Battery negative electrode material and preparation method thereof

A battery negative electrode and spiral technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of affecting the electrical properties of electrode materials, titanium dioxide agglomeration, and large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of battery negative electrode material, comprising the following steps:

[0029] heat-treating the helical carbon nanofibers to obtain modified helical carbon nanofibers;

[0030] The modified helical nano-carbon fiber, butyl titanate, solvent and glacial acetic acid are mixed and then subjected to solvothermal reaction to obtain the negative electrode material of the battery; the solvent includes a first solvent and a second solvent.

[0031] In the present invention, unless otherwise specified, the raw materials used in the present invention are conventional commercially available products.

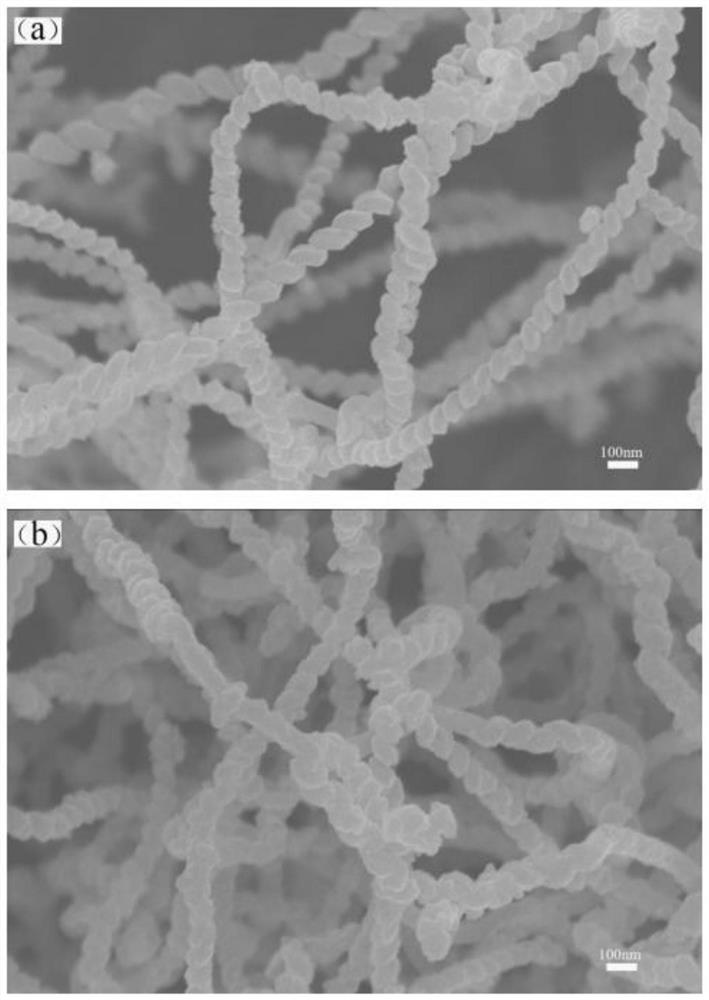

[0032] In the invention, the helical nano carbon fiber is heat-treated to obtain the modified helical nano carbon fiber. In the present invention, the helical carbon nanofibers are preferably prepared, and the preparation method of the helical carbon nanofibers preferably includes the following steps:

[0033] Using acetylene as a car...

Embodiment 1

[0074] Preparation of battery anode materials:

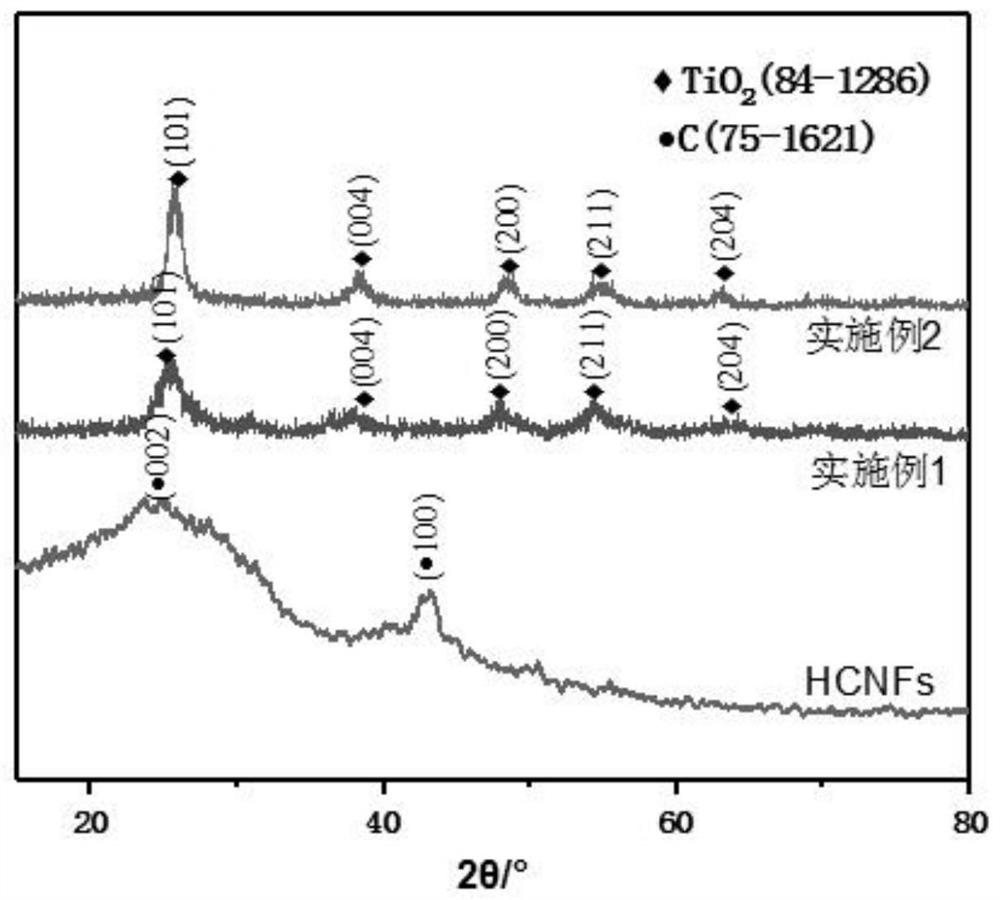

[0075] HCNFs (helical diameter 80nm) in a vacuum of 1 × 10 -1 Pa, heat treatment at 600°C for 2 hours to obtain modified HCNFs;

[0076] Ultrasonic dispersion of 0.5g modified HCNFs with 85mL ethanol and 3mL water at 180W for 30min to obtain a modified HCNFs dispersion;

[0077] Ultrasonic disperse 4mL butyl titanate and 50mL absolute ethanol at 180W for 30min to obtain a butyl titanate solution;

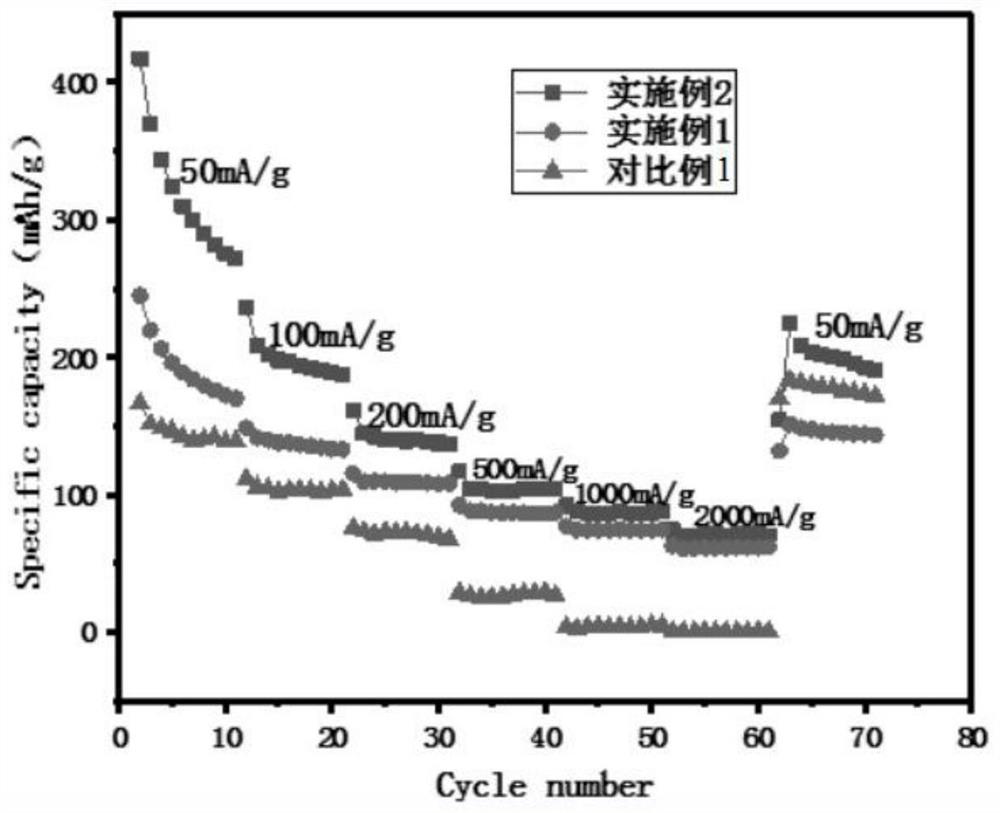

[0078] Stir the modified HCNFs dispersion and butyl titanate solution in an oil bath at 45°C at a speed of 350r / min for 30min, then add 3mL of glacial acetic acid for solvothermal reaction (100°C, 4h); After the product was air-cooled to room temperature, it was suction filtered and washed (absolute ethanol). When the acidity and alkalinity of the filtrate reached neutral, it was dried at 70°C for 6 hours to obtain the battery negative electrode material (TiO 2@HCNFs).

[0079] To prepare a sodium-ion battery:

[0080] Mix the ne...

Embodiment 2

[0084] Preparation of battery anode materials:

[0085] HCNFs (helical diameter 80nm) in a vacuum of 1 × 10 -1 Pa, heat treatment at 700°C for 3 hours to obtain modified HCNFs;

[0086] Ultrasonic dispersion of 0.5g modified HCNFs with 90mL absolute ethanol and 3mL water at 180W for 30min to obtain a modified HCNFs dispersion;

[0087] Ultrasonic disperse 6mL butyl titanate and 50mL absolute ethanol at 180W for 30min to obtain a butyl titanate solution;

[0088] Stir the modified HCNFs dispersion and butyl titanate solution in an oil bath at 45°C at a speed of 400r / min for 30min, then add 3mL of glacial acetic acid for solvothermal reaction (100°C, 6h); After the product was air-cooled to room temperature, it was suction filtered and washed (absolute ethanol). When the acidity and alkalinity of the filtrate reached neutral, it was dried at 75°C for 4 hours to obtain the battery negative electrode material (TiO 2 @HCNFs).

[0089] To prepare a sodium-ion battery:

[0090] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com