Sodium pyrophosphate modified water purification sludge/zeolite composite adsorbent and preparation method and application thereof

A composite adsorption and sodium pyrophosphate technology, applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc., can solve problems such as water quality and aquatic organism survival and growth hazards, physical exhaustion, dysfunction, etc. , to achieve active properties, small ionic radius and good removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

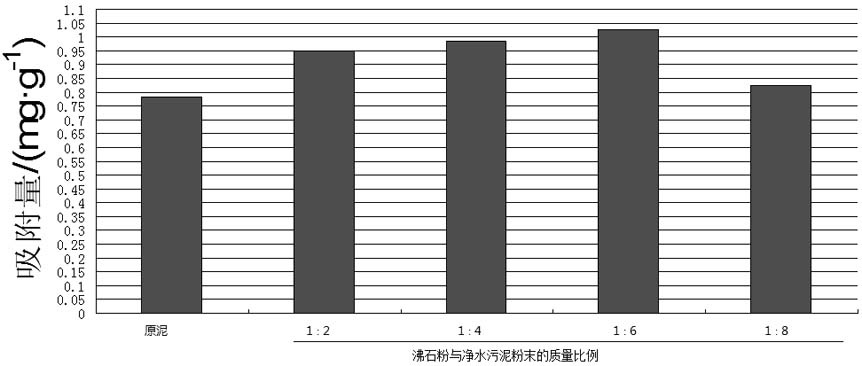

[0031] Example 1: Effect of water purification sludge / zeolite composite adsorbent on ammonia nitrogen removal

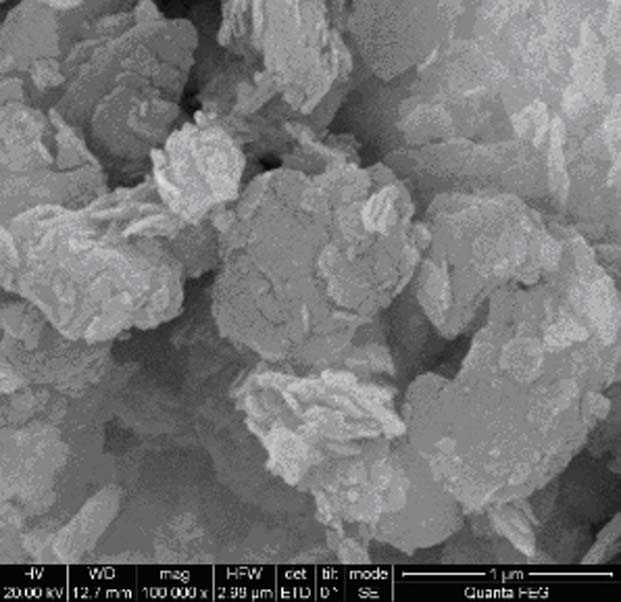

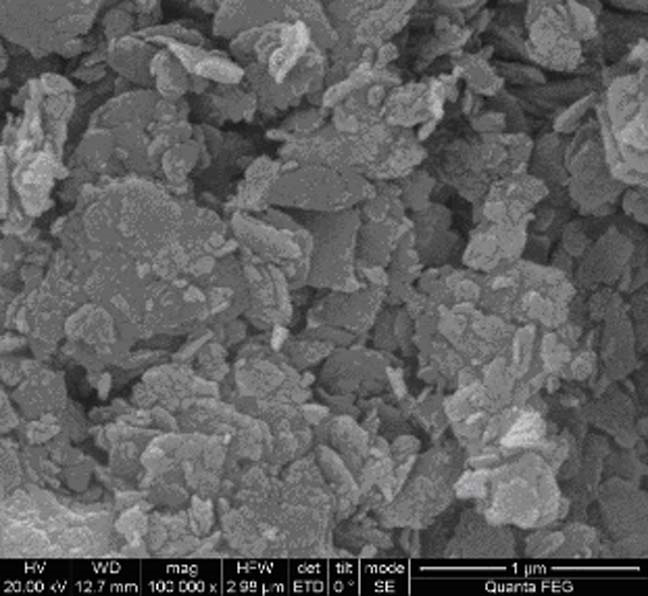

[0032] Mix 100-200 mesh zeolite powder and water purification sludge powder at a weight ratio of 1:2, 1:4, 1:6, and 1:8, add the same amount of distilled water, stir evenly, and put it into a granulator to make Granular, put it in an oven to dry for 5 hours, and calcinate the particles in a muffle furnace at 600°C for 2 hours to make a water purification sludge / zeolite composite adsorbent. The water purification sludge powder was granulated in the same way, dried and calcined at 600°C for 2 hours to obtain an undoped raw sludge adsorbent. The SEM image is shown in figure 1 .

[0033] Weigh 1.0g of adsorbent respectively and put them into different containers containing 50mL of NH with a concentration of 50mg / L. 4 In the Erlenmeyer flask of Cl solution, place the Erlenmeyer flask in a constant temperature oscillator, set the temperature to 25°C, the speed to 120r / mi...

Embodiment 2

[0034] Example 2 Water Purification Sludge / Zeolite Composite Adsorbent Effect on Ammonia Nitrogen Removal

[0035] Mix 100-200 mesh zeolite powder and water purification sludge powder at a weight ratio of 1:6, add the same amount of distilled water, stir evenly, put it into a granulator to make granules, and then put it in an oven to dry for 5 hours, and separate the granules Calcined in a muffle furnace for 2 hours to make a water purification sludge / zeolite composite adsorbent; the calcination temperatures were 400°C and 800°C respectively.

[0036] Weigh 1.0g of adsorbent respectively and put them into different containers containing 50mL of NH with a concentration of 50mg / L. 4 In the Erlenmeyer flask of Cl solution, place the Erlenmeyer flask in a constant temperature oscillator, set the temperature to 25°C, the speed to 120r / min, and shake at a constant temperature for 24 hours. After the adsorption, the solution was left to stand for 5 hours, and conventionally centrifug...

Embodiment 3

[0037] Example 3 Water Purification Sludge / Zeolite Composite Adsorbent Effect on Ammonia Nitrogen Removal

[0038]Mix 100-200 mesh zeolite powder and water purification sludge powder at a weight ratio of 1:6, add the same amount of distilled water, stir evenly, put it into a granulator to make granules, and then put it in an oven to dry for 5 hours, and separate the granules Calcined in a muffle furnace at 600°C for 3 hours to make a water purification sludge / zeolite composite adsorbent; weigh 1.0 g of the adsorbent and put it into different containers containing 50 mL of NH with a concentration of 50 mg / L 4 In the Erlenmeyer flask of Cl solution, place the Erlenmeyer flask in a constant temperature oscillator, set the temperature to 25°C, the speed to 120r / min, and shake at a constant temperature for 24 hours. After the adsorption, the solution was left to stand for 5 hours, and conventionally centrifuged. The absorbance of the supernatant was measured, and the adsorption cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com