Preparation method of novel flame-resistant material

A flame retardant material and a new technology, applied in the field of the preparation of flame retardant materials, can solve the problems of insufficient thermal stability, low flame retardant efficiency, poor water resistance, etc., achieve a good synergistic flame retardant effect, delay degradation and combustion, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

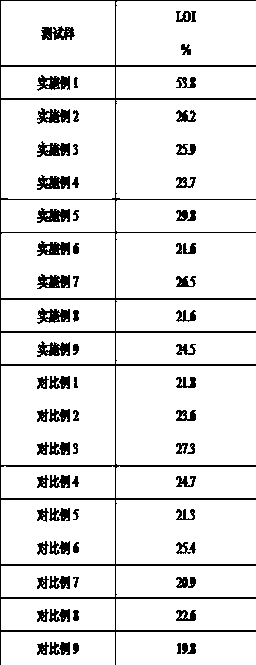

Examples

Embodiment 1

[0013] 1) Weigh 31.5 parts by weight of melamine and place it in a reaction kettle, add 250 parts by weight of deionized water, slowly add 16 parts by weight of nitric acid dropwise after ultrasonic treatment for 30 minutes, heat up to 90°C after magnetic stirring for 1 hour, and slowly add 33.8 parts by weight of pyrophosphoric acid Sodium, under the action of a magnetic field, pass in neon gas to purge for 1~2h, then continue to stir at 90~100°C, monitor the pH value of the reaction solution, when the pH value is ≥ 6.0, stop the reaction to obtain a white paste, use Wash with deionized water for 3 to 5 times, filter with suction, and then place in a vacuum drying oven at 100°C to dry to constant weight, crush and sieve to obtain melamine pyrophosphate powder for later use;

[0014] 2) Weigh 30 parts by weight of melamine pyrophosphate and 50 parts by weight of polypropylene, and blend them in an ML-E internal mixer at 170°C for 10 minutes, and then transfer the blend to an op...

Embodiment 2

[0018] It is exactly the same as Example 1, except that 24 parts by weight of melamine pyrophosphate and 12 parts by weight of pentaerythritol are added.

Embodiment 3

[0020] It is exactly the same as Example 1, except that 24 parts by weight of melamine pyrophosphate and 8 parts by weight of pentaerythritol are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com