Simple method for preparing polyimide film surface modified nano-hydroxyapatite coating

A technology of nano-hydroxyapatite and polyimide film, which is applied in the direction of coating, etc., can solve the problems of biocompatibility and limit wide application, and achieve the effect of fast reaction, mild reaction conditions and industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] (1) Take the polyimide film and cut it into 13x0.6cm strips, wash it with detergent, hydrochloric acid ethanol lotion, and water in sequence;

[0020] (2) soak the polyimide film after washing in 200mL0.05mol / L sodium hydroxide aqueous solution for 12 hours, then add 250mL0.2mol / L calcium hydroxide aqueous solution and let it stand for 6 hours, then add 50mL0.5mol / L diammonium hydrogen phosphate aqueous solution was left to react for 72 hours, keeping the pH of the reaction system = 8-14;

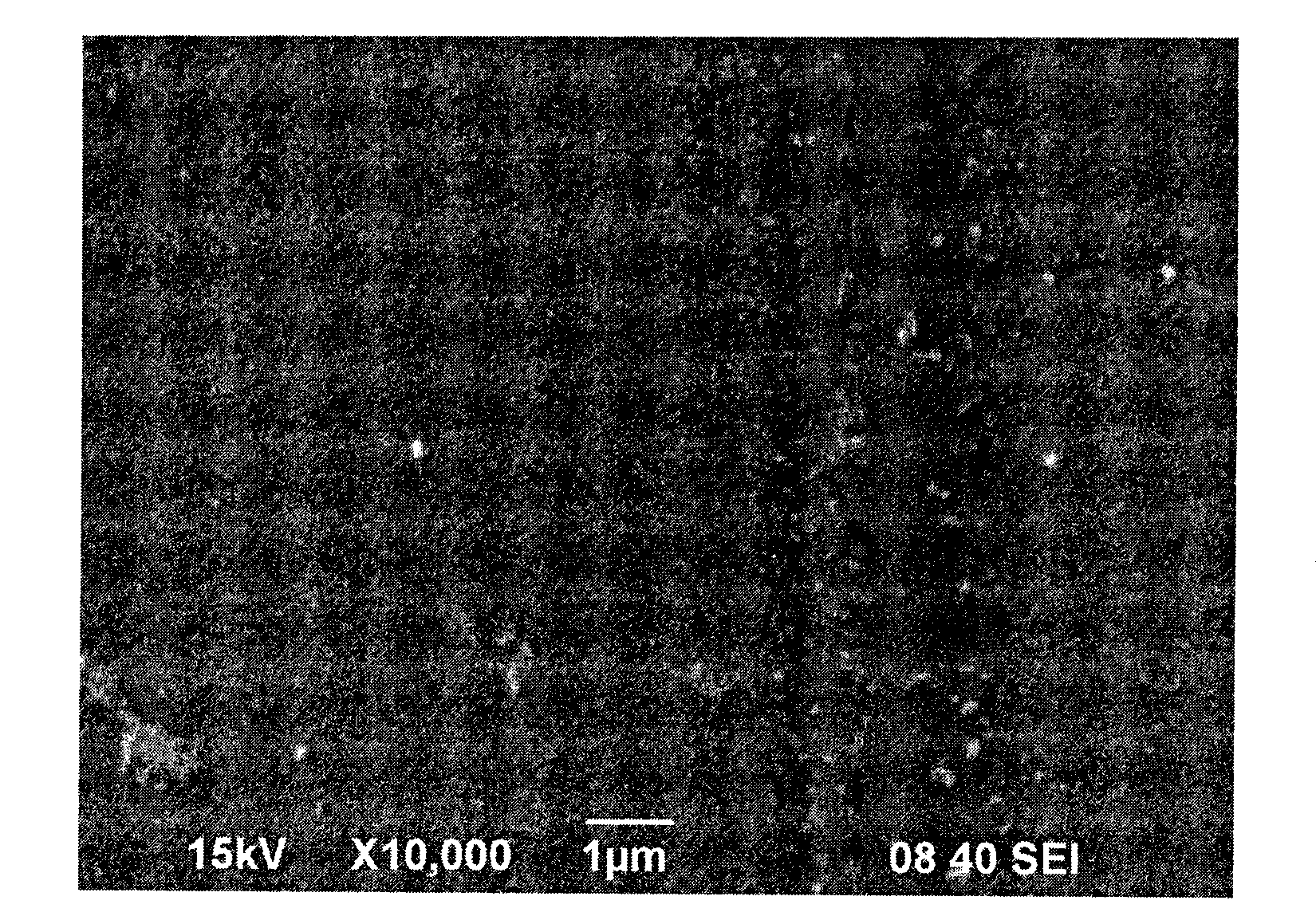

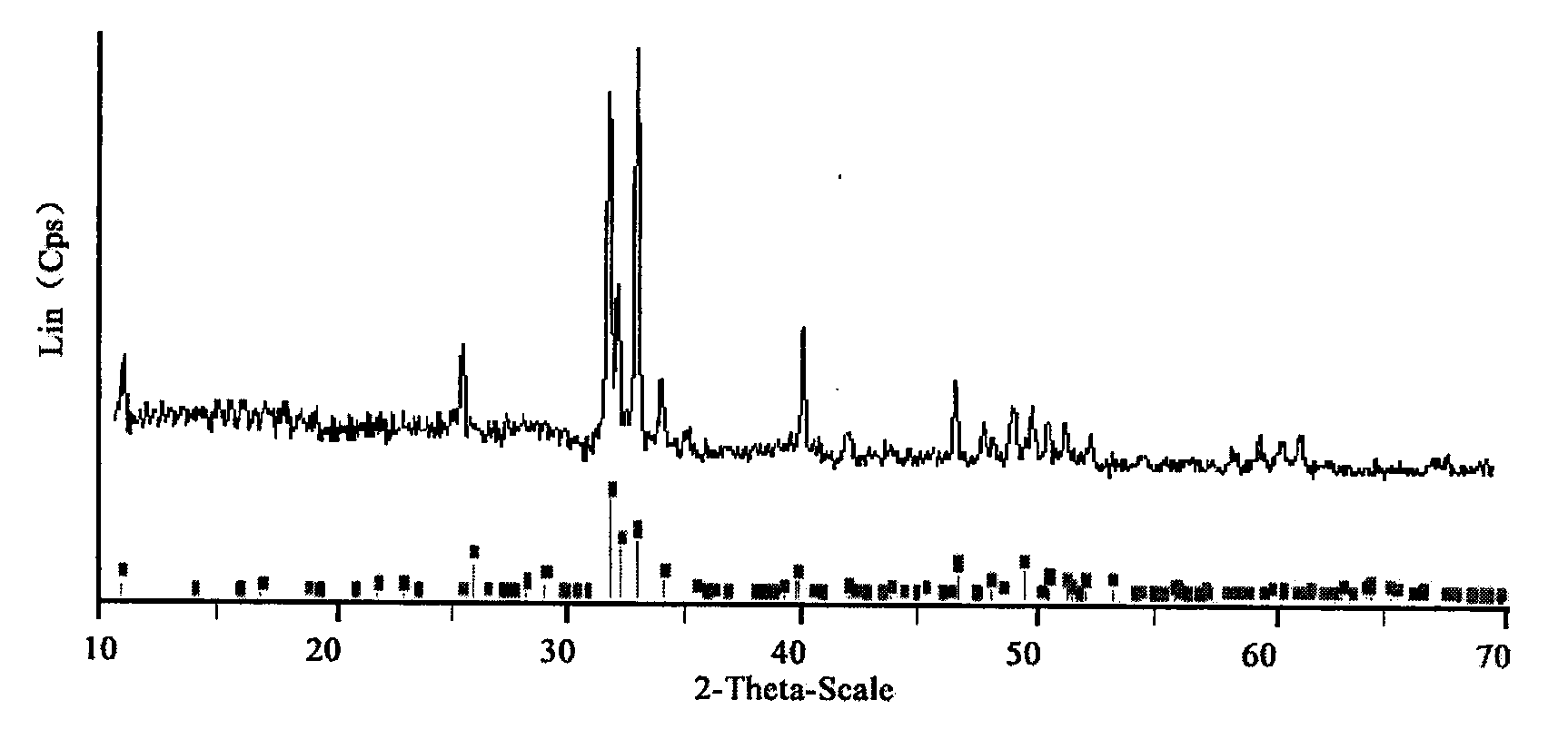

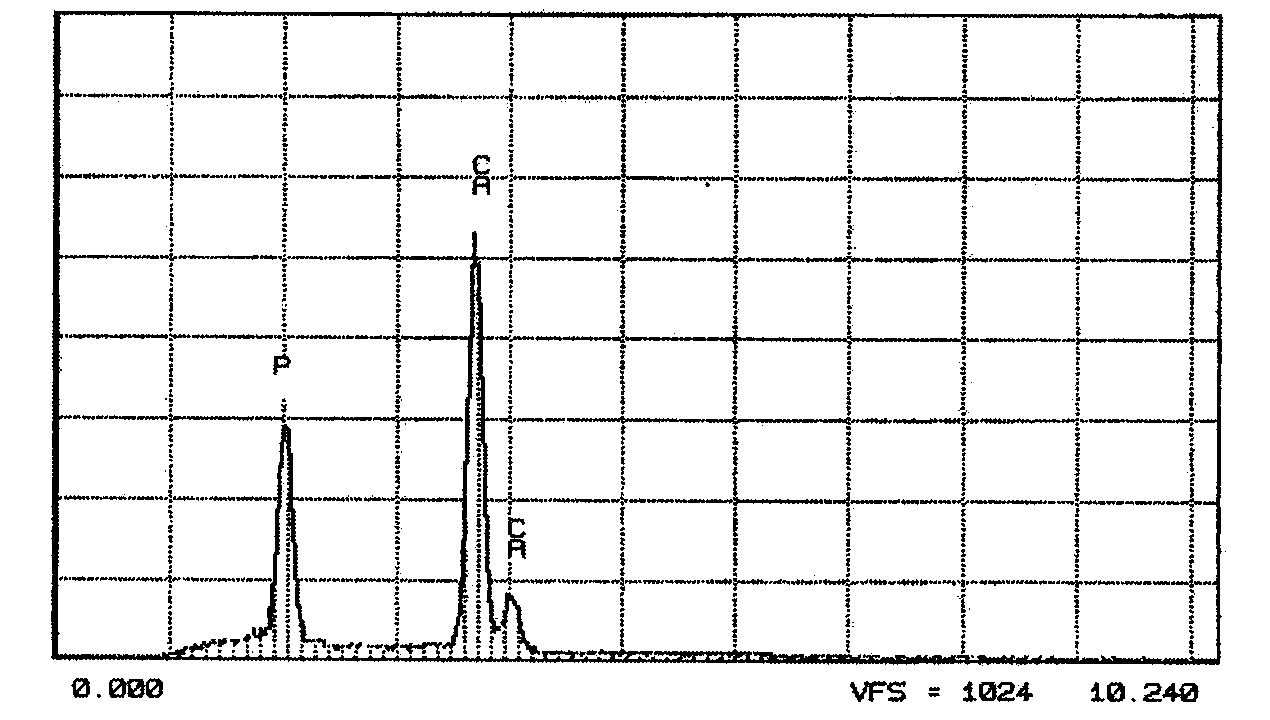

[0021] (3) Finally, the polyimide is taken out, rinsed and dried to obtain a polyimide film with a uniform surface and a surface-modified nano-hydroxyapatite coating. The scanning electron microscope photograph of the nano-hydroxyapatite coating modified on the surface of the obtained polyimide film is shown in figure 1 , X-ray diffraction pattern see figure 2 , and the EDS energy spectrum see image 3 .

Embodiment approach 2

[0023] (1) Take the polyimide film and cut it into 13x0.6cm strips, wash it with detergent, hydrochloric acid ethanol lotion, and water in sequence;

[0024] (2) soak and hydrolyze the polyimide film after washing in 200mL0.2mol / L aqueous potassium hydroxide solution for 5 hours, then add 250mL0.6mol / L calcium chloride aqueous solution and let it stand for 4 hours, then add 50mL1.8mol / L Potassium dihydrogen phosphate aqueous solution was left to react for 24 hours to keep the pH of the reaction system=8-14;

[0025] (3) Finally, the polyimide is taken out, rinsed and dried to obtain a polyimide film with a uniform surface and a surface-modified nano-hydroxyapatite coating. The scanning electron microscope photograph of the nano-hydroxyapatite coating modified on the surface of the obtained polyimide film is shown in figure 1 , X-ray diffraction pattern see figure 2 , and the EDS energy spectrum see image 3 .

Embodiment approach 3

[0027] (1) Take the polyimide film and cut it into 13x0.6cm strips, wash it with detergent, hydrochloric acid ethanol lotion, and water in sequence;

[0028] (2) Soak and hydrolyze the washed polyimide film in 200mL0.2mol / L aqueous potassium hydroxide solution for 6 hours, then add 250mL0.4mol / L calcium nitrate aqueous solution and let stand for 5 hours, then add 50mL1mol / L phosphoric acid The aqueous disodium hydrogen solution was left to react for 48 hours to keep the pH of the reaction system = 8-14;

[0029] (3) Finally, the polyimide is taken out, rinsed and dried to obtain a polyimide film with a uniform surface and a surface-modified nano-hydroxyapatite coating. The scanning electron microscope photograph of the nano-hydroxyapatite coating modified on the surface of the obtained polyimide film is shown in figure 1 , X-ray diffraction pattern see figure 2 , and the EDS energy spectrum see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com