Intermediate-temperature solid oxide fuel cell cathode material and preparation method and application thereof

A fuel cell cathode and solid oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high interface polarization resistance and low electrochemical catalytic activity, achieve low interface polarization impedance, simple operation, The effect of high electrochemical catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

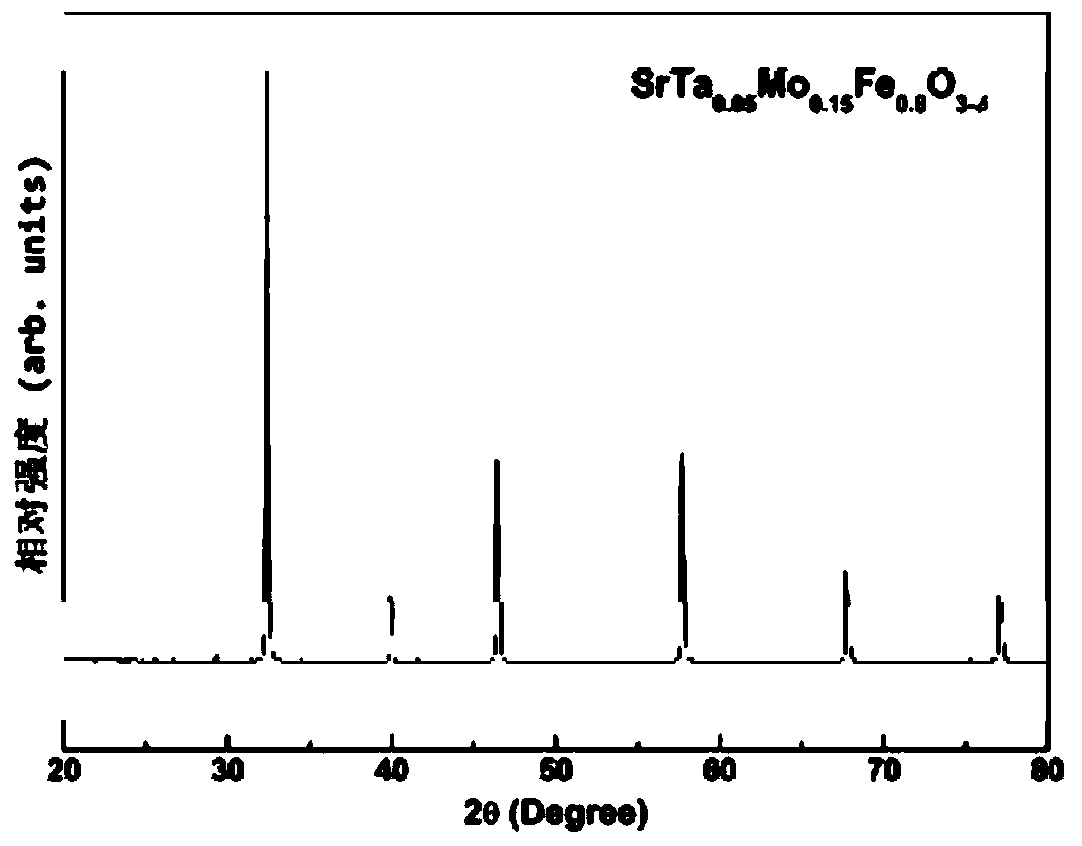

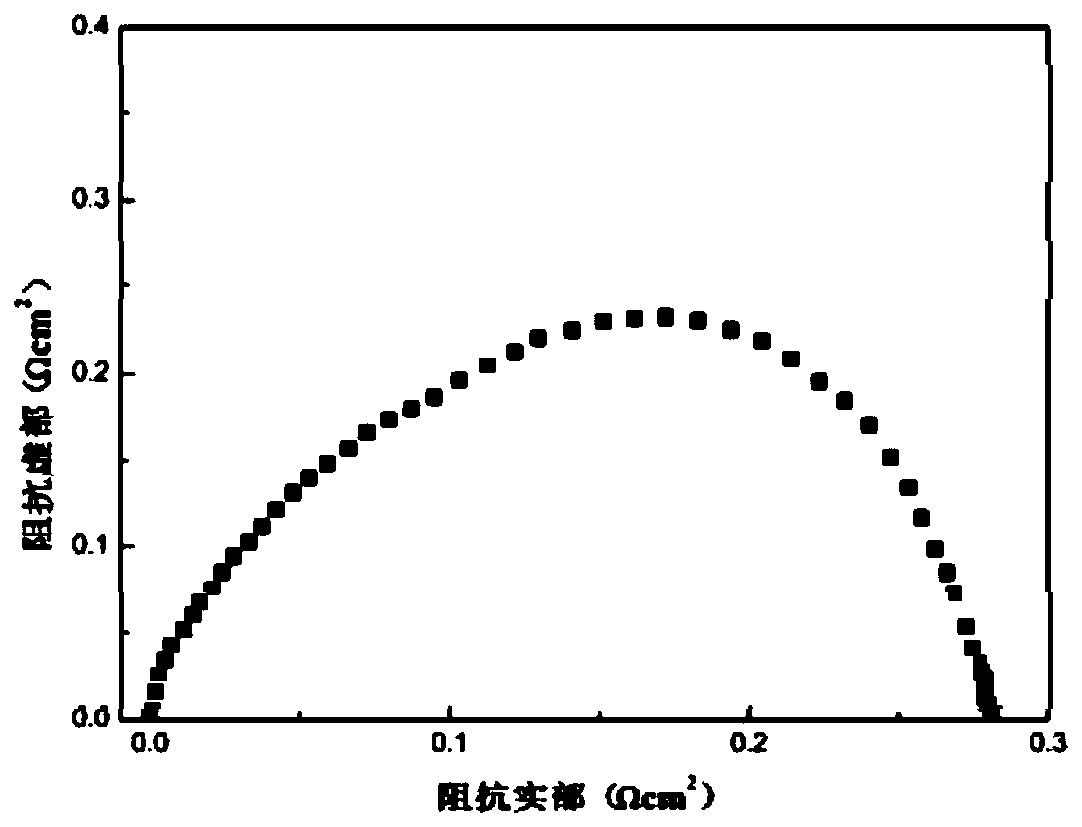

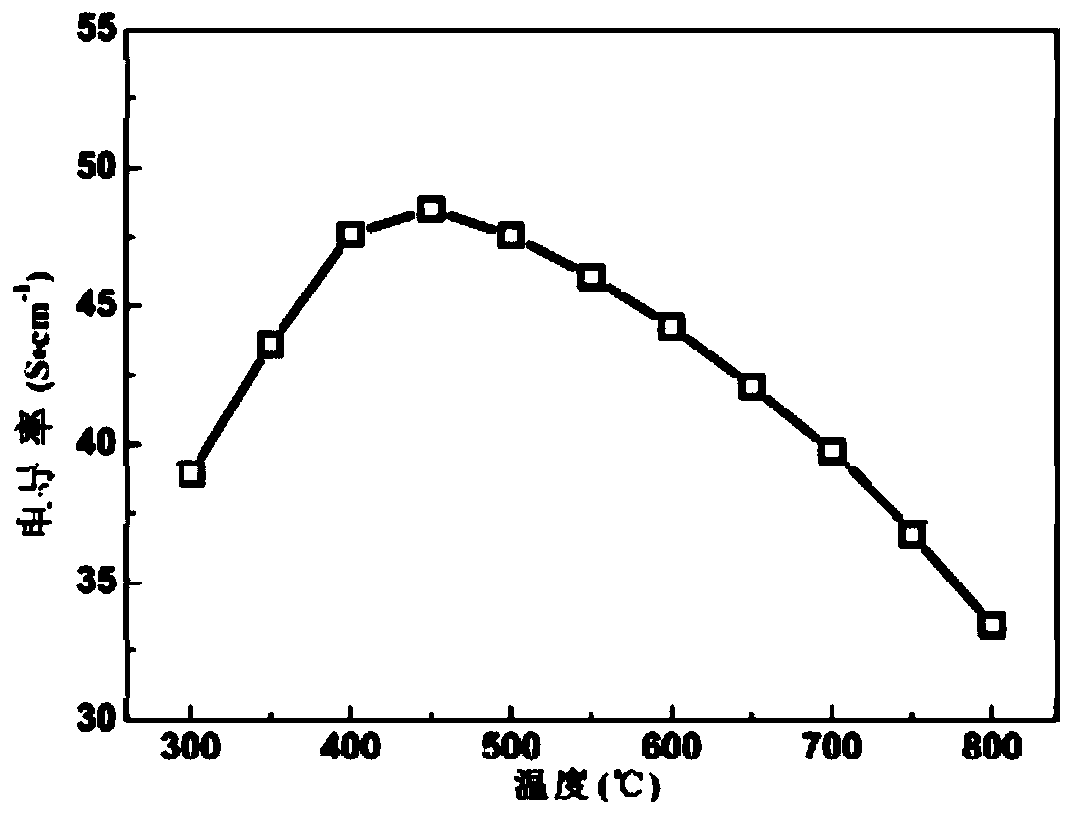

[0042] This embodiment provides a cathode material for an intermediate temperature solid oxide fuel cell, the chemical formula is SrTa 0.05 Mo 0.15 Fe 0.8 o 3-δ , δ is the content of oxygen vacancies, and the content of oxygen vacancies in the sample is measured by iodometric titration method δ=0.5.

[0043] In this example, SrTa 0.05 Mo 0.15 Fe 0.8 o 3-δ A method for preparing a cathode material for a medium-temperature solid oxide fuel cell, comprising the following steps:

[0044] (a) According to the stoichiometric ratio, weigh Sr(NO 3 ) 2 2.0775g, (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.2599g and Fe(NO 3 ) 3 9H 2 O 3.1726g, and dissolved in deionized water in turn to form a uniform metal ion precursor solution;

[0045] (b) Weigh 6.0338g of citric acid in a molar ratio of metal ions: citric acid: ethylenediaminetetraacetic acid = 1:1.5:1, dissolve 5.5941g of ethylenediaminetetraacetic acid in the above solution, heat and stir until the solution transparent;

[00...

Embodiment 2

[0056] This embodiment provides a cathode material for an intermediate temperature solid oxide fuel cell, the chemical formula is SrTa 0.1 Mo 0.1 Fe 0.8 o 3-δ , δ is the content of oxygen vacancies, and the content of oxygen vacancies in the sample is measured by iodometric titration method δ=0.25.

[0057] In this example, SrTa 0.1Mo 0.1 Fe 0.8 o 3-δ A method for preparing a cathode material for a medium-temperature solid oxide fuel cell, comprising the following steps:

[0058] (a) According to the stoichiometric ratio, weigh Sr(NO 3 ) 2 2.0348g, (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.1698g and Fe(NO 3 ) 3 9H 2 O 3.1075g, and dissolved in deionized water successively to form a uniform metal ion precursor solution;

[0059] (b) Weigh 5.7584g of citric acid and 5.3388g of ethylenediaminetetraacetic acid in the above solution with a ratio of metal ion: citric acid: EDTA of 1:1.5:1 in molar ratio, heat and stir until the solution is transparent;

[0060] (c) Transfer th...

Embodiment 3

[0070] This embodiment provides a cathode material for an intermediate temperature solid oxide fuel cell, the chemical formula is SrTa 0.15 Mo 0.05 Fe 0.8 o 3-δ , δ is the content of oxygen vacancies, and the content of oxygen vacancies in the sample is measured by iodometric titration method δ=0.1.

[0071] In this example, SrTa 0.15 Mo 0.05 Fe 0.8 o 3-δ A method for preparing a cathode material for a medium-temperature solid oxide fuel cell, comprising the following steps:

[0072] (a) According to the stoichiometric ratio, weigh Sr(NO 3 ) 2 1.9943g, (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.0832g and Fe(NO 3 ) 3 9H 2 O 3.0456g, and be dissolved in deionized water successively, form uniform metal ion precursor solution;

[0073] (b) Weigh 5.4951g of citric acid and 5.0947g of ethylenediaminetetraacetic acid in the above solution with the ratio of metal ion: citric acid: EDTA 1:1.5:1 in molar ratio, heat and stir until the solution is transparent;

[0074] (c) Transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com