Patents

Literature

517 results about "Pyrophosphate sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrasodium pyrophosphate. Tetrasodium pyrophosphate, also called sodium pyrophosphate, tetrasodium phosphate or TSPP, is a colorless transparent crystalline chemical compound with the formula Na4P2O7. It is a salt composed of pyrophosphate and sodium ions.

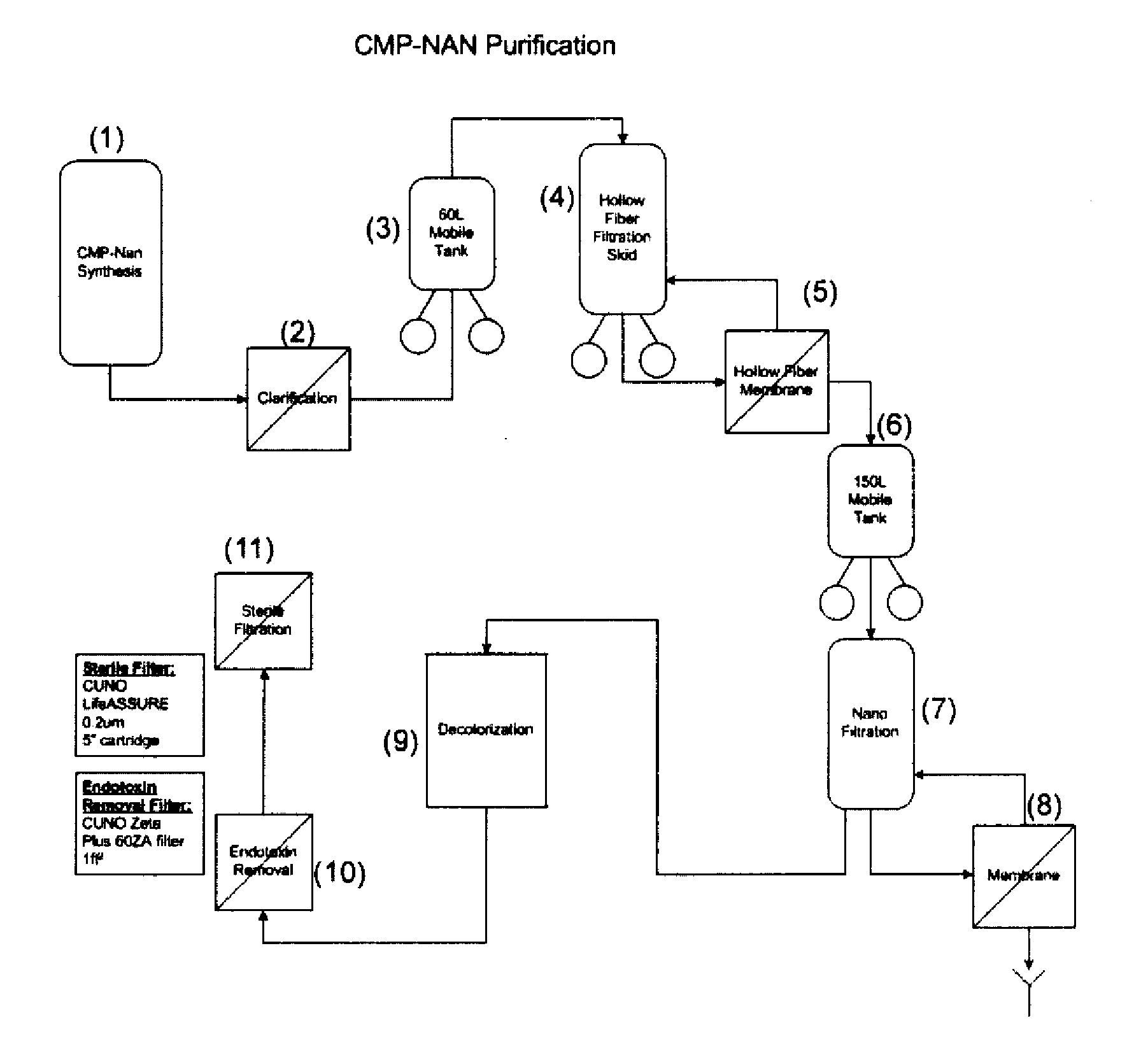

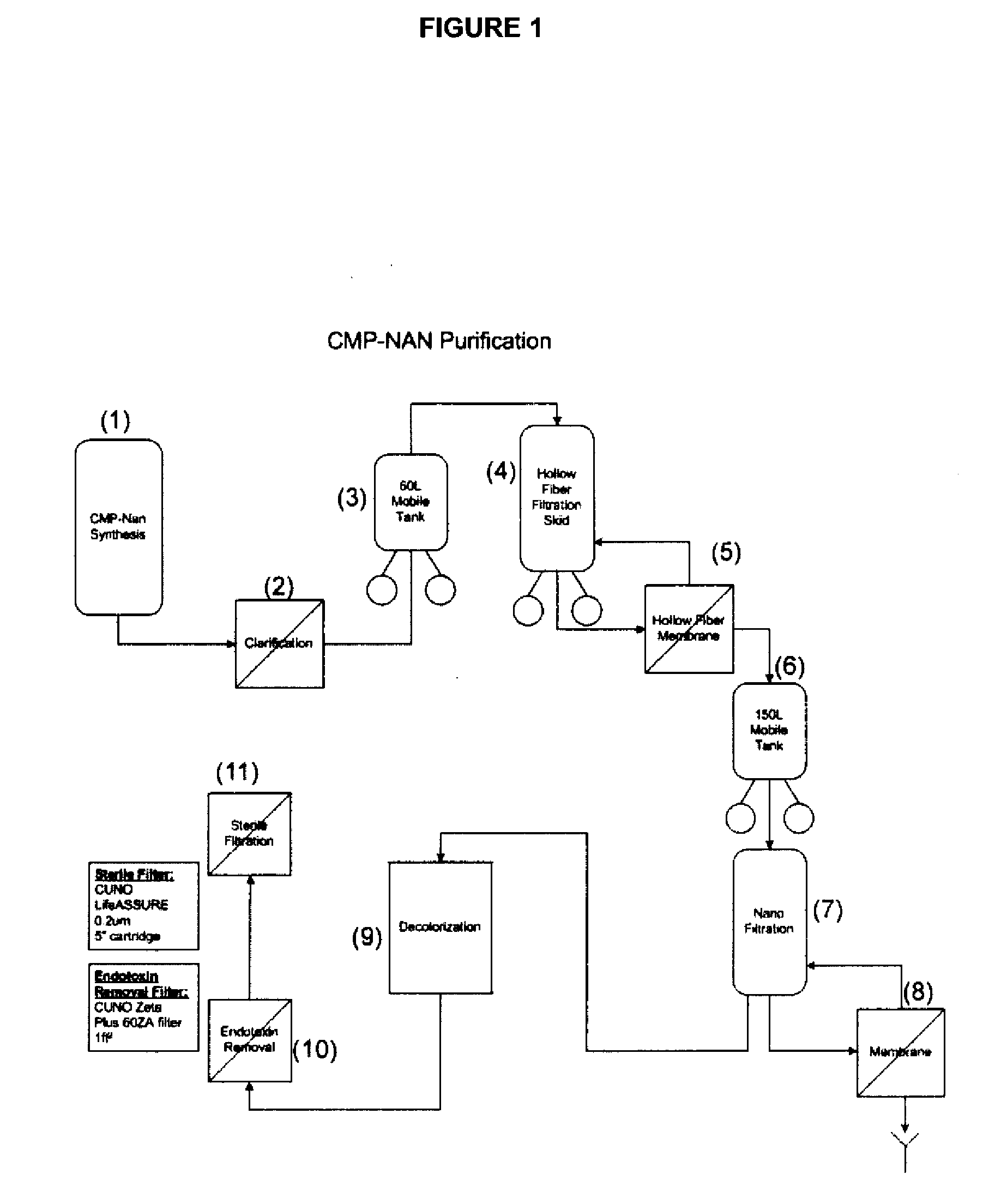

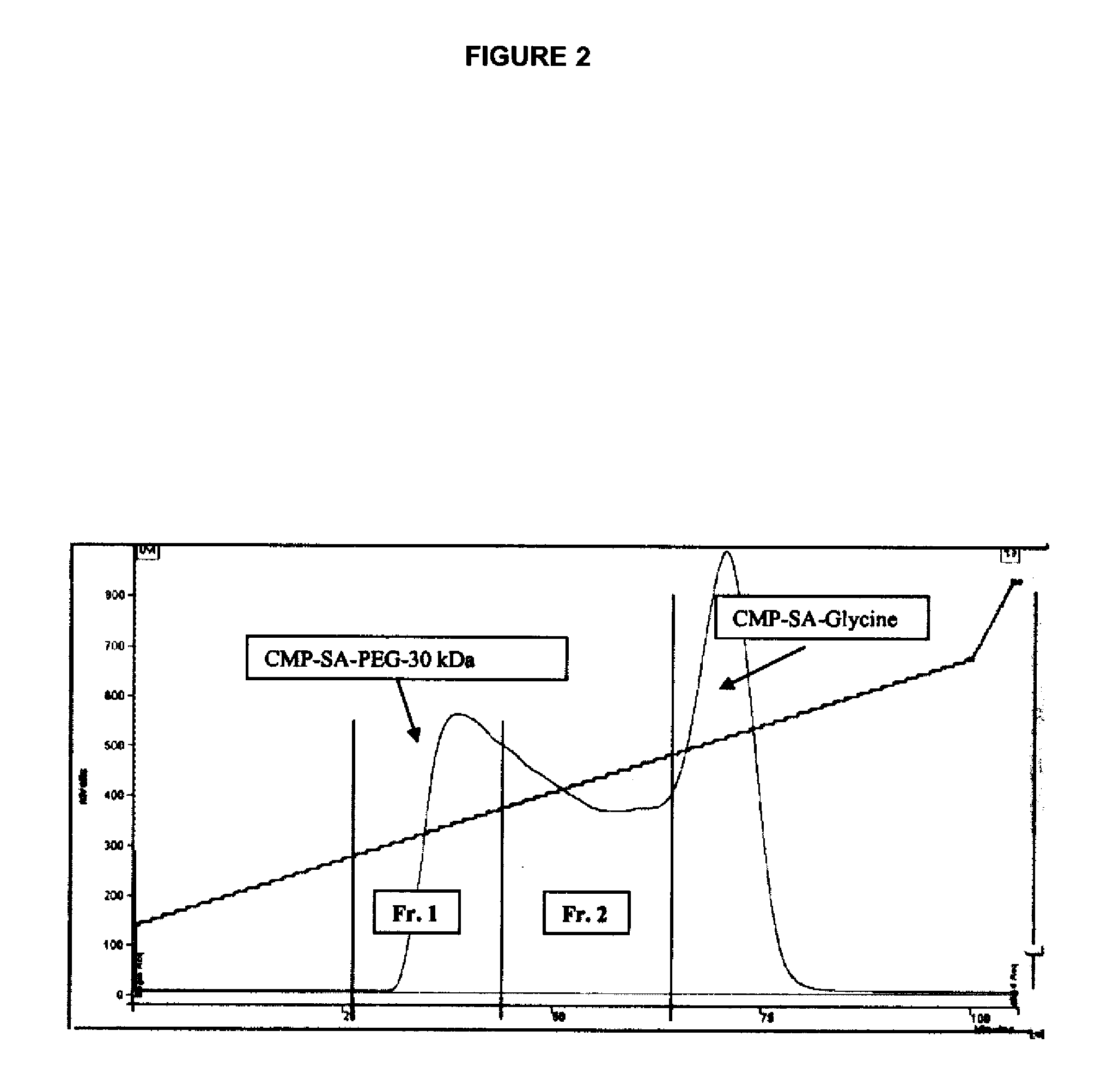

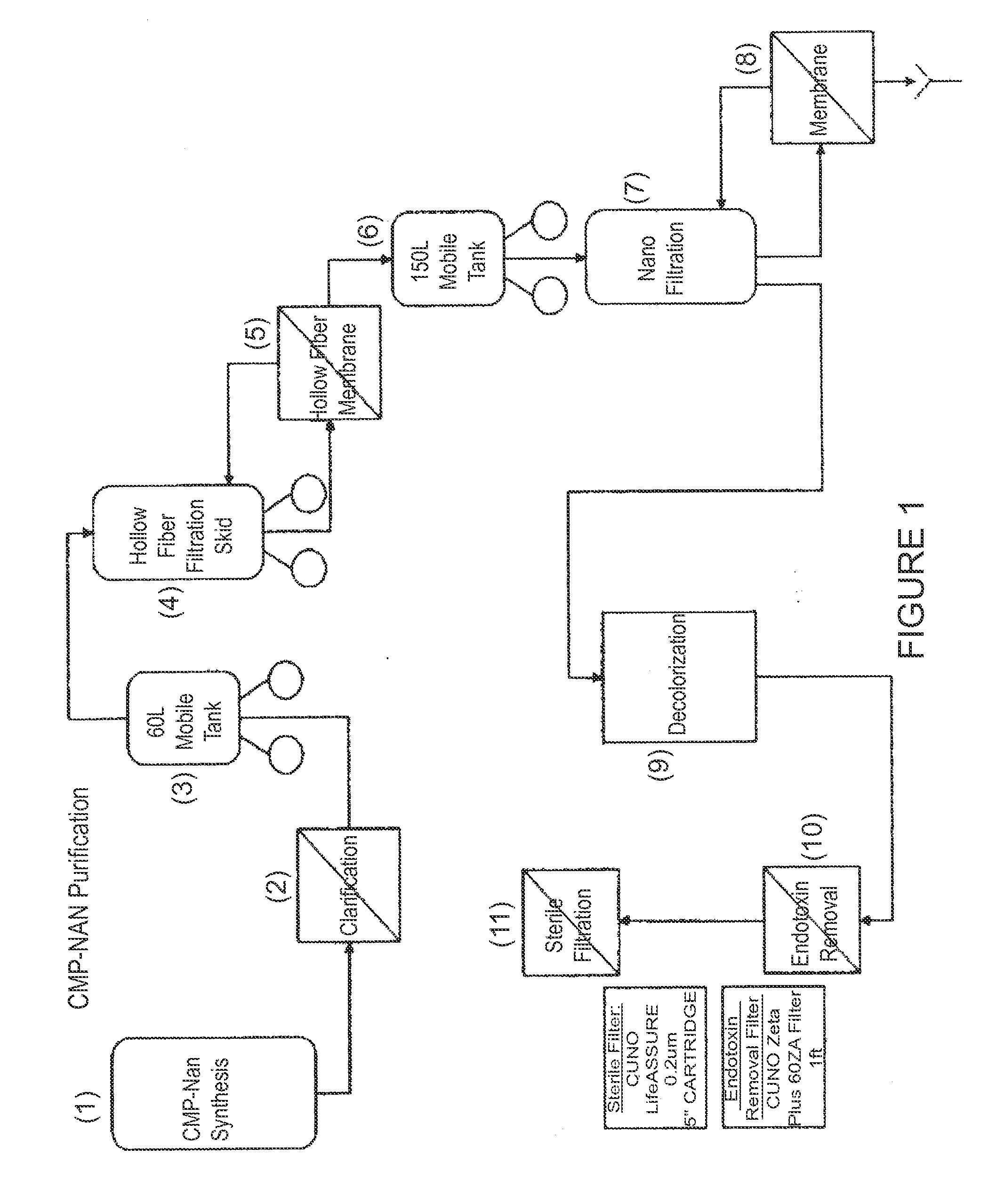

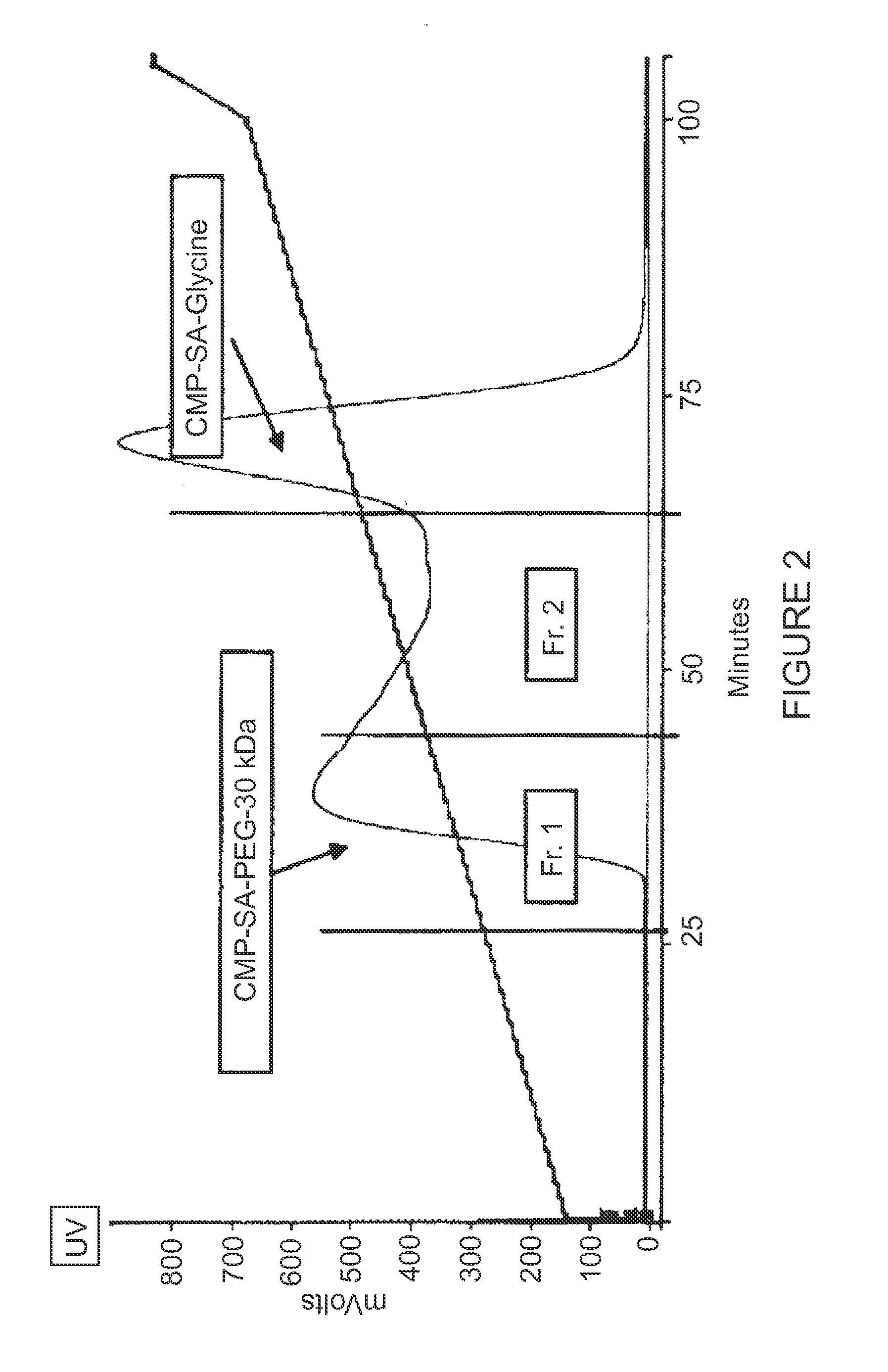

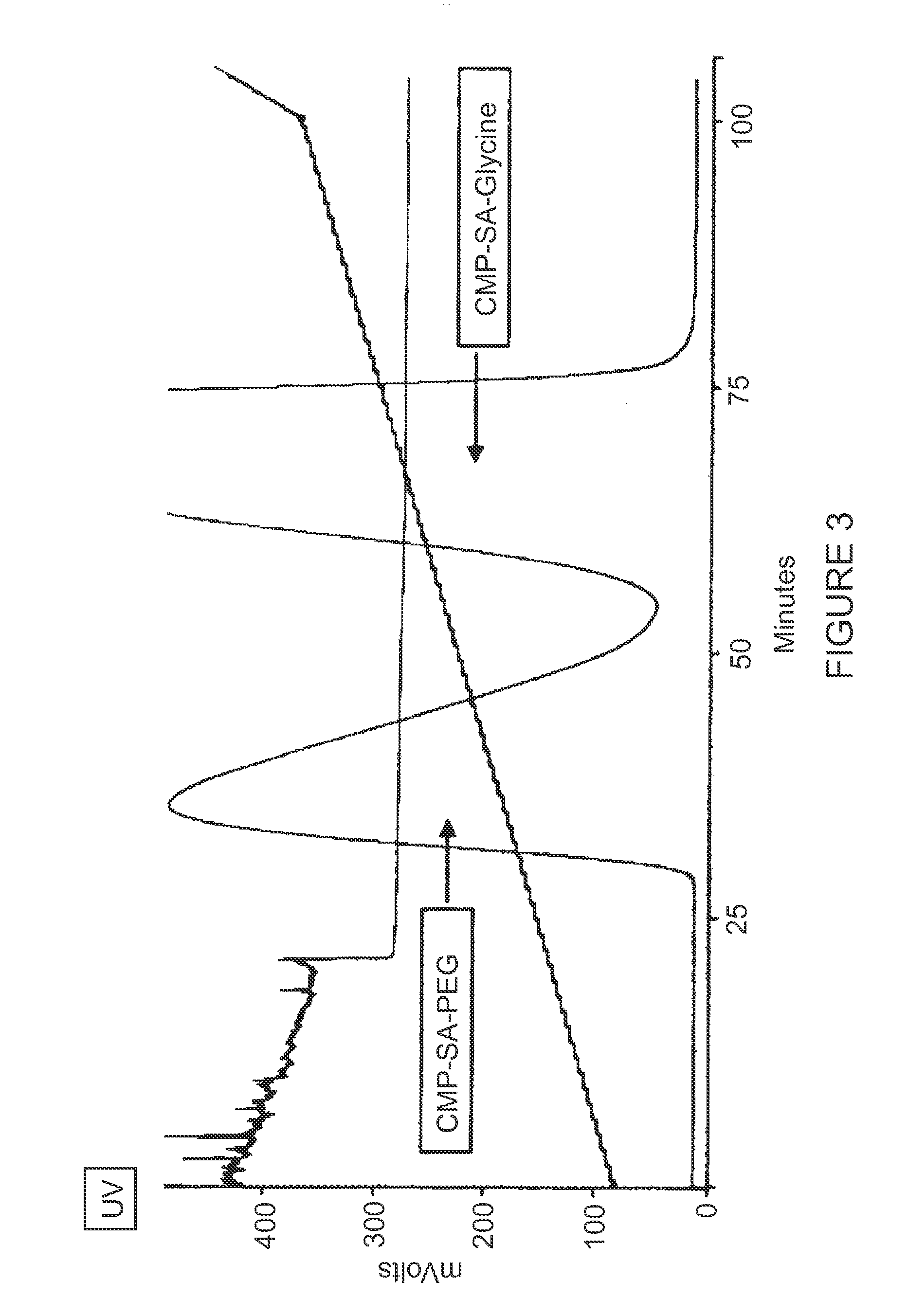

Nucleotide Sugar Purification Using Membranes

InactiveUS20090048440A1Raise the ratioReduce concentrationSugar derivativesChemical recyclingNucleotidePhosphate

The invention provides methods of removing contaminants from a mixture of a desired product and contaminants by pH adjustments and molecular weight cut-offs. The contaminants include phosphate groups, magnesium sulfate, sodium pyruvate and tetrasodium pyrophosphate groups. The desired product includes nucleotide sugars, glycolipids, LnNT, sialyl lactose, and salts.

Owner:NOVO NORDISK AS

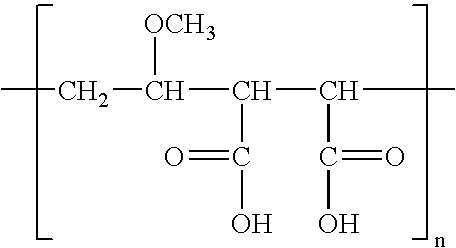

Stannous Salt and Sodium Tripolyphosphate Oral Care Compositions and Methods

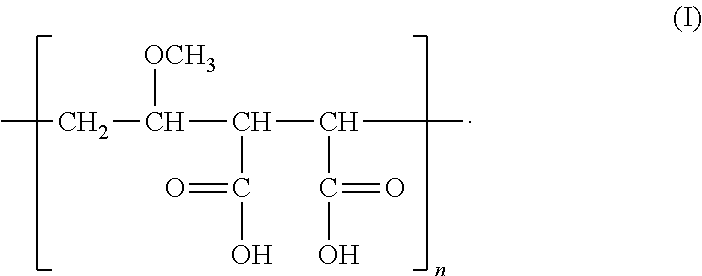

Oral care compositions containing a stannous salt and sodium tripolyphosphate are provided where stannous tripolyphosphate ionic intermediates comprise less than about 1% of the compositions Tetrasodium pyrophosphate, a methylvinyl ether-maleic anhydride copolymer and / or a silica oral polishing agent may be added for further efficacy. In a single phase blend, the oral care composition may be effectively limited to comprise less than about 10% water. In a dual-phase blend a mixture having the stannous salt in a first phase and the sodium tripolyphosphate in a second phase may be generated from a dual chamber storage tube (with each phase provided from a separate chamber) immediately prior to dental care usage.

Owner:COLGATE PALMOLIVE CO

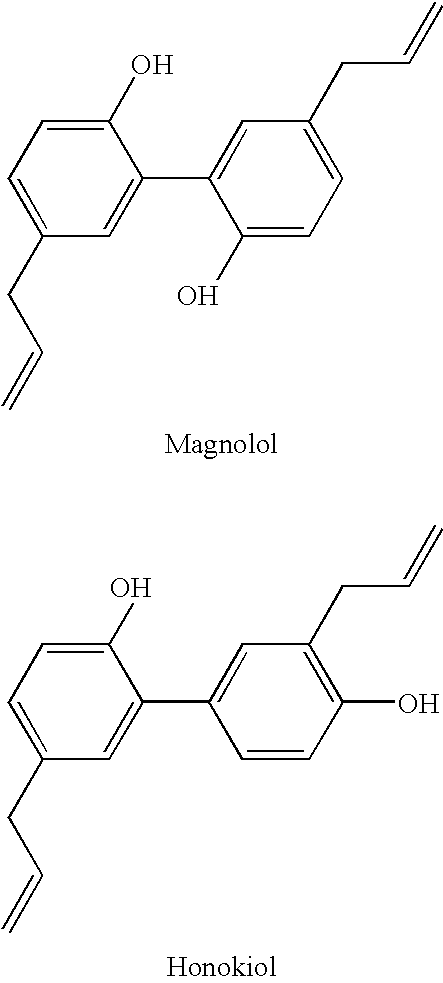

Tartar control oral care composition containing extract of magnolia

InactiveUS20060127329A1Stable and efficaciousSafe and effectiveCosmetic preparationsBiocideMouthwash Dosage FormAdditive ingredient

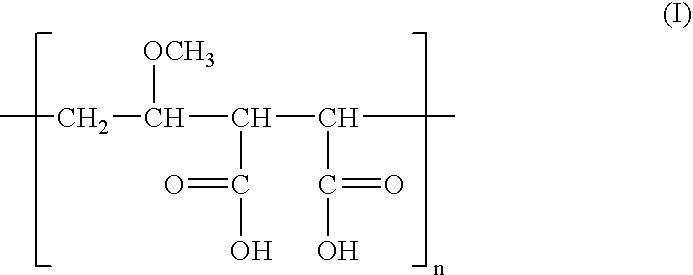

A stable and efficacious antiplaque, anticalculus, and antigingivitis oral composition is provided having an antibacterial ingredient comprising one or more active compounds found in an extract of magnolia combined with an anticalculus system comprising tetrasodium pyrophosphate (TSPP) about 1 to about 2.5% and sodium tripolyphosphate (STPP) about 1 to about 10%. The oral composition can be in the form of a mouth rinse or dentifrice, including toothpaste, gels, powders, as well as confectionaries, lozenges, and the like. Methods of making and using the oral composition are also provided.

Owner:COLGATE PALMOLIVE CO

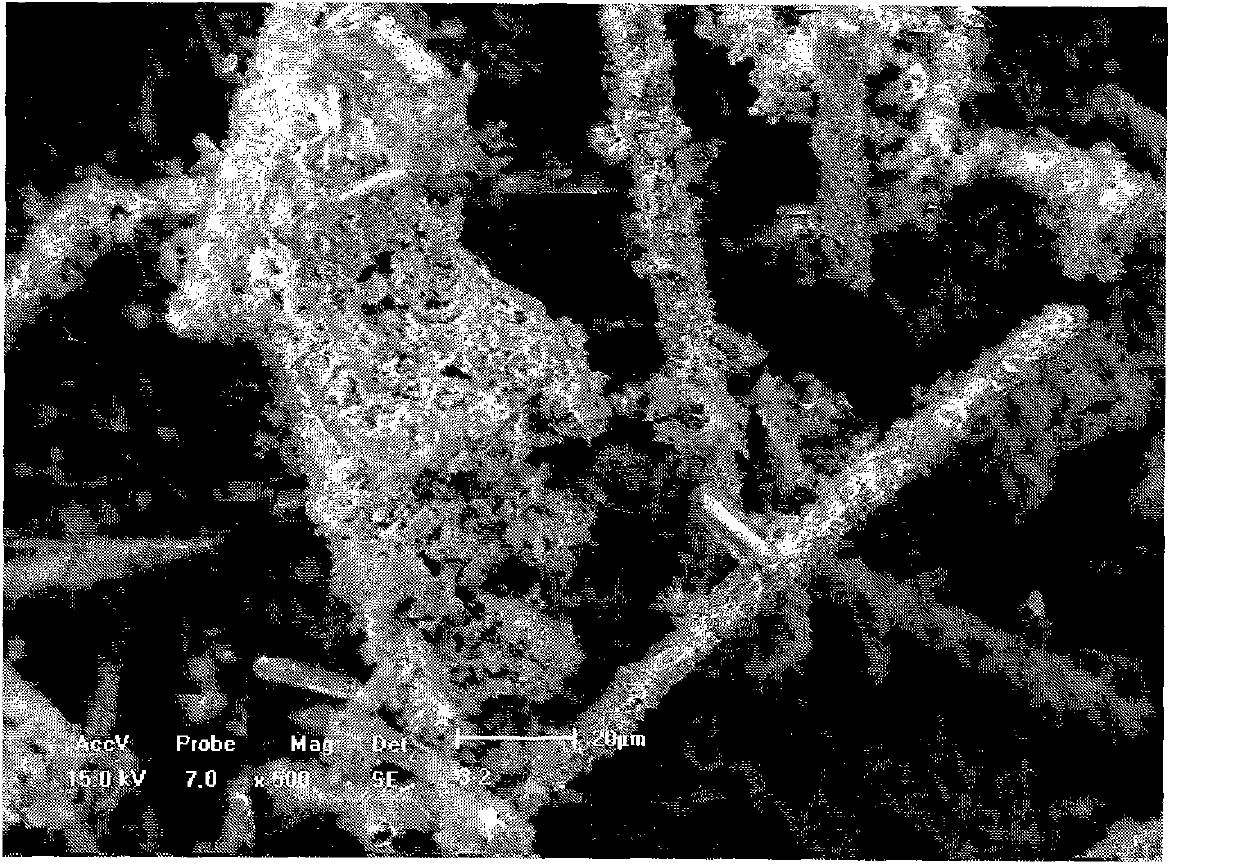

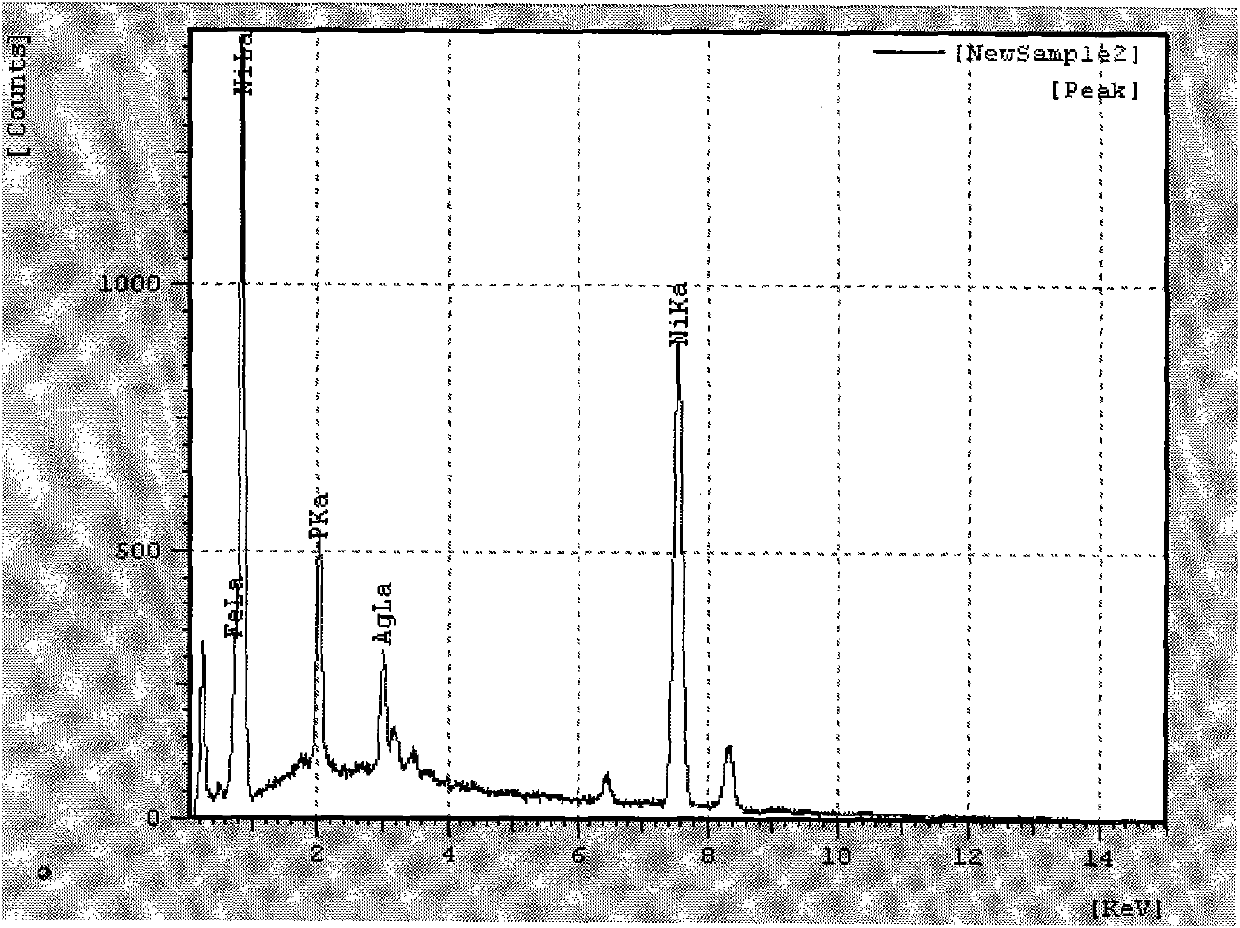

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

Nucleotide sugar purification using membranes

The invention provides methods of removing contaminants from a mixture of a desired product and contaminants by pH adjustments and molecular weight cut-offs. The contaminants include phosphate groups, magnesium sulfate, sodium pyruvate and tetrasodium pyrophosphate groups. The desired product includes nucleotide sugars, glycolipids, LnNT, sialyl lactose, and salts.

Owner:NOVO NORDISK AS

Pu'er tea toothpaste and preparation method thereof

InactiveCN102764207APreserve taste and flavorGreat tasteCosmetic preparationsToilet preparationsFiltrationToothpaste

The present invention relates to a Pu'er tea toothpaste and a preparation method thereof. The Pu'er tea toothpaste is characterized by comprising a Pu'er tea extract, which is obtained by steps of low temperature pulverization, ultrasonic extraction, pressure filtration, separation and concentration. The Pu'er tea extract is combined with food-grade auxiliary materials comprising glycerin, sorbitol, PEG400, tetrasodium pyrophosphate, sodium dihydrogen phosphate, sodium phytate, sodium carboxymethyl cellulose, xanthan gum, sodium lauryl sulfate, calcium phosphate dihydrate, hydrated silica and essence to prepare the Pu'er tea toothpaste. The method fundamentally eliminates quality issues such as spoilage, degeneration, color changing, flavor changing and chemical safety of the tea toothpaste, and effectively prolongs a shelf period of the tea toothpaste. The tea toothpaste has multiple special efficacies, such as removing scale, decomposing residual smoke stains, tea stains and coffee stains in slits between the teeth, reducing plaque, preventing breeding of harmful bacteria, disinfecting, diminishing inflammation, stopping bleeding, eliminating odor, promoting the secretion of saliva, moisturizing mouth, recovering taste buds, improving taste sense, and enabling a user to taste better flavor of food, and is a natural healthful tea toothpaste.

Owner:昆明顺普驰商贸有限公司

Peanut milk beverage emulsion stabilizer and preparation method thereof

ActiveCN101390582ANo floatStrong emulsifying abilityMilk preparationFood preparationFood additiveMonoglyceride

A peanut milk beverage emulsion stabilizer and a preparation method relate to a food additive and aim to provide a peanut milk beverage emulsion stabilizer which can effectively and fully emulsify and disperse the fat in the peanut milk beverage during the peanut milk beverage production so as to effectively prevent the fat circles and can make use of the synergy of several thickening agents to increase the viscosity of the peanut milk beverage and form stable spatial meshes in the peanut milk beverage to achieve strong suspending and thickening capability and improve the taste, and a preparation method thereof. The emulsion stabilizer has the following components: monoglyceride, tripolyglycerol fatty acid esters, sodium alginate, sucrose ester, modified soy lecithin, sodium carboxymethyl cellulose, guar gum and sodium pyrophosphate. The monoglyceride, tripolyglycerol fatty acid esters, sodium alginate, sucrose ester, modified soy lecithin, sodium carboxymethyl cellulose, guar gum and sodium pyrophosphate are mixed and evenly stirred so as to obtain the peanut milk beverage emulsion stabilizer in homogeneous powder state.

Owner:厦门磐谷生物技术有限公司 +1

Thickening system for products prepared with milk

A dry mix thickening system for preparation of a beverage product containing milk comprises a buffer, a hydrocolloid, and a chelating agent comprising tetrasodium pyrophosphate. When the dry mix thickening system is added to milk, viscosity builds within about 20 seconds to about 90 seconds to provide a thickened beverage product, without forming insoluble aggregates of the hydrocolloid. No heating is required. In addition, the only shear required to incorporate the dry mix thickening system into the milk is manual stirring.

Owner:KRAFT FOODS GRP BRANDS LLC

Fluorinated graphene reinforced lubricating oil and preparation method thereof

ActiveCN108130178AImprove performanceImprove wear resistanceLubricant compositionPlasticizerPyrophosphate

The invention provides a fluorinated graphene reinforced lubricating oil and a preparation method thereof, and relates to the technical field of lubricating oil. The fluorinated graphene reinforced lubricating oil comprises the main materials of 200-300 parts of base oil, 2-5 parts of modified fluorinated graphene, 10-15 parts of oleic acid, 10-15 parts of amine solvent, 20-25 parts of anti-wear phosphating solution, 10-15 parts of trimethylolpropane, 2-3 parts of ammonium borofluoride, 2-3 parts of sodium pyrophosphate, 0.5-1 part of a plasticizer, and 0.5-1 part of an emulsifying agent. Thefluorinated graphene is dispersed in the lubricating oil, the bearing capacity and the wear-resisting property of the lubricating oil are both effectively improved, and the fluorinated graphene reinforced lubricating oil has an excellent application prospect.

Owner:XIAMEN 6C TECH CO LTD

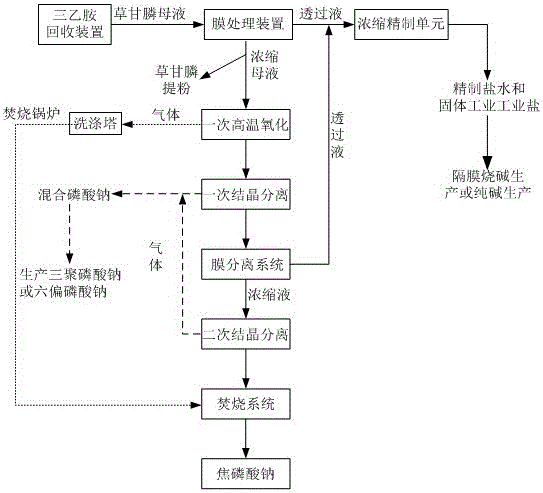

Incineration treatment process for glyphosate mother liquor

ActiveCN106082515ASolve the problem of low oxidation conversionSolve processing problemsGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisGlyphosateFlue gas

The invention discloses an incineration treatment process for glyphosate mother liquor. The incineration treatment process comprises the following steps: the glyphosate mother liquor is fed to a membrane treatment device, concentrated mother liquor and a permeate liquid are obtained; the concentrated mother liquor is subjected to glyphosate powder extraction and subjected to primary oxidation, primary crystalizing separation, treatment with a membrane separation system and secondary crystalizing separation, a product enters an incineration system, tetrasodium pyrophosphate is obtained, and flue gas produced through incineration is subjected to secondary burning after dust separation and then is emitted. The membrane treatment concentration technique for the glyphosate mother liquor is combined with the incineration process for the first time and used for completely solving the problem about treatment of the glyphosate mother liquor, salt obtained after incineration can be recycled, the flue gas produced through incineration is subjected to dust separation and secondary burning, so that dioxin in the flue gas can be reduced remarkably, and the environmental requirements are met.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Method for extracting small-molecule humic acid from soil through XAD resin

InactiveCN105203374AImprove extraction efficiencyReduce the likelihood of a reactionPreparing sample for investigationSoil scienceSodium phosphates

The invention discloses a method for extracting small-molecule humic acid from soil through XAD resin. The method comprises the following steps of a, treating soil, b, extracting soil humic acid through sodium pyrophosphate, c, extracting soil humic acid through sodium hydroxide, d, removing fulvic acid impurities in the humic acid, e, separating large-molecule humic acid from small-molecule humic acid, f, removing silicon minerals from the humic acid, and g, performing concentration and extraction on the small-molecule humic acid. The method can well separate the small-molecule humic acid in the soil and provide sample security for the research on comprehensively understanding the environmental behavior of the humic acid.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

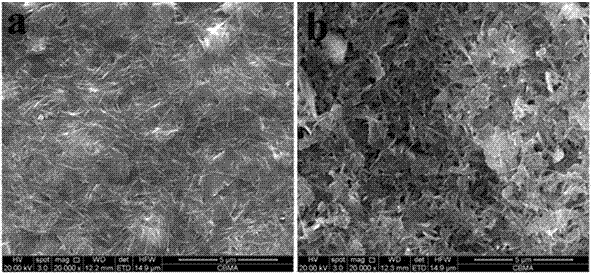

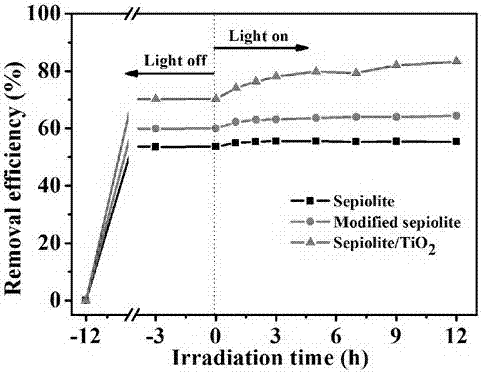

Multi-passage-structure and high-adsorption-performance sepiolite/TiO2 composite material and preparation method thereof

InactiveCN107344093AThe method is simple and energy-savingExtensive sources of raw materialsGas treatmentPhysical/chemical process catalystsFiberPyrophosphate

The invention discloses a preparation method of a multi-passage-structure and high-adsorption-performance sepiolite / TiO2 composite material. The preparation method comprises the following steps of firstly, carrying out acid modification on sepiolite to obtain modified sepiolite; afterwards, carrying out debundling dispersion on the sepiolite through adding a dispersant; finally, synthesizing the sepiolite / TiO2 composite material under the assistance of ammonia sulfate by adopting an ammonia water precipitation method and using TiCl4 as a titanium source. The morphology of the composite material prepared by the method is that TiO2 nano particles are highly uniformly dispersed on the surface of the fiber-plate-shaped sepiolite; TiO2 particles are combined with the sepiolite to form a loose whole; the composite material shows a multi-passage stricture. According to the preparation method, the sepiolite / TiO2 composite material is prepared under the action of the dispersant of sodium polymetaphosphate, sodium ortho-metaphosphate or sodium pyrophosphate and the like and by using the modified sepiolite as a raw material and the TiCl4 as the titanium source and adopting the ammonia water precipitation method; the TiO2 nano particles are uniformly loaded on a fiber plate of the sepiolite; moreover, the obvious aggregation does not exist; the compound is of the multi-passage structure, high in adsorption performance and is time-saving and environment-friendly in synthesis condition.

Owner:湘潭海泡石科技有限公司 +2

Glucose-control porridge and preparation technology

ActiveCN103478567ARole clarificationInnovativeFood ingredient functionsFood preparationPolygonum fagopyrumSucrose

The invention discloses glucose-control porridge and belongs to the field of food. A formula of the porridge comprises that main ingredients and auxiliary ingredients are added into water per 1L, wherein the main ingredients comprise oat, buckwheat, brown rice, corn grits, pearl barley, peanuts, ormosia and kidney beans; and the auxiliary ingredients comprise functional dietary fibers such as Arabic gum and resistant starch, emulsifying agents such as sucrose ester, sodium tripolyphosphate and sodium pyrophosphate, a preservative such as sodium erythorbate, a sweetening agent such as acesulfame potassium and a flavor enhancer such as ethyl maltol. A preparation technology comprises the steps as follows: the main ingredients are washed clean, the peanuts, the ormosia and the kidney beans in the main ingredients are added into water in proportion and cooked for 10min by big fire in advance; other main ingredients are added and cooked for 10min by the big fire; the auxiliary ingredients are added sequentially and cooked for 30min in a 110-DEG C high-pressure sterilization pot; and the porridge is tinned and sealed. According to the glucose-control porridge, dissolution and absorption of glucose in the porridge can be reduced remarkably, so that rising of blood glucose after dining can be reduced remarkably. The porridge tastes good and is more complete in nutrition for diabetics and stronger in health-care function; and the defects that glucose-control products often taste hard, are inconvenient to eat and the like are overcome.

Owner:NANCHANG UNIV

Flour improver for instant frozen dumplings, method for manufacturing flour improver and application thereof

InactiveCN104663763AGood lookingGreat tasteDough treatmentDough preparationBiotechnologySODIUM METAPHOSPHATE

The invention discloses a flour improver for instant frozen dumplings, a method for manufacturing the flour improver and application thereof. The flour improver for the instant frozen dumplings comprises, by weight, 2-5 parts of xanthan gum, 2-4 parts of guar gum, 2-4 parts of monostearin, 5-9 parts of stearic calcium and sodium lactate, 1-4 parts of composite phosphate, 1-3 parts of glutamine transaminase and 2-6 parts of sodium chloride. The composite phosphate comprises tetrasodium pyrophosphate, sodium tripolyphosphate and sodium hexametaphosphate. The method includes respectively sieving the xanthan gum, the guar gum, the monostearin, the stearic calcium and sodium lactate, the tetrasodium pyrophosphate, the sodium tripolyphosphate, the sodium hexametaphosphate, the glutamine transaminase and the sodium chloride by the aid of Number-CB36 sieves; mixing the xanthan gum, the guar gum, the monostearin, the stearic calcium and sodium lactate, the tetrasodium pyrophosphate, the sodium tripolyphosphate, the sodium hexametaphosphate, the glutamine transaminase and the sodium chloride with one another to obtain the improver for the instant frozen dumplings. The flour improver, the method and the application have the advantages that problems of frost cracking and the like of dumpling wrappers of existing instant frozen dumplings during instant freezing, mechanical packaging and low-temperature storing can be solved by the aid of the improver for the instant frozen dumplings, the smoothness, the boiling fastness and the freeze-thaw stability of the instant frozen dumplings can be enhanced, and the taste and the appearance of the instant frozen dumplings can be obviously improved.

Owner:SHANGHAI INST OF TECH

Dry powder gel face mask formula

InactiveCN104490626AImprove stabilityIncrease elasticityCosmetic preparationsToilet preparationsVitamin CSulfate

The invention discloses a dry powder gel face mask formula. The dry powder gel comprises, 5% to 15% of calcium sulfate decahydrate, 15% to 25% of sodium alginate, 55% to 65% of glucose powder, 1.5% to 2.5% of tetrasodium pyrophosphate decahydrate, 1.2% to 2% of xanthan gum, 0.3% to 0.7% of amino acid, 0.5% to 0.9% of vitamin C, 0.6% to 1% of talcum powder, 3% to 5% of collagen, and 0.3% to 0.5% of sodium hyaluronate. The dry powder gel face mask has the advantages of being good in stability, elasticity, moisture retention and plasticity, stable in size, free of reactions with face non-woven materials chemically, low in price, convenient to use and the like.

Owner:董庆国

Radix ginseng toothpaste and preparation method thereof

InactiveCN107184481AWith sterilizationKeep your mouth freshCosmetic preparationsToilet preparationsCelluloseCarrageenan

The invention belongs to the field of toothpaste, and in particular relates to radix ginseng toothpaste. The radix ginseng toothpaste is prepared from the following components: 60-70% of sorbitol, 15-20% of hydrated silica, 1.0-10% of glycerin, 1.0-5% of polyethylene glycol-8, 2.0-2.5% of sodium lauryl sulfate, 1.0-1.5% of edible essence, 0.5-1.0% of carrageenan, 0.5-1.0% of cellulose gum, 0.2-0.25% of sodium saccharin, 0.2-0.5% of paeonol, 0.1-0.5% of tranexamic acid, 0.1-0.2% of tetrasodium pyrophosphate, 0.1-0.3% of sodium benzoate, 0.08% of a radix ginseng extract and the balance of water, wherein the sum of percents of the components is 100%. The radix ginseng toothpaste has the beneficial effects of having the functions of killing bacteria, maintaining the oral cavity to be fresh and preventing gingival bleeding.

Owner:广州市博真电子科技有限公司

Dyeing process of micro-denier acrylic fiber wool top

InactiveCN105274867AHigh color fastnessImprove dyeing uniformityDyeing processPyrophosphateSodium sulfate

The invention discloses a dyeing process of a micro-denier acrylic fiber wool top. The dyeing process comprises the following steps: (1) adding 0.6 part by mass of sodium persulfate, 1.3 parts by mass of tristyrylphenol polyoxyethylene ether sulfonated ammonium, 2.1 parts by mass of dibutyl phthalate, 1.8 parts by mass of garden balsam extract, 9 parts by mass of natural plant pigment, 22 parts by mass of water, 0.7 parts by mass of sodium pyrophosphate and 2.4 parts by mass of cocoanut fatty acid diethanolamide and stirring the raw materials evenly; (2) soaking the wool top to a dye vat for 50 minutes; (3) drying the soaked wool top at 75 DEG C; (4) immersing the dried wool top into clean water and rinsing for 5 minutes; and (5) taking out the rinsed wool top and naturally airing. According to the dyeing process of the micro-denier acrylic fiber wool top, the color fastness of the dyed wool top is high; the dyeing uniformity is good; and dyeing defect is avoided.

Owner:常熟市新华源有色毛条厂

Sugar-free grain yoghurt

The invention relates to sugar-free grain yoghurt and a preparation method of the sugar-free grain yoghurt. Dairy products are matched with stabilizing agents, non-sugar sweeteners, sugar alcohol and hippophae rhamnoides powder to be subjected to strain fermentation and grain particle addition for obtaining the sugar-free grain yoghurt, wherein the stabilizing agents are selected from combinationof pectin, gelatin, modified starch, sodium chloride and sodium pyrophosphate. The yoghurt provided by the invention solves the problems that in the prior art, hippophae rhamnoides are rich in vitamin C (Vc), the acidity is strong, and the flavor is special, so the casein crystallization is caused, the tissue state of the yoghurt is changed, and the flavor of the yoghurt is influenced. In addition, the yoghurt realizes various health care and nutrition effects of grains, various kinds of probiotics and the hippophae rhamnoides and belongs to good yoghurt meal replacing food. The yoghurt provided by the invention is suitable for being drunk by customers who cannot take sugar, and in addition, the deserved sweetness of the yoghurt is maintained.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

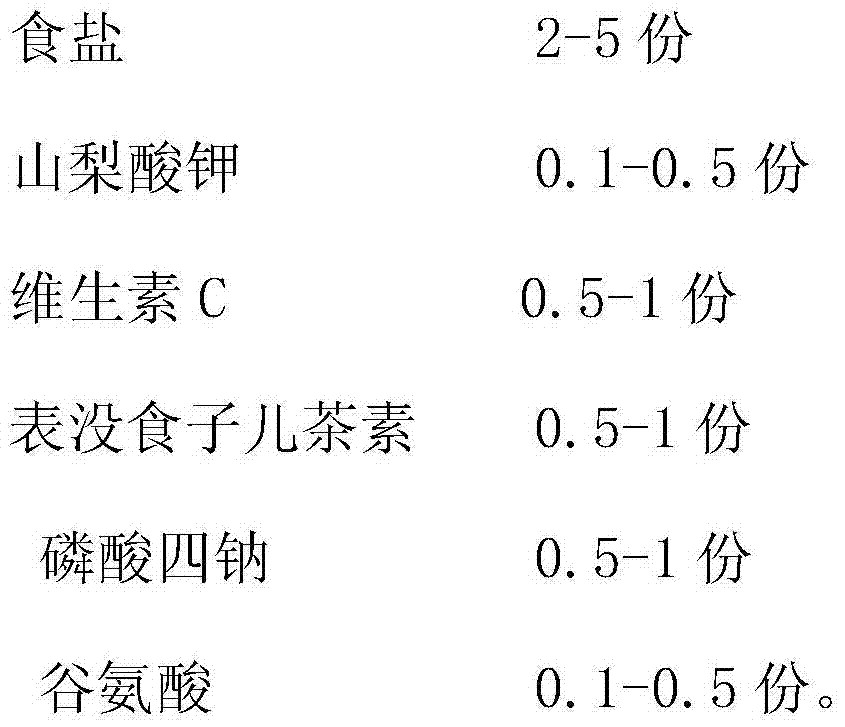

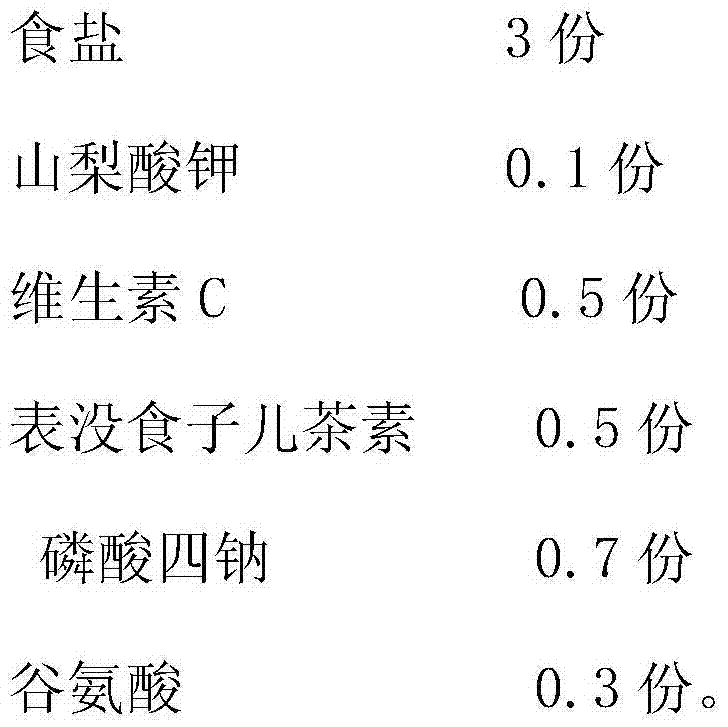

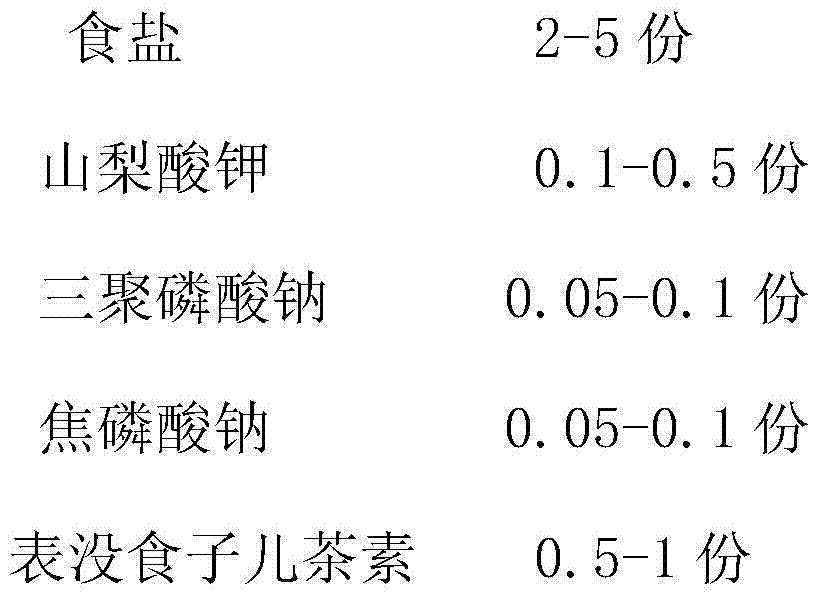

Shrimp preservative and using method thereof

ActiveCN103749645AKeep the tasteMaintain colorMeat/fish preservation using chemicalsVitamin CPhosphoric acid

The invention provides a shrimp preservative and a using method of the shrimp preservative. The shrimp preservative comprises the following components in parts by weight: 2-5 parts of edible salt, 0.1-0.5 part of potassium sorbate, 0.5-1 part of vitamin C, 0.5-1 part of epigallocatechin, 0.5-1 part of tetrasodium pyrophosphate and 0.1-0.5 part of glutamic acid. Another shrimp preservative comprises the following components in parts by weight: 2-5 parts of edible salt, 0.1-0.5 part of potassium sorbate, 0.05-0.5 part of sodium tripolyphosphate, 0.05-0.1 part of sodium pyrophosphate, 0.5-1 part of epigallocatechin, 0.5-1 part of tetrasodium pyrophosphate and 0.1-0.5 part of glutamic acid. The using method for the shrimp preservative provided by the invention comprises the steps of mixing the preservative and broken ice to make preservative ice; putting fresh shrimps into the preservative ice for refrigeration under 0-4 DEG C. Compared with the prior art, the shrimp preservative has the advantages that the storage period is prolonged from 8 days of single use of the broken ice to 17 days; the preservative effect is good, and the shrimps can not discolor or go bad; furthermore, the preservative provided by the invention is also suitable for other sea food.

Owner:安徽利海新城镇开发有限公司

Motor vehicle antifreeze fluid additive with high corrosion inhibition performance and preparation method thereof

ActiveCN105255455ANo fouling problemLowering the freezing pointHeat-exchange elementsSodium phosphatesActive agent

The invention relates to a motor vehicle antifreeze fluid additive with high corrosion inhibition performance and a preparation method thereof and belongs to the technical field of antifreeze fluid. The motor vehicle antifreeze fluid additive is prepared from, by weight, 5-10 parts of ammonium nitrate, 3-5 parts of sodium pyrophosphate, 2-4 parts of sodium phosphate, 1-2 parts of sodium molybdate benzene, 1-3 parts of benzotriazole, 0.5-1 part of itaconic acid homopolymer, 0.1-0.3 part of methyl benzotriazole, 0.1-0.3 part of polyoxyethylene alkylphenol ether, 0.2-0.4 part of thiourea or thiourea derivative, 0.1-0.3 part of mildew preventive, 0.2-0.4 part of hydrocarbon imidazoline quaternary ammonium salt and 0.5-1 part of nonionic surfactant. Amine, borax and silicate are not added to the antifreeze fluid additive, environment is not influenced, the problem of scaling is avoided, the freezing point is low, and good corrosion resistant performance is achieved.

Owner:DONGYING HAOMING LUBRICATION TECH CO LTD

Low-temperature phase-change heat storage material and preparation method thereof

InactiveCN102757768AAdd a small proportionSimple recipeHeat-exchange elementsWater bathsSodium carbonate anhydrous

The invention provides a low-temperature phase-change heat storage material and a preparation method thereof. The low-temperature phase-change heat storage material comprises the following components in percentage by weight: 90%-92% of sodium acetate trihydrate, 3%-5% of tetrasodium pyrophosphate decahydrate, 2%-3% of anhydrous sodium carbonate and 1%-2% of polyacrylamide. The preparation method comprises the following steps of: grinding the four components until the granularity is 30-50 meshes respectively, mixing uniformly, and heating the mixture in a water bath at the temperature of 74-79 DEG C, so as to completely melt all the components to form a colloidal liquid; after stirring uniformly, injecting the colloidal liquid into a container, wherein the injected volume is 88%-90% of the volume of the container; and after the colloidal liquid is cooled to room temperature, sealing the container. According to the invention, the adding ratio of an additive is low, the stability of the material is high, the phase-change latent heat is large, the crystallization temperature is moderate, and the supercooling degree is not more than 2 DEG C; and the phase-change heat storage material is the colloidal liquid in melting, so that the phase separation phenomenon is avoided, the preparation process is simple, the packaging is easy and the production is convenient.

Owner:路生吉

High temperature resisting magnesium phosphate adhesive with high strength and preparation method thereof

InactiveCN103305134AHigh bonding strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveO-Phosphoric AcidMagnesium phosphate

The invention relates to a high temperature resisting magnesium phosphate adhesive with high strength and a preparation method thereof. The invention provides a phosphate-based metal adhesive. The adhesive comprises the following components in parts by weight: 30-50 parts of magnesium hydroxide, 80-100 parts of phosphoric acid, 5-10 parts of aluminum hydroxide, 40-60 parts of silicon sol, 10-20 parts of alumina sol, 5-10 parts of aluminum borate, 3-5 parts of sodium fluosilicate, 3-5 parts of sodium pyrophosphate, 5-8 parts of triethanolamine, 3-6 parts of natural rubber, 2-4 parts of acrylic ester, 5-10 parts of a polyvinyl acetate emulsion, 3-6 parts of an acrylic emulsion, 20-30 parts of ethanol, 5-10 parts of bentonite, 5-10 parts of silicon carbide, 3-5 parts of quartz sand, 5-10 parts of borax, 2-4 parts of zinc powder, 3-6 parts of methyl methacrylate, 3-5 parts of a surfactant and 30-50 parts of water. The combining strength of the phosphate adhesive to a ceramic wafer can reach over 2.8MPa. After high temperature endurance test, the adhesive can still reach better bonding strength.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Complex nutritional flavorous enhancer

The invention belongs to the field of seasoning technology and particularly relates to a complex nutritional flavorous enhancer, which consists of the following raw materials by weight part: 10-25 parts of glycine, 35-65 parts of monosodium glutamate, 5-15 parts of L-aspartic acid, 3-10 parts of I+G, 1-5 parts of DL alanine, 0.5-1.5 parts of DL-serine, 1-5 parts of L-lysine hydrochloride, 0.5-5 parts of methionine, 2-10 parts of pyrophosphate sodium, 2-10 parts of L-histidine hydrochloride, 0.5-5 parts of disodium succinate, 4-10 parts of animal protein hydrolysates, 4-10 parts of plant protein hydrolysates and 2-8 parts of mushroom powder. The complex nutritional flavorous enhancer preserves the original flavor of raw materials and has strong and ample flavor. With the animal protein hydrolysates, plant protein hydrolysates and mushroom powder added to the complex nutritional flavorous enhancer, the complex nutritional flavorous enhancer has high nutritional value, and does not make one thirsty upon using it.

Owner:广东百味佳味业科技股份有限公司

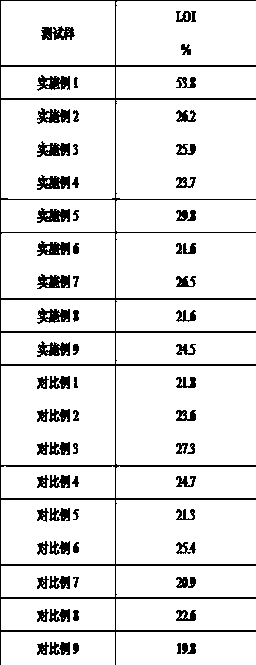

Preparation method of novel flame-resistant material

The invention discloses a preparation method of a novel flame-resistant material. Melamine, nitric acid, tetrasodium pyrophosphate and the like are taken as raw materials, an antioxidant 1330 and a Sb2O3-diatomite / MOF-5 composite are introduced, and the novel flame-resistant material is prepared through methods including ultrasonic treatment, organic synthesis, physical compounding and the like. The prepared novel flame-resistant material has excellent flame retardancy, is low in production cost and high in flame-retardant efficiency and can meet the flame-retardant requirements through littleaddition.

Owner:宁波科邦华诚技术转移服务有限公司

Special treating agent for galvanizing surface chemical conversion and treating technique thereof

ActiveCN104498921AReduce pollutionSimple methodMetallic material coating processesSodium phosphatesActive agent

The invention discloses a special treating agent for galvanizing surface chemical conversion and a treating technique thereof, belonging to the field of surface protection of transmission and transformer equipment components. The conversion treating method mainly comprises the steps of pretreatment, water washing, chemical conversion, water washing, natural drying and the like. The pretreatment agent is composed of Na2CO3, NaH2PO4, NaHPO4, sodium pyrophosphate, copper salt, nickel salt and titanium salt. In the treatment process, the conversion agent is composed of H3PO4 and ZnO, the corrosion inhibitor is one or both of thiocarbamide and hexamethylenetetramine, the complexing agent is composed of one or more of citric acid, tartaric acid and monobutyric acid, the surfactant is composed of one or more of OS-15, OP-10 and sodium dodecyl benzene sulfonate, and the accelerator is composed of one or more of sodium nitrate, sodium nitrate, hydrogen peroxide, potassium permanganate and potassium chlorate. The galvanizing substrate surface treated by the technique is a compact corrosion-resistant film with insulation resistance. The treating agent and treating technique can effectively enhance the corrosion resistance of the material and enhance the corrosion resistance and service life of the transmission and transformer equipment metal components.

Owner:STATE GRID CORP OF CHINA +1

Preparation method for phosphoric acid sodium salts

ActiveCN104843662AReduce manufacturing costSolve the worries of environmental protectionPhosphorus compoundsO-Phosphoric AcidSodium phosphates

The invention discloses a preparation method for phosphoric acid sodium salts, wherein the preparation method comprises the steps: using sodium pyrophosphate as a raw material, carrying out a mixed hydrolysis reaction with wet-process phosphoric acid to obtain sodium orthophosphate, then adding purified wet-process phosphoric acid, adjusting the pH value to obtain disodium phosphate and / or trisodium phosphate, and next carrying out a polymerization reaction to obtain sodium tripolyphosphate. The novel preparation method for the phosphoric acid sodium salts is a new method adopting crude by-products sodium pyrophosphate and sodium hydroxide generated in Caoanning production as the main raw materials and adopting high-temperature and high-pressure hydrolysis process to produce the phosphoric acid sodium salt products. The preparation method is characterized in that the production process is easy to control, the product quality is stable, and the production cost is 35-45% lower than that of a traditional process.

Owner:MIANYANG SHENLONG FEEDSTUFF CO LTD

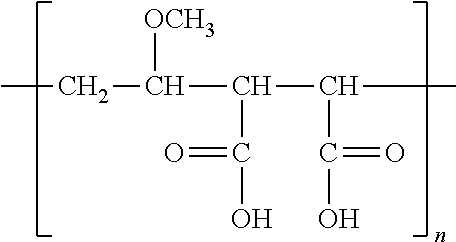

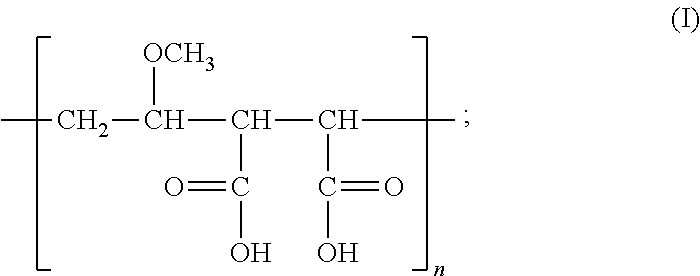

Stannous salt and sodium tripolyphosphate oral care compositions and methods

Oral care compositions containing a stannous salt and sodium tripolyphosphate are provided where stannous tripolyphosphate ionic intermediates comprise less than about 1% of the compositions Tetrasodium pyrophosphate, a methylvinyl ether-maleic anhydride copolymer and / or a silica oral polishing agent may be added for further efficacy. In a single phase blend, the oral care composition may be effectively limited to comprise less than about 10% water. In a dual-phase blend a mixture having the stannous salt in a first phase and the sodium tripolyphosphate in a second phase may be generated from a dual chamber storage tube (with each phase provided from a separate chamber) immediately prior to dental care usage.

Owner:COLGATE PALMOLIVE CO

Liquid compound fertilizer for swelling fruit period and preparation method thereof

InactiveCN105399577ANutritional balanceReduce leaching lossFertilizer mixturesSoil scienceSodium phosphates

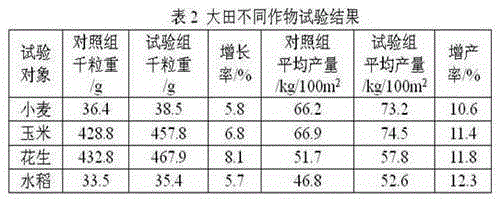

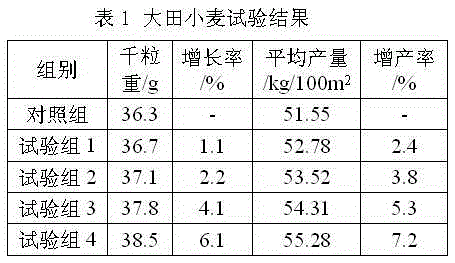

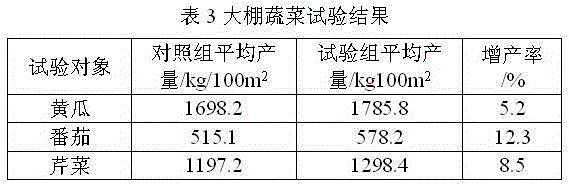

The invention discloses a liquid compound fertilizer for a swelling fruit period, which belongs to the technical field of fertilizers, and comprises raw materials in every 1L: nitrogenous fertilizer calculated by nitrogen (N) 170-180g, phosphatic fertilizers calculated by phosphorus pentoxide (P2O5) 80-100g, potash fertilizers calculated by potassium (K) 250-260g, microelements 2.475-3.425g, xanthan gum 1.4-4.2g, sodium pyrophosphate 5.6-8.4g and potassium humate 30-40g, and the other is water. A method for preparing the liquid compound fertilizer for the swelling fruit period comprises steps: the potash fertilizers, the xanthan gum and the sodium pyrophosphate are added into the water to mix, then are added with the nitrogenous fertilizer, the phosphatic fertilizers c and the potassium humate to stir and dissolve, then are added with the microelements to stir and dissolve, are metered volume to 1L through the water, and are uniformly stirred, thereby obtaining the liquid compound fertilizer for the swelling fruit period by filling after grinding. The liquid compound fertilizer for the swelling fruit period is a suspension type liquid compound fertilizer with balanced, steady and uniform in nutrition, reduces leaching loss in soil, improves utilization rate in the soil, and is excellent in increase yield of crops.

Owner:河南晋开集团雨露复合肥有限公司 +1

Yoghurt containing hippophae rhamnoides

The invention relates to health preserving yoghurt containing hippophae rhamnoides and a preparation method of the health preserving yoghurt. Dairy products are matched with hippophae rhamnoides powder, stabilizing agents and sugarcane to be subjected to strain fermentation, wherein the stabilizing agents are selected from combination of pectin, gelatin, modified starch, sodium chloride and sodium pyrophosphate. The health preserving yoghurt provided by the invention solves the problems that in the prior art, hippophae rhamnoides are rich in vitamin C (Vc), the acidity is strong, and the flavor is special, so the casein crystallization is caused, the tissue state of the yoghurt is changed, and the flavor of the yoghurt is influenced. In addition, the health preserving yoghurt realizes various health care and nutrition effects of various kinds of probiotics and the hippophae rhamnoides.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

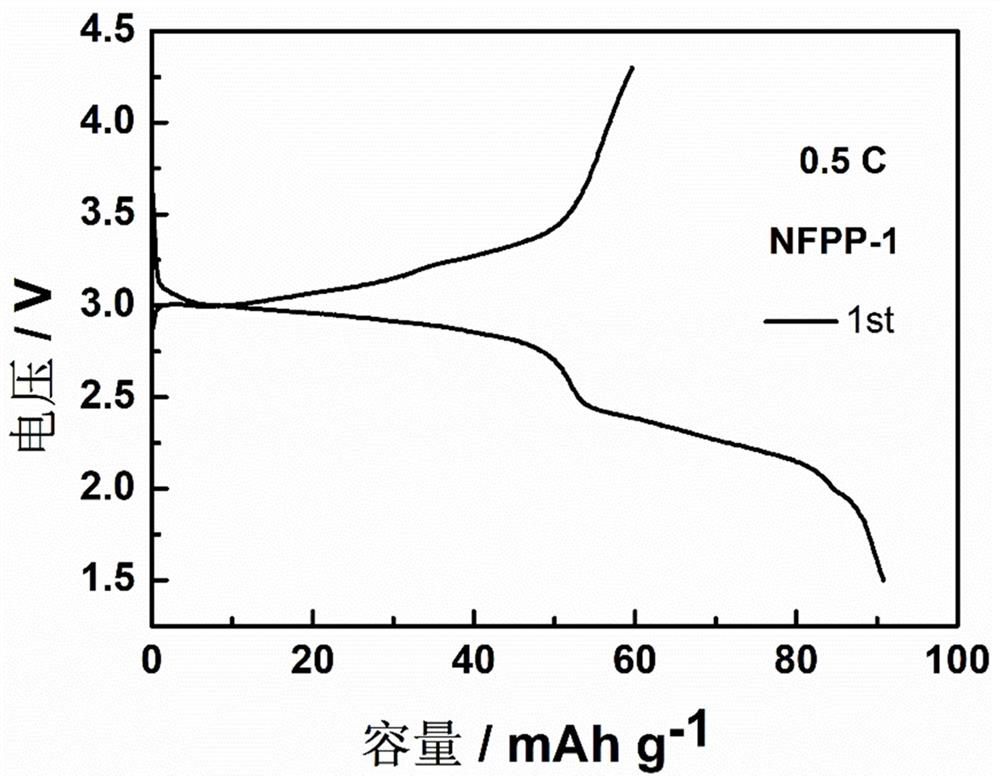

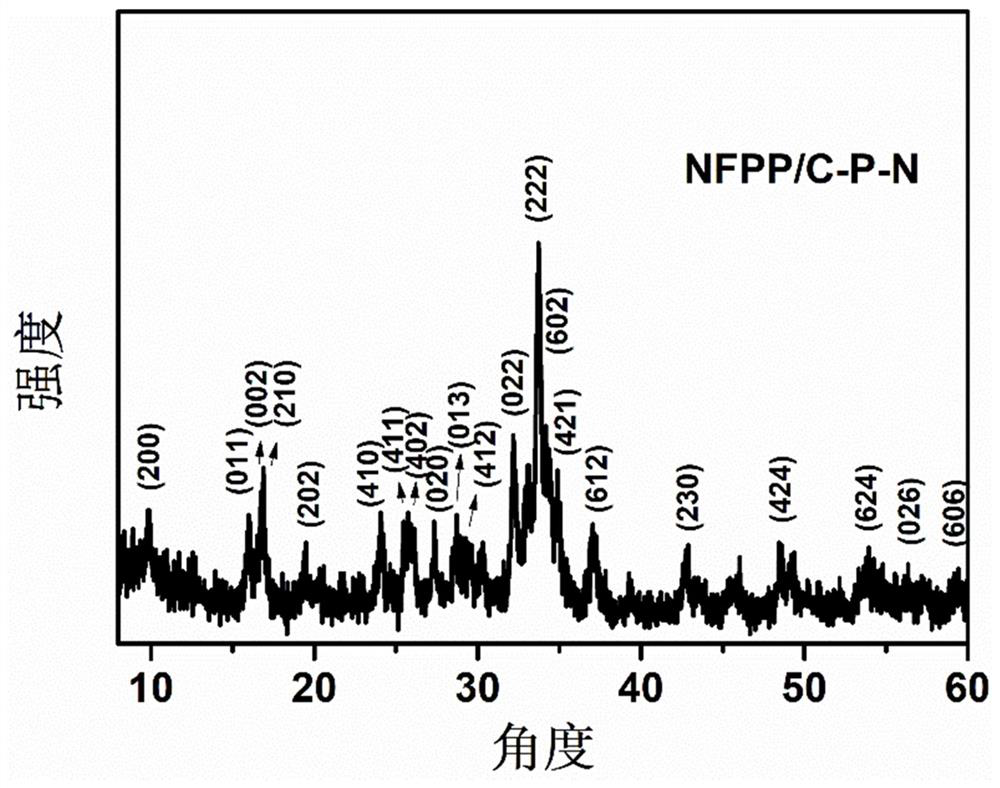

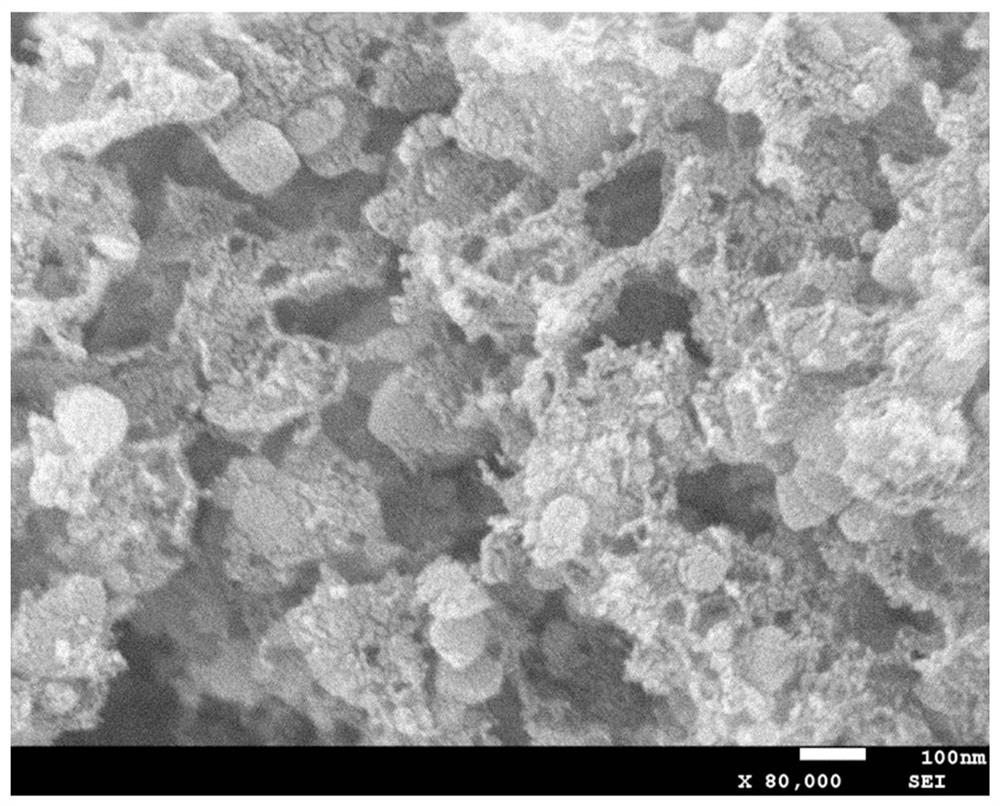

Preparation method for porous carbon modified ferric sodium pyrophosphate/carbon positive electrode material of sodium ion battery

ActiveCN113104828AImproved magnification performanceImprove cycle stabilityCell electrodesSecondary cellsPorous carbonSodium phosphates

The invention relates to a preparation method for a porous carbon modified ferric sodium pyrophosphate / carbon positive electrode material of a sodium ion battery. The preparation method comprises the following steps: dissolving ferric nitrate nonahydrate and citric acid in deionized water to form a solution A, dissolving ammonium dihydrogen phosphate and sodium pyrophosphate in deionized water to form a solution B, and dissolving polyvinylpyrrolidone and sodium chloride in deionized water to form a solution C; adding the solution A into the solution B at a constant speed, and conducting stirring while dropwise adding the solution A until the mixed solution becomes a yellow green suspension after dropwise adding is completed, thereby obtaining a solution D; adding the solution D into the solution C at a constant speed, continuing stirring for 7 hours, performing freezing for 24 hours, and conducting drying for 36 hours by using a freeze dryer to obtain a precursor; and finally, putting the precursor into a tubular furnace, conducting pre-burning for 6 hours at 300 DEG C in an Ar-H2 mixed atmosphere, then finally burning the precursor at 500 DEG C, and finally, carrying out cleaning with deionized water multiple times to obtain the porous carbon modified Na4Fe3(PO4)2P2O7 / C composite positive electrode material.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com