Method for producing ultra-fine cryolite

A production method and technology of cryolite, which is applied in the field of ultrafine cryolite production, can solve problems such as limiting the application of cryolite, and achieve the effects of saving drying costs, easy operation and control, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

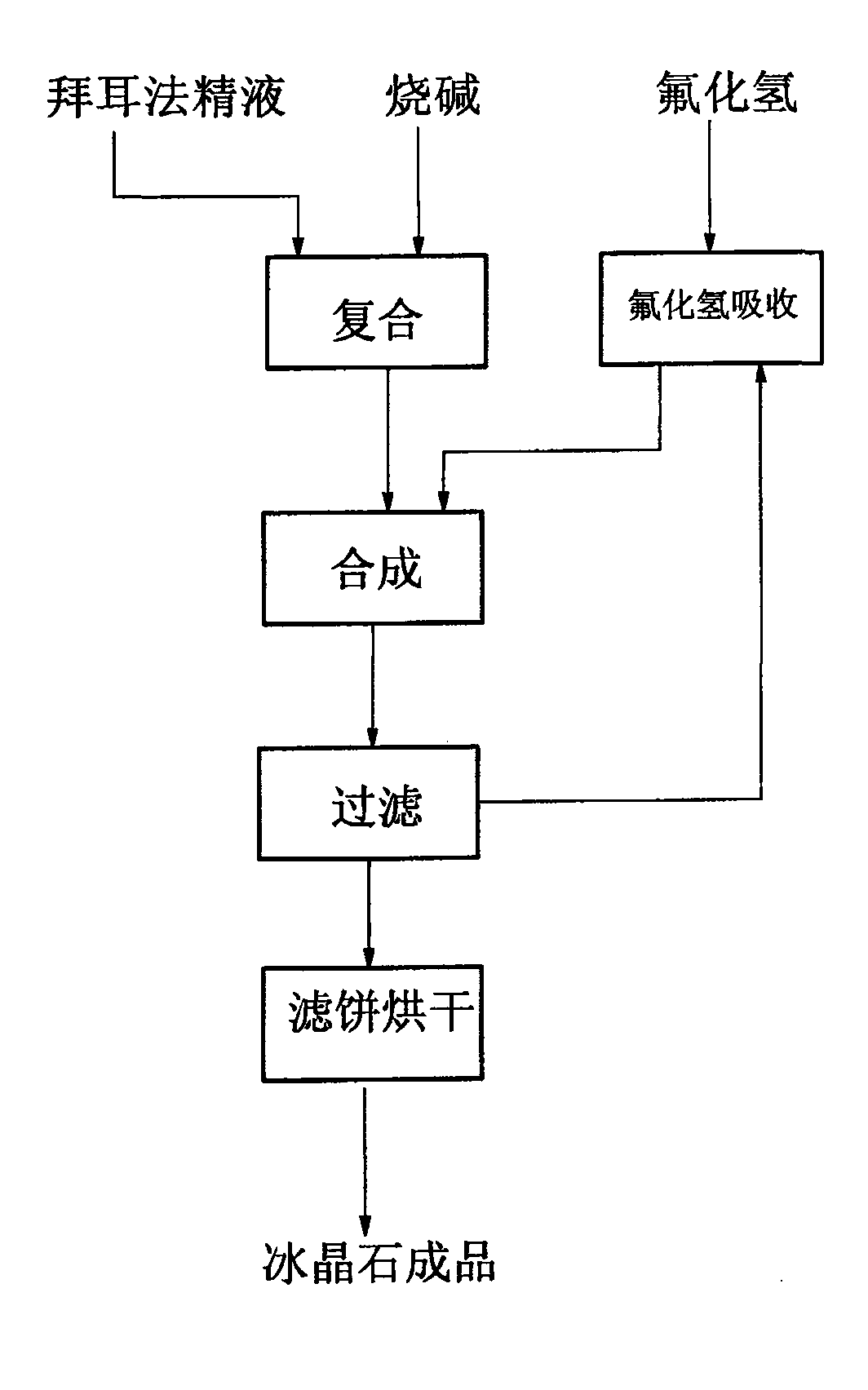

[0028] Embodiment one: the production method of ultrafine cryolite, see appendix figure 1 , including the following steps,

[0029] (1) Raw materials and dosage: use Bayer method semen, caustic soda and hydrofluoric acid as raw materials, and the molar ratio of raw materials is Al:Na:F=1:3:6, that is, Al 3+ :Na + :F - =1:3:6;

[0030] Requirements: caustic ratio α of Bayer semen k =1.5~2.0, including Al 2 o 3 140~150g / L, SiO 2 2 o 3 2 SiF 6 The mass percentage of <0.3%.

[0031] (2) Add caustic soda to the Bayer method semen during synthesis, stir while adding to dissolve the caustic soda, and obtain a composite solution after mixing;

[0032] (3) 40% composite solution is added to the synthesis tank earlier, then hydrofluoric acid and the remaining composite solution are gradually added to the synthesis tank under stirring, and the rotating speed is 100 rpm during the stirring, by controlling the feed rate in the feeding process, so that The reaction temperature i...

Embodiment 2

[0035] Embodiment two: the production method of ultrafine cryolite, no longer repeat with the same part of embodiment one, difference is,

[0036] (1) Raw materials and dosage: take Bayer method semen, caustic soda and hydrofluoric acid as raw materials, and the molar ratio of raw materials is Al:Na:F=1:3:5;

[0037] (2) 20% of the composite solution is added to the synthesis tank earlier, stirred, then hydrofluoric acid and the remaining composite solution are gradually added to the synthesis tank under stirring, and the rotating speed is 150 rpm during the stirring, and the feed rate is controlled during the feeding process. , keep the reaction temperature between 50-60°C, and the pH of the reaction solution ≥ 10; stop the reaction after the feeding is completed, control the pH at the end point to 12, and then age the slurry for 20 minutes;

[0038] (3) Filter the aged slurry with a belt filter to obtain a filter cake and filtrate, and dry the filter cake at 300° C. by airfl...

Embodiment 3

[0039] Embodiment three: the production method of ultrafine cryolite, no longer repeat with the same part of embodiment one, difference is,

[0040] (1) Raw materials and dosage: take Bayer process semen, caustic soda and hydrofluoric acid as raw materials, and the molar ratio of raw materials is Al:Na:F=1:2:6;

[0041] (2) 70% of the composite solution is added to the synthesis tank first, stirred, and then hydrofluoric acid and the remaining composite solution are gradually added to the synthesis tank under stirring. During the feeding process, the feeding speed is controlled, and the stirring speed is 120 rpm. , keeping the reaction temperature between 40 and 50°C, and the pH of the reaction solution ≥ 10; stop the reaction after the feeding is completed, and then age the slurry for 30 minutes;

[0042] (3) Filter the aged slurry with a belt filter to obtain a filter cake and filtrate, and dry the filter cake at 200° C. by airflow flashing until the water content is below 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com