Anti-PID effect assembly and preparation method and application thereof

An effect and component technology, applied in the field of anti-PID effect components and their preparation, which can solve problems such as affecting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

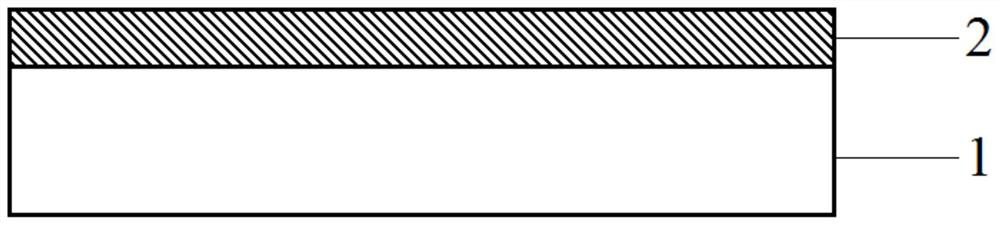

[0042] The second aspect of the embodiment of the present application provides a method for preparing an anti-PID effect component, including the following steps:

[0043] S01. Provide glass substrate,

[0044] S02. A tin oxide layer is provided on either side of the glass substrate to obtain an anti-PID component.

[0045] The preparation method of the anti-PID effect component provided by the second aspect of the present application is that the anti-PID effect component can be obtained by directly setting the tin oxide layer 2 on any side of the glass substrate 1. The preparation process is simple and convenient, and the operation is fast and effective. Facilitate large-scale use.

[0046] In step S01, a glass substrate 1 is provided, and the provided glass substrate 1 is cleaned to remove impurities to ensure that a clean and impurity-free glass substrate 1 is obtained for use.

[0047] In step S02, a tin oxide layer 2 is provided on either side of the glass substrate 1 t...

Embodiment 1

[0060] Components resistant to PID effects

[0061] Components resistant to PID effects

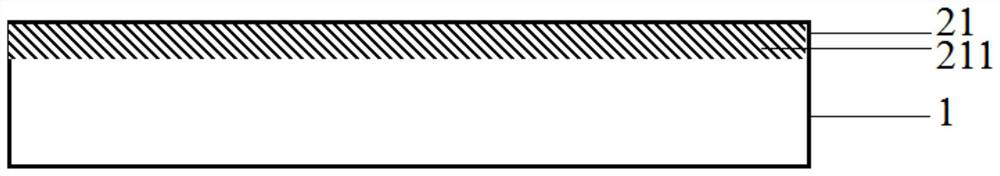

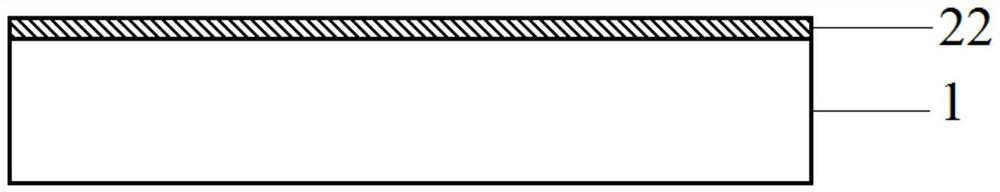

[0062] The anti-PID effect component includes a glass substrate 1; a tin oxide layer 2 arranged on either side of the glass substrate, the tin oxide layer 2 includes a first tin oxide layer 21, and the first tin oxide layer 21 is formed by penetrating into the surface layer of the glass substrate 1 Transition zone; the anti-reflection film layer 3 provided on the surface of the tin oxide layer 2 away from the glass substrate 1 .

[0063] Wherein, the glass substrate is selected from silicate glass, and the iron content in the provided silicate glass is controlled to be 91%, and the thickness of the glass substrate is 2mm;

[0064] The thickness of the first tin oxide layer is 2 microns;

[0065] The anti-reflection film layer is selected from silicon nitride layers, and the thickness of the anti-reflection film layer is 150 nanometers.

[0066] Preparation method of components resi...

Embodiment 2

[0073] Components resistant to PID effects

[0074] Components resistant to PID effects

[0075] The anti-PID effect component includes a glass substrate 1; a tin oxide layer 2 arranged on either side of the glass substrate, the tin oxide layer 2 includes a first tin oxide layer 21, and the first tin oxide layer 21 is formed by penetrating into the surface layer of the glass substrate 1 Transition zone; the anti-reflection film layer 3 provided on the surface of the tin oxide layer 2 away from the glass substrate 1 .

[0076] Wherein, the glass substrate is selected from silicate glass, and the iron content in the provided silicate glass is controlled to be 91%, and the thickness of the glass substrate is 2mm;

[0077] The thickness of the first tin oxide layer is 10 microns;

[0078] The anti-reflection film layer is selected from silicon nitride layers, and the thickness of the anti-reflection film layer is 150 nanometers.

[0079] Preparation method of components res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com