Multi-passage-structure and high-adsorption-performance sepiolite/TiO2 composite material and preparation method thereof

A composite material and sepiolite technology, applied in the field of sepiolite/TiO2 composite material and its preparation, can solve the problems of uncontrollable particle size, poor dispersion, long time, etc. The method is simple, energy-saving, and widely used Prospects, the effect of low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

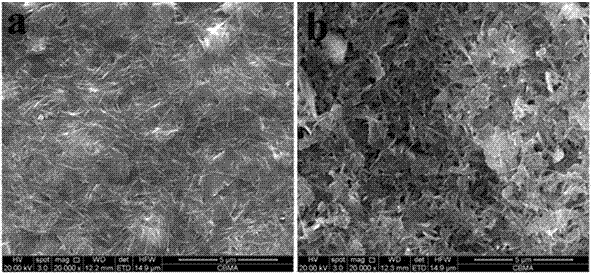

[0028] (1) Sepiolite modification: Add 12 g of sepiolite powder to 300 g of water at room temperature, then add 20 g of concentrated hydrochloric acid, stir for 4 hours, filter, wash, and dry to obtain modified sepiolite;

[0029] (2) Disperse the sepiolite modified in step (1) in water, add sodium pyrophosphate as a dispersant, stir for 30 min, and add 125 mL of 0.6 mol / L TiCl dropwise 4aqueous solution, stirred for 5 min, and then added 40 mL of 1.0 mol / L (NH 4 ) 2 SO 4 The solution was heated to 80 ° C for 2 h, and ammonia water was added to adjust the pH value to 6, and naturally cooled to room temperature to obtain a brown precipitate;

[0030] (3) Wash the precipitate obtained in step (2) with distilled water, dry it at 80°C, and grind it into powder;

[0031] (4) Calcinate the powder obtained in step (3) at a temperature of 550 °C for 2 h to obtain the product sepiolite / TiO 2 Complex.

Embodiment 2

[0033] (1) Sepiolite modification: Add 12 g of sepiolite powder to 300 g of water at room temperature, then add 20 g of concentrated hydrochloric acid, stir for 4 hours, filter, wash, and dry to obtain modified sepiolite;

[0034] (2) Disperse the sepiolite modified in step (1) in water, add sodium pyrophosphate as a dispersant, stir for 30 min, and add 167mL of 0.6mol / L TiCl dropwise 4 aqueous solution, stirred for 5 min, and then added 40 mL of 1.0 mol / L (NH 4 ) 2 SO 4 The solution was heated to 80 ° C for 2 h, and ammonia water was added to adjust the pH value to 6, and naturally cooled to room temperature to obtain a brown precipitate;

[0035] (3) Wash the precipitate obtained in step (2) with distilled water, dry it at 80°C, and grind it into powder;

[0036] (4) Calcinate the powder obtained in step (3) at a temperature of 550°C for 2 h to obtain the product sepiolite / TiO 2 Complex.

Embodiment 3

[0038] (1) Sepiolite modification: Add 12 g of sepiolite powder to 300 g of water at room temperature, then add 20 g of concentrated hydrochloric acid, stir for 4 hours, filter, wash, and dry to obtain modified sepiolite;

[0039] (2) Disperse the sepiolite modified in step (1) in water, add sodium pyrophosphate as a dispersant, stir for 30 min, and add 250 mL of 0.6 mol / L TiCl dropwise 4 aqueous solution, stirred for 5 min, and then added 40 mL of 1.0 mol / L (NH 4 ) 2 SO 4 The solution was heated to 80 ° C for 2 h, and ammonia water was added to adjust the pH value to 6, and naturally cooled to room temperature to obtain a brown precipitate;

[0040] (3) Wash the precipitate obtained in step (2) with distilled water, dry it at 80°C, and grind it into powder;

[0041] (4) Calcinate the powder obtained in step (3) at a temperature of 550°C for 2 h to obtain the product sepiolite / TiO 2 Complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com