Application of a doped double perovskite structure cathode material for intermediate temperature solid oxide fuel cells

A solid oxide, double perovskite technology, applied in battery electrodes, metal/metal oxide/metal hydroxide catalysts, structural parts, etc., can solve problems such as the reduction of catalytic oxygen reduction reaction ability, and achieve good electrocatalysis Activity, increased polarizability, strong conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

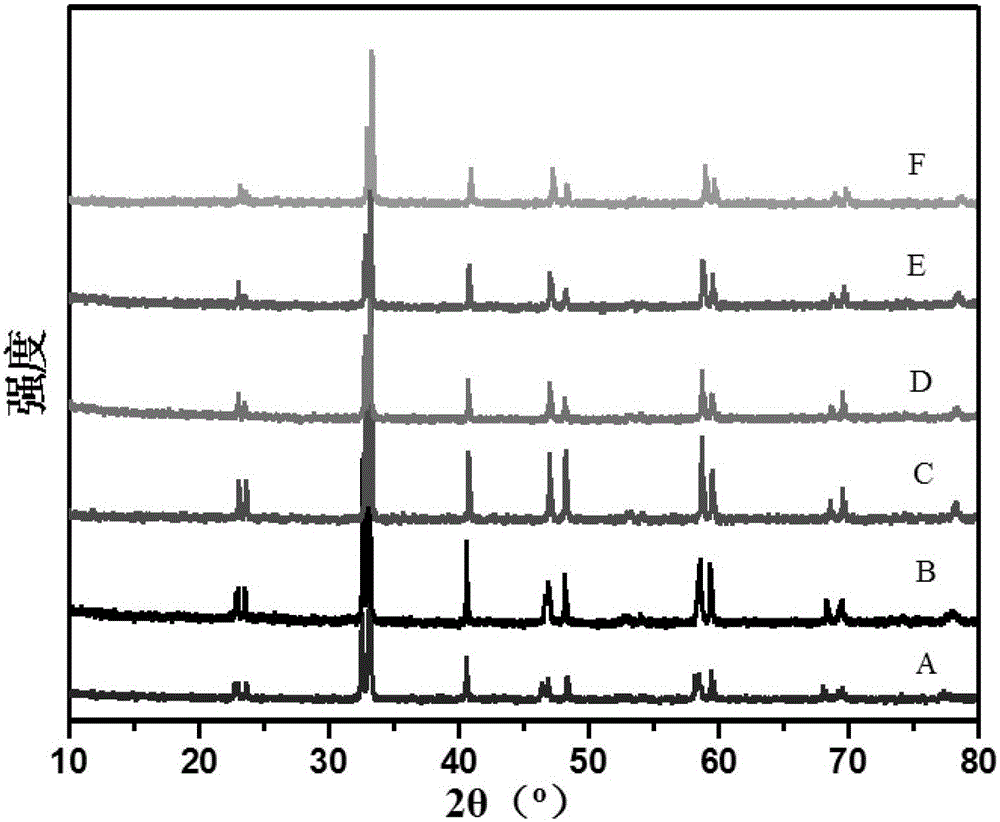

[0013] Specific embodiment 1: This embodiment is a double perovskite powder material doped with an alkaline earth element Sr as the cathode material of a medium temperature solid oxide fuel cell doped with a double perovskite structure, and the chemical formula is EuBa 1-x Sr x co 2 o 5+δ , where 0<x≤0.5, 0.4≤δ≤0.5.

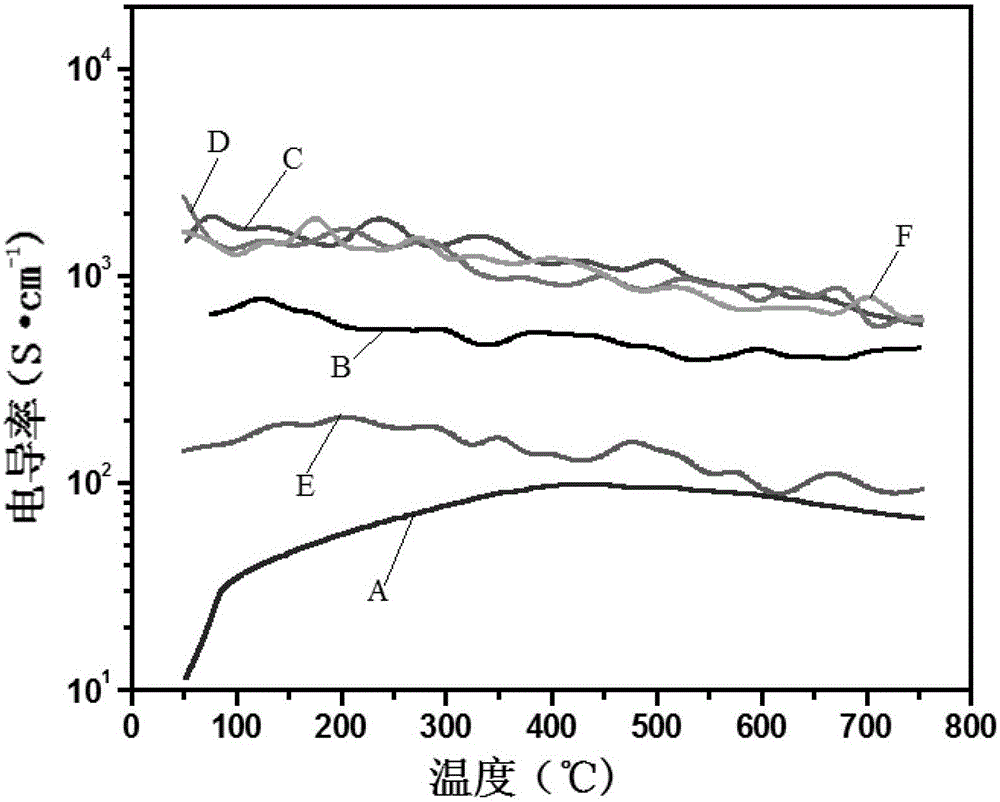

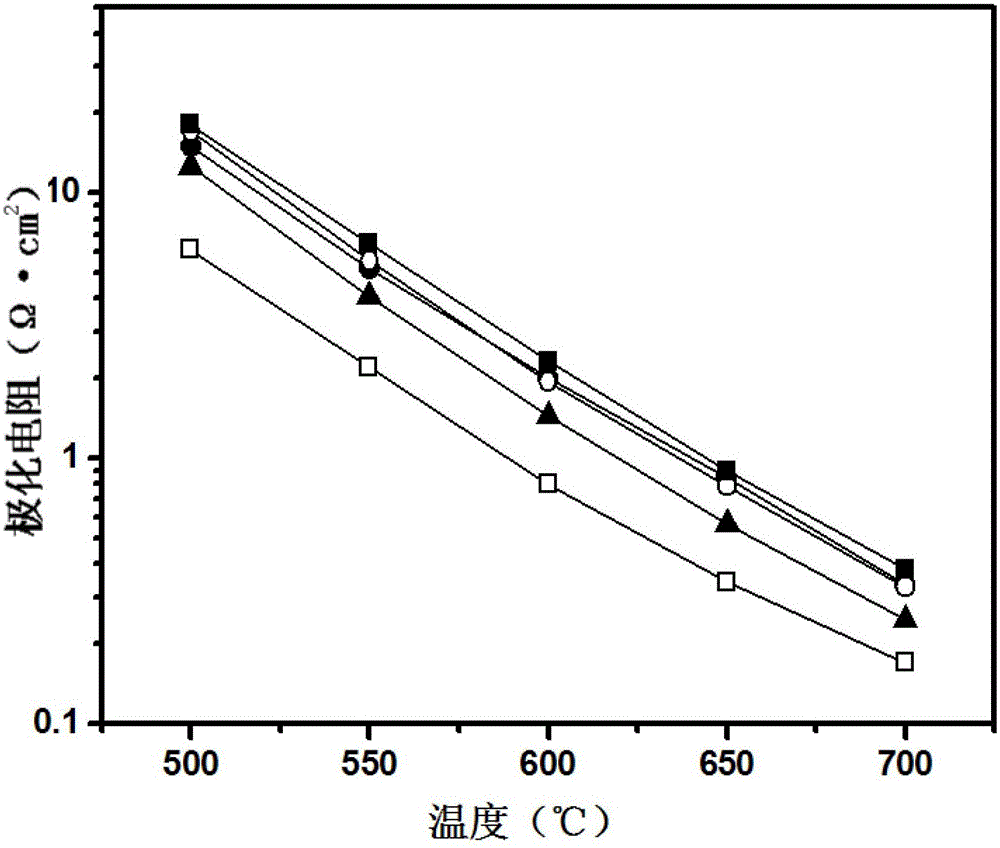

[0014] The intermediate temperature solid oxide fuel cell doped double perovskite structure cathode material described in this embodiment has a chemical formula of EuBa 1-x Sr x co 2 o 5+δ The advantages of the alkaline earth element Sr-doped double perovskite powder material are high crystallinity and strong conductivity, thus exhibiting good electrocatalytic activity.

[0015] The intermediate temperature solid oxide fuel cell doped double perovskite structure cathode material described in this embodiment utilizes the doped ion Sr 2+ has a ratio of Ba 2+ The smaller ionic radius of ions increases the polarization ability of oxygen ions, which improves t...

specific Embodiment approach 2

[0016] Specific embodiment 2: This embodiment is a method for preparing a cathode material with a doped double perovskite structure for a medium-temperature solid oxide fuel cell, and the chemical formula is EuBa 1-x Sr x co 2 o 5+δ The alkaline earth element Sr-doped double perovskite powder material is specifically completed according to the following steps:

[0017] 1. Weighing: According to the chemical formula EuBa 1-x Sr x co 2 o 5+δ Weigh Eu according to Eu:Ba:Sr:Co=1:(1-x):x:2 2 o 3 、BaCO 3 , SrCO 3 and Co 3 o 4 ; the EuBa 1-x Sr x co 2 o 5+δIn 0

[0018] 2. Grinding: Eu 2 o 3 、BaCO 3 , SrCO 3 and Co 3 o 4 Put into the mortar and grind and mix to obtain the mixed material;

[0019] 3. Calcination: Calcinate the mixed material obtained in step 2 at a temperature of 1100-1250°C for 12h-24h to obtain the chemical formula EuBa 1-x Sr x co 2 o 5+δ Alkaline earth element Sr doped double perovskite powder material.

[0020] The pr...

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the specific operation of the grinding and mixing described in step two is as follows: the Eu weighed in step one 2 o 3 、BaCO 3 , SrCO 3 and Co 3 o 4 Put it into an agate mortar and grind and mix for 8min to 12min to obtain the initial mixed raw material, then add absolute ethanol to the initial mixed raw material, and continue to grind and mix for 25min to 35min to obtain the mixed material; the volume of the anhydrous ethanol The mass ratio to the starting mixed raw material is 10mL:(4g~7g). The other specific embodiment two is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com