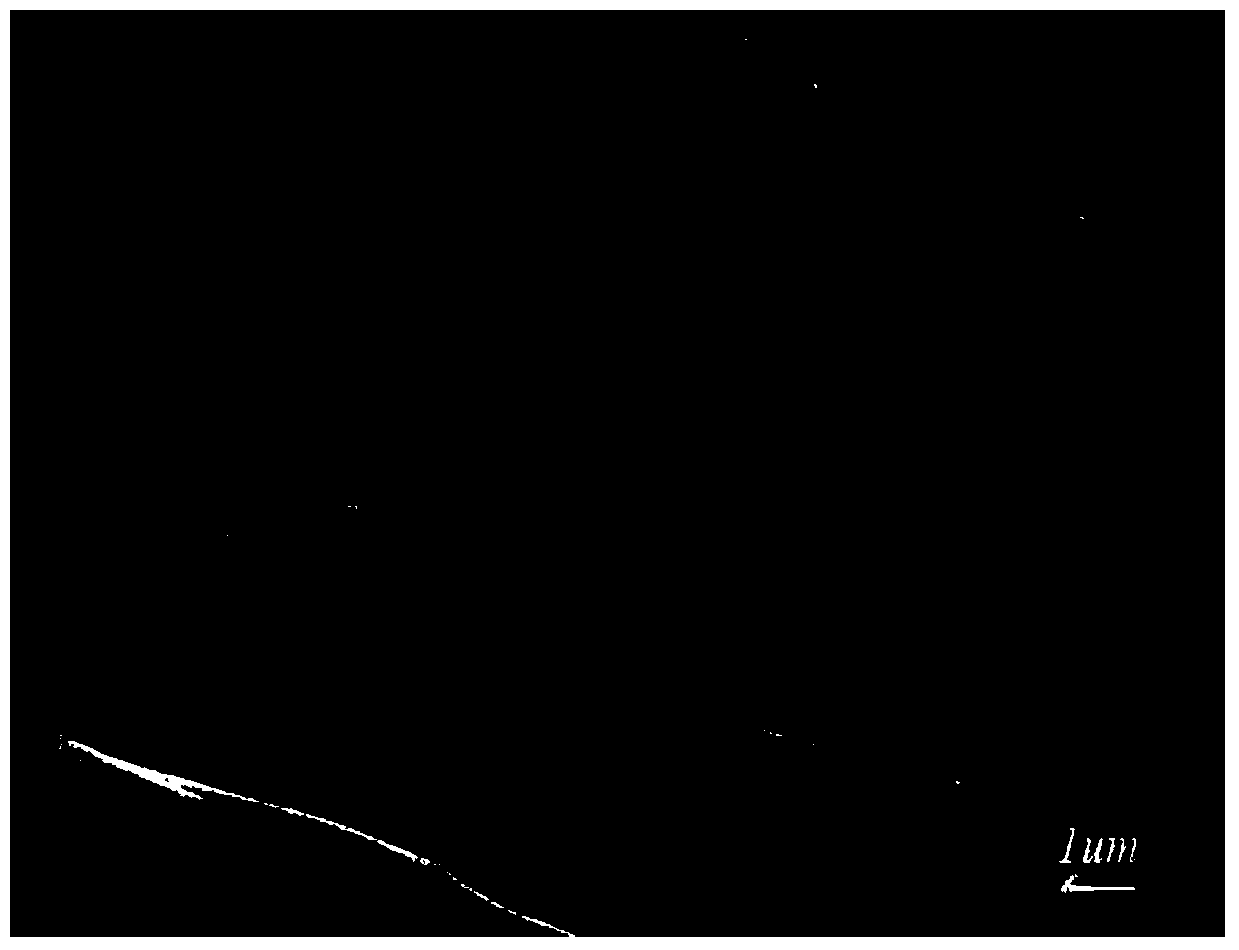

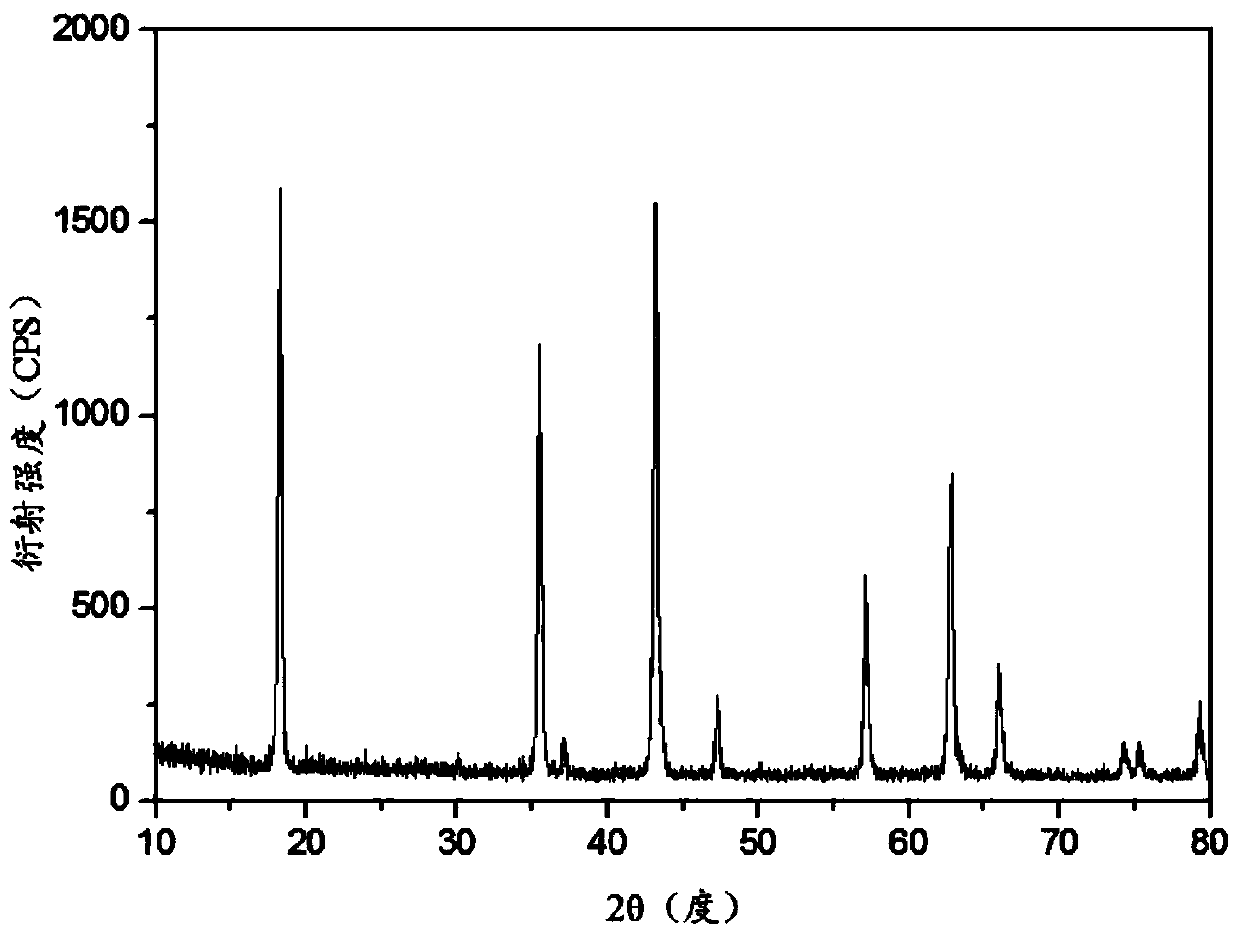

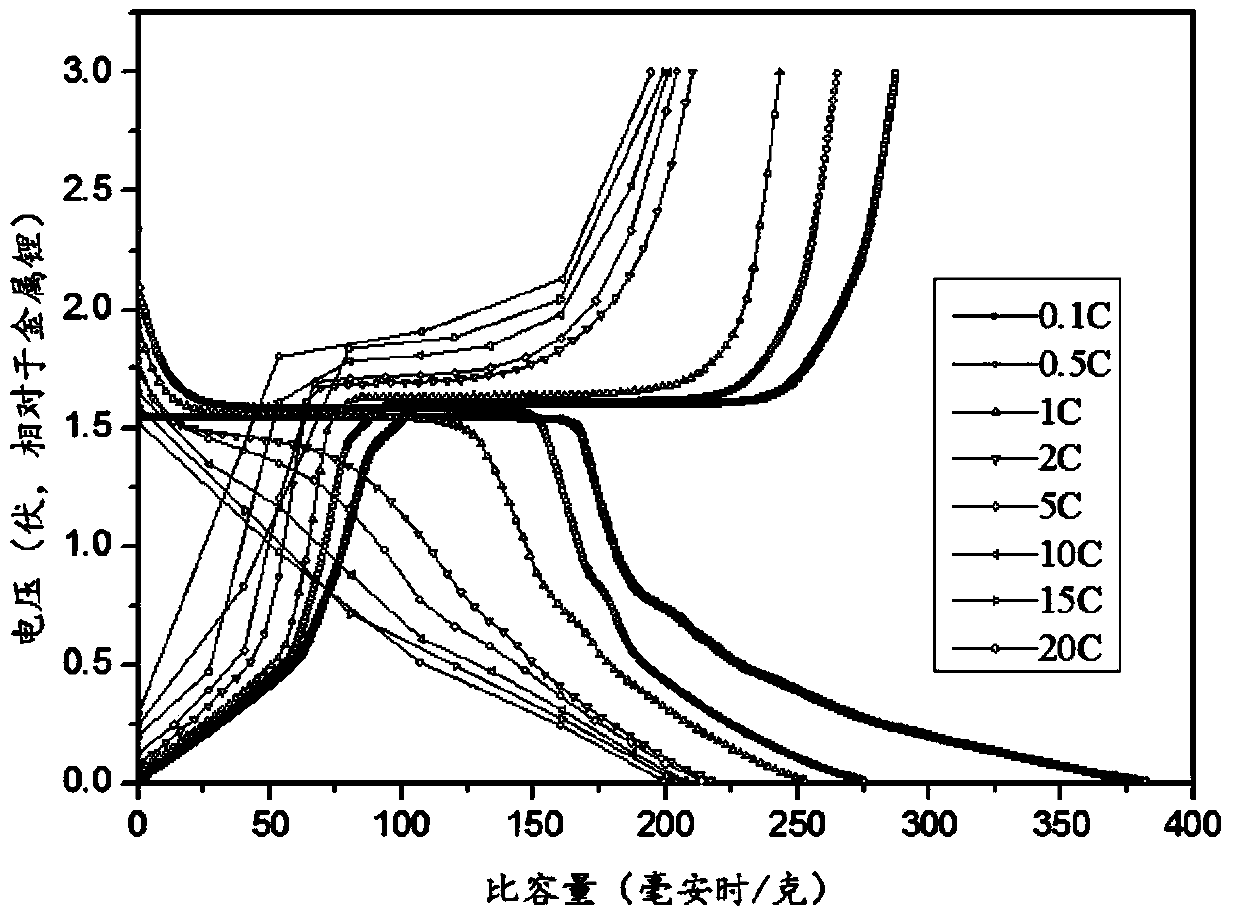

Preparation method of lithium titanate-nickel oxide nanofiber composite material for lithium battery

A technology of nanofibers and composite materials, applied in nanotechnology, battery electrodes, nanotechnology, etc. for materials and surface science, it can solve the problems of poor cycle performance and large particle agglomeration, and achieve fine particle size and high specific capacity. , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of lithium titanate-nickel oxide nanofiber composite material for lithium battery comprises the following steps:

[0027] (1) Select polyvinyl alcohol (PVA) as the polymer carrier, sodium dodecylbenzenesulfonate as the surfactant, and water as the solvent to prepare 15% PVA and 1% sodium dodecylbenzenesulfonate The solution is stirred by ultrasonic vibration to form a uniform, stable and clear carrier solution.

[0028] (2) The mass fraction of the lithium source in the solution is 17.76%, and the mass fraction of the nickel source in the solution is 1%. Add industrial grade lithium nitrate and nickel acetate to the water respectively, and stir at a constant temperature of 80° C. until the solute is dissolved.

[0029] (3) Add hydrogen peroxide accounting for 5% of the solution mass to the solution in step (2), stir evenly, add technical grade titanium propoxide according to the molar ratio of titanium and lithium at 4:5, and add ammonia to adjust...

Embodiment 2

[0034] (1) Select polyvinylpyrrolidone (PVP) as the polymer carrier, sodium dodecylbenzenesulfonate as the surfactant, and ethanol as the solvent to prepare 50% PVP and 1% sodium dodecylbenzenesulfonate The solution is stirred by ultrasonic vibration to form a uniform, stable and clear carrier solution.

[0035](2) According to the mass fraction of the lithium source in the solution being 20%, and the mass fraction of the nickel source in the solution being 9.89%, add chemically pure lithium hydroxide and nickel acetate to water respectively, and stir at a constant temperature of 30°C until the solute is in a dissolved state .

[0036] (3) Add hydrogen peroxide accounting for 1% of the solution mass fraction to the solution in step (2), stir evenly, add chemically pure tetrabutyl titanate according to the titanium and lithium molar ratio of 4:5, and add ammonia water to adjust the pH to 10.5 , heated at a constant temperature of 30°C and stirred vigorously until all dissolved...

Embodiment 3

[0041] (1) Select polyacrylonitrile (PAN) as the high molecular polymer carrier, Polyethylene Glycol is surfactant, N-N dimethylformamide is solvent, prepares the solution that contains 6%PAN, 0.6% Polyethylene Glycol, After ultrasonic vibration and stirring, a uniform, stable and clear carrier solution is formed.

[0042] (2) The mass fraction of the lithium source in the solution is 9%, and the mass fraction of the nickel source in the solution is 14.16%. Add analytically pure lithium acetate and nickel acetate in water respectively, and stir at a constant temperature of 80° C. until the solute is dissolved.

[0043] (3) Add hydrogen peroxide accounting for 3% of the solution mass fraction to the solution in step (2), stir evenly and add analytically pure titanium acetylacetonate at a molar ratio of titanium to lithium of 4:5, and add ammonia to adjust the pH to 8.5, and keep the temperature constant Heat at 50°C and stir vigorously until all dissolved to obtain a uniform an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com