Method for producing large grain size cryolite

A production method and cryolite technology are applied in the production field of large-diameter cryolite, which can solve the problems of complex process and achieve the effects of simple process, less flying loss and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

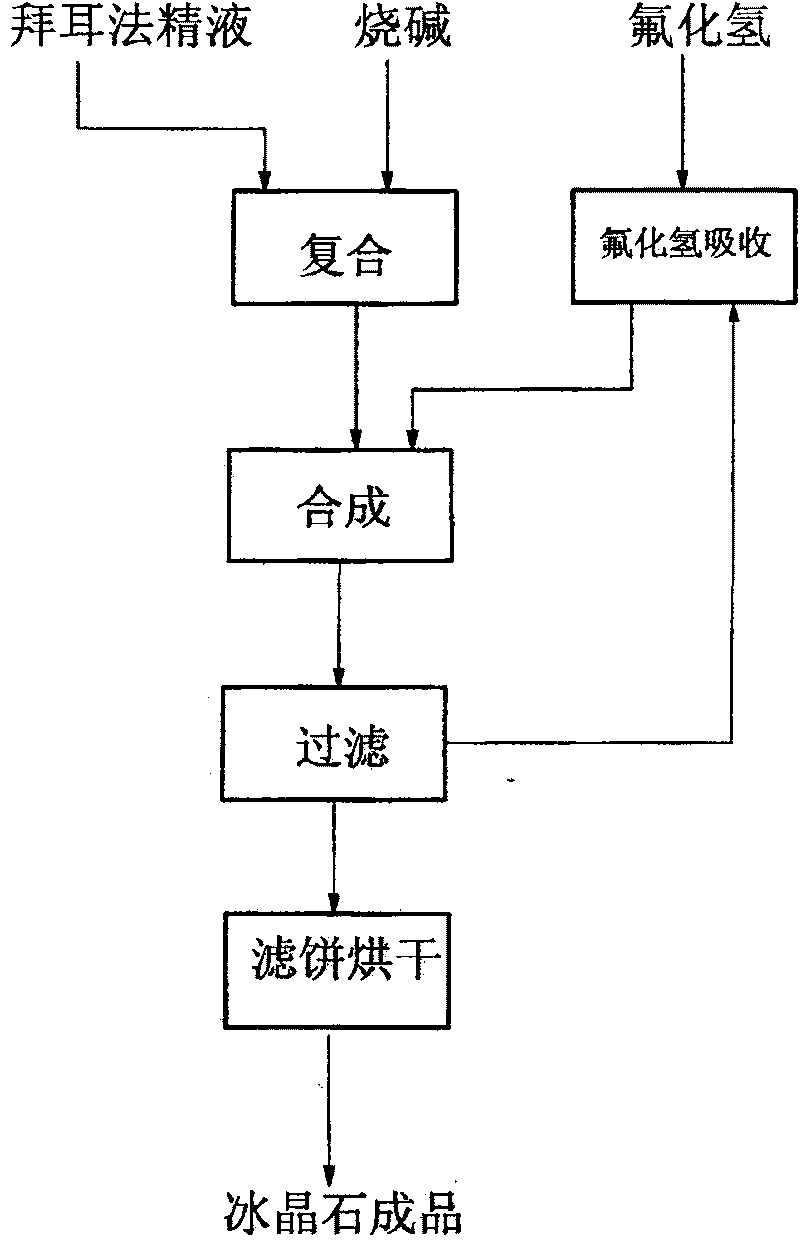

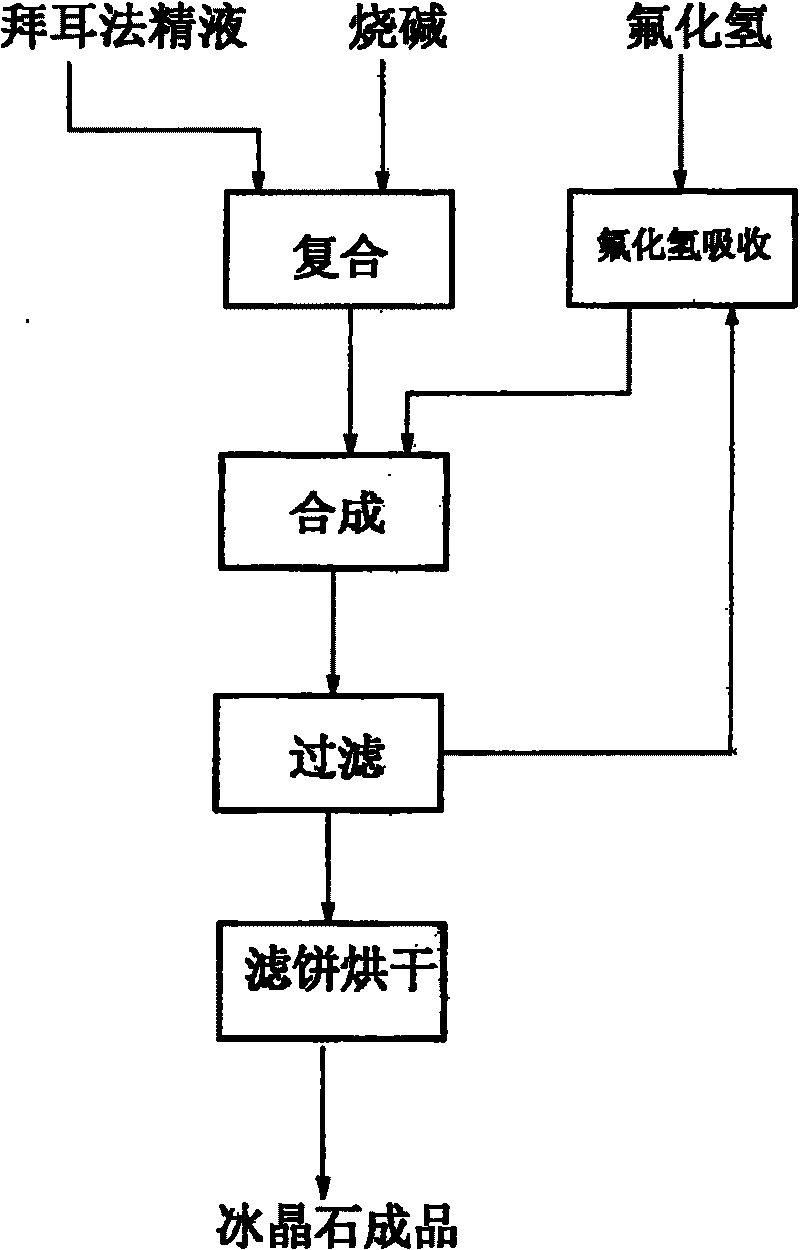

[0029] Embodiment one: the production method of large particle diameter cryolite, see appendix figure 1 , including the following steps,

[0030] (1) Raw materials and dosage: with Bayer method semen, caustic soda and hydrofluoric acid as raw materials, the molar ratio of raw materials is Al:Na:F=1:3:6; 3+ :Na + :F - =1:3:6;

[0031] Requirements: Bayer semen caustic ratio α k =1.5~2.0, including Al 2 o 3 140~150g / L, SiO 2 2 o 3 2 SiF 6 The mass percentage of <0.3%.

[0032] (2) Composite liquid preparation: when synthesizing, add caustic soda to the Bayer method seminal fluid that temperature is 90 ℃, stir, mix to obtain compound liquid;

[0033] (3) Synthesis of cryolite: gradually add the composite solution and hydrofluoric acid into the synthesis tank in proportion under stirring, and control the feeding speed during the feeding process so that the reaction temperature is between 90-95 °C and the pH of the reaction solution is ≤ 2; the feeding is completed Then ...

Embodiment 2

[0035] Embodiment two: the production method of large particle diameter cryolite, no longer repeat with the same part of embodiment one, difference is,

[0036] (1) Raw materials and dosage: take Bayer method semen, caustic soda and hydrofluoric acid as raw materials, and the molar ratio of raw materials is Al:Na:F=1:3:5;

[0037] (2) Composite liquid preparation: when synthesizing, add caustic soda to the Bayer method seminal fluid that temperature is 95 ℃, stir, mix to obtain compound liquid;

[0038] (3) Cryolite synthesis: add part of the circulating filtrate to the synthesis tank, and the amount of addition reaches the height of the stirring shaft with the amount of filtrate. Under continuous stirring, the compound liquid and hydrofluoric acid are gradually added to the synthesis tank in proportion from the metering tank at the same time , control the feed rate, so that the reaction temperature is between 85 and 90°C; the pH of the reaction end point is ≤3, and the aging ...

Embodiment 3

[0040] Embodiment three: the production method of large particle diameter cryolite, no longer repeat with the same part of embodiment one, difference is,

[0041] (1) Raw materials and dosage: take Bayer process semen, caustic soda and hydrofluoric acid as raw materials, and the molar ratio of raw materials is Al:Na:F=1:2:6;

[0042] (2) Composite liquid preparation: when synthesizing, add caustic soda to the Bayer method seminal fluid that temperature is 90 ℃, stir, mix to obtain compound liquid;

[0043] (3) Synthesis of cryolite: gradually add the composite solution and hydrofluoric acid to the synthesis tank in proportion under stirring, the reaction temperature is 88-90°C; aging for 25 minutes;

[0044] (4) press-filter the aged cryolite slurry to obtain filter cake and filtrate, and the moisture content of the filter cake is 16%; then the filter cake is directly heated and dried in a rotary kiln at 160°C until the moisture content is 0.19% ( mass ratio), that is, cryoli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com