Multi-element stable zirconium oxide corrosion-resistant thermal barrier coating material

A technology of thermal barrier coating and multi-component stabilization, which is applied in the field of multi-component stabilized zirconia anti-corrosion thermal barrier coating materials, can solve problems such as poor corrosion performance of molten salts, and achieve the effect of increasing glass viscosity and excellent corrosion performance of molten salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

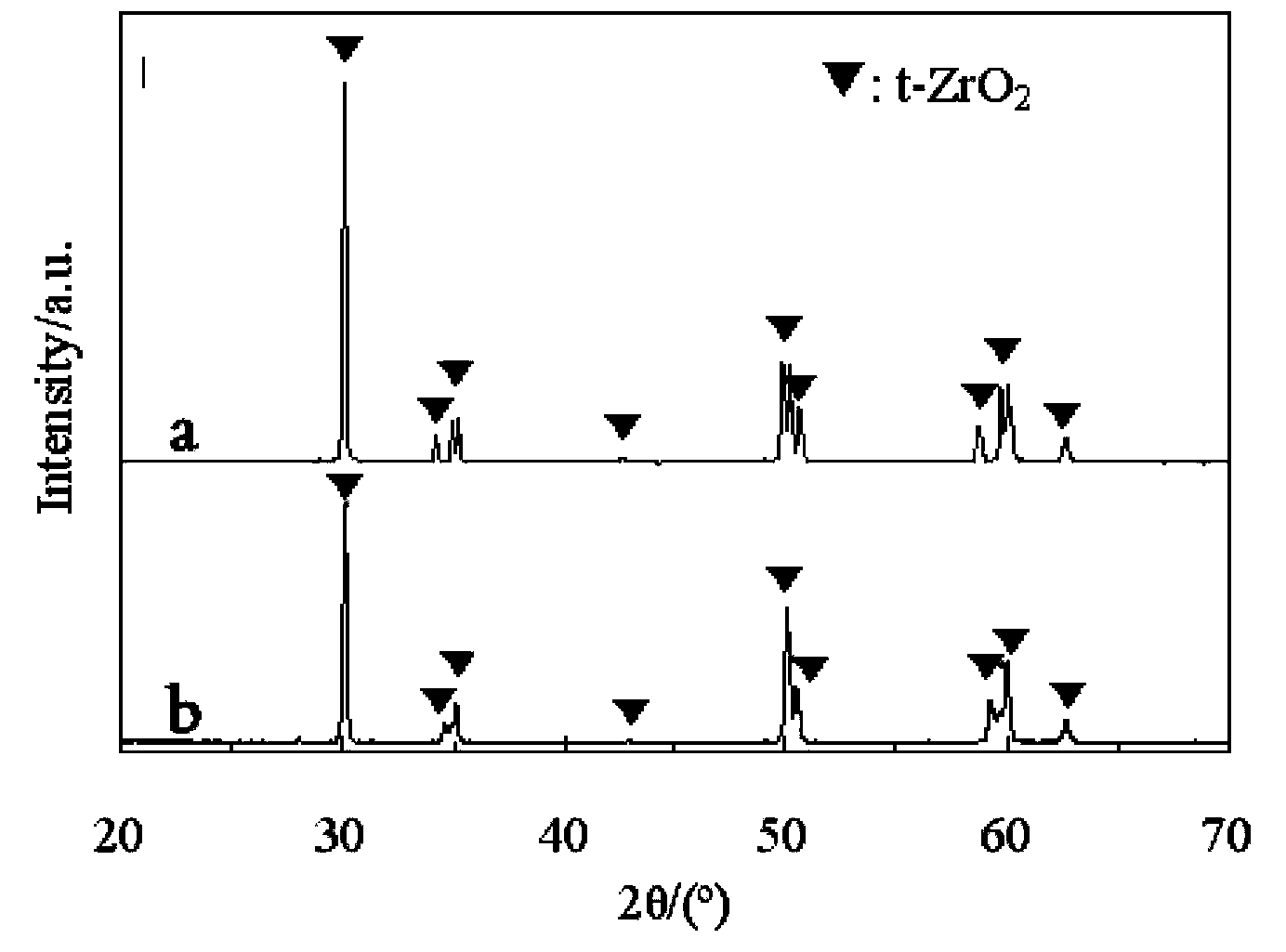

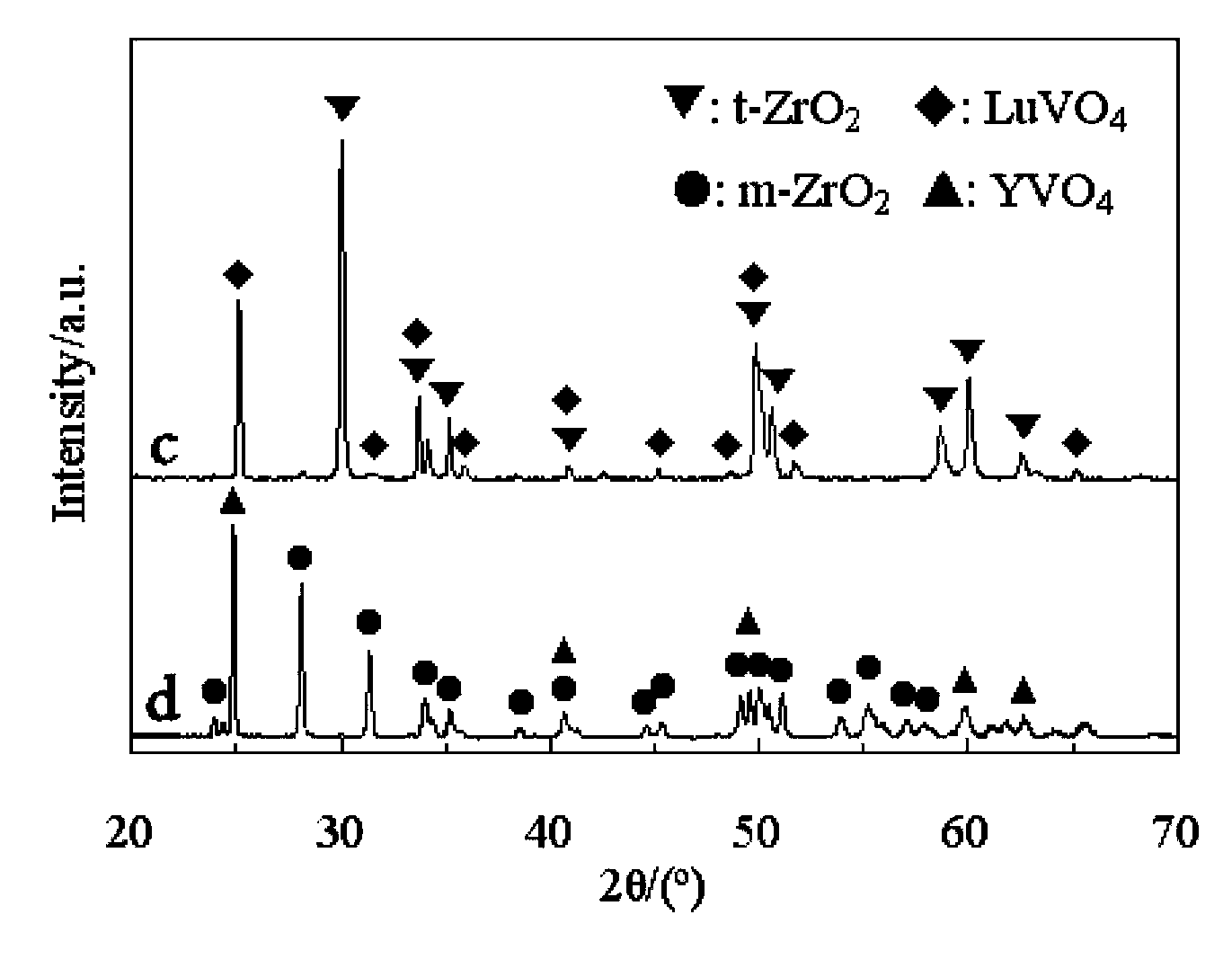

Embodiment 1

[0031] In this example, the multi-component stabilized zirconia anti-corrosion thermal barrier coating material is made by ball milling the main agent and the stabilizer, and the main agent is ZrO 2 , the stabilizer is Nb 2 o 5 、TiO 2 and a mixture of rare metal oxides, the Nb in the multi-component stabilized zirconia anti-corrosion thermal barrier coating material 2 o 5 、TiO 2 , rare metal oxides and ZrO 2 The molar ratio is 5:7.5:5:82.5, and the rare metal oxide is Lu 2 o 3 or In 2 o 3 , this embodiment is preferably Lu 2 o 3 ; The speed of the ball milling is 200r / min, and the time of the ball milling is 3h.

Embodiment 2

[0033] In this example, the multi-component stabilized zirconia anti-corrosion thermal barrier coating material is made by ball milling the main agent and the stabilizer, and the main agent is ZrO 2 , the stabilizer is Nb 2 o 5 、TiO 2 and a mixture of rare metal oxides, the Nb in the multi-component stabilized zirconia anti-corrosion thermal barrier coating material 2 o 5 、TiO 2 , rare metal oxides and ZrO 2 The molar ratio is 4:6:4:86, and the rare metal oxide is Lu 2 o 3 or In 2 o 3 , this embodiment is preferably In 2 o 3 ; The speed of the ball milling is 300r / min, and the time of the ball milling is 2h.

Embodiment 3

[0035] In this example, the multi-component stabilized zirconia anti-corrosion thermal barrier coating material is made by ball milling the main agent and the stabilizer, and the main agent is ZrO 2 , the stabilizer is Nb 2 o 5 、TiO 2 and a mixture of rare metal oxides, the Nb in the multi-component stabilized zirconia anti-corrosion thermal barrier coating material 2 o 5 、TiO 2 , rare metal oxides and ZrO 2 The molar ratio is 6:9:6:79, and the rare metal oxide is Lu 2 o 3 or In 2 o 3 , this embodiment is preferably Lu 2 o 3 ; The speed of the ball milling is 300r / min, and the time of the ball milling is 2.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com