Integrated vertical cabinet type drying machine of coal firing stove with rear fan and hot blast stove

A hot blast stove, vertical cabinet technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

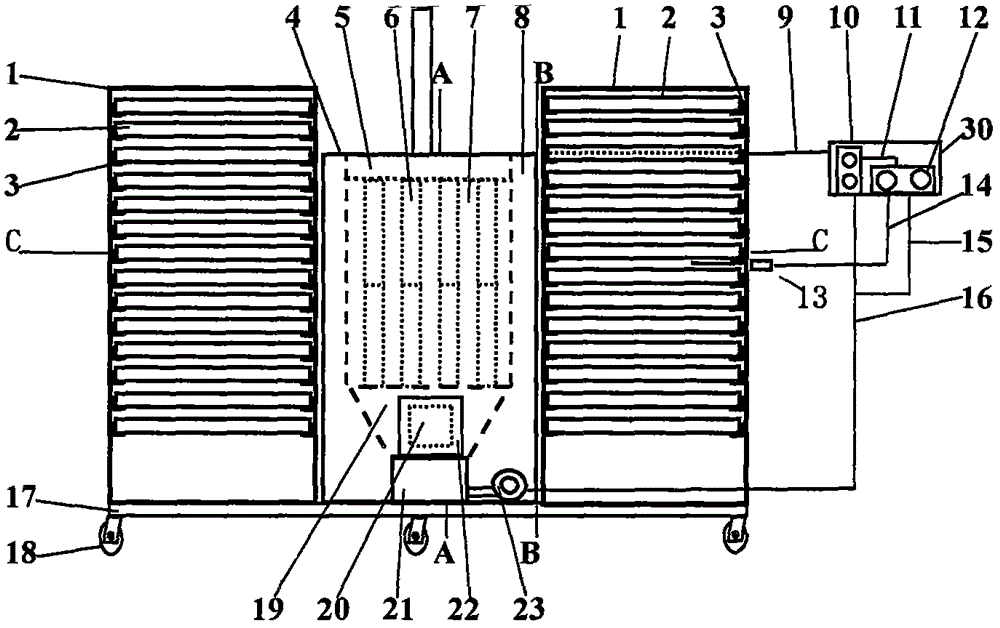

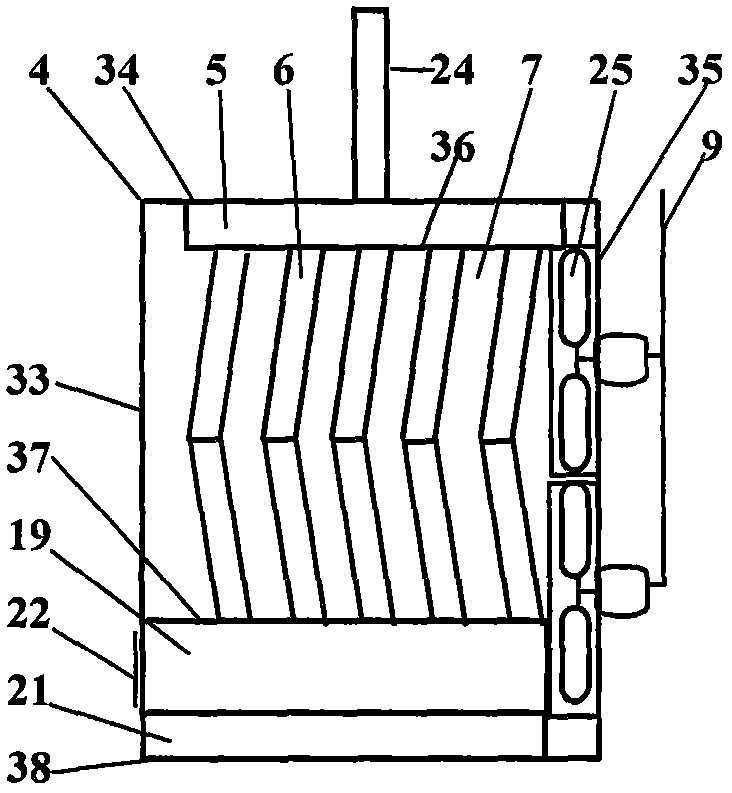

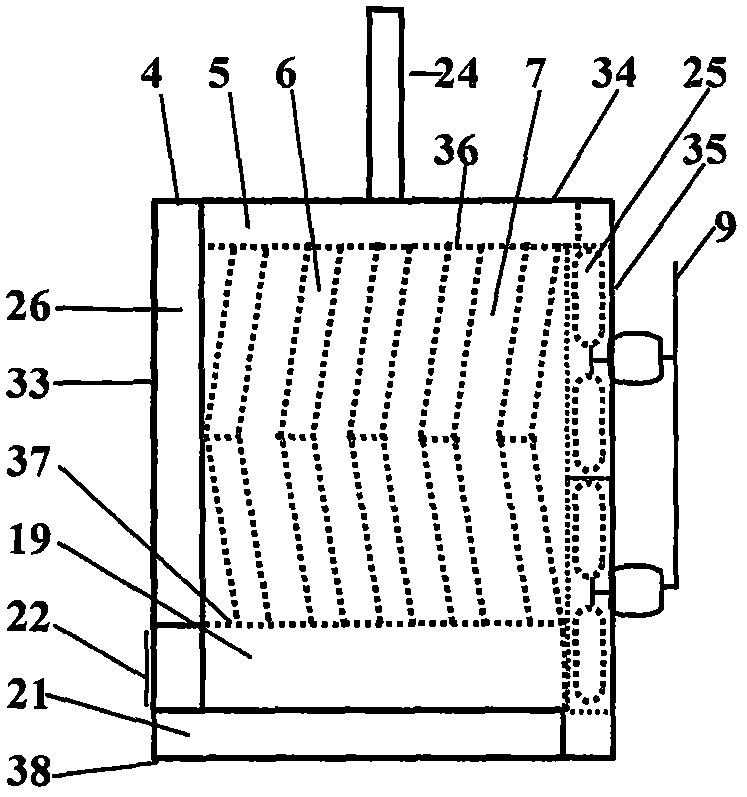

[0008] 1. A design of a vertical cabinet dryer with an integrated coal-burning stove and a hot blast stove on the fan, see the accompanying drawings in the manual.

[0009] 2. Purchase of raw materials

[0010] The raw materials are purchased according to the design drawings. The finished parts mainly include: blower, power switch, automatic temperature controller, instrument box, electric fan, screws, nails, etc. The main materials to be processed are: 0.2-0.3 cm thick steel plate, diameter 10 Centimeter steel pipe, angle iron, drying box wood strip, drying plate wood strip, density board, drying plate screen, etc.

[0011] 3. Processing and installation of sub-components and equipment

[0012] (1) Drying box production: the drying box is composed of the drying box body 1, the drying box door 31, the door hinge 32, the drying plate 2, the drying plate bracket 3, and the drying box body. Style, made of wooden strips and density boards, the inner side length and width are 90 cm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com