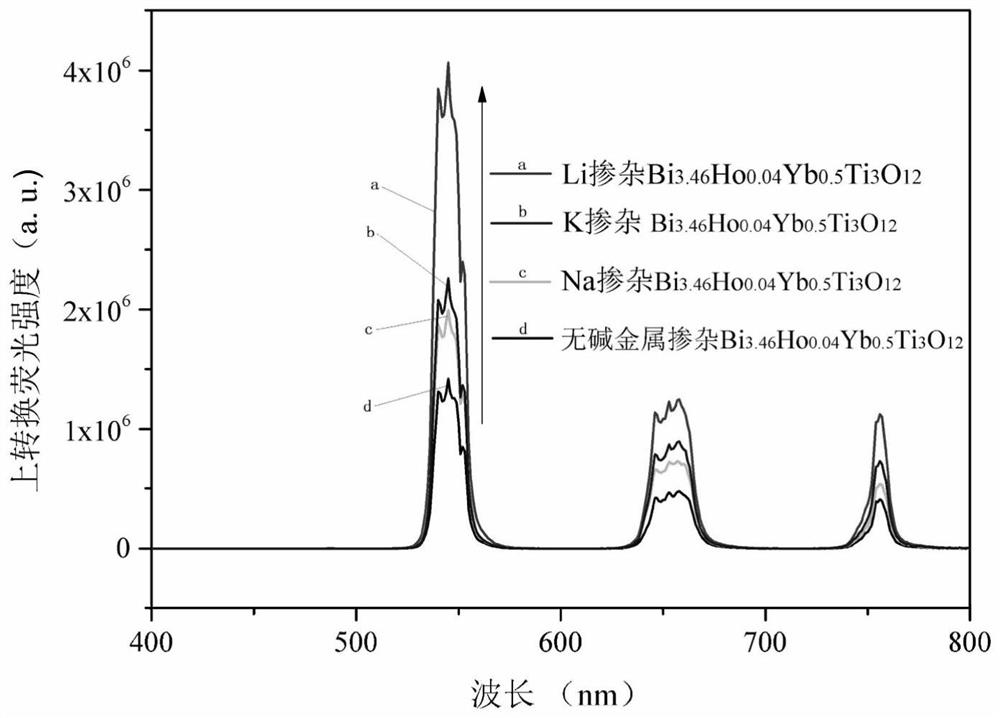

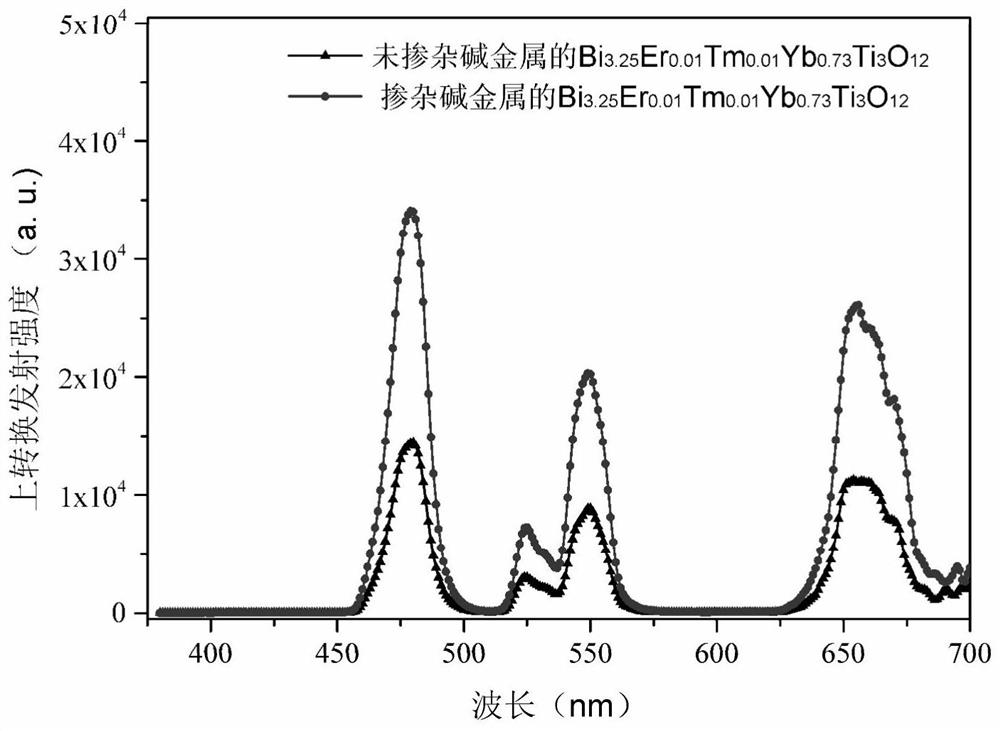

Method used

Image

Examples

Embodiment 1

[0039] By Bi 3.46 Ho 0.04 Yb 0.5 Ti 3 o 12 :0.02Li as an example, the method is a chemical solution method, mainly including: S1, the preparation of the precursor solution; S2, gel preparation, S3 three steps of sintering, the specific steps are as follows:

[0040] S1. Preparation of precursor solution:

[0041] According to the chemical formula Bi of the upconverting phosphor 3.46 Ho 0.04 Yb 0.5 Ti 3 o 12 : 0.02Li, take by weighing 3.5086g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), 0.0318g holmium nitrate pentahydrate (Ho(NO 3 ) 3 ·5H 2 O), 0.4205g ytterbium nitrate hexahydrate (Yb(NO 3 ) 3 ·6H 2 O), 0.0028g lithium nitrate (LiNO 3 ) into a beaker as the precursors of Bi, Ho, Yb, and Li respectively, add 15ml of glacial acetic acid solution to the beaker, heat and stir it on a constant temperature magnetic stirrer, the heating temperature is 60°C, the holding time is 20min, cool to room temperature to form A liquid;

[0042] Tetrabutyl titanate (...

Embodiment 2

[0051] By Bi 3.46 Ho 0.04 Yb 0.5 Ti 3 o 12 :0.05Li as an example, the specific steps are as follows:

[0052] S1. Preparation of precursor solution: according to the chemical formula Bi of the up-conversion phosphor 3.46 Ho 0.04 Yb 0.5 Ti 3 o 12 : 0.05Li, weigh 3.5086g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), 0.0318g holmium nitrate pentahydrate (Ho(NO 3 ) 3 ·5H 2 O), 0.4205g ytterbium nitrate hexahydrate (Yb(NO 3 ) 3 ·6H 2 O), 0.0069g lithium nitrate (LiNO 3 ) into a beaker as the precursors of Bi, Ho, Yb, and Li respectively, add 15ml of glacial acetic acid solution to it, place it on a constant temperature magnetic stirrer to heat and stir, the heating temperature is 60°C, the holding time is 15min, cool to room temperature to form A solution;

[0053] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) as a Ti precursor, 1.85ml tetrabutyl titanate was added to 15ml ethylene glycol methyl ether, and stirred at a speed of 800r / min for 2min at room tempera...

Embodiment 3

[0058] with Bi 3.46 Ho 0.04 Yb 0.5 Ti 3 O 12 :0.05Na as an example, the specific steps are as follows:

[0059] S1. Preparation of precursor solution: according to the chemical formula Bi of the up-conversion phosphor 3.46 Ho 0.04 Yb 0.5 Ti 3 O 12 : 0.05Na, weigh 3.5086g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), 0.0318g holmium nitrate pentahydrate (Ho(NO 3 ) 3 ·5H 2 O), 0.4205g ytterbium nitrate hexahydrate (Yb(NO 3 ) 3 ·6H 2 O), 0.0085g sodium nitrate (NaNO 3 ) into a beaker as the precursors of Bi, Ho, Yb, and Na respectively, add 15ml of glacial acetic acid solution to it, place it on a constant temperature magnetic stirrer, heat and stir, the heating temperature is 60°C, the holding time is 15min, cool to room temperature to form A solution;

[0060] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) as a Ti precursor, 1.85ml tetrabutyl titanate was added to 15ml ethylene glycol methyl ether, and stirred at a speed of 800r / min for 2min at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com