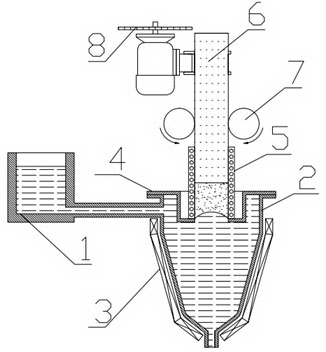

High-purity aluminum continuous purifying device

A high-purity, molten aluminum technology, applied in the field of metal aluminum purification, can solve the problems of high temperature control requirements, low specific gravity segregation, low purification efficiency, etc., and achieve the effect of improving purification efficiency, uniform purity, and reducing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

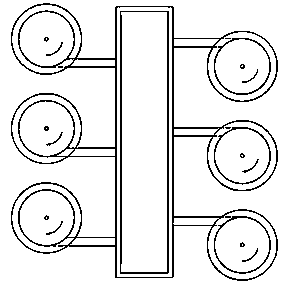

Embodiment 1

[0030] like image 3 Shown is a structure in which multiple groups of purification devices are used in combination. In this embodiment, the six purification devices share the same tundish to facilitate the centralized control of the raw material aluminum liquid. In this embodiment, 4N7 aluminum liquid raw material is used to produce high-purity aluminum rods with a diameter of 200 mm, the product purity reaches 5N3, and the hourly output is 50 kg.

Embodiment 2

[0032] like Figure 4 Shown is another structure used in combination of multiple sets of purification devices. The tail liquid produced by the first set of purification devices directly enters the second set of equipment below, so as to make reasonable use of the first set of devices to produce the tail liquid. The first set of devices in this embodiment uses 4N7 liquid aluminum raw materials to produce high-purity aluminum rods with a diameter of 200mm, the product purity reaches 5N3, and the output per hour is 8kg; the second set of purification devices produces high-purity aluminum rods with a diameter of 100mm. Aluminum rods with a product purity of 4N7 , the output per hour is 2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com