Preparing method of nanometer active carbon fiber

An activated carbon fiber and nanotechnology, applied in nanotechnology, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of high cost and cumbersome preparation process of nanometer activated carbon fiber, avoid hydrolysis, environmental protection, cheap and easy to obtain raw materials , The method is simple and the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

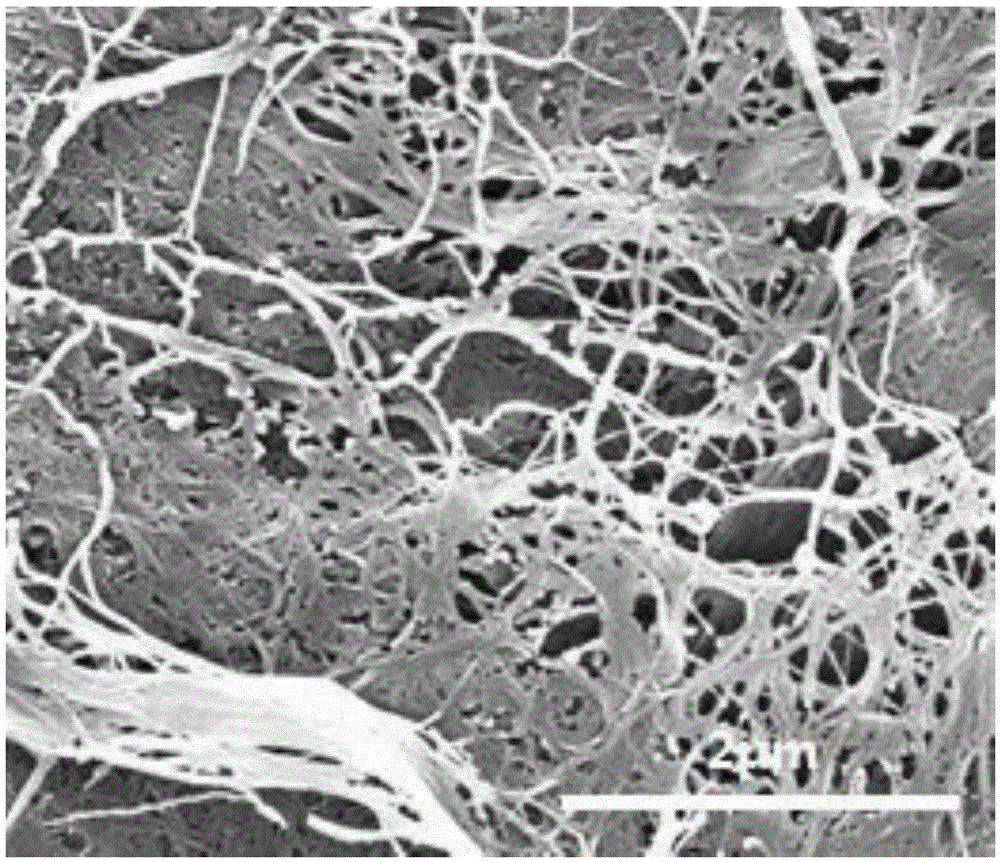

[0019] Specific embodiment one: the preparation method of a kind of nano-activated carbon fiber of present embodiment, carry out as follows:

[0020] 1. Soak bacterial cellulose in deionized water and ultrasonically wash it, then freeze it with liquid nitrogen and freeze-dry it for 15-30 hours to obtain spare bacterial cellulose;

[0021] 2. Soak the spare bacterial cellulose in an aqueous potassium hydroxide solution and absorb to saturation to obtain potassium hydroxide / bacterial cellulose;

[0022] 3. Freeze-dry the potassium hydroxide / bacterial cellulose with liquid nitrogen for 40 hours to obtain the potassium hydroxide / bacterial cellulose precursor;

[0023] 4. Put the potassium hydroxide / bacterial cellulose precursor in a tube furnace for high-temperature pyrolysis to obtain nano-activated carbon fibers.

[0024] Bacterial cellulose in this embodiment is a commercially available product.

[0025] This embodiment uses potassium hydroxide / bacterial cellulose as a precur...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the bacterial cellulose is bacterial cellulose leftovers. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the condition of the ultrasonic cleaning in step 1 is ultrasonic time of 10 hours, and the deionized water is replaced every hour. Others are the same as in the first or second embodiment.

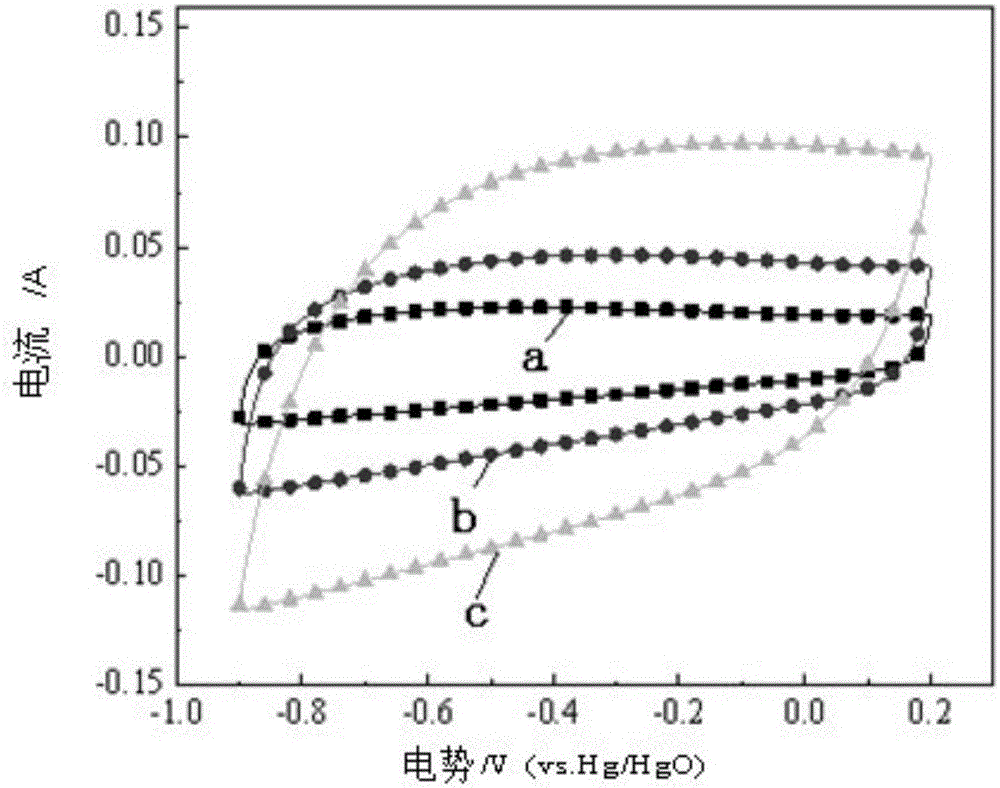

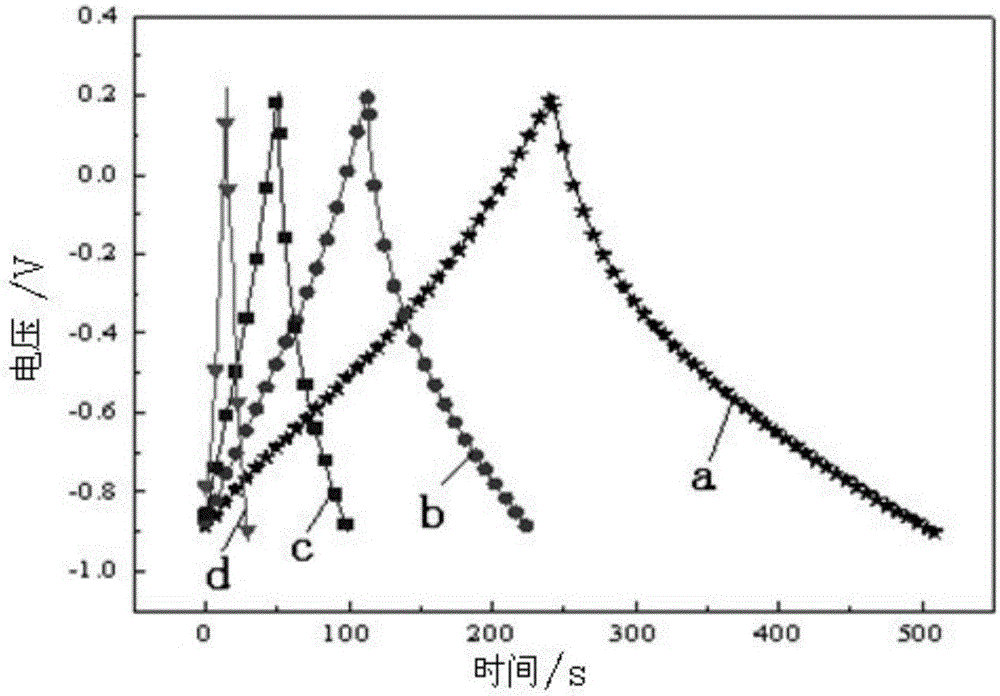

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com