A kind of granular cryolite and preparation method for regulating its molecular ratio

A cryolite and granular technology, which is applied in the field of granular cryolite and its preparation, can solve the problems of fragile granular ice and high cost, and achieve the effects of stable quality, simple control, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

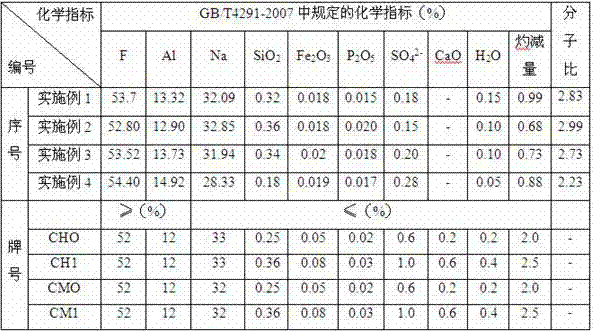

Examples

reference example 1

[0034] The preparation method of the seed crystal solution obtained by preliminary ammonolysis of sodium fluorosilicate: mix 600kg sodium fluorosilicate with 14m 3 Cryolite mother liquor (concentration of main components: F: 8.4g / L, Na: 4.1g / L, NH 4 + : 22.4g / L, specific gravity 1.05), stir the ingredients in the reaction tank, add ammonia water until the pH value is 7, age for 40min, and serve.

[0035] The preparation method of sodium aluminate solution: prepare 4.4m 3 Sodium hydroxide solution with a mass concentration of 33.2wt% was heated to 110°C by steam, 3000kg of aluminum hydroxide was added, and the reaction was stirred until the solution was clear to obtain a sodium aluminate solution (among them, the concentration of Al was 198.72 g / L, and the concentration of Na is 218.96 g / L, caustic ratio is 1.29).

reference example 2

[0037] The preparation method of sodium aluminate solution: prepare 4.4m 3 Sodium hydroxide solution with a mass concentration of 33.1wt% was heated to 115°C by steam, 3000kg of aluminum hydroxide was added, and the reaction was stirred until the solution was clear to obtain a sodium aluminate solution (among them, the concentration of Al was 197.37 g / L, and the concentration of Na is 212.98 g / L, and the caustic ratio is 1.2).

reference example 3

[0039] The preparation method of sodium aluminate solution: prepare 4.4m 3 A sodium hydroxide solution with a mass of 32.4wt% was heated to 120°C by steam, 3000kg of aluminum hydroxide was added, and the reaction was stirred until the solution was clear to obtain a sodium aluminate solution (wherein, the concentration of Al was 185.44g / L, and the concentration of Na was 196.88 g / L, caustic ratio is 1.25).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com