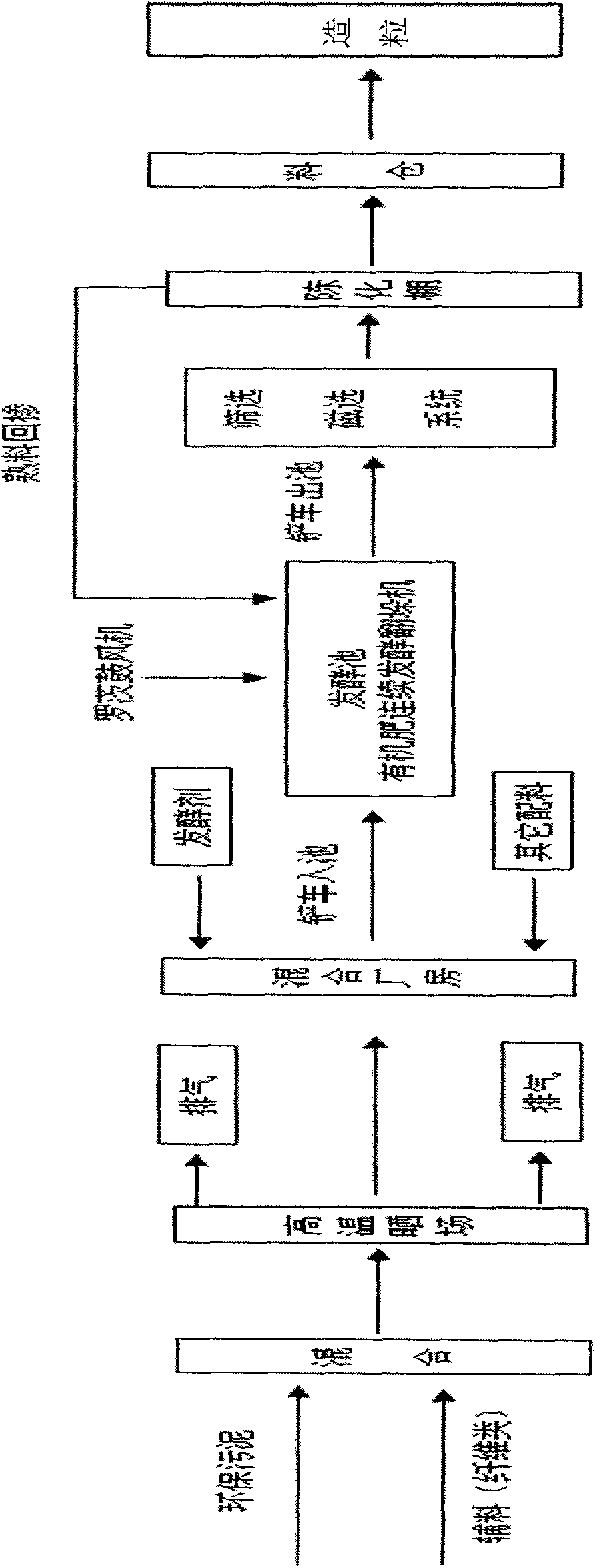

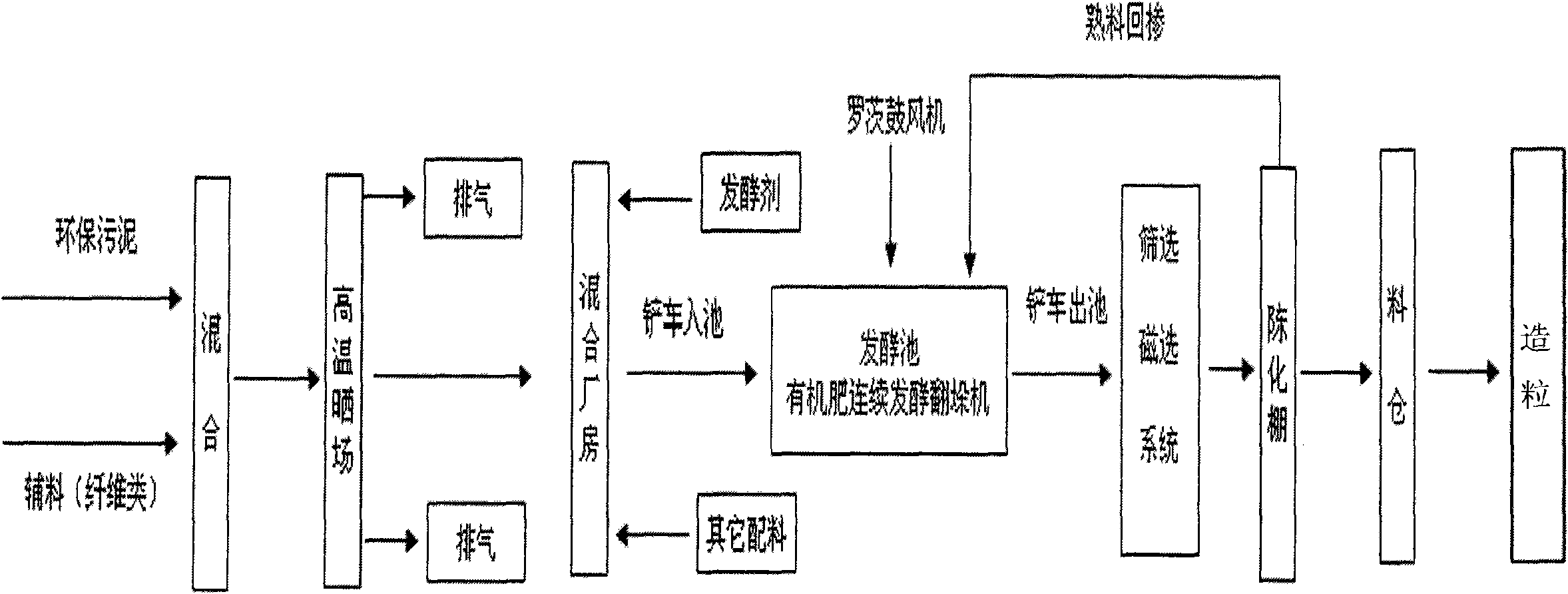

Method for preparation of granular organic fertilizer by industrial floc sludge

A granular organic fertilizer and flocculent sludge technology, which is applied in the preparation of organic fertilizers, organic fertilizers, sewage/sludge fertilizers, etc., can solve the problems of large equipment investment, high energy consumption, unfavorable granulation technology progress and popularization and application, etc. problem, to achieve the effect of low operating cost, high degree of automation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] About 10t of flocculent sludge with a moisture content of 88% produced during the biochemical treatment of citric acid industrial organic wastewater is uniformly mixed with 1.3t of peanut bran, the main auxiliary material, and then sent to the solar panel solar greenhouse, which is set on the top and side of the greenhouse There is a strong heat-absorbing sun board, high temperature drying, stirring twice during the drying, the sludge moisture 57.2% after drying, adding 1.8‰ Aspergillus niger in the mixing zone, mixing and placing it in a shallow fermentation tank, the fermentation cycle is 7 days , The sludge thickness is 65cm, and the bottom is ventilated by Roots blower. When the temperature rises above 60 degrees, the stacker is used to turn the stack, and the temperature drops to about 50 degrees after the stack is turned. After the fermentation, the water content of the clinker is 33.62%. After screening, magnetic separation and aging, the bentonite and high-concent...

Embodiment 2

[0025] After mixing about 20t of flocculent sludge with 87.2% moisture content and 2.6t of corn stalks as an auxiliary material during the biochemical treatment of citric acid industrial organic wastewater, the forklift is put into the shed for high-temperature drying, stirring 3 times during the period, and the sludge after drying. With a moisture content of 56.6%, add 2‰ strains in the mixing zone, remix 0.5t of fermented clinker in Example 1, and mix again, and the moisture content is 53.9%. The mixed raw materials are mixed into the shallow fermentation tank with a forklift. The fermentation cycle is 8 days and the stack height is 70cm. When the temperature rises above 60 degrees, the stacker is used to turn the stack. After the stack is turned, the temperature drops to 50-55 degrees. After the fermentation, the water content of the clinker is 34.5%. After sieving, magnetic separation and aging, the bentonite and high-concentration humus with a total weight of 5.0‰ of the cl...

Embodiment 3

[0027] After mixing about 10t of flocculent sludge with 85.4% moisture content and 1.2t of auxiliary material wheat bran produced during the biochemical treatment of citric acid industrial organic wastewater, the forklift is put into the shed, and the drying is carried out at high temperature. The sludge is stirred twice during the drying process. The water content is 57.1%, 2.2‰ strains are added to the mixing zone, 0.5t of fermented clinker in Example 2 is remixed, and the water content is 54.9%. The mixed raw materials are mixed into the shallow fermentation tank with a forklift. The fermentation cycle is 8 days and the stack height is 65cm. When the temperature rises above 60 degrees, the stacker is used to turn the stack. After the stack is turned, the temperature drops to 50-55 degrees. After the fermentation, the moisture content of the clinker is 32.8%. After screening, magnetic separation and aging, the bentonite and high-concentration humus of 5.5‰ of the total weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com