Composite material and its preparation method and quantum dot light-emitting diode

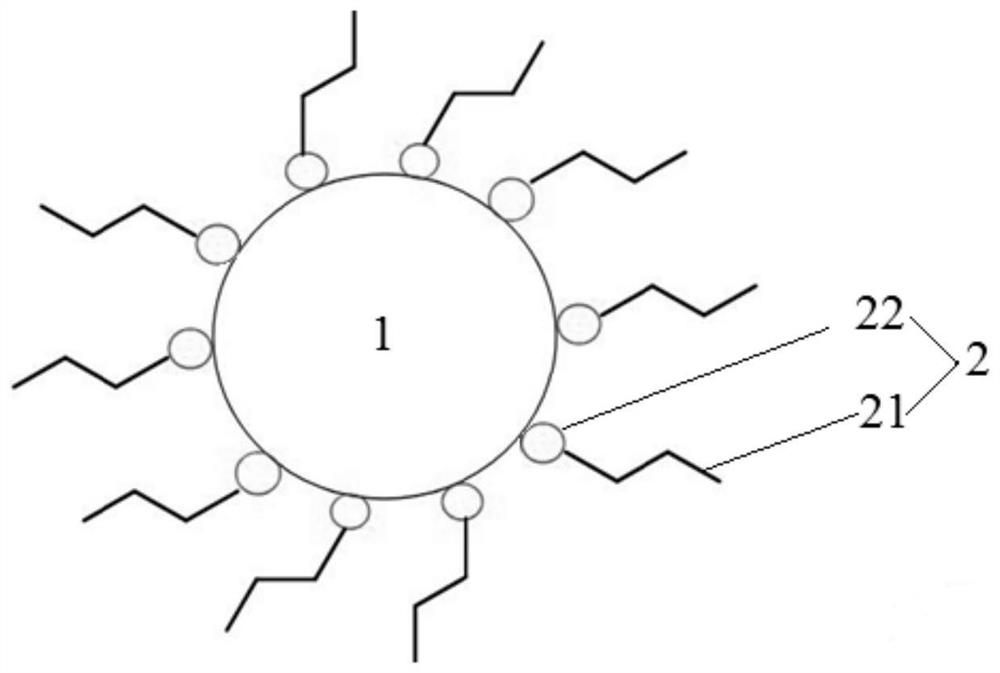

A technology of composite materials and quantum dots, which is applied in the field of quantum dot light-emitting diodes, composite materials and their preparation, can solve the problem of low carrier transport capacity, increase composite luminescence rate, improve dispersion, and increase output coupling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

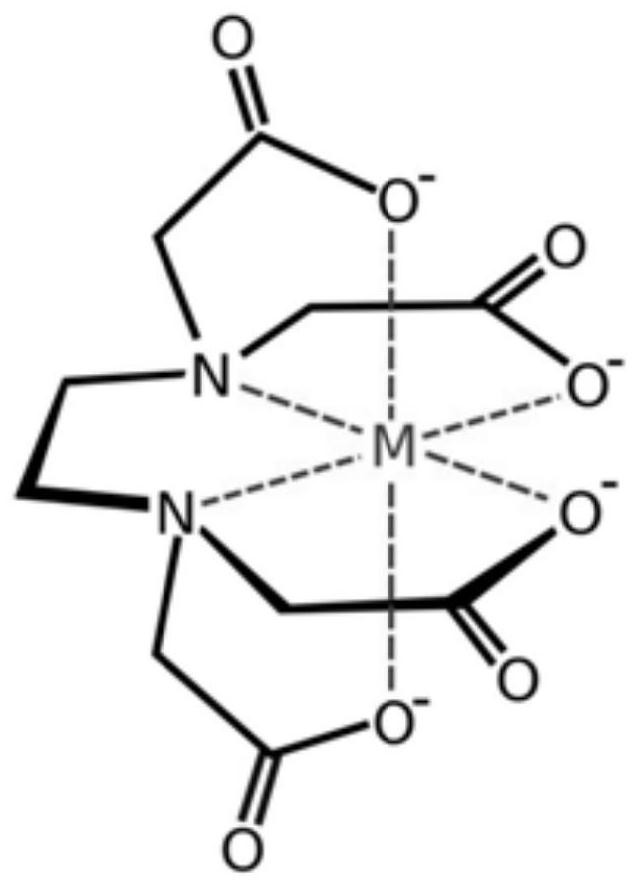

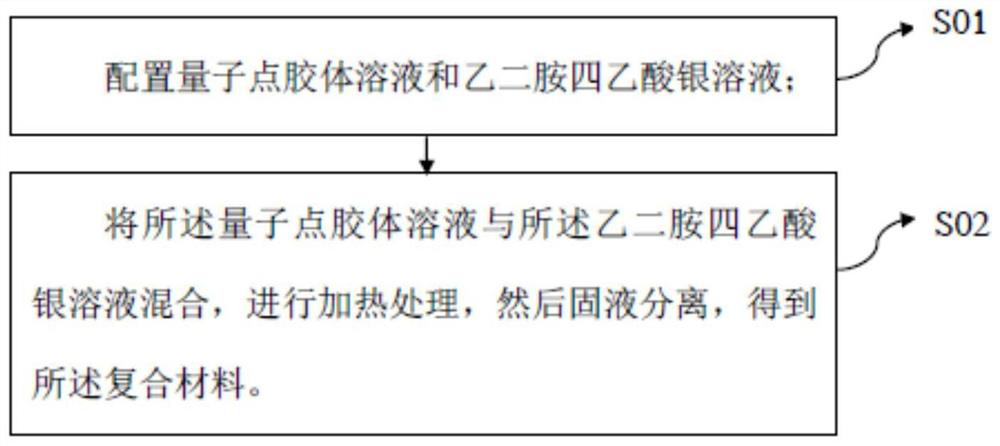

[0027] Correspondingly, on the other hand, the embodiment of the present invention also provides a method for preparing a composite material, such as image 3 Shown, this preparation method comprises the steps:

[0028]S01: Prepare quantum dot colloidal solution and silver EDTA solution;

[0029] S02: mixing the quantum dot colloidal solution with the silver EDTA solution, performing heat treatment, and then separating the solid and liquid to obtain the composite material.

[0030] In the preparation method of the composite material provided by the embodiment of the present invention, the composite material can be obtained by directly mixing the configured quantum dot colloid solution and the silver ethylenediamine tetraacetate solution, heating, and performing ligand exchange, which has the advantages of simple process and low cost. It is suitable for large-scale and large-scale preparation, and the final composite material can be used in the quantum dot light-emitting layer...

Embodiment 1

[0052] Taking the use of silver oxide, EDTA, CdS / ZnS, ODE, and n-hexane as examples, the preparation process of composite materials is introduced in detail.

[0053] 1) Put 1g of EDTA in a small beaker, first add 10ml of distilled water to form a solution with a total concentration of 1M, keep warm at 80°C, and slowly add an appropriate amount of silver oxide (molar ratio, EDTA:Ag + =1:1), reacted for 2h. The EDTA-Ag solution was prepared and dried in an oven.

[0054] 2) Add an appropriate amount of CdS / ZnS to 20ml ODE to form a quantum dot colloid solution with a total concentration of 20mg / mL.

[0055] 3) Dissolve an appropriate amount of EDTA-Ag into 5ml ODE, and then mix it with the quantum dot colloidal solution evenly (mass molar ratio, quantum dot: EDTA-Ag=1g:0.1mol), and continue to stir at 200°C for 0.5h. After the reaction, after the reaction solution was cooled to room temperature, it was precipitated and washed step by step with ethyl acetate + ethanol and aceto...

Embodiment 2

[0057] Taking the use of silver oxide, EDTA, CdSe / ZnS, ODE, and n-hexane as examples, the preparation process of composite materials is introduced in detail.

[0058] 1) Put 1g of EDTA in a small beaker, first add 10ml of distilled water to form a solution with a total concentration of 1M, keep warm at 80°C, and slowly add an appropriate amount of silver oxide (molar ratio, EDTA:Ag + =1.2:1), reacted for 2h. The EDTA-Ag solution was prepared and dried in an oven.

[0059] 2) Add an appropriate amount of CdSe / ZnS to 20ml ODE to form a quantum dot colloid solution with a total concentration of 30mg / mL.

[0060] 3) Dissolve an appropriate amount of EDTA-Ag into 5ml ODE, and then mix it with the quantum dot colloidal solution (mass molar ratio, quantum dot: EDTA-Ag=1g:0.05mol), and continue to stir at 200°C for 0.5h. After the reaction, after the reaction solution was cooled to room temperature, it was precipitated and washed step by step with ethyl acetate + ethanol and acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com