Patents

Literature

74results about How to "Improve drying process efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

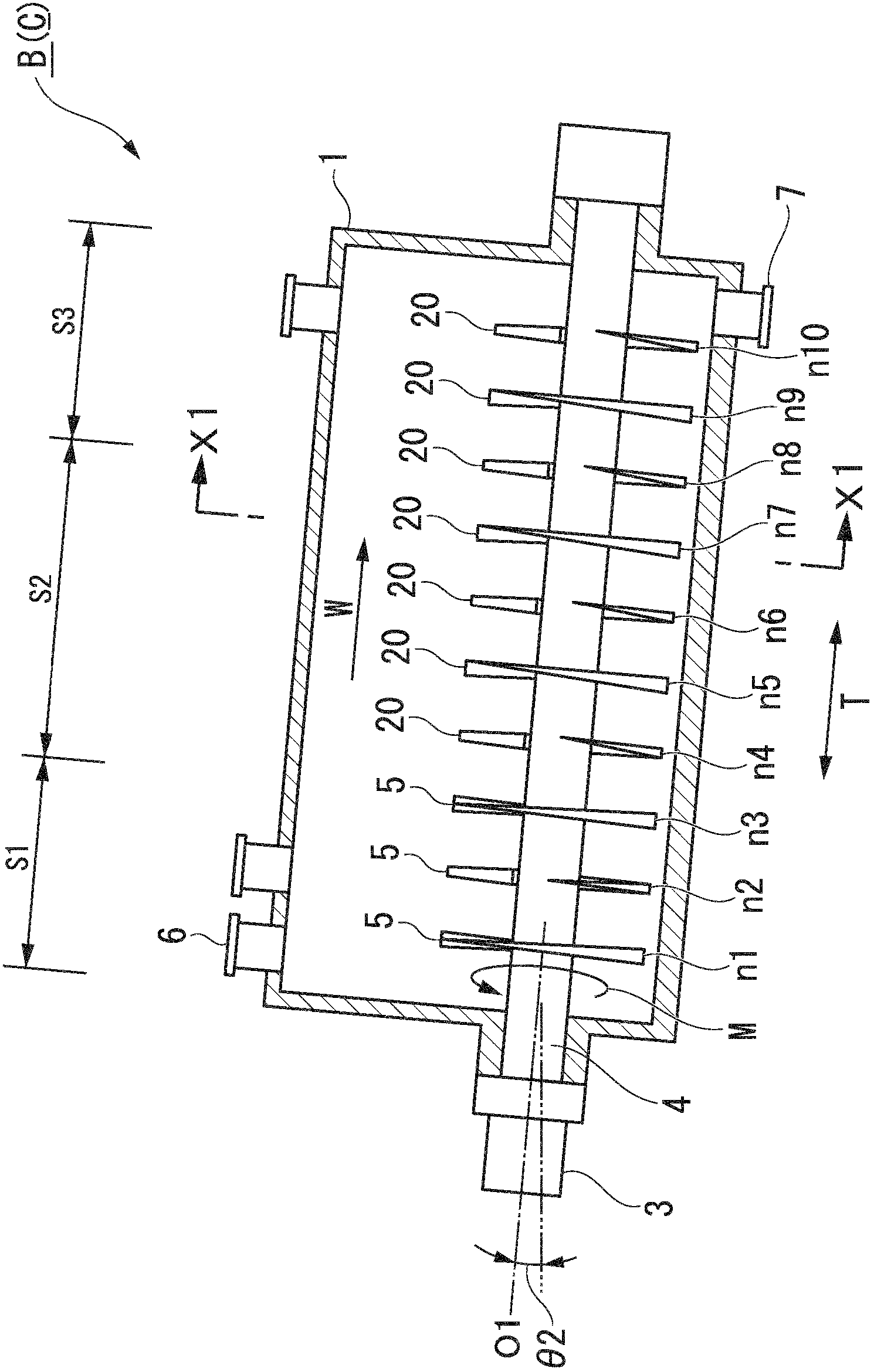

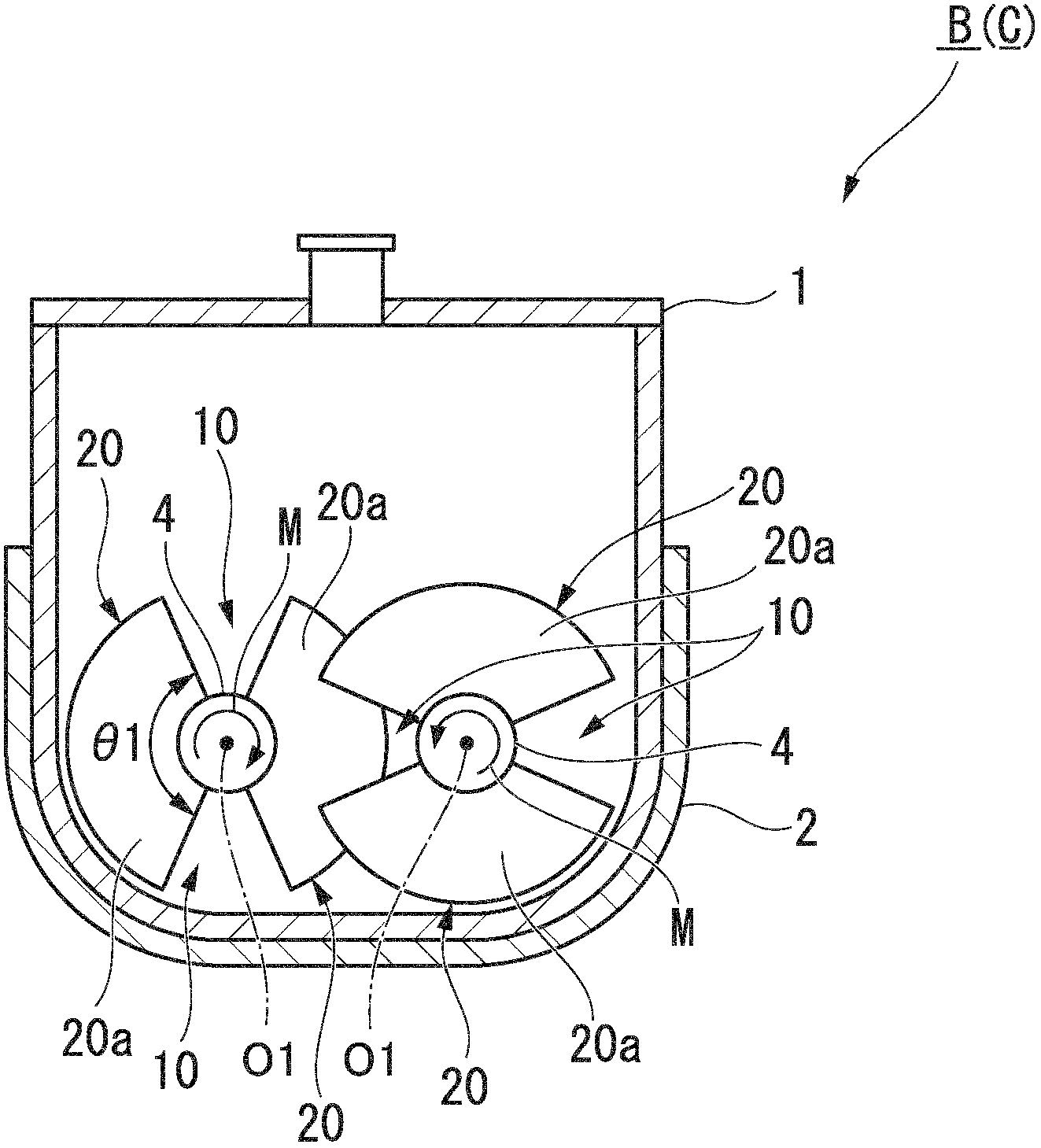

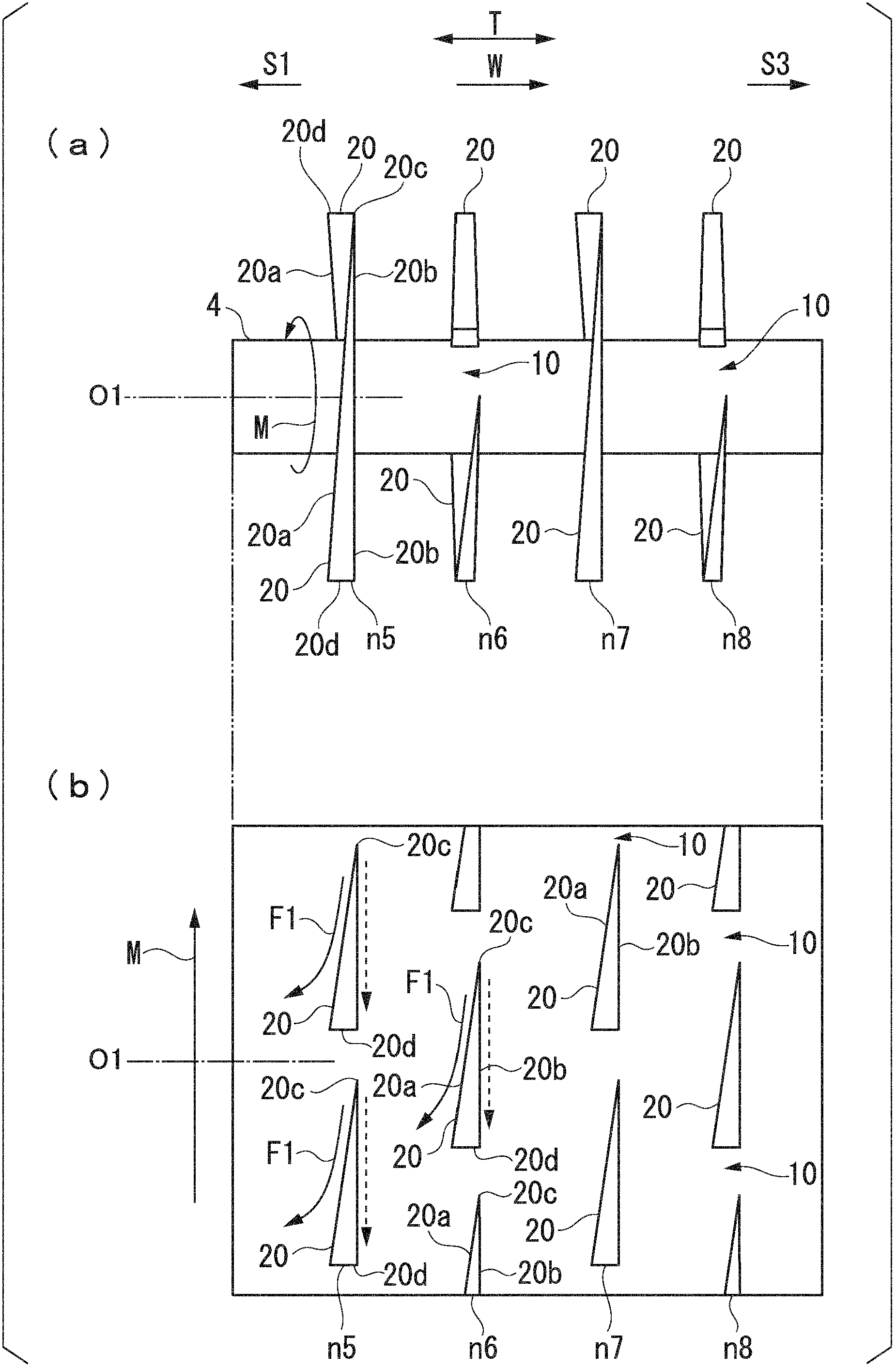

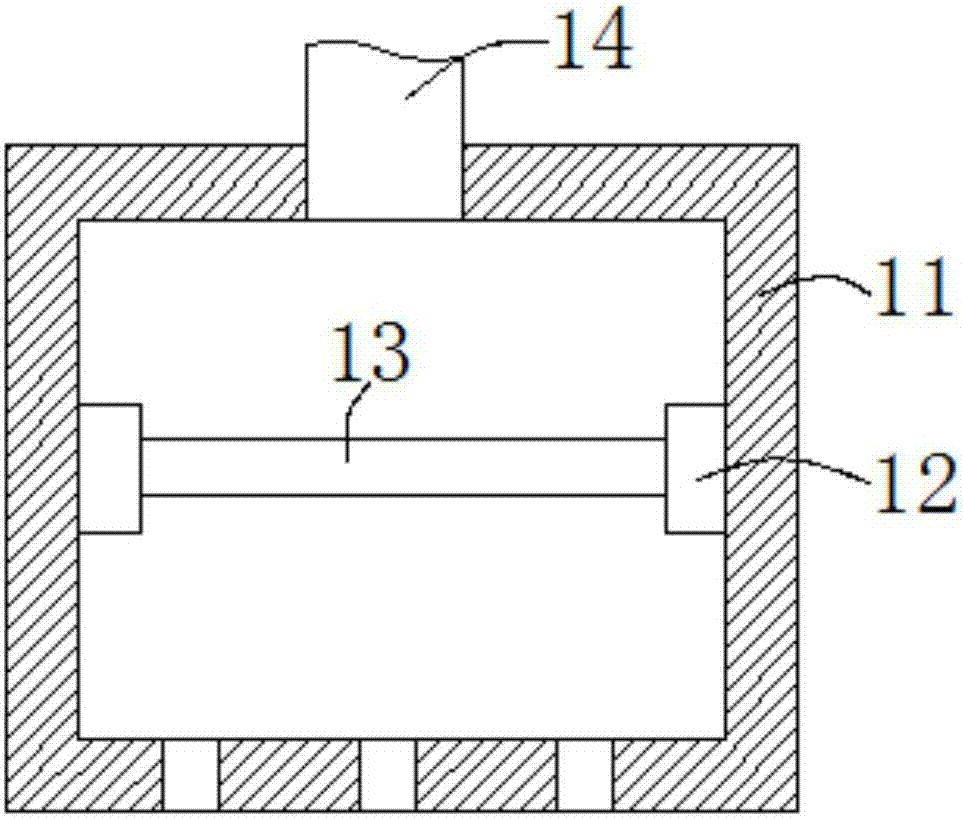

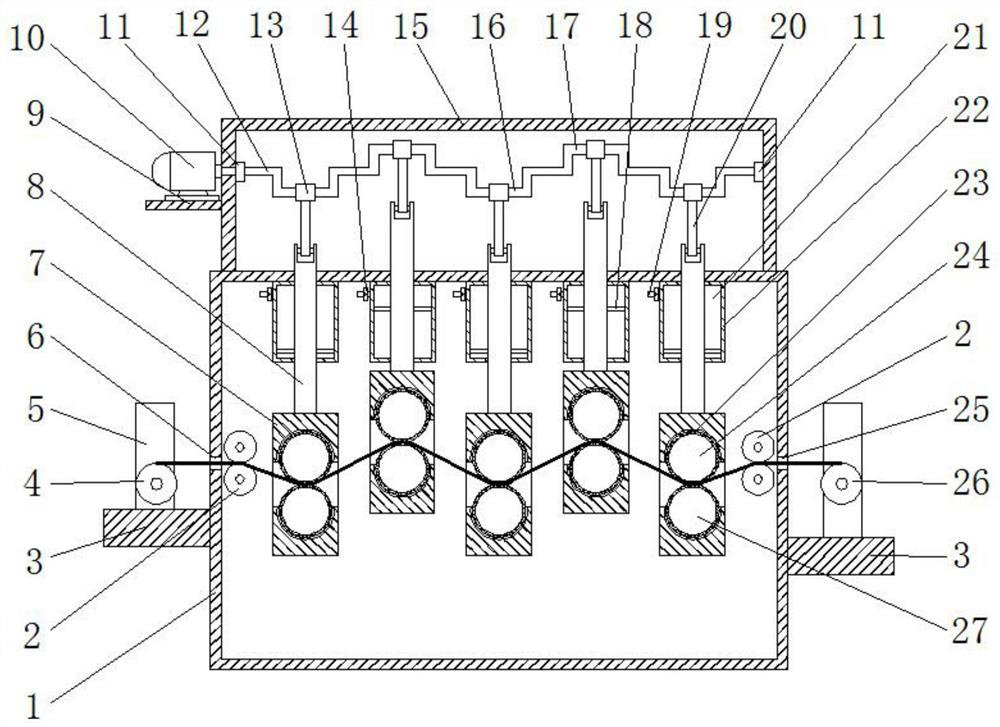

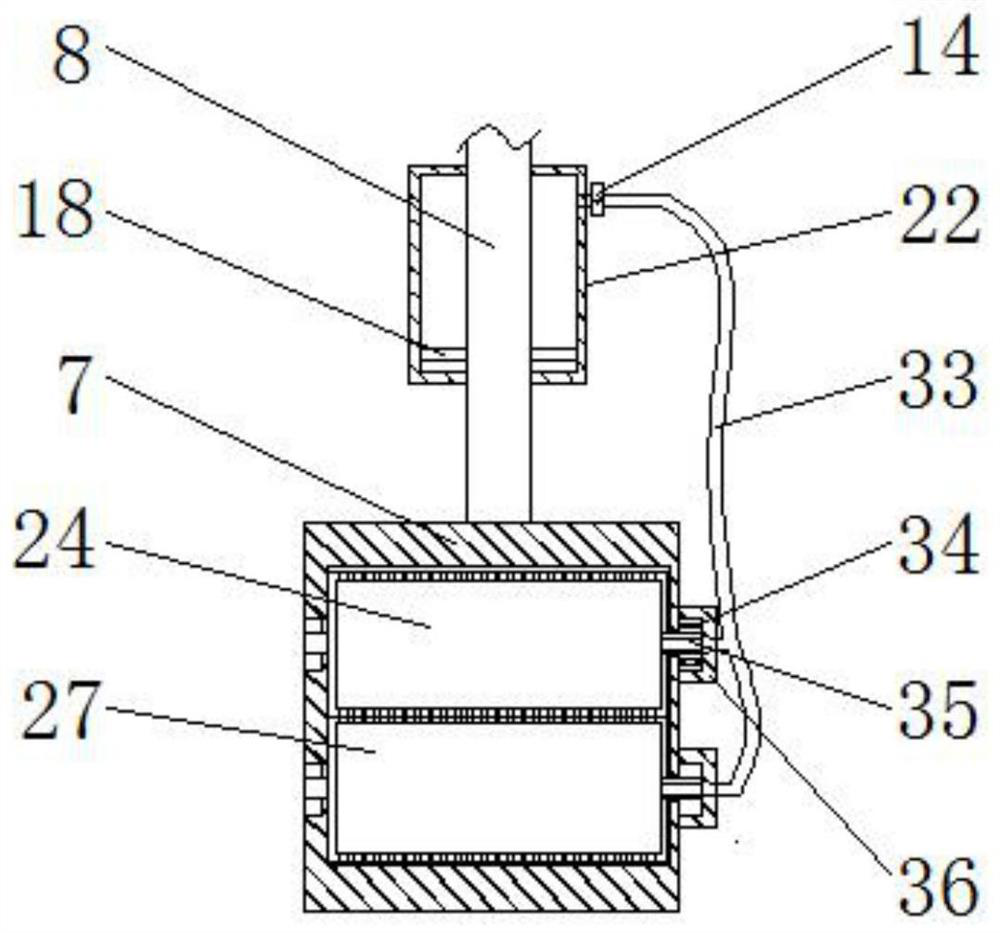

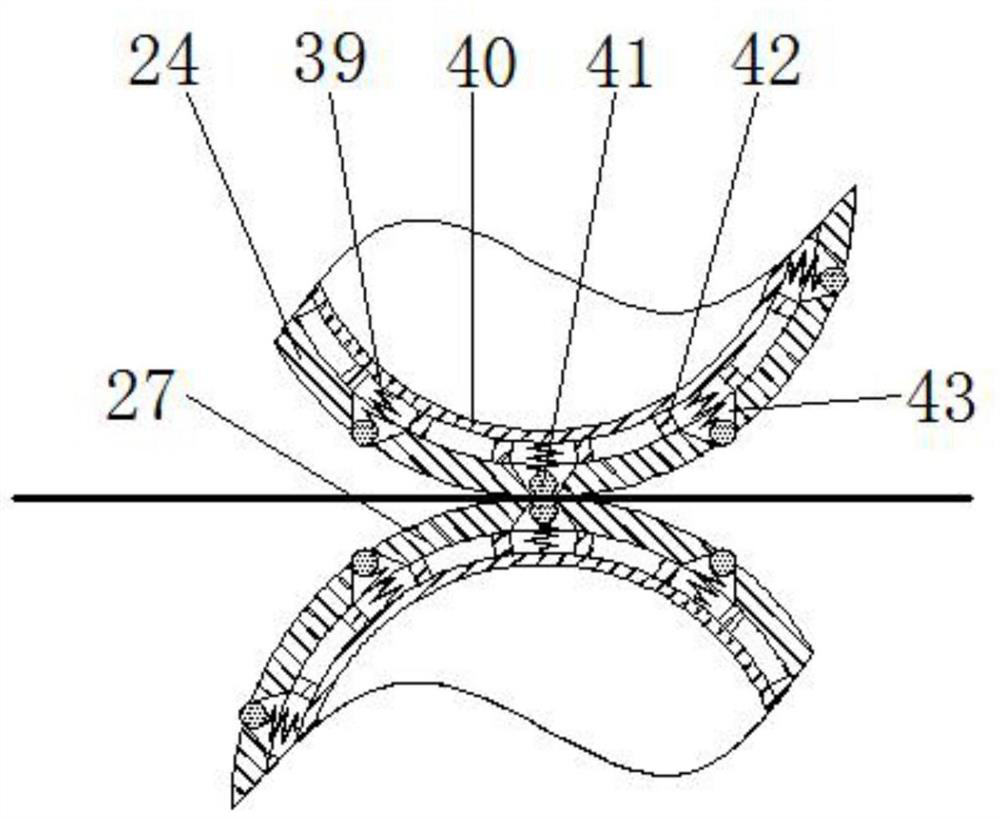

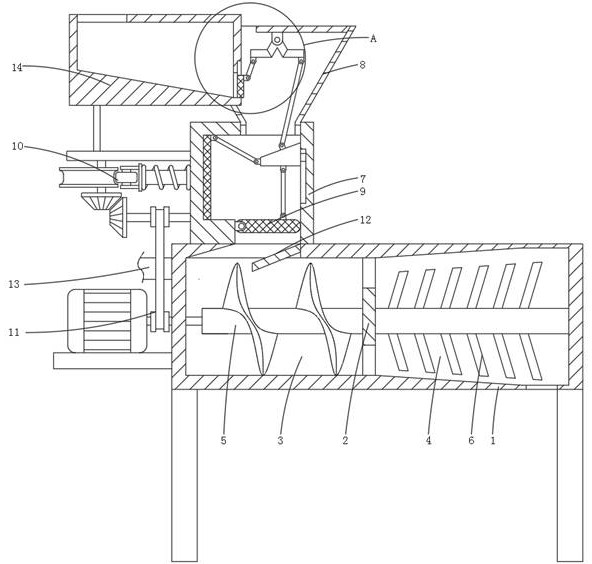

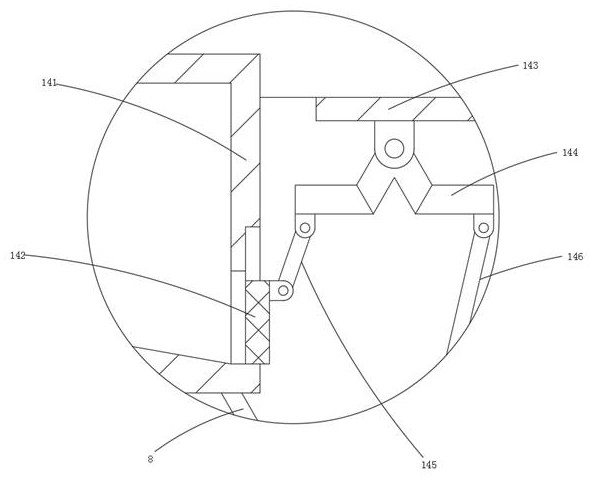

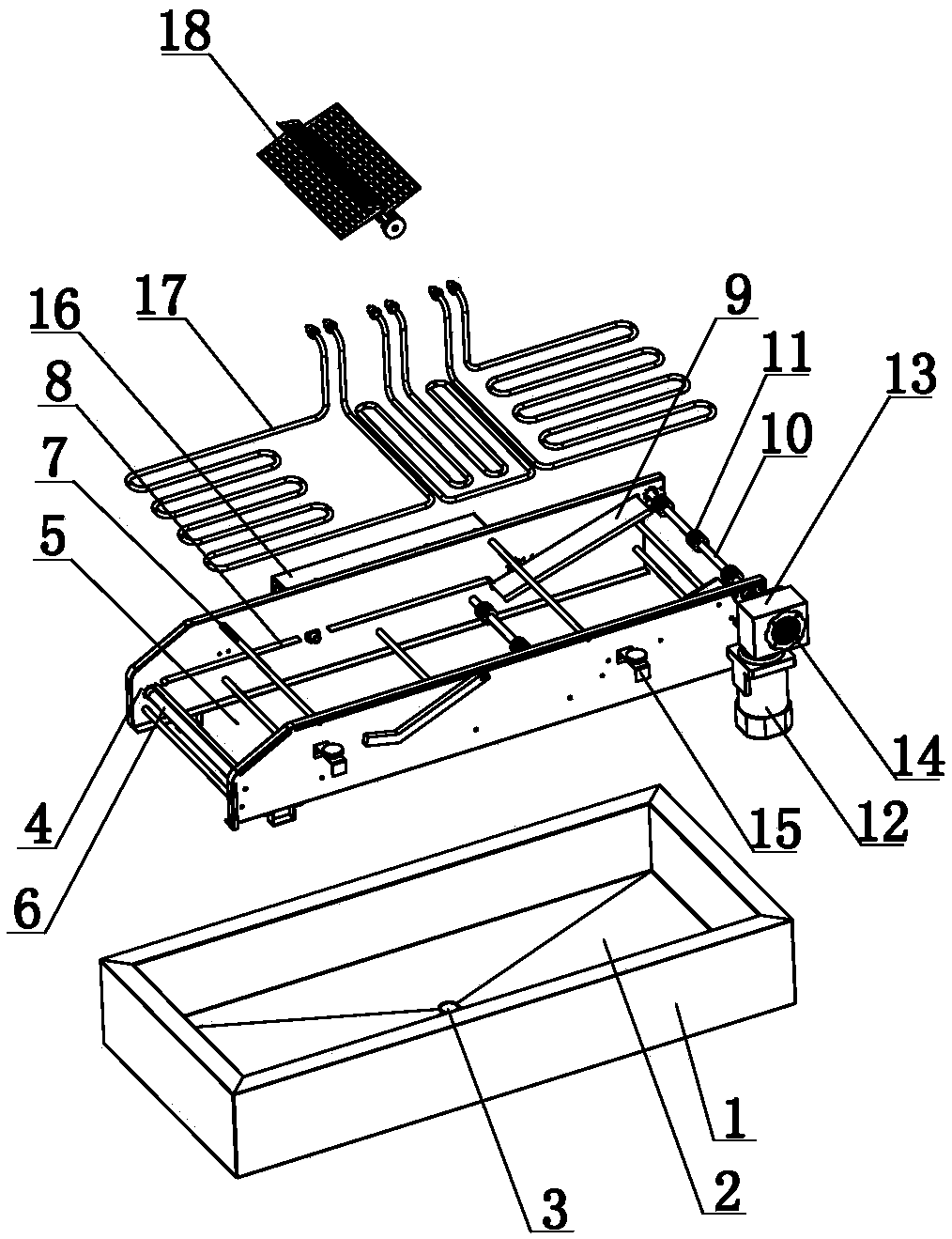

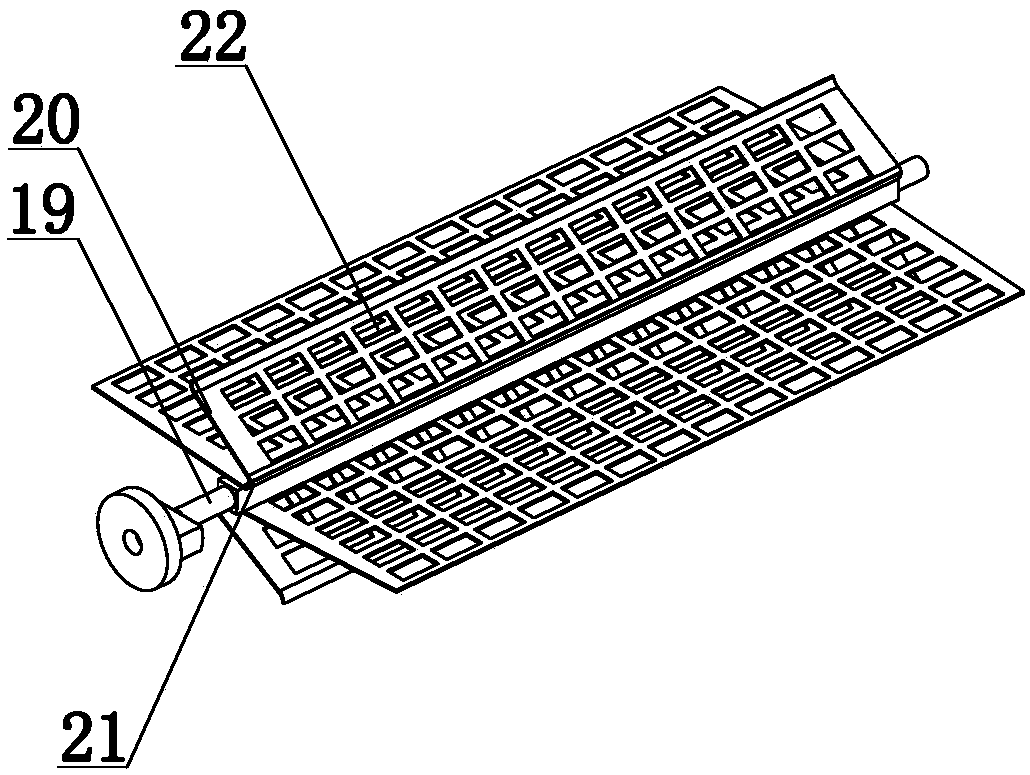

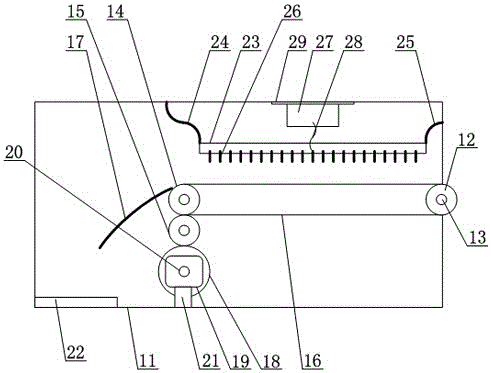

Indirect heating type dryer

ActiveCN103256799AImprove fill rateLarge and effective reverse transport effectDrying solid materialsDrying machinesFilling rateEngineering

The invention provides an indirect heating type dryer which can realize volume reduction of a dried object with drying processing, the high filling rate of a dried object and the uniformity of a dried objected in a housing. The indirect heating type dryer indirectly heat the dried object in the housing for drying process by circulating a heating medium in a rotation shaft (4) and stirring wings (20), wherein the stirring wings (20) are of a wedge shape. Each stirring wing has a front side (S1) facing the housing, a first wing surface (20a) and a second wing surface (20b), wherein the first wing surface (20a) gradually inclines to the front side (S1) from a front end part (20c) of a front side of the rotation shaft (4) in a rotation direction (M) to a rear end part (20d) of a rear side toward the rotation direction (M).

Owner:MITSUBISHI HEAVY IND ENVIRONMENTAL & CHEM ENG CO LTD

Preparation method of friction-resistant drainage pipeline

InactiveCN110790964AUniform coatingImprove drying process efficiencyPretreated surfacesAnti-corrosive paintsSilicon dioxideAntibacterial agent

The invention discloses a preparation method of a friction-resistant drainage pipeline. A formula comprises the following raw materials in parts by weight, 80-90 parts of chlorinated polyethylene, 15-20 parts of fluororubber, 8-12 parts of nano silicon dioxide, 4-9 parts of nano silicon carbide, 6-8 parts of nano calcium carbonate, 3-5 parts of nano bamboo charcoal powder, 6-10 parts of glass fiber, 1-2 parts of titanate coupling agent, 2-3 parts of an antibacterial agent, 3-5 parts of a plasticizer, 1-3 parts of an antioxidant and 1-3 parts of a light stabilizer. Nano silicon dioxide, nano silicon carbide and nano calcium carbonate are used as mixed auxiliary materials for preparing the drainage pipeline, so that polymer material strength can be increased; the nano bamboo charcoal powderis added in drainage pipeline material preparation process, the nano bamboo charcoal powder and the antibacterial agent are combined to improve the antibacterial property of the pipeline material, thedrainage pipeline corrosion resistance is improved further, and drainage pipeline service life is prolonged.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

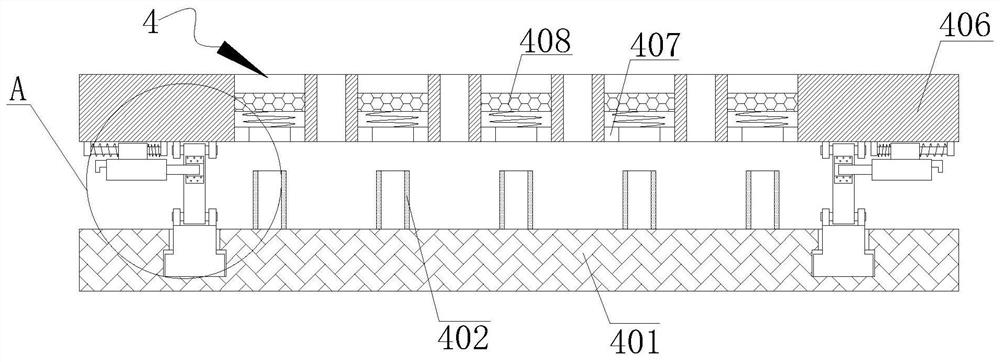

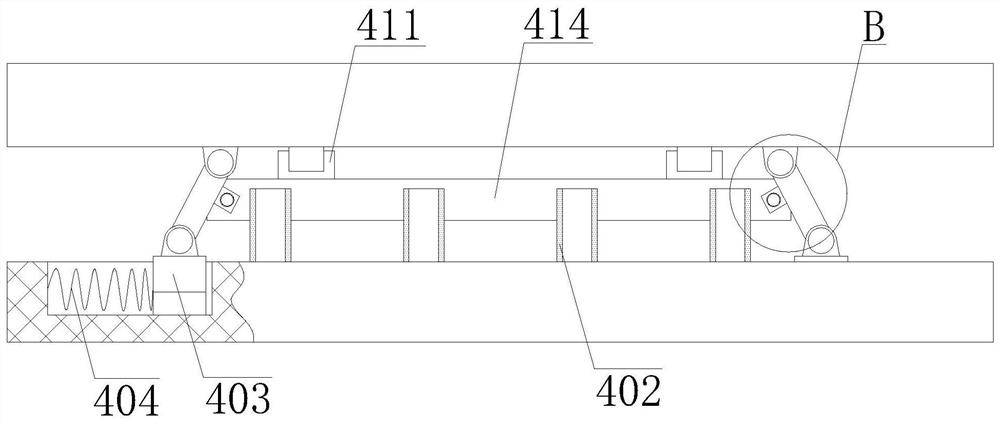

Suspension type drying room structure

InactiveCN107036418ASimple structureImprove thermal insulation performanceDrying chambers/containersDrying machines with progressive movementsEngineeringDrive motor

The invention discloses a suspension type drying room structure. The suspension type drying room structure comprises a three-dimensional frame, wherein the three-dimensional frame is composed of a top plate, a left side plate, a right side plate and a bottom plate, and openings are formed in the front end and the rear end of the three-dimensional frame correspondingly. A conveying structure is arranged on the inner surface of the top plate and comprises driving motors, a circulating conveying chain in the horizontal direction and a plurality of suspension rods, wherein the driving motors are located at the two ends of the circulating conveying chain and fixedly connected with the top plate; and the upper ends of the suspension rods are fixed to the circulating conveying chain at equal intervals, and the suspension rods are driven by the circulating conveying chain to move. A plurality of heating pipes are distributed on the side plates at interval intervals. A plurality of temperature sensors are distributed on the top plate, the side plates and the bottom plate correspondingly. The suspension type drying room structure further comprises a PLC, and the driving motors, the heating pipes and the temperature sensors are all electrically connected with the PLC. The suspension type drying room structure is suitable for suspension drying of big articles or heavyweight products, heat-preservation and heat-insulation effects are good, the constant-temperature state at the temperature of 160-170 DEG C is maintained, and the product drying effect is guaranteed.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

Dryer waste heat reutilization device

InactiveCN105972982AEfficient recyclingImprove drying effectDrying gas arrangementsImpurityHeating energy

A dryer waste heat recycling device, comprising a fabric pre-dryer and a dehumidification and impurity removal bin, one end of the dehumidification and impurity removal bin is connected to the top of the cloth dryer through a ventilation pipe, and the other end is connected to the top of the cloth dryer through a plurality of blowing equipment. The bottom of the fabric pre-dryer is connected, and the hot and humid exhaust gas discharged from the fabric dryer is discharged into the dehumidification and impurity removal bin through the air induction equipment and the ventilation pipe on the top of the cloth dryer. The moisture and impurities in the hot and humid exhaust gas will settle under the action of its own weight, and the hot exhaust gas after dehumidification and impurity removal will be blown into the fabric pre-dryer through the blower equipment to pre-dry the fabric. The waste heat recycling device of the dryer provided by the invention fully utilizes the heat energy in the waste gas discharged from the textile dryer, and pre-dries the textile cloth, thereby realizing effective recovery and utilization of waste heat, energy saving and environmental protection.

Owner:WUXI ANG YIDA MACHINERY

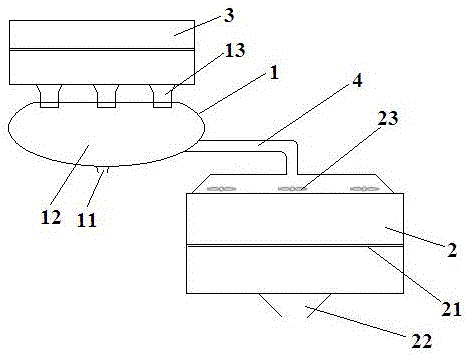

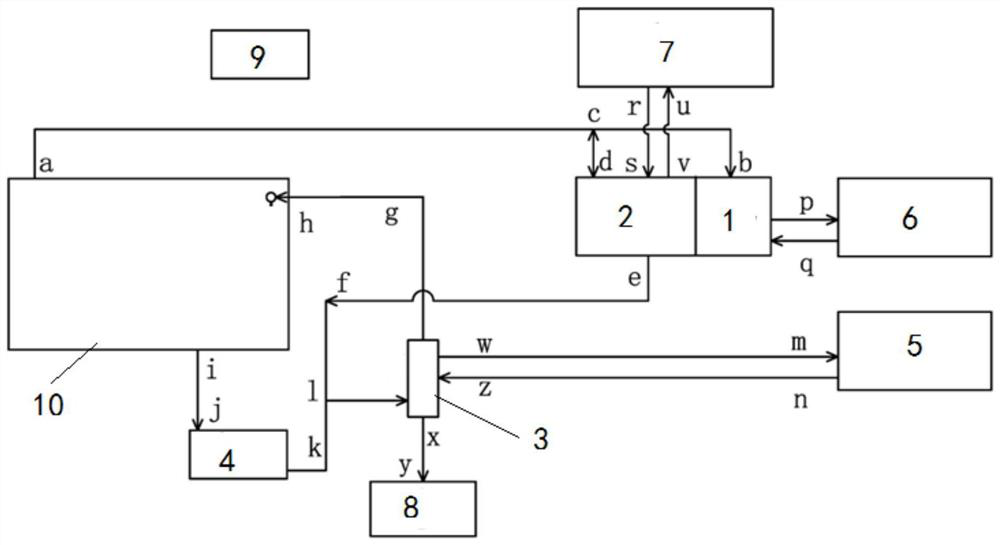

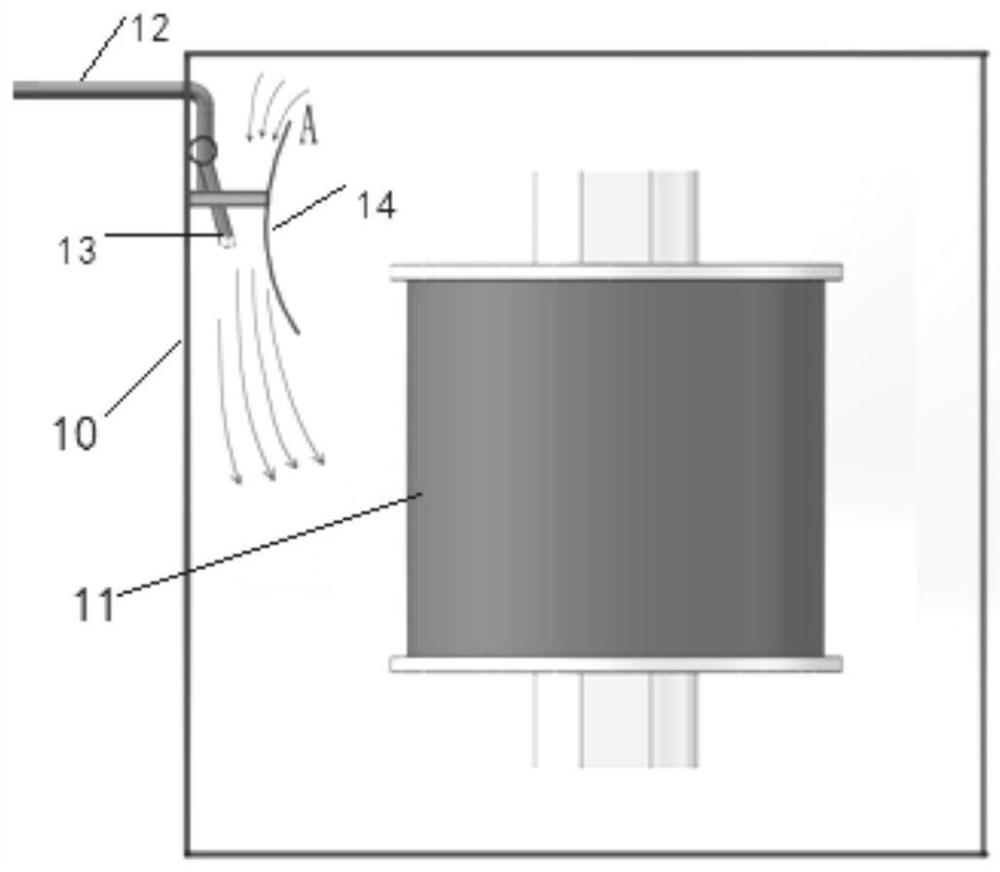

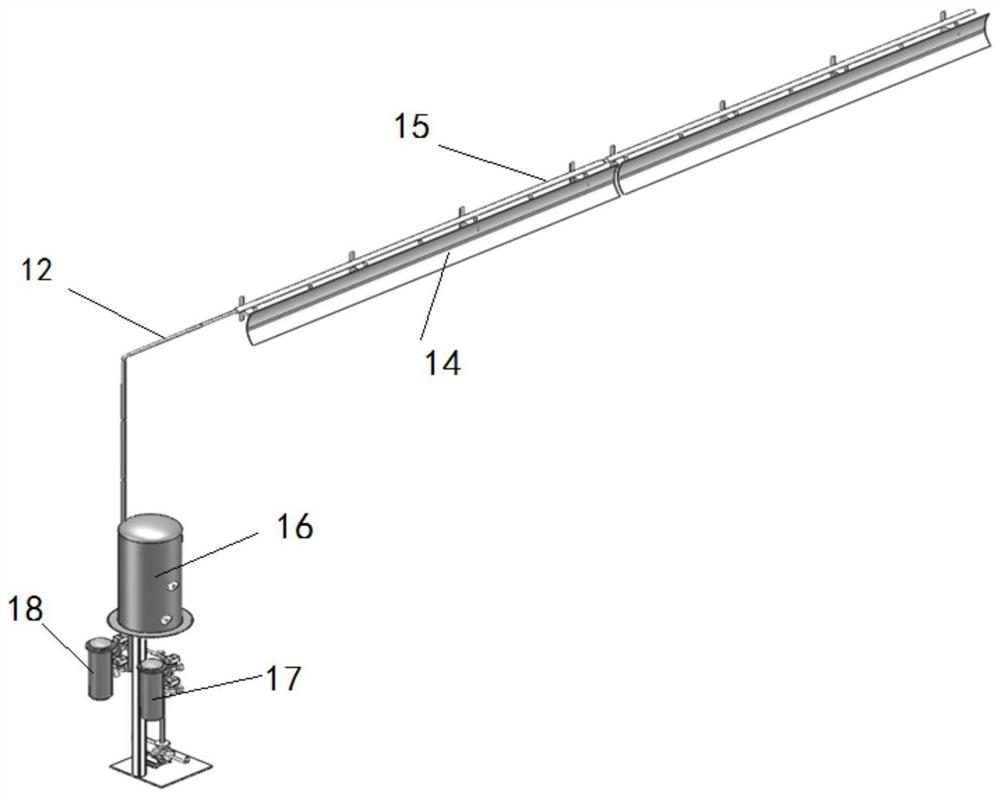

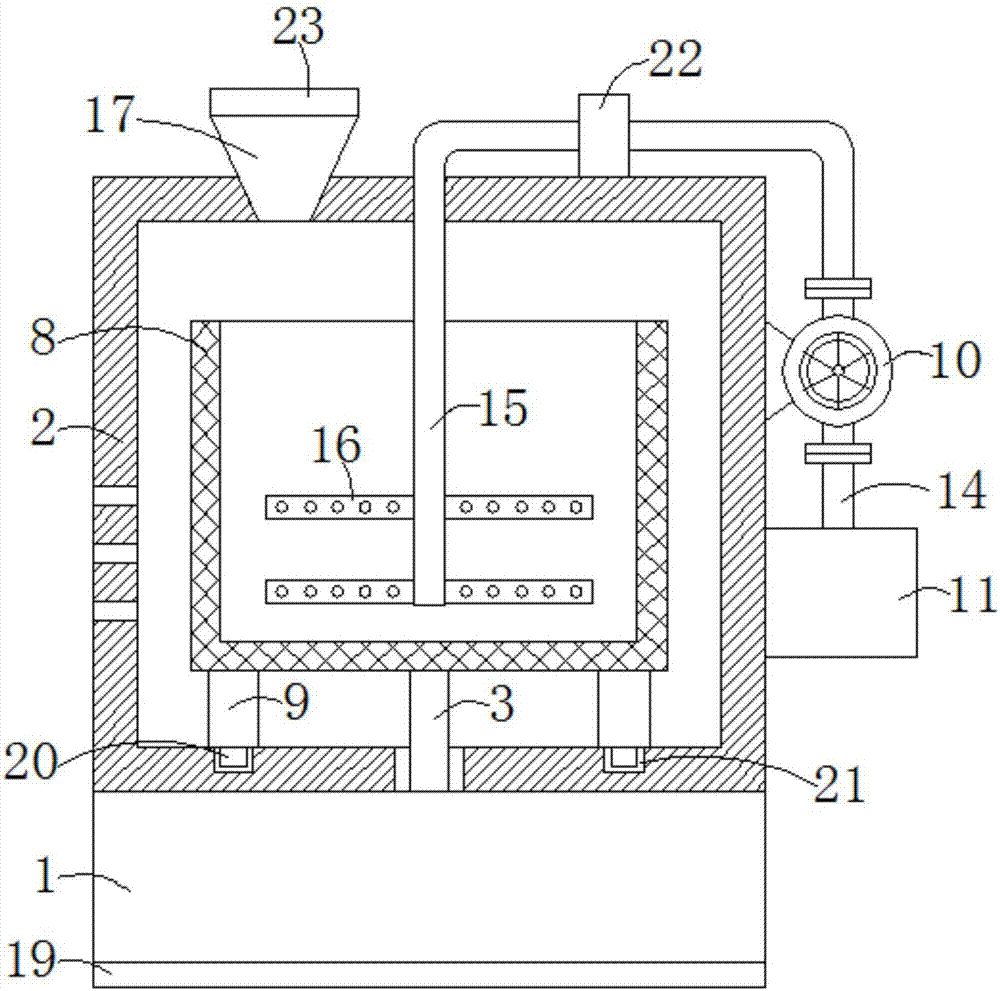

Jet evaporation vapor phase drying equipment

PendingCN111829298AImprove drying process efficiencyPrevent the core from rustingDrying solid materials without heatDrying gas arrangementsTransformerEngineering

The embodiment of the invention discloses jet evaporation vapor phase drying equipment. The jet evaporation vapor phase drying equipment comprises an evaporator module. The evaporator module is arranged outside a vacuum tank. The evaporator module adopts a plate type heat exchanger to realize heating and evaporation treatment of a liquid solvent, so that the liquid solvent reaches an over-heat supersaturated state, the liquid solvent enters the vacuum tank through a main spray pipeline and is sprayed out from a plurality of preset nozzles, jet evaporation is formed, and a transformer in the tank is heated; and venturi baffles are arranged at the front portions of the nozzles. By the adoption of the jet evaporation vapor phase drying equipment, the drying treatment efficiency of transformerproducts is improved, the drying time is shortened, the energy consumption is reduced, and meanwhile, the adopted plate type heat exchanger is small in size and higher in heating efficiency.

Owner:沈阳诚桥真空设备有限公司

Waste heat recycling device of textile cloth dryer

InactiveCN105972984AEfficient recyclingReduce moisture contentDrying gas arrangementsDrying solid materialsEngineeringPre treatment

The invention discloses a waste heat recycling device of a textile cloth dryer. The waste heat recycling device comprises a cloth pre-dryer and a waste gas pretreatment bin, wherein one end of the waste gas pretreatment bin is connected to the top of a cloth dryer through a ventilating pipe; the other end of the waste gas pretreatment bin is connected to the bottom of the cloth pre-dryer through air-blasting equipment; humid and hot waste gas exhausted by the cloth dryer is exhausted into the waste gas pretreatment bin through air inducing equipment on the top of the cloth dryer and the ventilating pipe; and after being subjected to humidity-removal and impurity-removal treatment of the waste gas pretreatment bin, the humid and hot waste gas is blast into the cloth pre-dryer through the air-blasting equipment for pre-drying cloth. According to the waste heat recycling device for the textile cloth dryer provided by the invention, heat energy in exhausted waste gas of the textile dryer is sufficiently utilized and textile cloth is pre-dried, so that waste heat is effectively recycled, and therefore, the waste heat recycling device is energy-saving and environmentally-friendly.

Owner:WUXI ANG YIDA MACHINERY

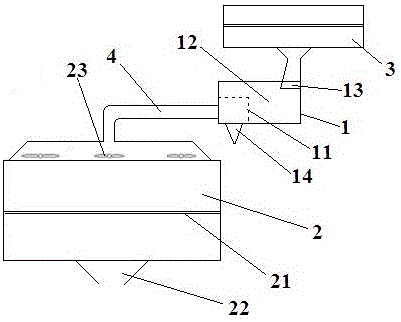

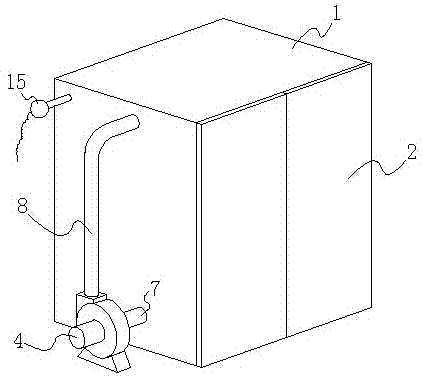

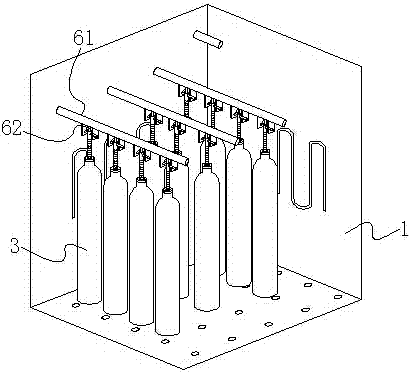

Drying method for drying interior of gas bottle

ActiveCN104713311AAvoid wastingFirmly connectedDrying solid materials with heatDrying gas arrangementsGas cylinderProcess engineering

The invention discloses a drying method for drying the interior of a gas bottle. The drying method includes the steps that the gas bottle is placed in a drying oven, and the drying oven transfers heat to water in the gas bottle in the hybrid heating mode formed by combining a heat convection inner heating mode and a heat conduction outer heating mode so that the interior of the gas bottle can be dried. Through the drying method, drying speed is further increased, the drying effect is improved, heat waste can be avoided, heat is saved, drying cost is reduced, and drying efficiency is improved.

Owner:HUNAN TIEDA ENERGY TECH

Biomass drying method

InactiveCN105861098AImprove drying process efficiencyHigh degree of processing automationBiofuelsDrying gas arrangementsEconomic benefitsAssembly line

The invention discloses a biomass drying method. The method comprises the following steps of raw material treatment, primary drying, secondary drying, tertiary drying and final treatment. According to the method, biomass is effectively and thoroughly dried, meanwhile, the drying efficiency is improved, the manual labor intensity is lowered, the different emphasis points of biomass drying are carried out one by one through separately set multi-stage drying processes, biomass is scientifically and systematically dried, the whole process is high in automation degree, the biomass is treated in an assembly line mode, and good economic benefits are achieved.

Owner:ANHUI XINSHENGLI BIOLOGY TECH

Drying processing technology and drying processing device for thunberg fritillary bulb

The invention discloses a drying processing technology and a drying processing device for thunberg fritillary bulb. The drying processing technology comprises the following steps of: rinsing fresh thunberg fritillary bulb clean and draining off moisture; slicing the thunberg fritillary bulb, wherein the slicing thickness is 3 to 4mm; placing thunberg fritillary bulb slices on a feed inlet of a conveying belt of a tunnel-type hot air dryer, controlling a conveying speed of a conveying belt into the range of 42.5cm per minute to 56.5cm per minute, controlling a 0-3.5m tunnel hot air temperature of the conveying belt along a conveying direction of the conveying belt into the range of 100 to 110 DEG C, controlling a 3.5-6.5m tunnel hot air temperature of the conveying belt along the conveying direction of the conveying belt into the range of 80 to 85 DEG C, controlling an over-6.5m tunnel hot air temperature of the conveying belt along the conveying direction of the conveying belt into the range of 70 to 75 DEG C and controlling whole drying time in the range of 15 to 20 minutes; spreading out the dried thunberg fritillary bulb slices, cooling to the room temperature and then packaging the thunberg fritillary bulb slices. The drying processing technology and the drying processing device for the thunberg fritillary bulb has the advantages of high drying processing efficiency, good shapes of the processed thunberg fritillary bulb slices and high selling price.

Owner:文成县华兴药材种植有限公司

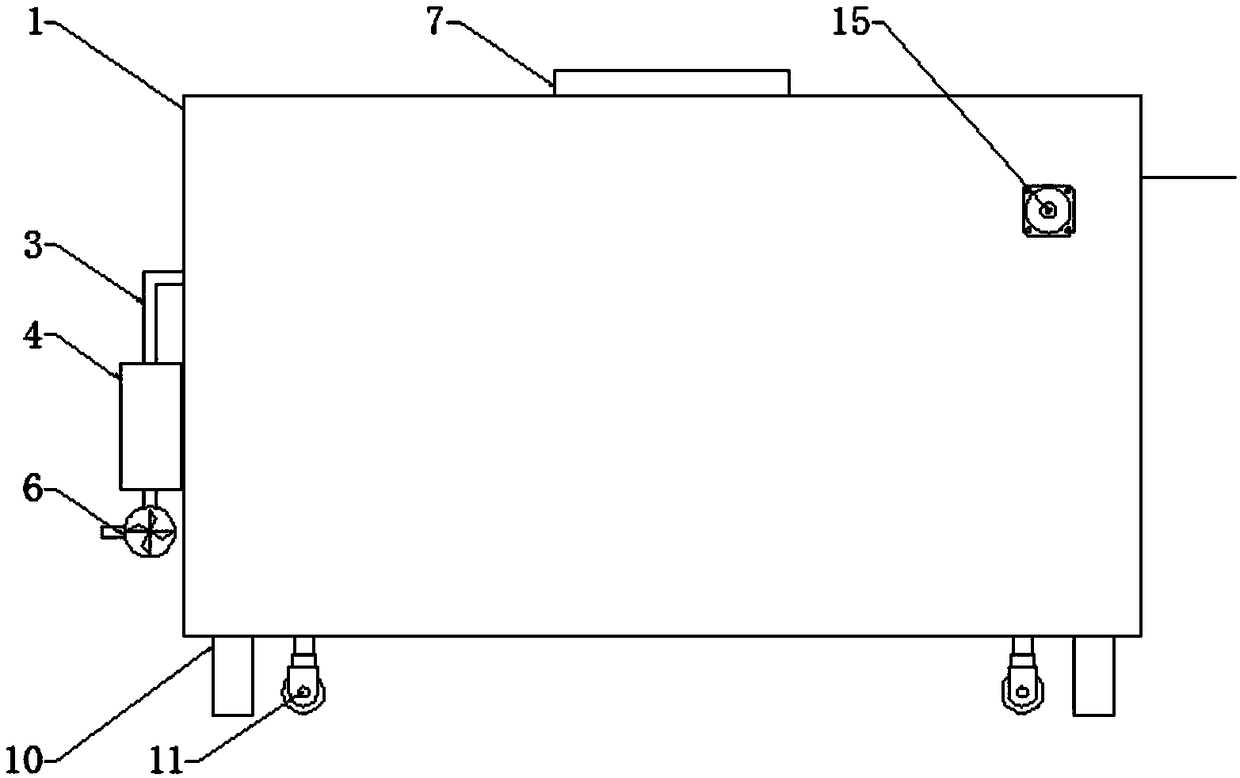

Drying device for tablet production

InactiveCN111895734AThe problem of preventing falling groundReduce wasteDrying gas arrangementsDrying chambers/containersStructural engineeringProcess engineering

The invention relates to the technical field of tablet drying and discloses a drying device for tablet production. The drying device comprises a drying box. A partition is fixedly connected between the inner top wall and the inner bottom wall of the drying box. A plurality of support plates are fixedly connected at equal intervals between the left side face of the partition and the left side innerwall of the drying box as well as between the right side face of the partition and the right side inner wall of the drying box. Tray mechanisms are placed at the top of the support plates. Two heating plates are symmetrically and fixedly installed on the inner bottom wall of the drying box. Two dehumidification boxes and two air suction fans are symmetrically and fixedly connected to the left andright side faces of the drying box. Through the drying device, the problems that in most existing tablet drying devices, a supporting plate of which the top is provided with a plurality of tablet holding cavities is adopted for holding tablets, the tablets cannot be fully dried and cannot be taken out conveniently, and thus the drying processing effect and efficiency are influenced are solved.

Owner:赵鸿菓

Fast drying device for agricultural fertilizers

InactiveCN107228546AImprove drying efficiencyEfficient dryingManure dryingDrying gas arrangementsDrive wheelAgricultural engineering

The invention discloses a quick drying device for agricultural fertilizers, which comprises a base, the top of the base is fixedly connected with a casing, and the central axis at the bottom of the inner wall of the base is movably connected with a connecting column, and the surface of the connecting column is sleeved There is a driven wheel, a motor is fixedly connected to the bottom right side of the inner wall of the base, and a driving wheel is fixedly connected to the output end of the motor. The present invention is equipped with a base, a housing, a connecting column, a driven wheel, a motor, a driving wheel, a belt, a cage, a movable block, a fan, a heating box, a heating base, a heating pipe, a first pipeline, a second pipeline, and an air outlet pipe. , The combination of feeding hopper and box door, high drying efficiency, thorough drying of agricultural fertilizers, energy saving and environmental protection.

Owner:长兴佳诚苗木有限公司

High-efficiency dyed cloth drying device

ActiveCN112050596AMove at a constant speedGuaranteed uniformityDrying gas arrangementsDrying machines with progressive movementsExhaust pipeCotton material

The invention discloses a high-efficiency dyed cloth drying device, and belongs to the field of drying equipment. The high-efficiency dyed cloth drying device comprises a box body internally providedwith an electric heating element, two or more lifting frame bodies are arranged in the box body at equal intervals, the tops of the lifting frame bodies are connected with lifting rods, and the upperends of the lifting rods are connected with a lifting driving mechanism; an upper roller and a lower roller used for clamping a cloth are arranged in each lifting frame body, through holes are evenlyspread over the side faces of the upper rollers and the lower rollers, the upper rollers communicate with a first air cylinder arranged at the top in the box body through a first exhaust pipe, the opening diameter of each through hole is gradually reduced from the inner side end to the outer side end of the through hole, and a blocking assembly used for blocking an outer port of each through holeis arranged in the through hole; and the blocking assemblies each comprise a blocking ball with the diameter between the diameter of an inner port and the diameter of the outer port of the corresponding blocked through hole, and a spring connected to the plugging ball. The high-efficiency dyed cloth drying device is high in drying treatment efficiency, good in uniformity, and capable of thoroughlydrying the cloth and treating water vapor generated in the drying process in time, only needs one power driving mechanism, is convenient to control and can save energy.

Owner:泉州台商投资区飞翔机械设计服务中心

Gas circulation rapid drying oven

ActiveCN109708438APrevent overflowImprove processing efficiencyDrying gas arrangementsDrying chambers/containersProduct gasProcess engineering

The invention discloses a gas circulation rapid drying oven comprising a drying box shell. A heating plate is fixedly mounted on the bottom of an inner cavity of the drying box shell; the inner wall of the drying box shell is fixedly connected with a supporting horizontal plate; and the top of the supporting horizontal plate is fixedly connected with a containing platform. According to the gas circulation rapid drying oven, hot air generated by the heating plate continuously circulates, heat is absorbed and preserved for a long time during processing in combination with a heat storage box, andwhen a one-way outward opening door is opened, it is difficult for the heat to dissipate in a very short time; thus, in the process of changing a mold, the heating plate continues heating the gas without being closed, the hot gas generated by the heating plate can also be preserved, and thus the processing efficiency is improved; meanwhile, the situation that a large amount of heat overflows dueto opening of the one-way outward opening door is avoided; and the effect of the gas circulation fluidity inside the drying box shell is improved by the targeted design, and accordingly the efficiencyof the mold drying process is improved.

Owner:浙江华义检测有限公司

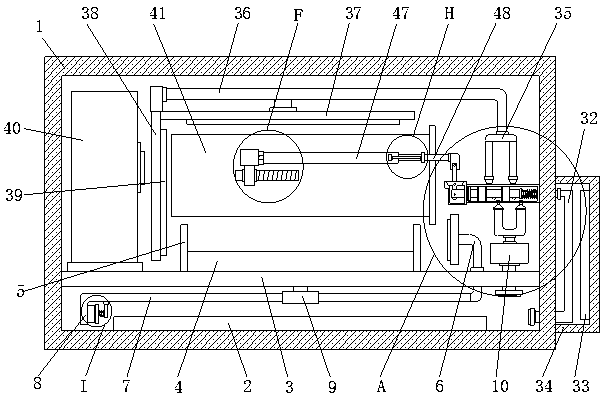

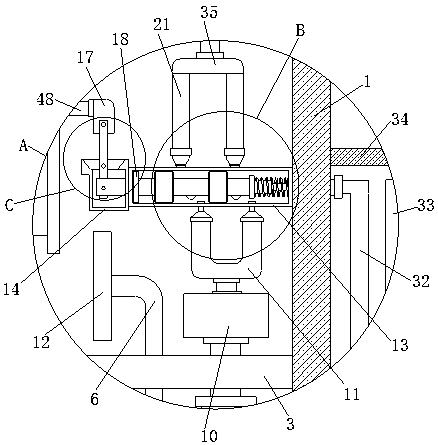

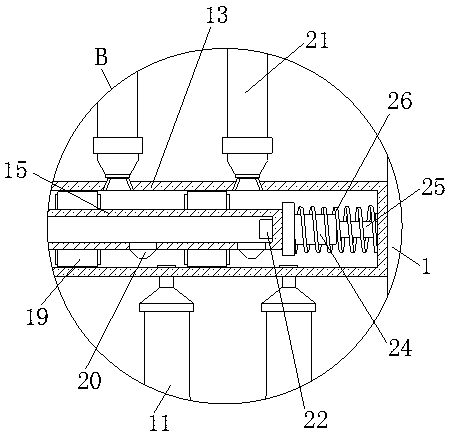

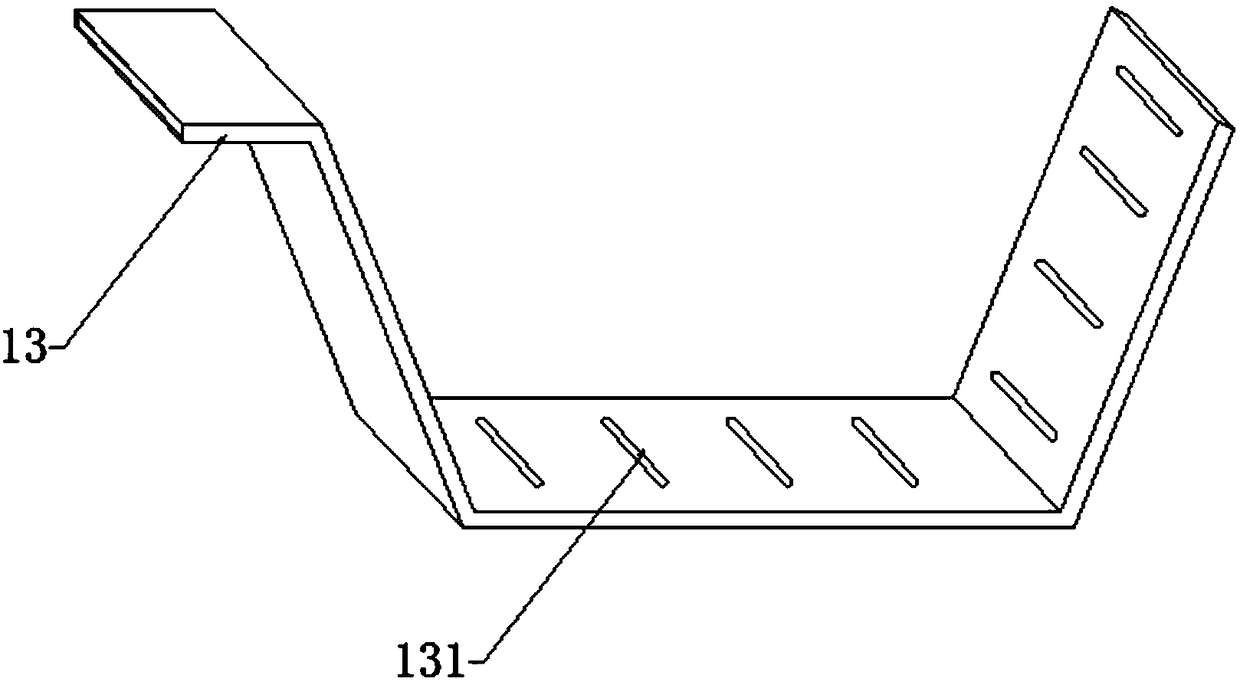

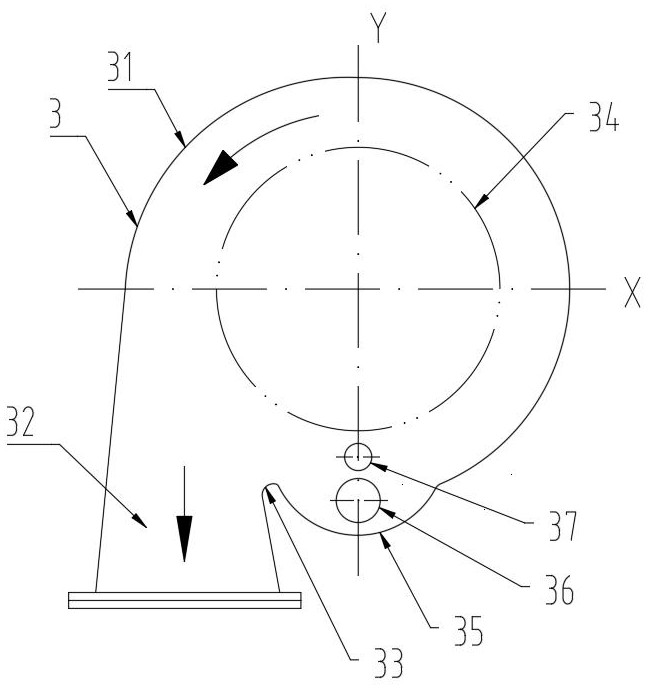

Leather drying processing method

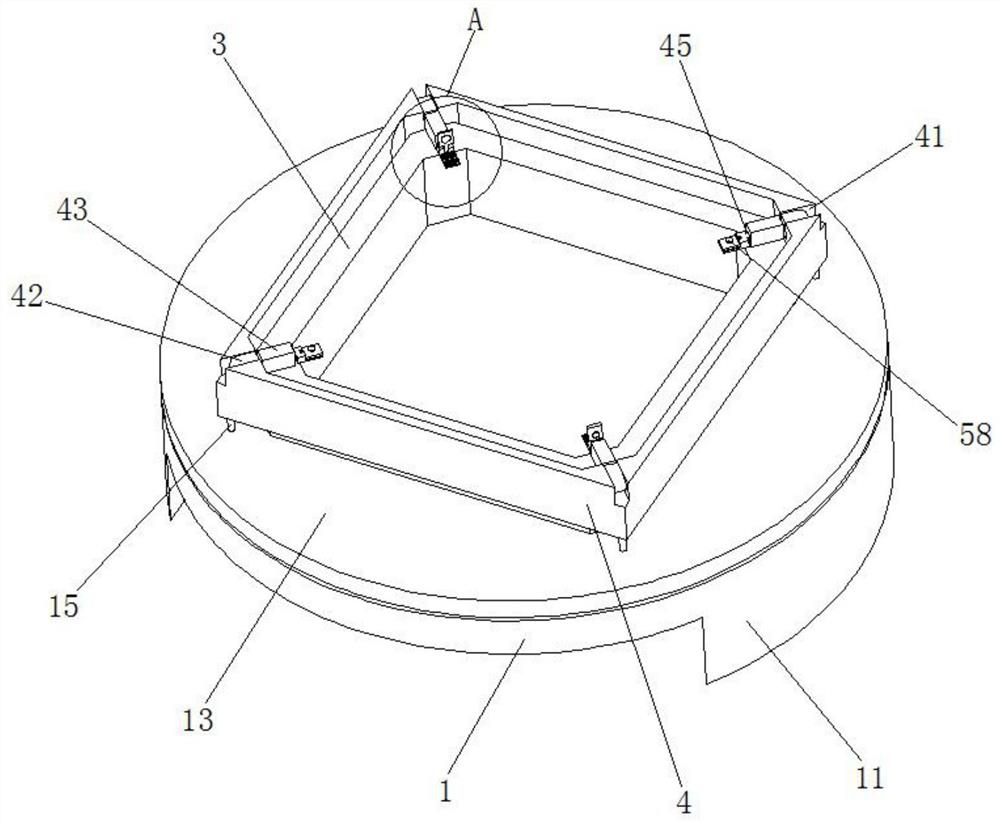

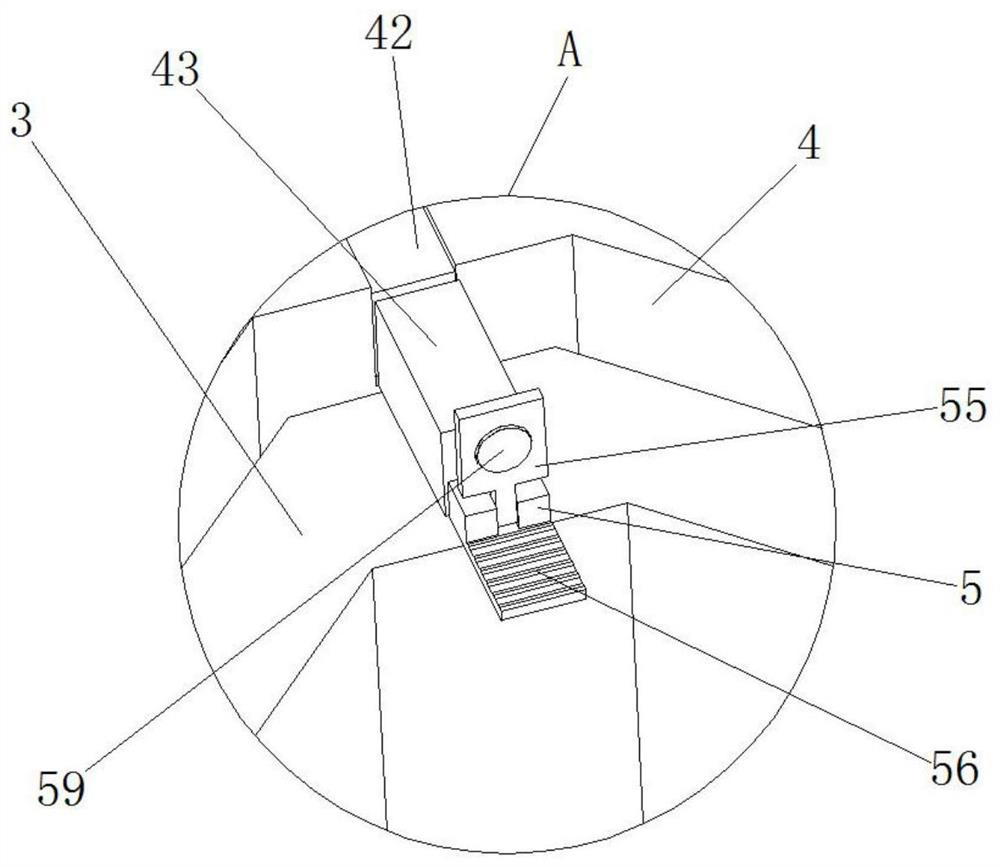

InactiveCN111850181AKeep dryImprove drying process efficiencySkins/hides/leather/fur manufacturing apparatusLeather dryingStructural engineeringMechanical engineering

The invention relates to the field of leather manufacturing, in particular to a leather drying processing method. A drying processing device is used. The drying processing device comprises a clampingframe and a drying frame, first inserting blocks are symmetrically and fixedly installed at the bottom of the clamping frame, the drying frame is of a circular ring structure, a plurality of second inserting blocks are symmetrically and fixedly installed on the drying frame, the second inserting blocks are symmetrically arranged in pairs, and the second inserting blocks are symmetrical to the first inserting blocks in a mutual inserting and connecting mode. A clamping groove with a circular ring structure is formed in the top of the clamping frame, a rotating ring is arranged at the top of theclamping frame, a clamping rail with an annular structure is fixedly installed at the bottom of the rotating ring, the clamping rail is symmetrical to the clamping groove in a mutual inserting and connecting mode, a fixed frame with a concentric-square-shaped structure is fixedly installed at the top of the rotating ring, and a lifting frame with a concentric-square-shaped structure sleeves the outer side of the fixed frame. According to the leather drying processing method, the leather drying speed and efficiency can be improved, rapid feeding and discharging of leather can be realized, andthe leather drying processing method is suitable for being popularized.

Owner:张浩

Waste-heat utilization device for textile drying machine

InactiveCN105972983AEfficient recyclingReduce moisture contentDrying gas arrangementsCold airThermal energy

A waste heat utilization device for a textile dryer, including a fabric pre-dryer and a heat exchange device, the heat exchange device is placed on the top of the fabric dryer, and includes a damp and hot exhaust gas channel and a fresh dry air channel, which are respectively used for pumping into the fabric for drying The hot and humid exhaust gas and dry cold air discharged from the machine, a heat exchange device is arranged between the hot and humid exhaust gas channel and the fresh and dry air channel, and the dry cold air circulating in the fresh and dry air channel uses the principle of heat exchange to absorb the wet and hot exhaust gas flowing through the hot and humid exhaust gas channel. The heat is discharged into the fabric pre-drying machine through the ventilation pipe to pre-dry the fabric. The waste heat reuse device of the dryer provided by the invention fully utilizes the heat energy in the exhaust gas discharged from the textile dryer, and pre-dries the textile fabric, thereby realizing the effective recovery and utilization of waste heat, energy saving and environmental protection.

Owner:WUXI ANG YIDA MACHINERY

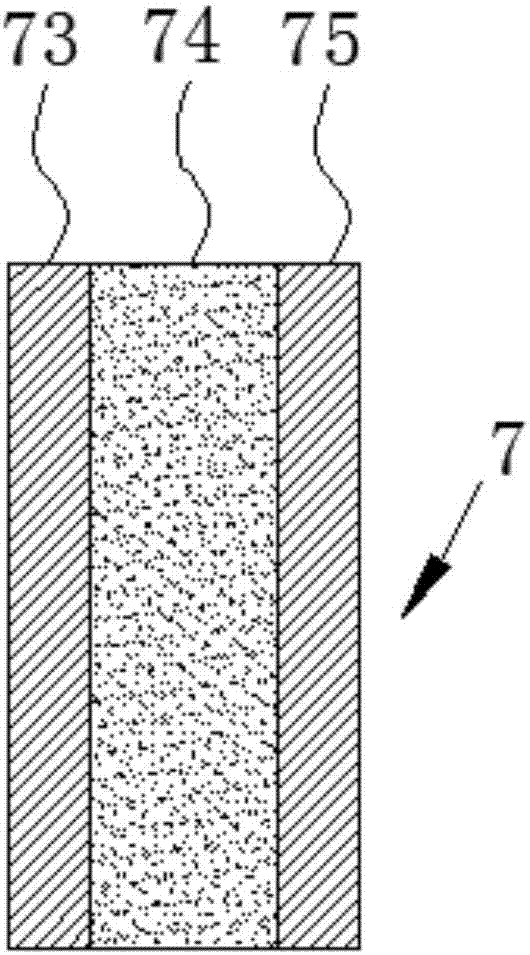

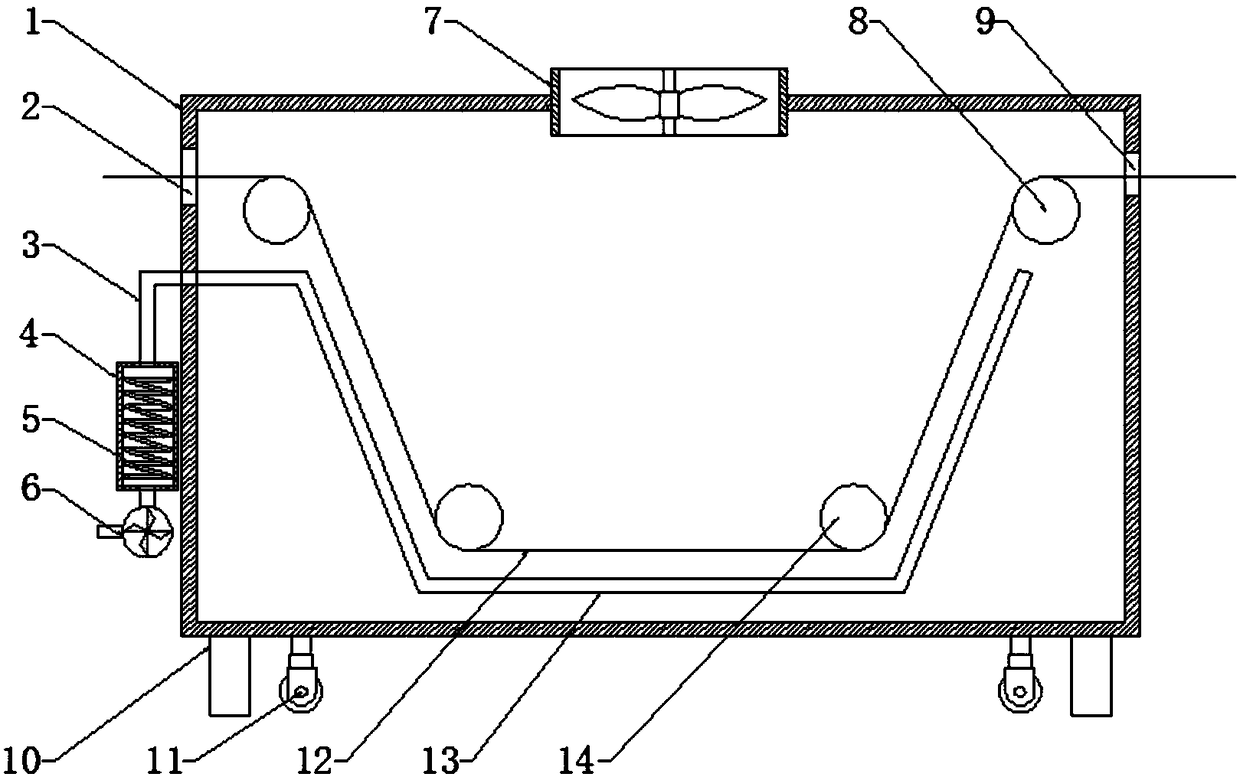

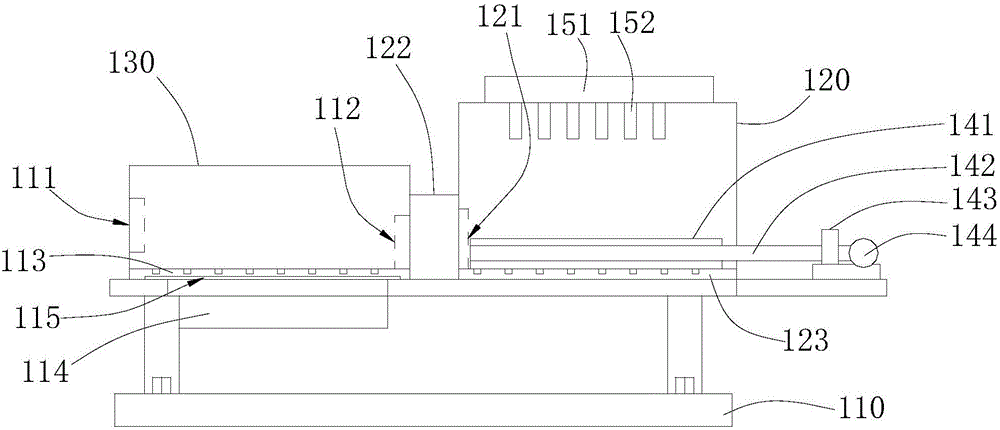

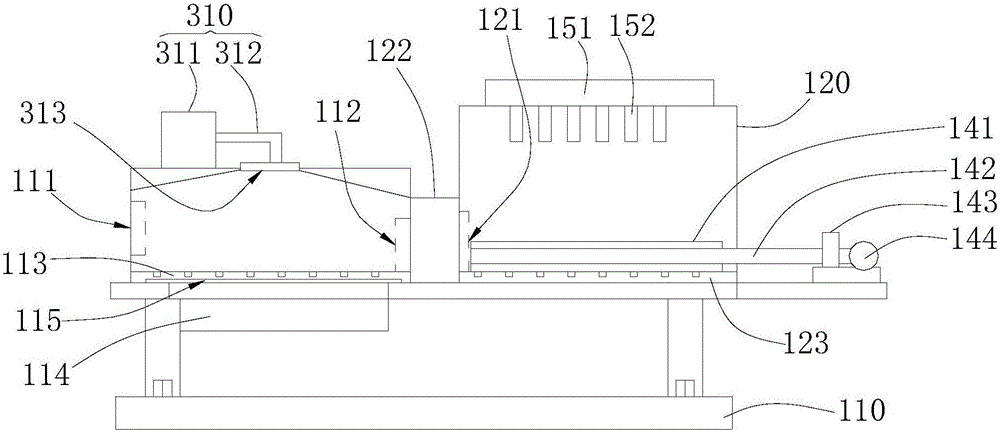

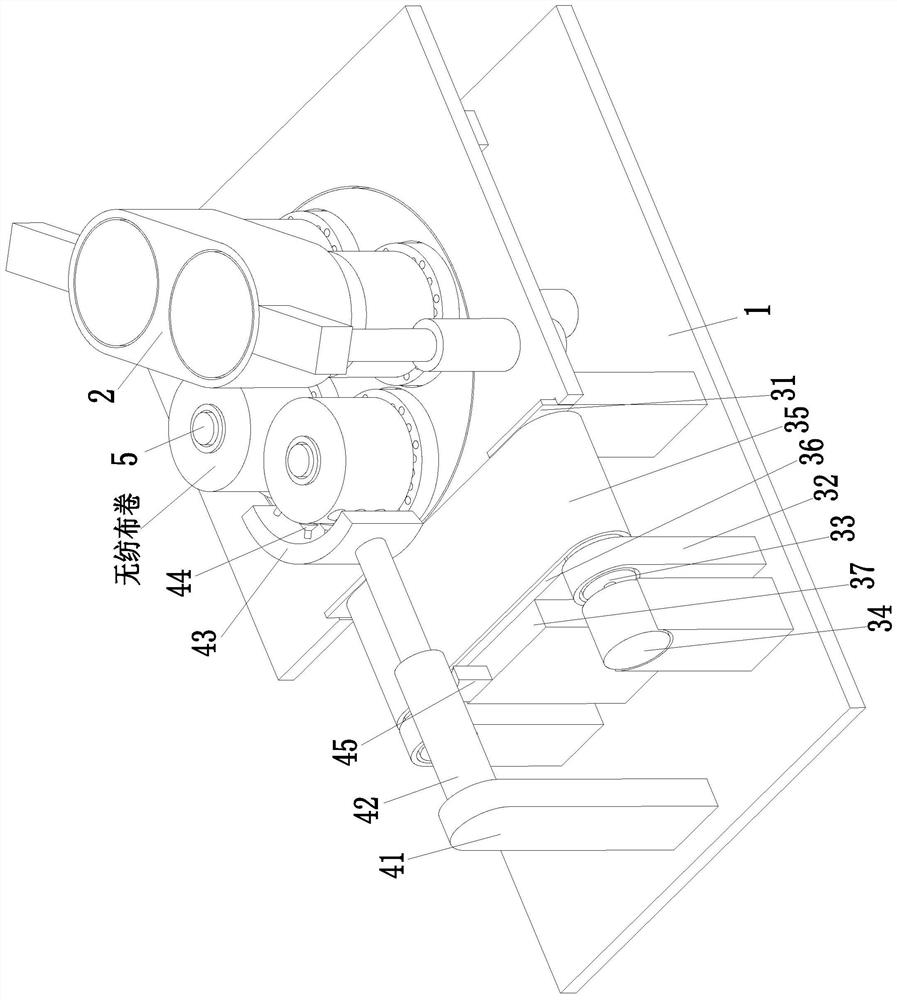

Drying device for non-woven fabric production

PendingCN108800868AGuaranteed drying effectImprove drying process efficiencyDrying gas arrangementsDrying chambers/containersHeating timeNonwoven fabric

The invention discloses a drying device for non-woven fabric production. The drying device comprises a drying box, a heating barrel, an electric heating coil, a draught fan, an exhaust fan, a drivingroller, supporting legs, a non-woven fabric, driven rollers and a motor. The three driven rollers and the driving roller are sequentially arranged on the inner side of the drying box from left to right, and a fabric inlet and a fabric outlet are formed in the positions, close to the upper end, of the left end face and the right end face of the drying box correspondingly. According to the drying device for non-woven fabric production, through forming of a ventilation channel profiled with the trend of a non-woven fabric belt and an air outlet formed in the face, facing the non-woven cloth, of the ventilation channel, the whole non-woven fabric in the drying box is dried, the drying area is large, heating is even, the heating time is prolonged, the drying effect of the non-woven fabric is ensured, and meanwhile the drying and processing efficiency of the non-woven fabric is improved as well. An adjusting idler wheel constituted by an electric telescopic rod and a universal wheel, is supported by extending of the electric telescopic rod when the drying device needs to be moved, moving of the drying device is facilitated, and good using flexibility is achieved.

Owner:浙江洁呈新材料科技股份有限公司

Temperature-adjustable tea leaf drying equipment and using method thereof

InactiveCN112006127AImprove drying process efficiencyExpedited drying processPre-extraction tea treatmentEngineeringStructural engineering

The invention provides temperature-adjustable tea leaf drying equipment and a using method thereof, and relates to the technical field of tea leaf production. The equipment includes a supporting mechanism, a pre-drying mechanism is arranged on the inner side of the supporting mechanism; a drying mechanism is arranged on the inner side of the supporting mechanism and located below the pre-drying mechanism, a material turning assembly is arranged on the inner side of the drying mechanism, the supporting mechanism comprises a supporting frame, the upper end of the supporting frame is fixedly connected with an installation top frame, an air heater is fixedly installed at the upper end of the installation top frame, and an air outlet port of the air heater fixedly communicates with a drying aircover. According to the invention, tea leaves can be subjected to rapid pre-drying treatment; a first material scattering frame and a second material scattering frame can be used for carrying out scattering treatment on passing tea leaves, so that the tea leaves are prevented from being caked and influencing drying quality; and the tea leaves are turned over by a rotating material turning frame in the drying process, so that the tea leaves can be fully and uniformly heated and dried, the working efficiency of drying treatment of the tea leaves is improved, and the drying treatment effect of the tea leaves is improved.

Owner:马鞍山司匹诺机械科技有限公司

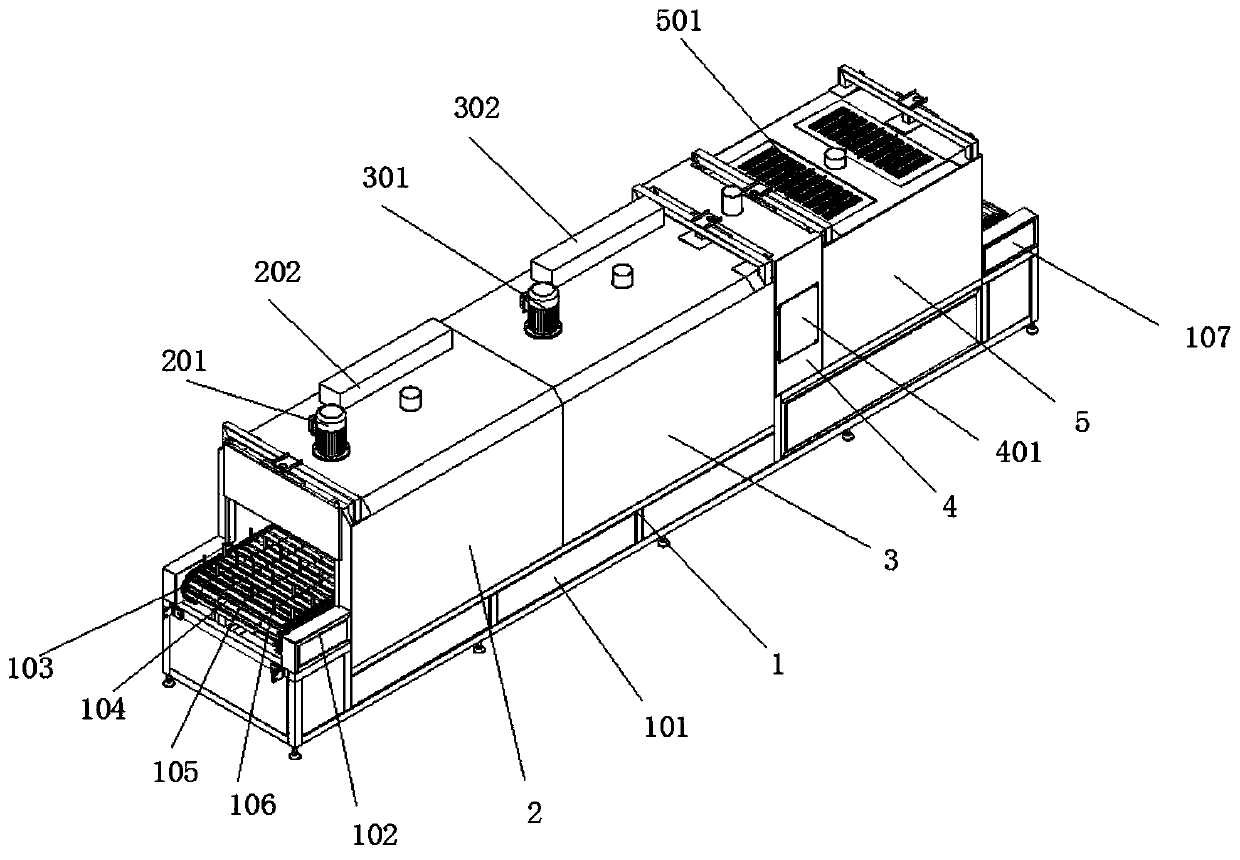

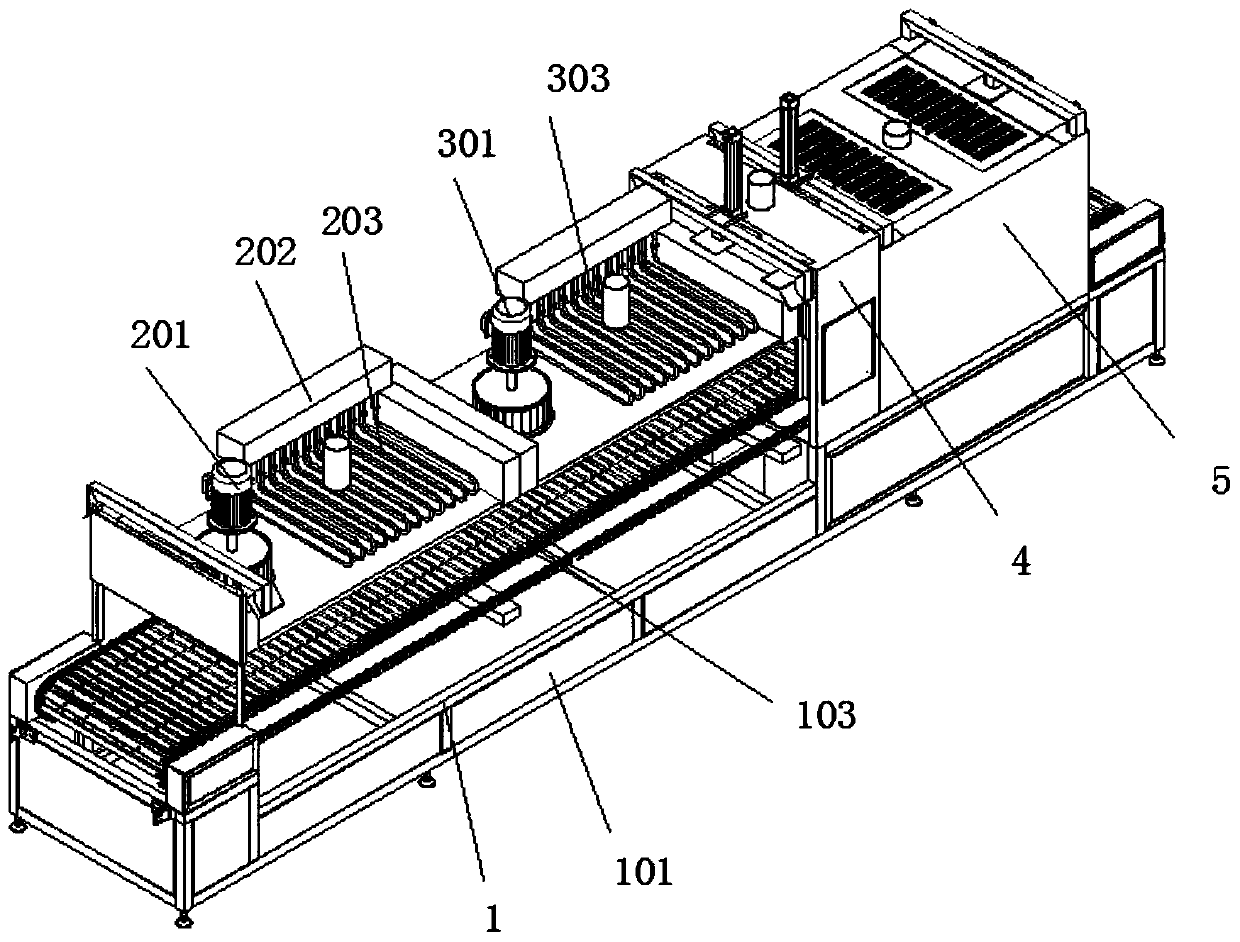

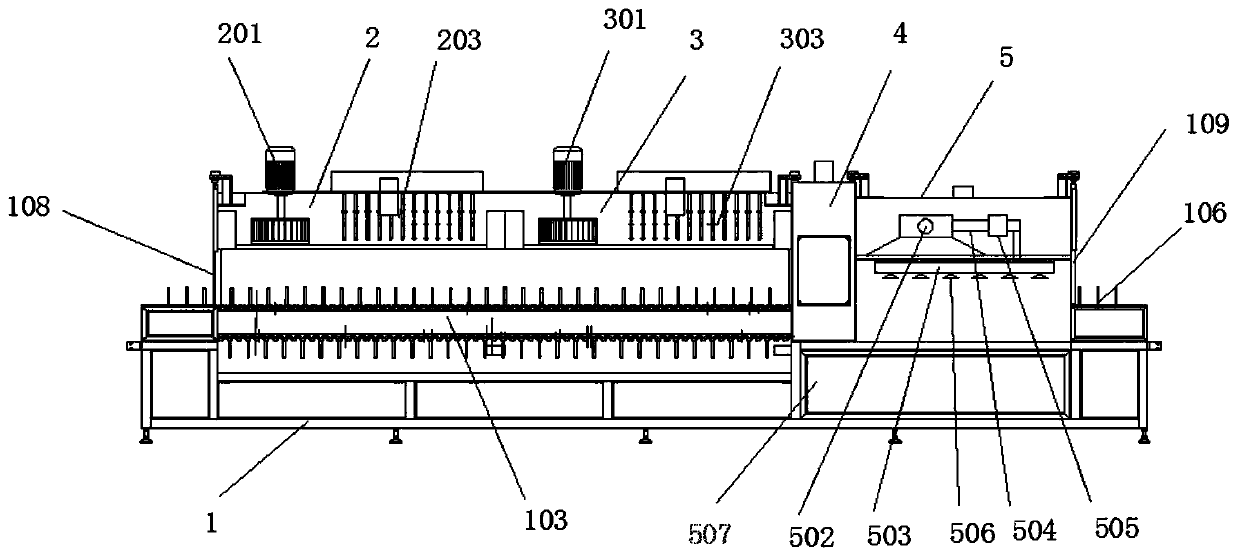

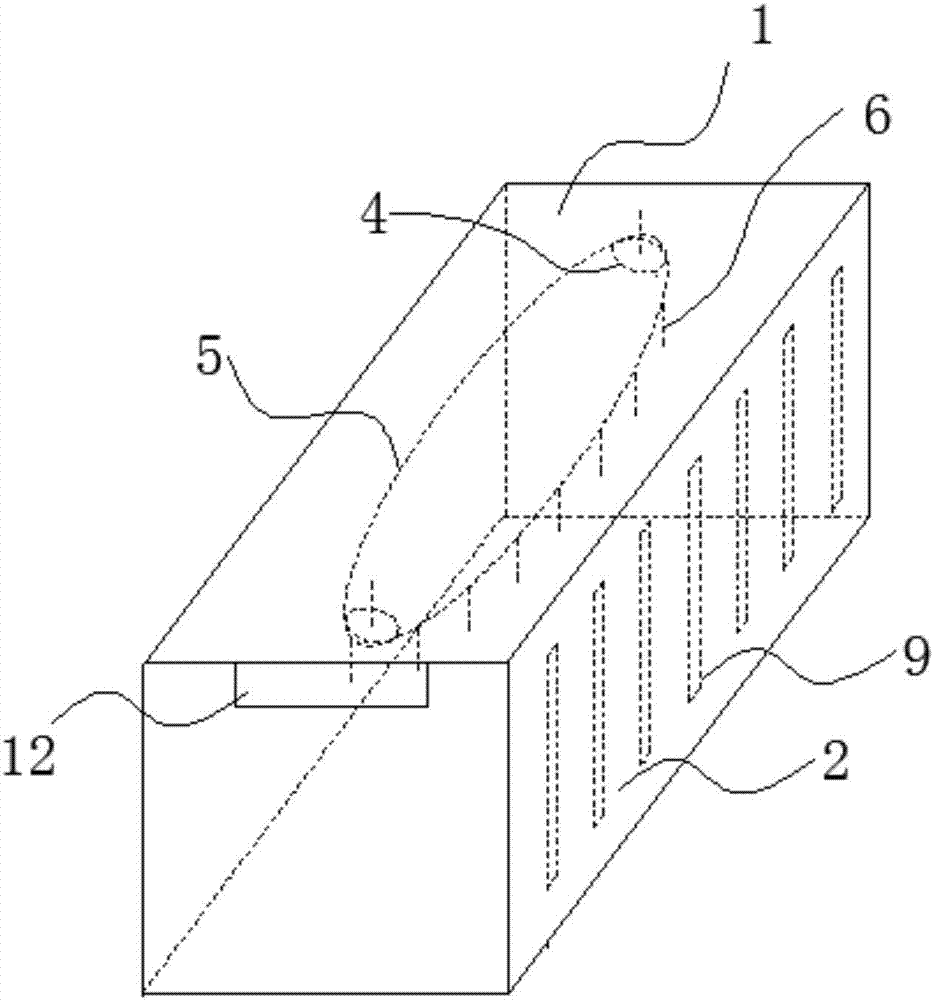

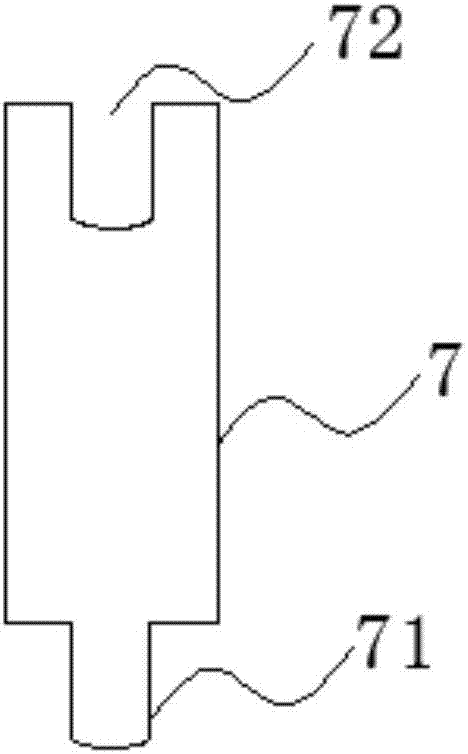

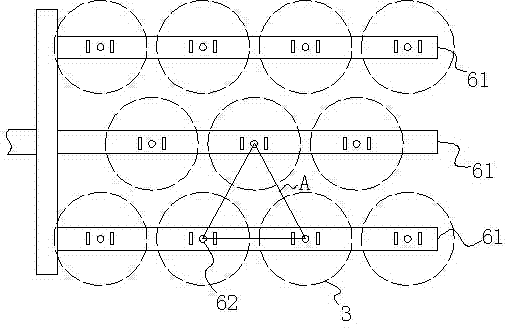

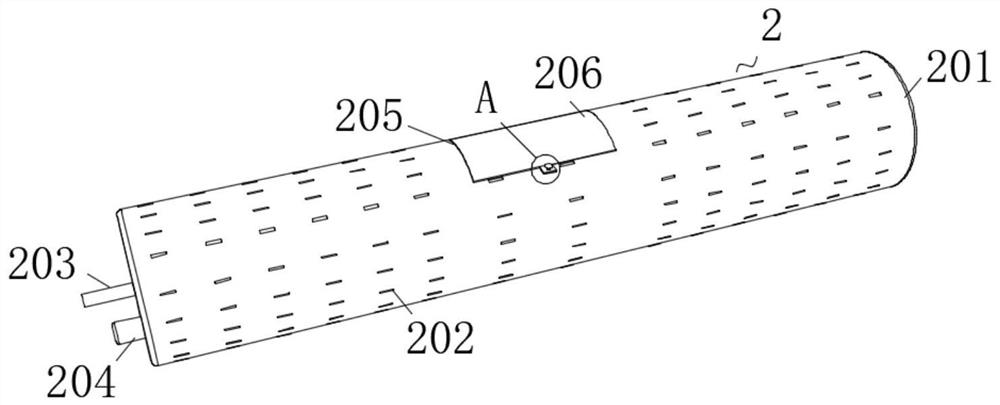

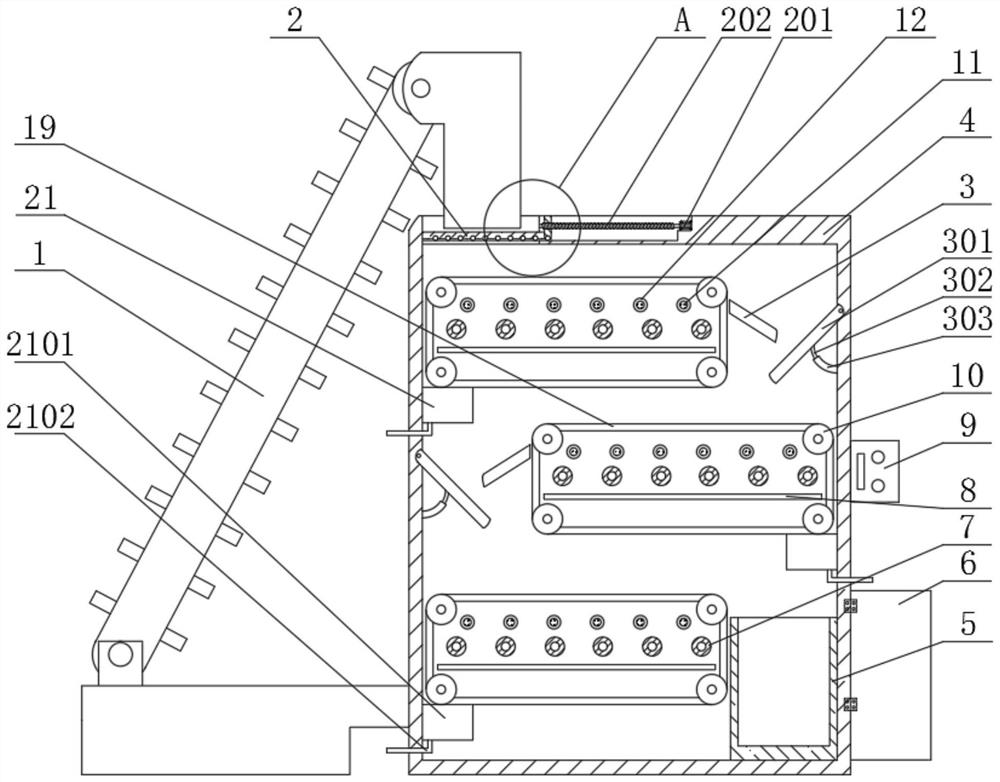

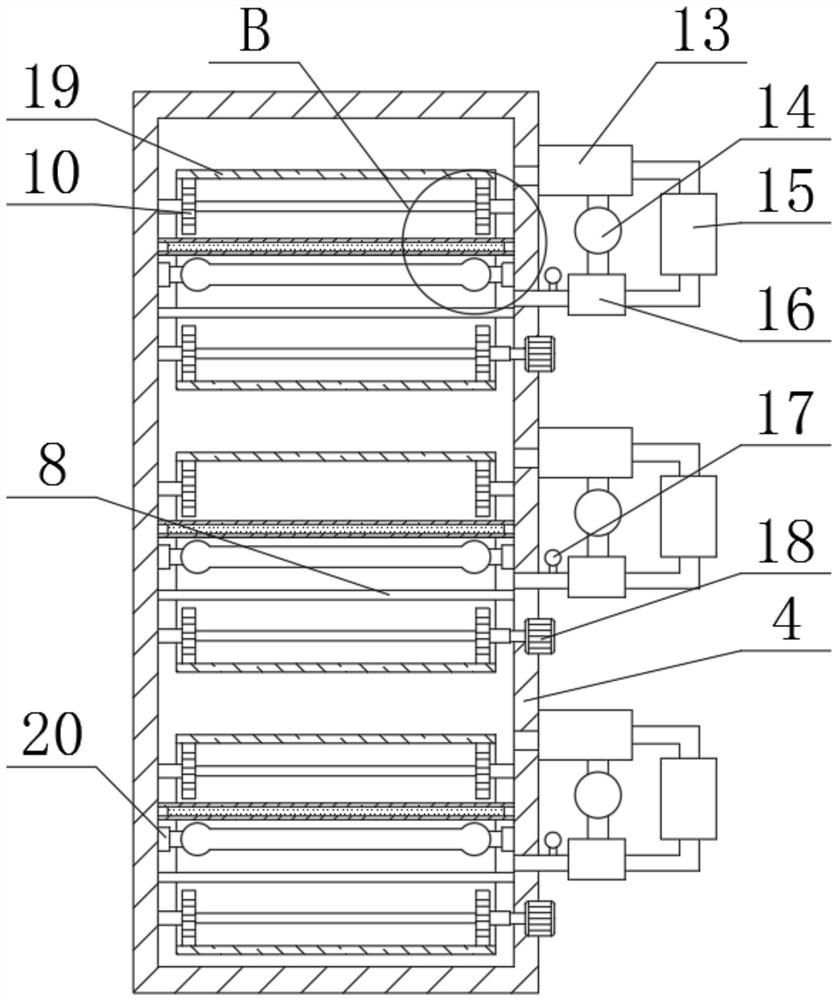

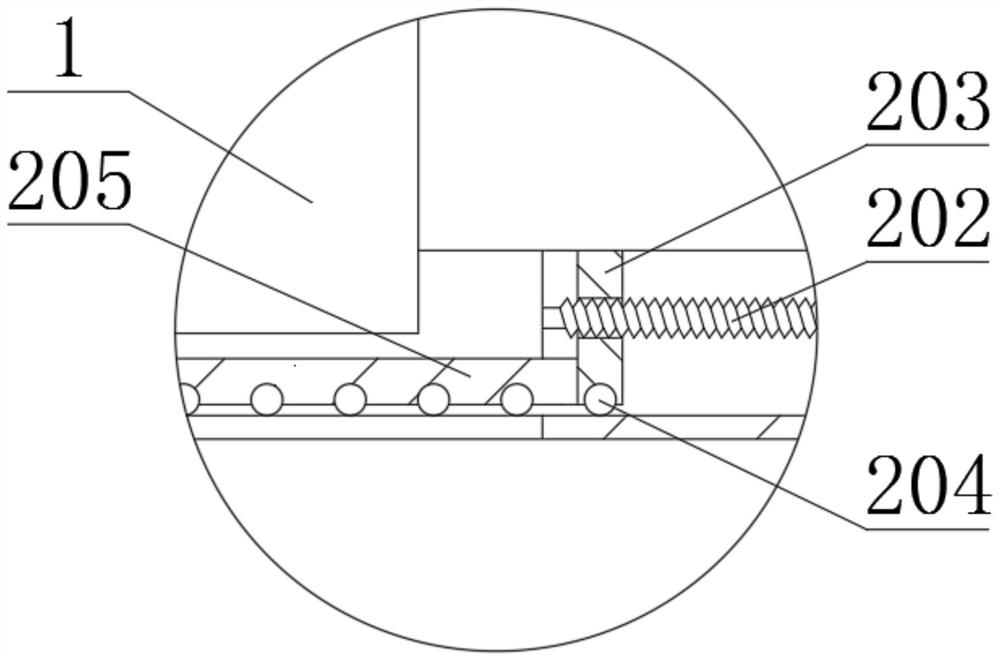

Ultrasonic wave and dry air combined production line drying equipment

PendingCN111707060AWill not affect normal feedingAvoid enteringDrying solid materials without heatDrying gas arrangementsProduction lineEngineering

The invention relates to the technical field of food washing, in particular to ultrasonic wave and dry air combined production line drying equipment. The ultrasonic wave and dry air combined production line drying equipment comprises an elevator and a drying shell; the drying shell is fixedly connected to the right end of the elevator; an anti-dust device is fixedly connected to the internal sideof the top end of the drying shell; a buffering device is fixedly connected to the internal side of the drying shell; a controller is fixedly connected to the right end of the drying shell; a door plate is rotationally connected to the right end of the drying shell through a hinge; a collection box is arranged at the bottom end of the drying shell; and a chain wheel is rotationally connected to the internal side of the drying shell. According to the ultrasonic wave and dry air combined production line drying equipment, by arranging a stainless steel water pipe, an insulation pipe, a condensingdehumidifier, a centrifugal fan, an air energy heat pump and a heating heat exchanger, the labor is saved through continuous conveying, and the labor intensity is reduced; and ultrasonic wave and static electricity are combined with dry air with a heat pump as a heat source, the product is sterilized and uniformly water-evaporated under the double effect of the ultrasonic wave and the static electricity at a lower temperature, and therefore, the drying time is shortened and is 1 / 4 of the common drying time.

Owner:福建一创机械设备有限公司

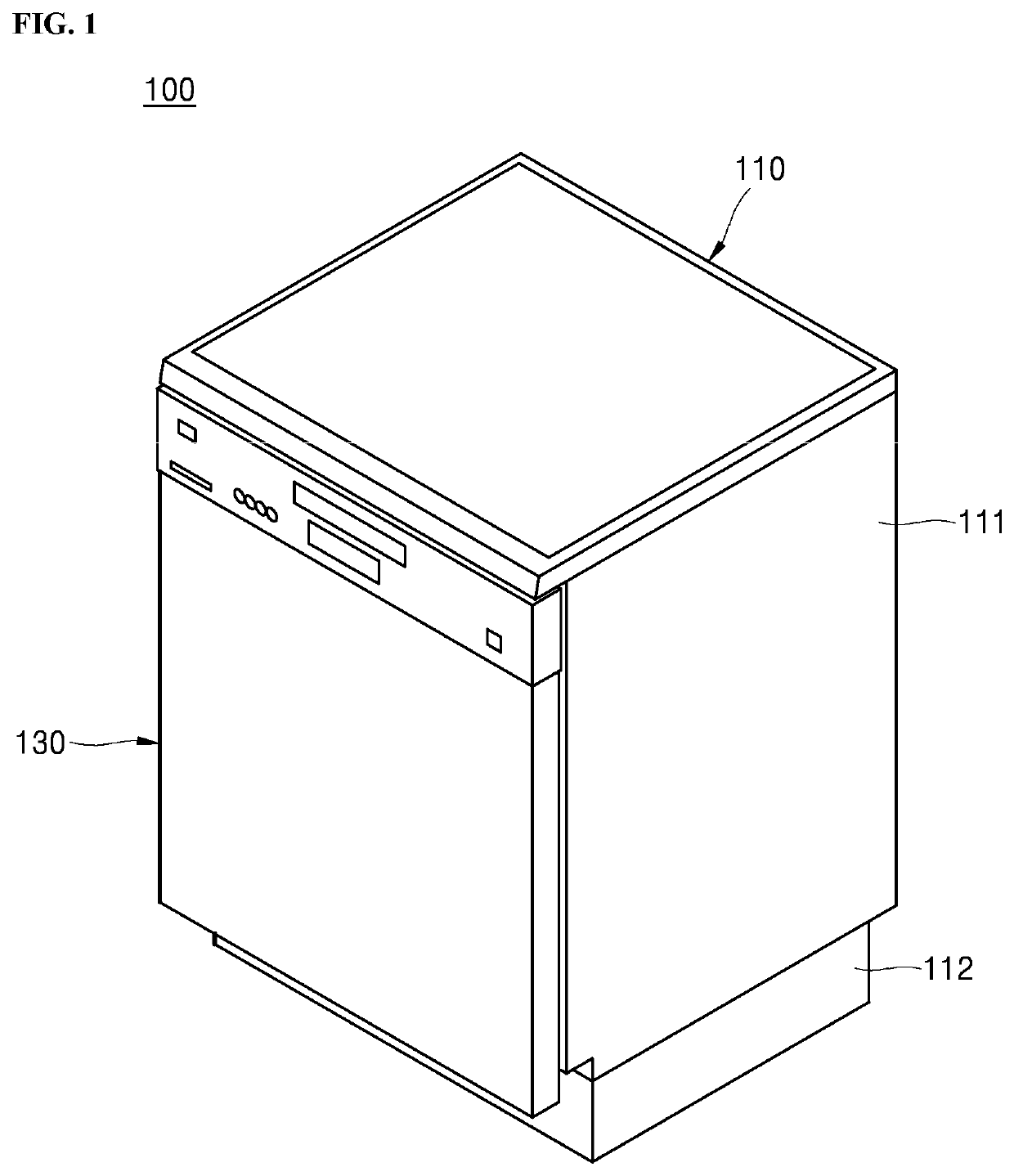

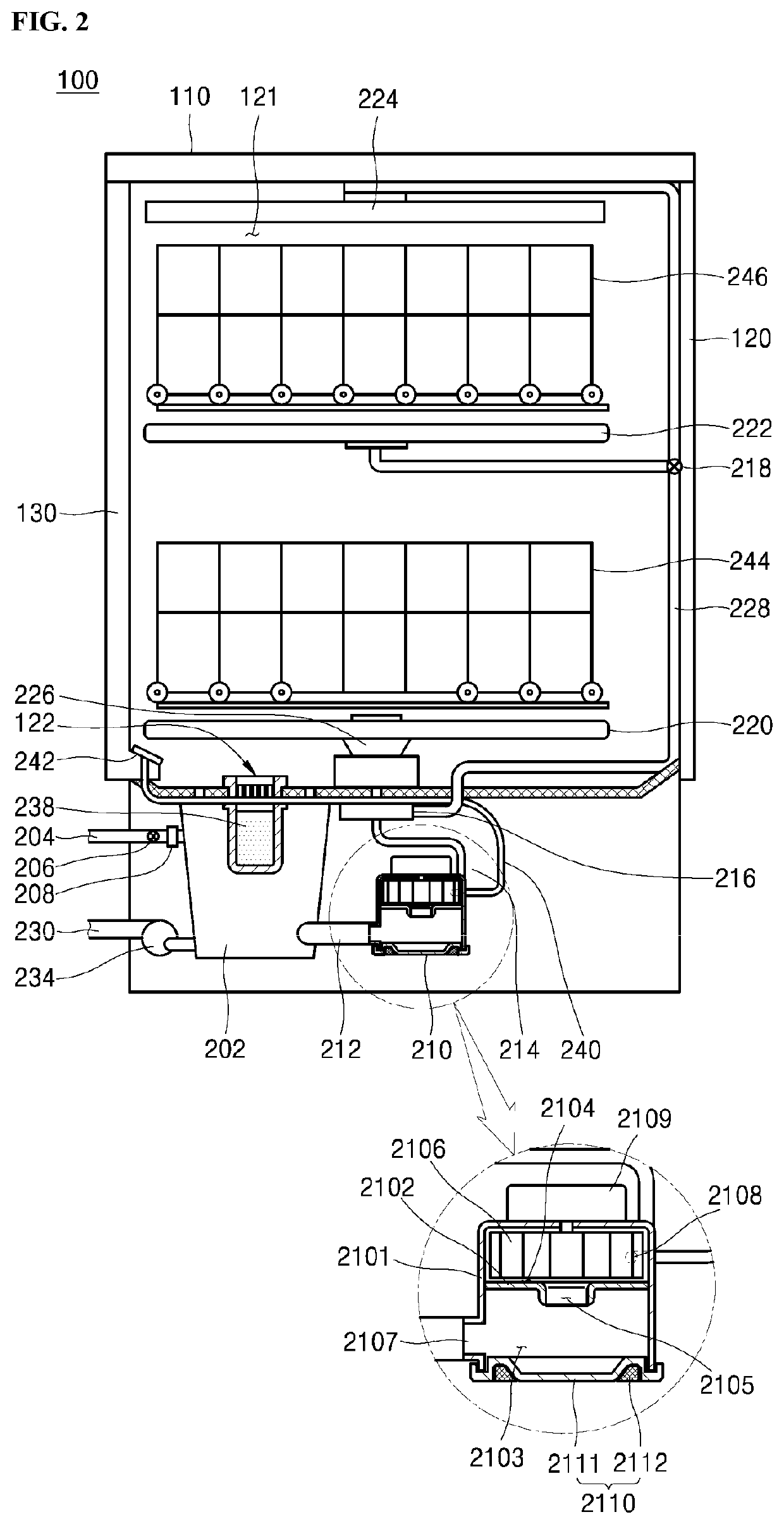

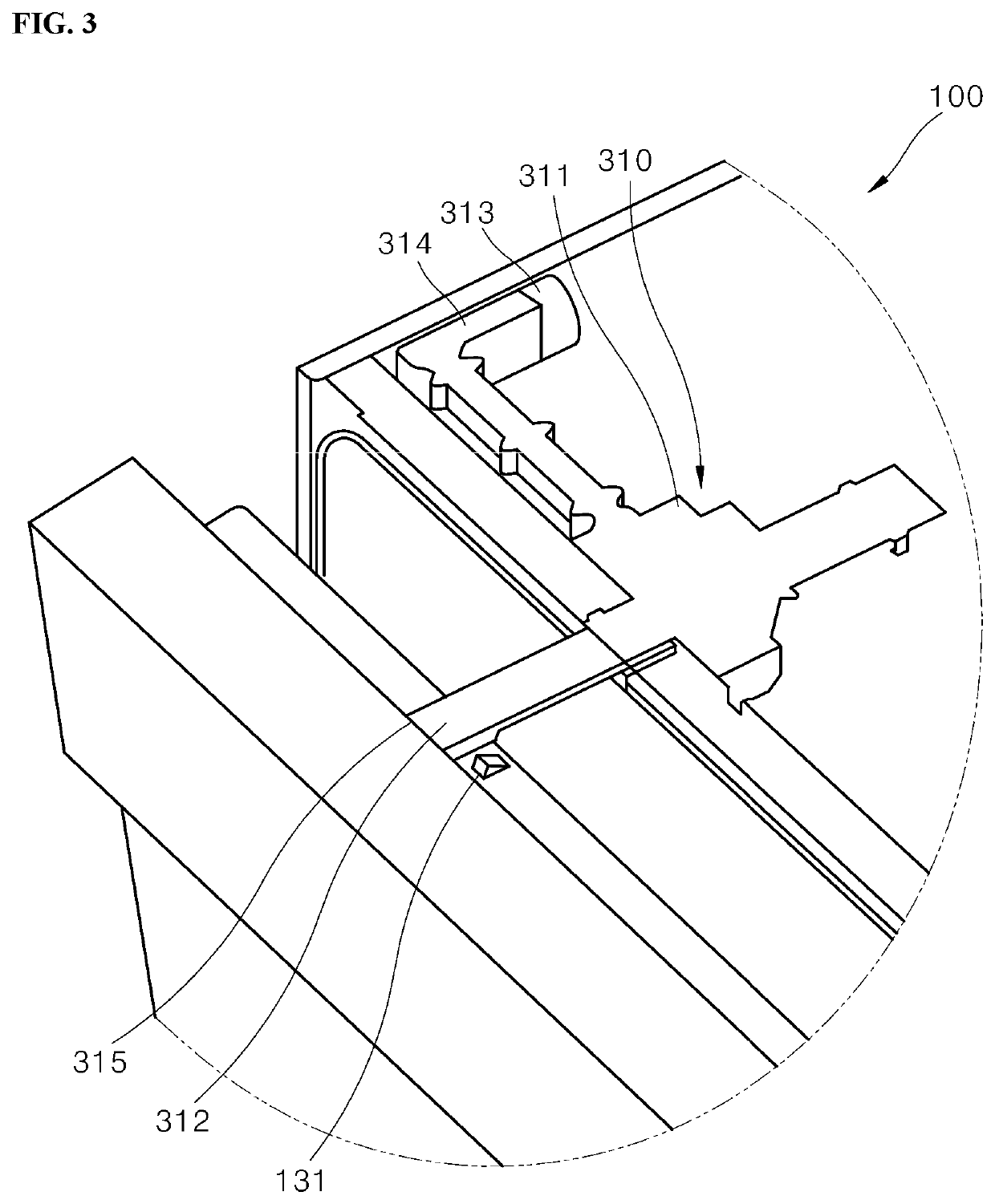

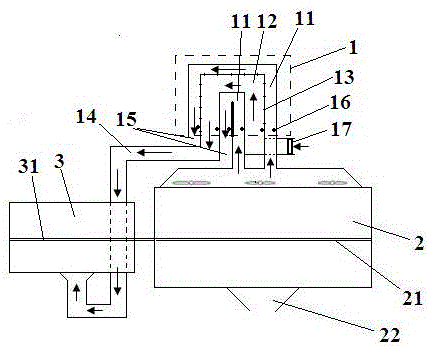

Dishwasher

PendingUS20210353125A1Improve drying process efficiencyImprove drying efficiencyTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionProcess engineeringThermodynamics

A dishwasher is disclosed. When the dishwasher performs a drying process, the dishwasher increases a temperature of a washing space before air inside the washing space is discharged, thereby maintaining the temperature of the washing space at an appropriate drying temperature and increasing efficiency of the drying process.

Owner:LG ELECTRONICS INC

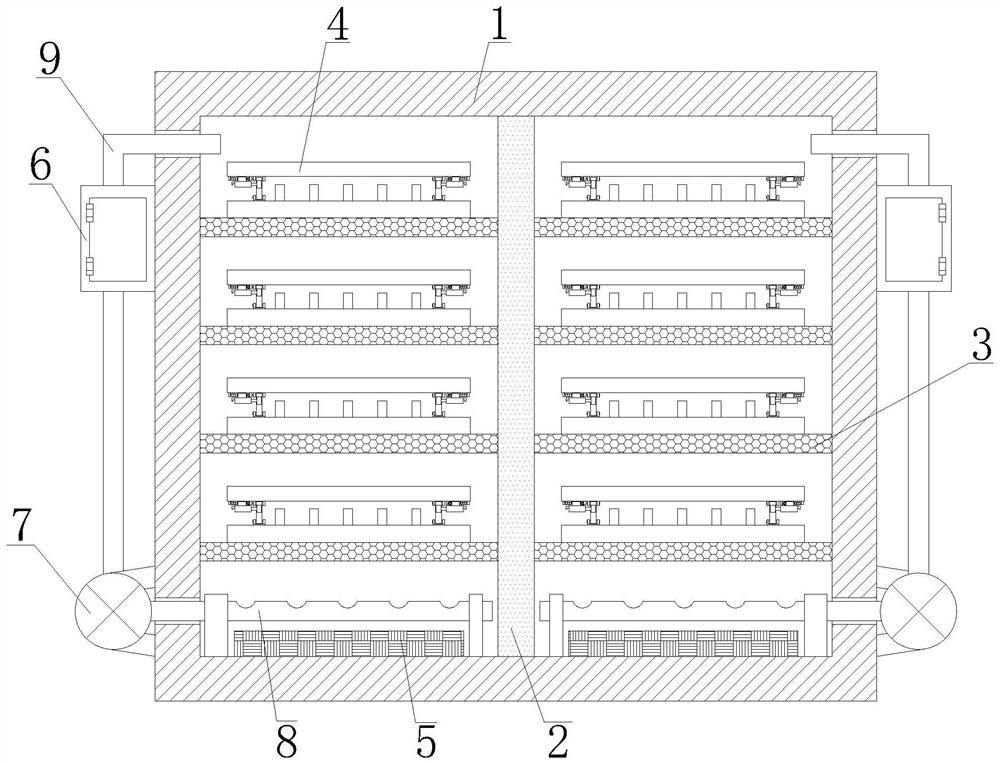

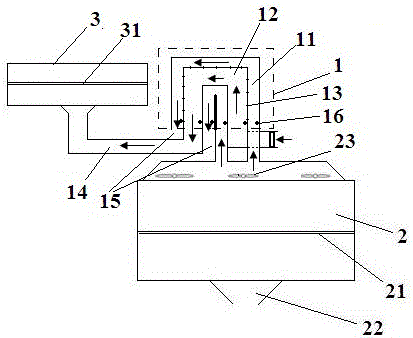

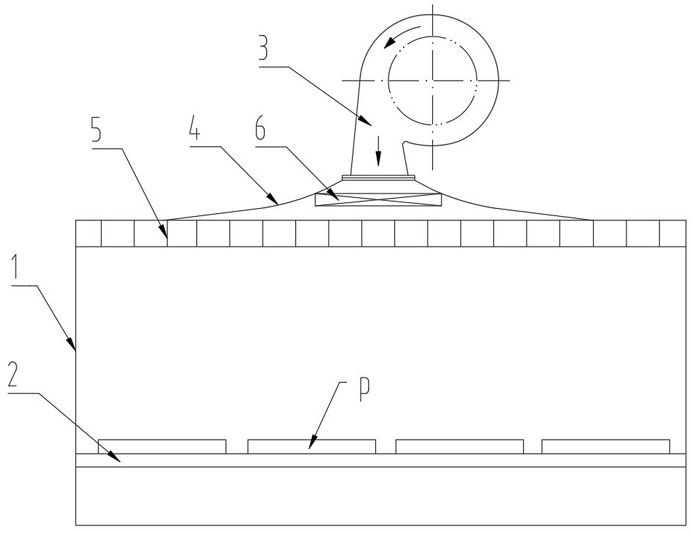

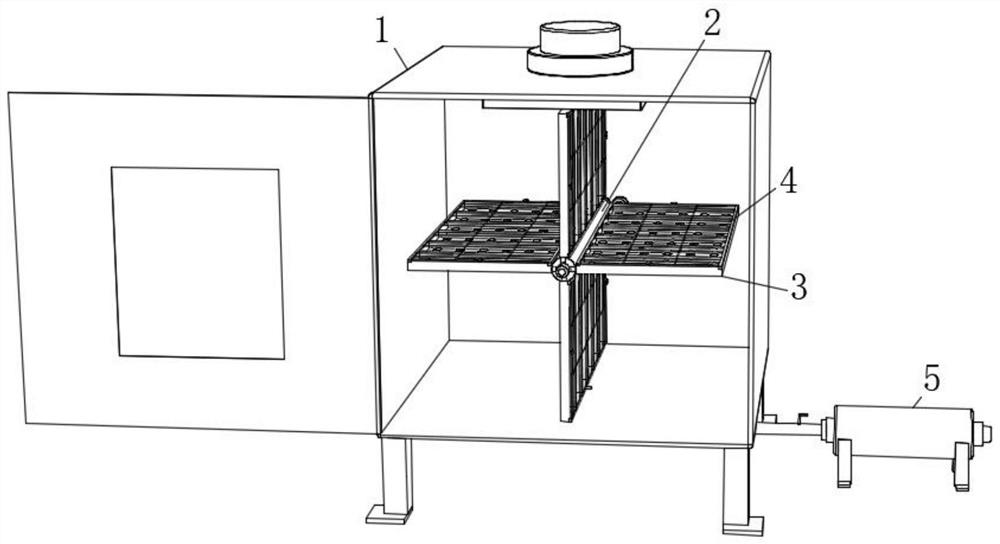

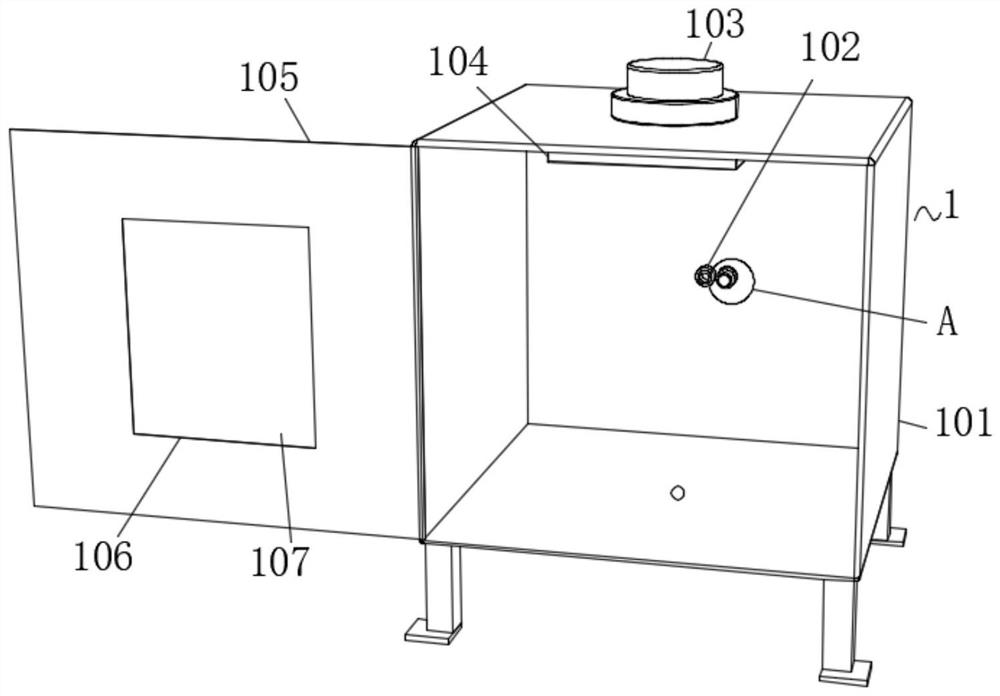

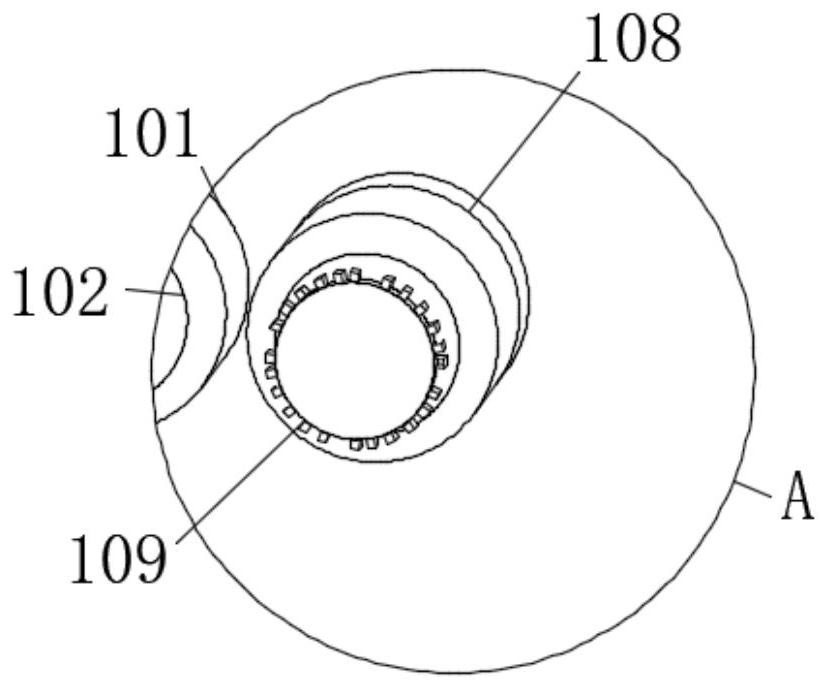

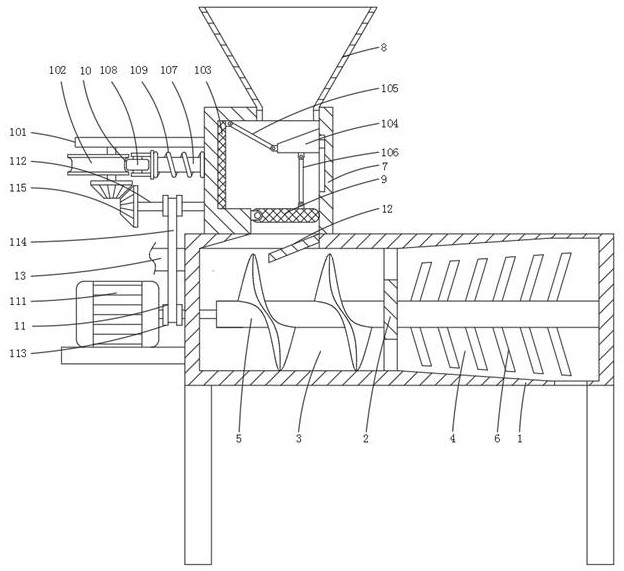

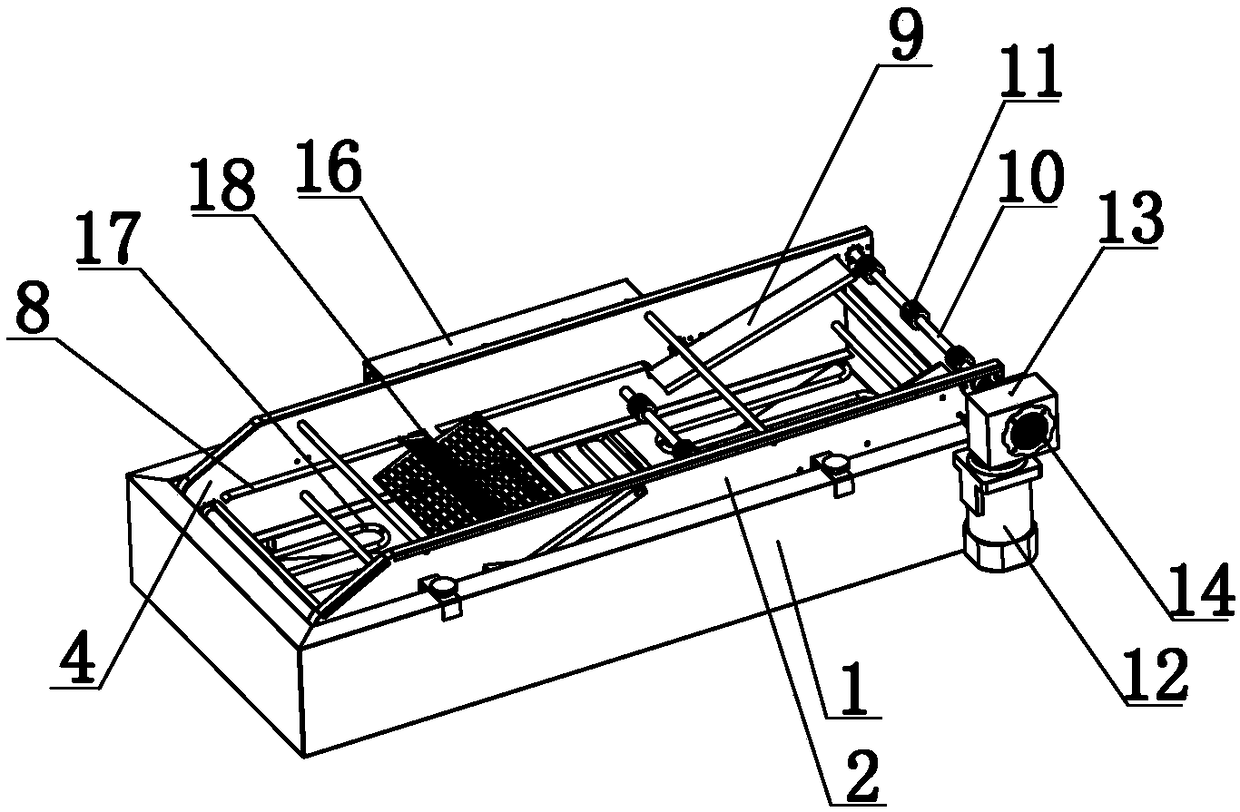

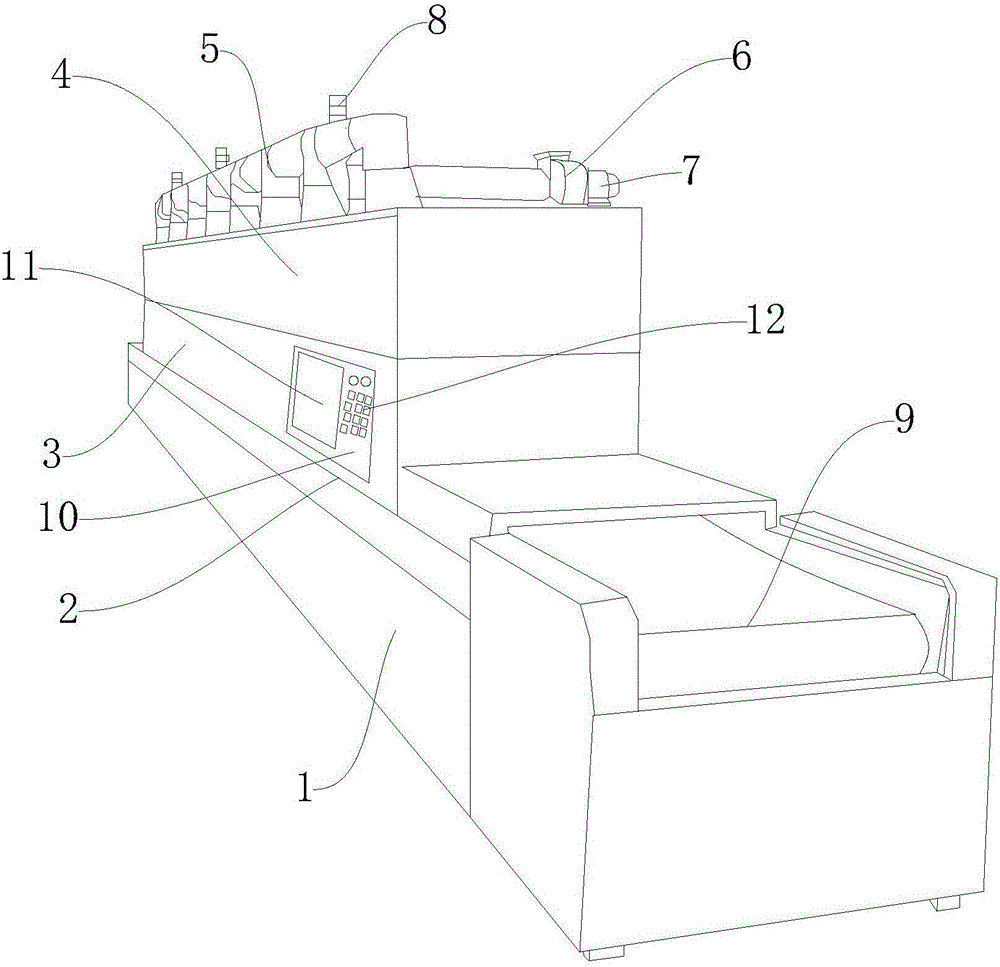

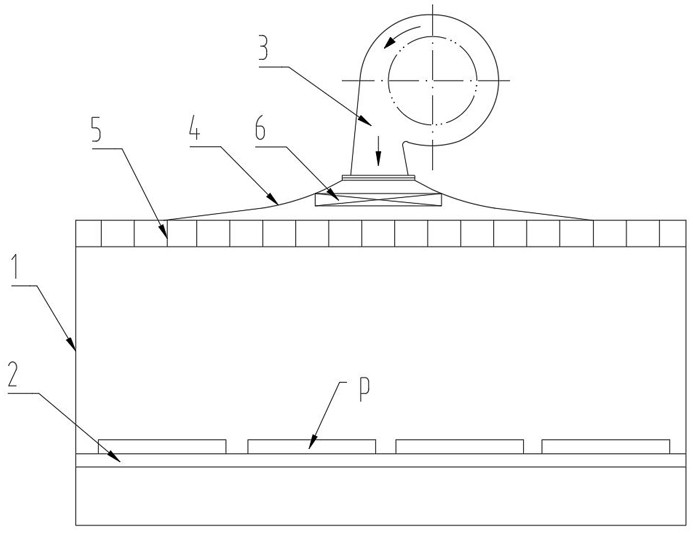

Drying device for ceramic tile drying treatment

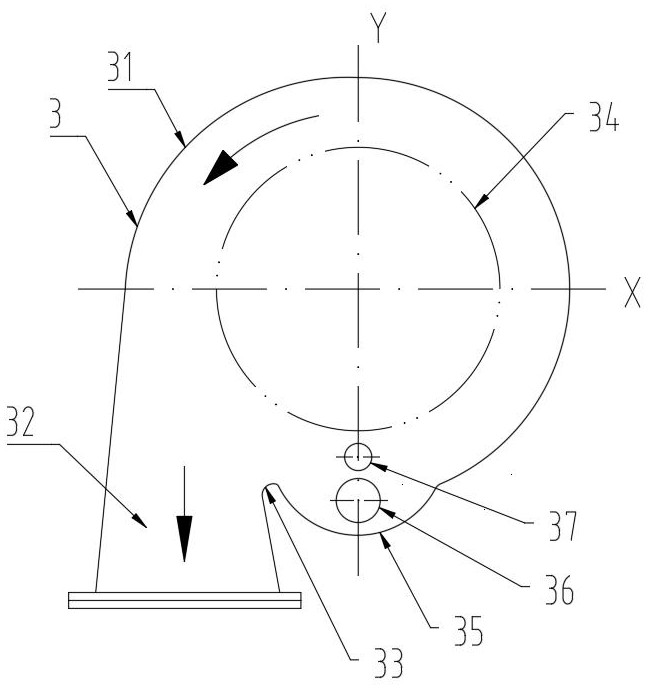

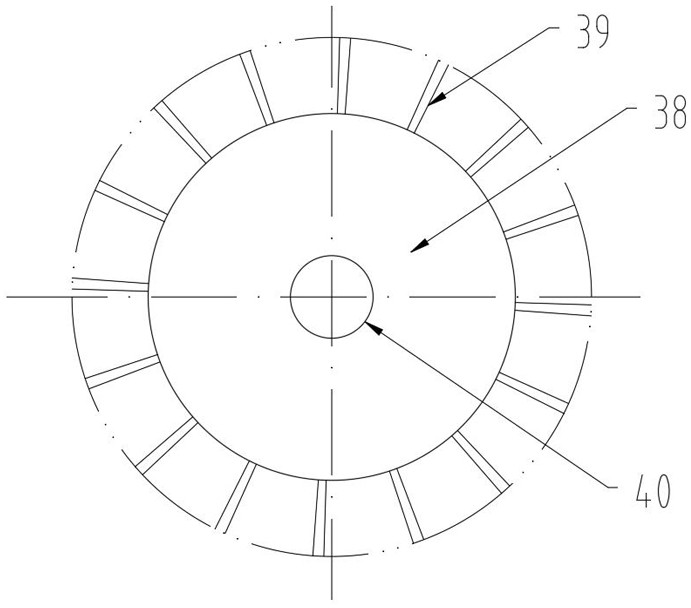

ActiveCN113028803AImprove drying process efficiencyImprove the wind power of the vortexDrying gas arrangementsCeramic shaping apparatusAir volumeCeramic tiles

The invention discloses a drying device for ceramic tile drying treatment. The drying device comprises a drying treatment chamber (1), a conveying mechanism (2), an air blower (3), a conical cover (4), a rectification grid (5) and a heating mechanism (6), wherein a ceramic tile P is placed on the conveying mechanism, and the air blower comprises a volute (31), an air outlet pipe (32), a tongue part (33) and a centrifugal impeller (34). The drying device is characterized in that the air blower is provided with an X coordinate axis and a Y coordinate axis, the Y axis is parallel to the center line / axis of the air outlet pipe, the volute is provided with an arc-shaped part (35), the arc-shaped part is arranged adjacent to the tongue part, a first rotating wheel (36) and a second rotating wheel (37) are arranged between the arc-shaped part and the centrifugal impeller, and the first rotating wheel and the second rotating wheel are rotationally connected with the volute. Through the arrangement of the first rotating wheel and the second rotating wheel, the air outlet vortex wind power of the air blower can be improved / adjusted, the air outlet of the air blower has higher vortex wind power and larger air outlet amount, and therefore the drying treatment efficiency of ceramic tiles is improved.

Owner:JIANGXI CIMIC CERAMICS

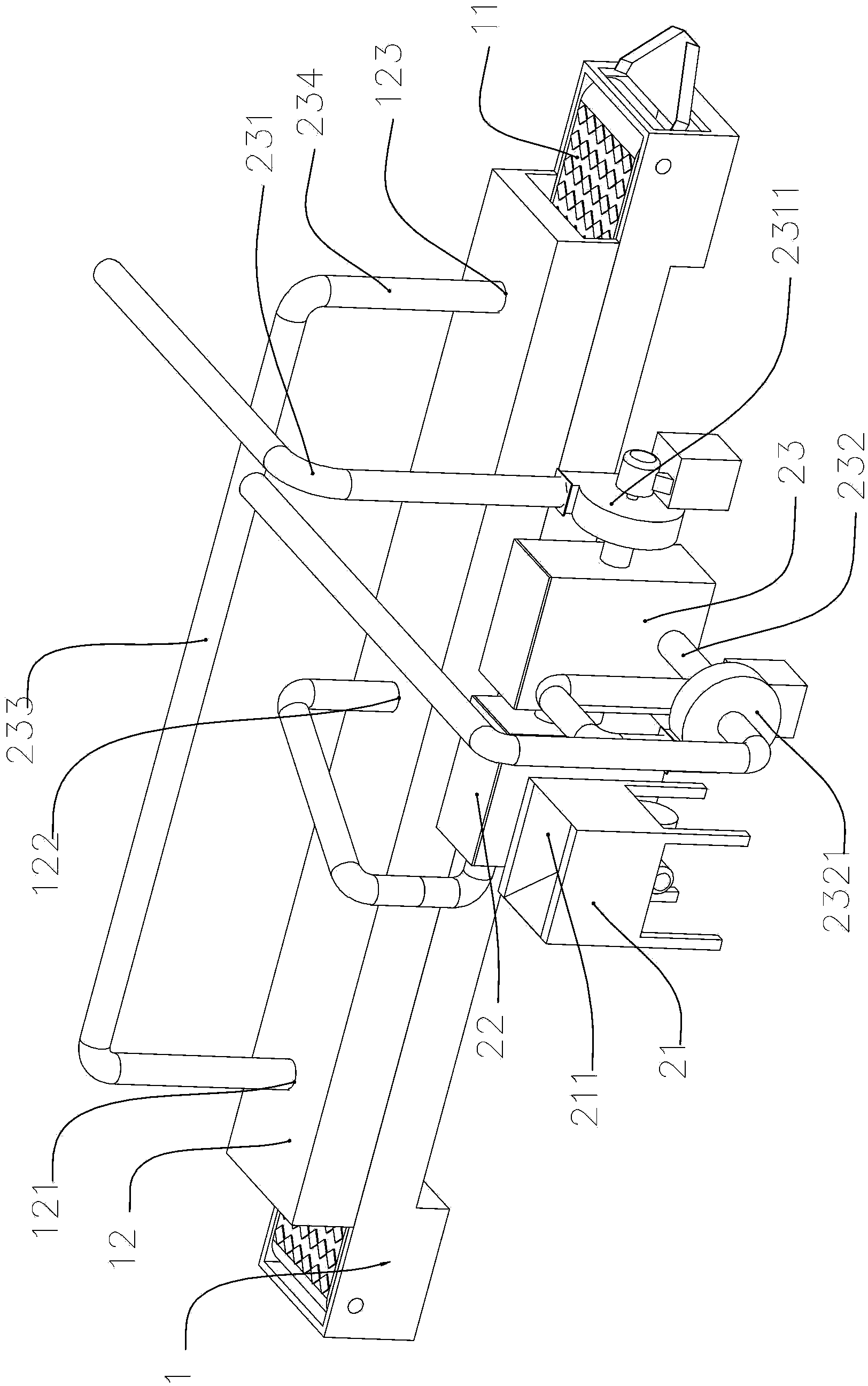

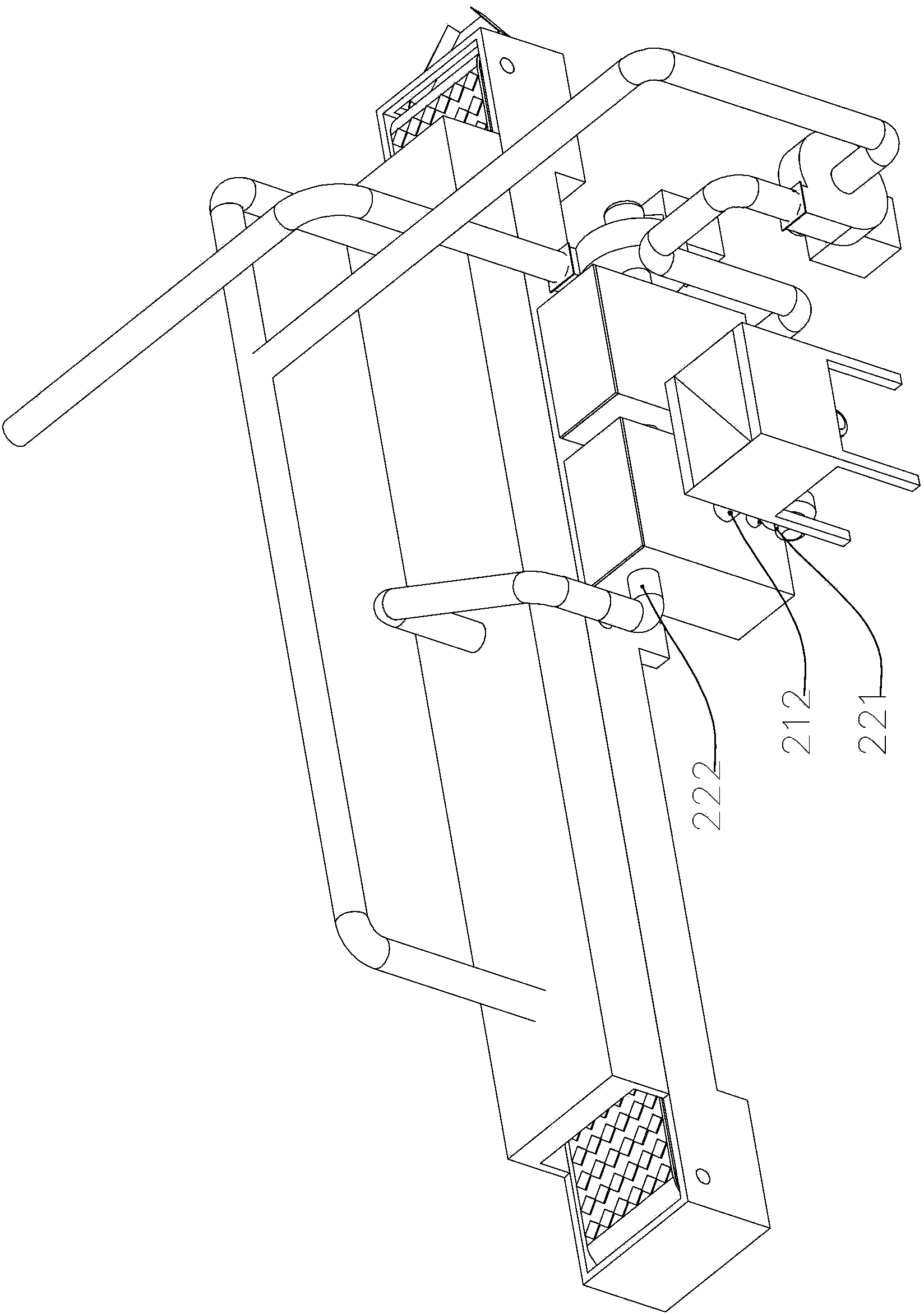

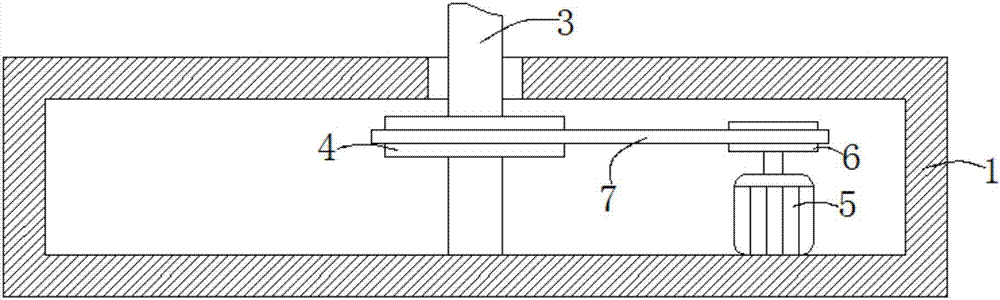

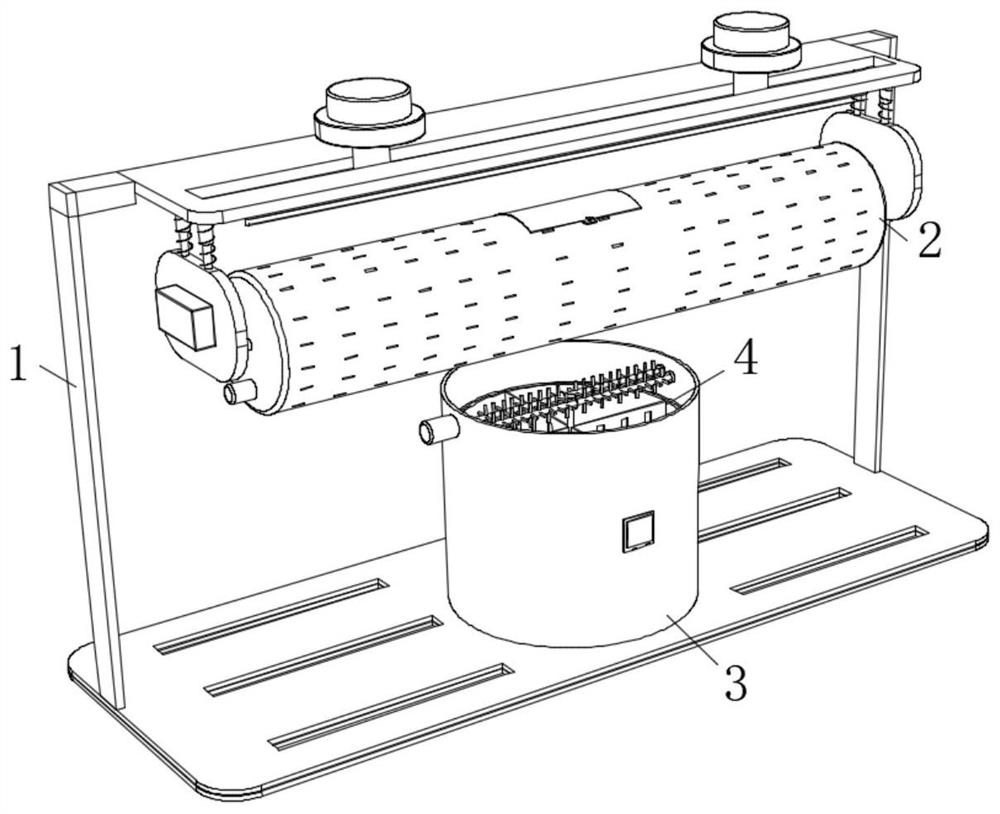

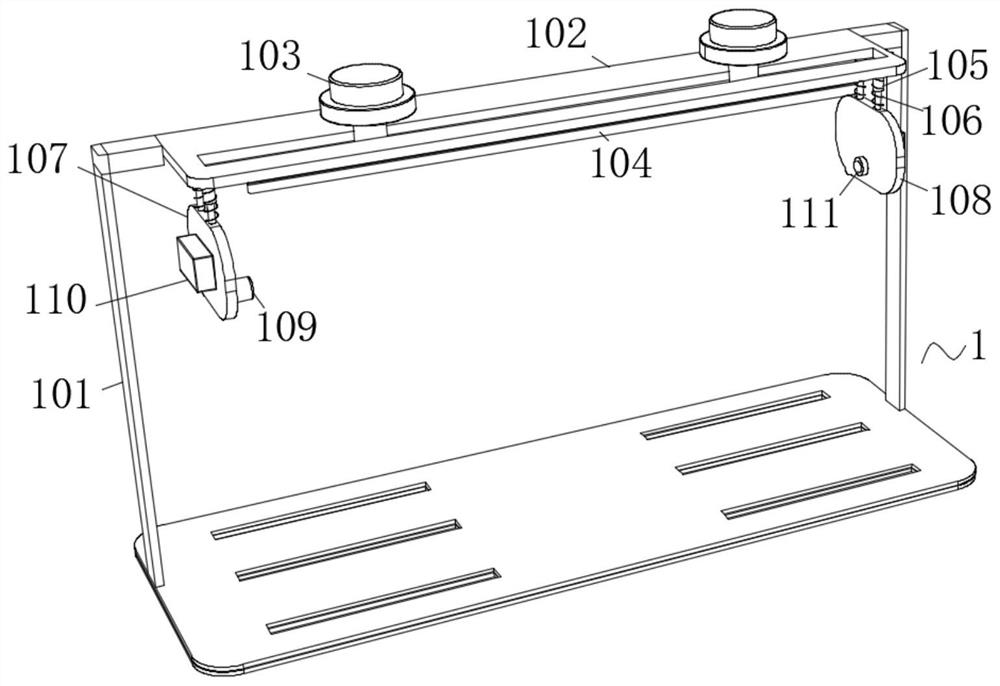

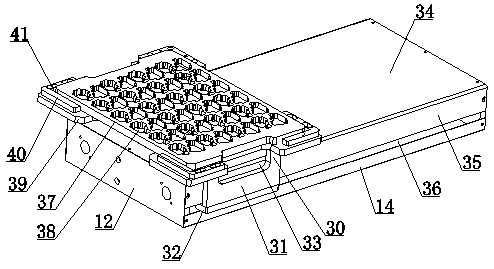

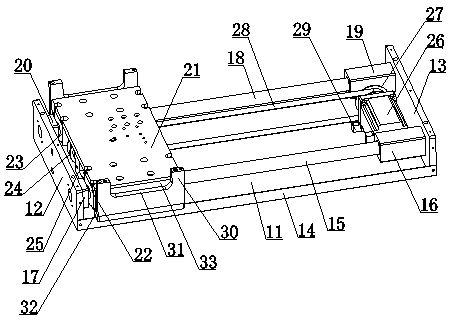

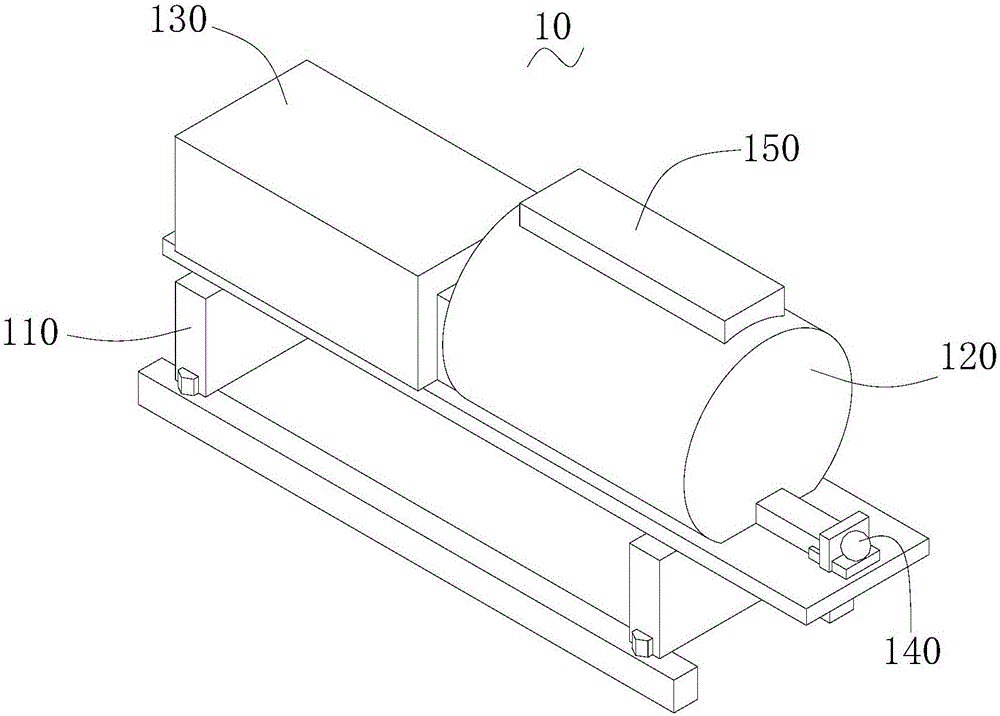

Movable manipulating device used for led module drying treatment

InactiveCN107588295AEasy to move and adjustImprove drying process efficiencyStands/trestlesIdentification meansDrive wheelDrive shaft

The invention discloses a movable manipulating device used for led module drying treatment. The movable manipulating device comprises a bottom plate, side plates are arranged at the two sides of the bottom plate respectively, and guide rails are arranged between the two sides of the side plate; guide shafts are arranged between the side plates, a moving base is arranged on the bottom plate, multiple sliding bases are arranged at the bottom of the moving base and arranged on the peripheral faces of the guide shafts in a sleeving mode, and a traction wheel is arranged at the bottom of the movingbase; a driving motor is arranged on the bottom plate, the peripheral face of a driving shaft of the driving motor is sleeved with a driving wheel, and the driving wheel is connected with the traction wheel through a driving belt. The moving base moves and drives connecting plates to move along corresponding guiding grooves, a limiting cavity moves along a buckle plate, and movement adjusting stability is higher. An installing plate can be installed on the moving base in a limited mode through a limiting plate, an led module can be firmly installed through the installing plate, and thereforemovement adjustment can be conducted on the led module. The movable manipulating device is used for led module drying treatment.

Owner:SUZHOU XINHANG MICROELECTRONICS

Drying device for wood furniture production and drying method thereof

InactiveCN112082353ADry evenlyImprove drying process efficiencyDrying gas arrangementsDrying chambers/containersPulp and paper industryMechanical engineering

The invention discloses a drying device for wood furniture production and a drying method thereof, and relates to the technical field of furniture production. The drying device comprises a drying ovenmechanism, wherein a rotating roller mechanism is arranged inside the drying oven mechanism, a material carrying assembly is arranged on the outer side of the rotating roller mechanism, a pressing assembly is arranged on the outer side of the material carrying assembly, a filtering mechanism is arranged on one side of the drying oven mechanism, the drying oven mechanism comprises a drying oven body, and a first bearing seat is fixedly arranged on the inner side wall of the drying oven body. According to the drying device, a material carrying frame is convenient to load and unload, so that rawmaterial wood of all parts in the drying oven body can be intermittently and periodically close to a drying fan cover, the raw material wood can be rapidly and uniformly dried, the drying treatment working efficiency of the raw material wood is improved, the drying treatment effect of the raw material wood for furniture production is improved, peculiar smell impurities can be filtered and adsorbed, and the situation that the external environment is easily influenced due to the fact that air in the drying oven body is directly discharged is prevented.

Owner:马鞍山思哲知识产权服务有限公司

Tea leaf drying device

PendingCN111829325AKeep dryAvoid uneven dryingPre-extraction tea treatmentTea dryingReciprocating motionAgricultural engineering

The invention relates to the technical field of tea drying, in particular to a tea leaf drying device. The tea leaf drying device comprises a drying box. The interior of the drying box is divided intoa feeding chamber and a drying chamber through a partition plate, a spiral blade is rotationally connected in the feeding chamber, and a stirring rod connected with the spiral blade is arranged in the drying chamber. The top of the drying chamber communicates with a storage box, a feeding hopper penetrates through the top of the storage box, and a baffle is rotationally connected to the bottom ofthe storage box. Through driving of a driving motor, a cam rotates to drive a push plate to do reciprocating motion in the storage box. When the push plate moves towards the feeding hopper, the baffle swings in a reciprocating mode, tea leaves in the storage box are pushed by the push plate to enter a position above a flow guide plate, and hot air is preliminarily blown to the tea leaves througha hot air pipe for primary drying. Spiral feeding is conducted through the spiral blade, the tea leaves reach the interior of the drying chamber, the stirring rod is driven to rotate, so that the tealeaves in the drying chamber are dried more evenly, and the drying effect of the tea leaves is improved.

Owner:荆门市漳河绿玉茶叶专业合作社

Pre-drying system utilizing waste heat of textile drier

InactiveCN106017059AEnable recyclingEfficient recyclingAir heatersStationary tubular conduit assembliesCold airHeating energy

The invention discloses a pre-drying system utilizing waste heat of a textile drier. The pre-drying system comprises a cloth pre-drier and a heat exchange device, wherein the heat exchange device is arranged on the top of a cloth drier, and comprises a damp hot waste gas passage and a fresh dry air passage which are separately used for pumping in damp hot waste gas and dry cold air which are emitted by the cloth drier; a heat transfer device is arranged between the damp hot waste gas passage and the fresh dry air passage; dry cold air flowing in the fresh dry air passage absorbs heat of damp hot waste gas flowing by the damp hot waste gas passage by utilizing a heat exchange principle, and then is emitted into the cloth pre-drier through a vent pipe for pre-drying cloth; and the cloth pre-drier is located on the inlet side of the cloth drier, and is used for rolling the pre-dried cloth into the cloth drier for drying. According to the drier waste heat reutilization device provided by the invention, heat energy in the waste gas emitted by the textile drier is fully utilized, and the textile cloth is pre-dried, so that effective recycle for the waste heat is realized; energy is saved; and the environment is protected.

Owner:WUXI ANG YIDA MACHINERY

Drying device for aluminium-foil paper of film laminating machine

InactiveCN108372613AEasy to heat and dryImprove drying process efficiencyFlat articlesDrive shaftDrive motor

The invention discloses a drying device for aluminium-foil paper of a film laminating machine. The drying device comprises a drying rack, wherein the top part of the drying rack is in an opening structure; a conveying rack is arranged in the drying rack and is provided with a conveying cavity; the two ends of the conveying rack are respectively provided with a driven shaft; a plurality of buttingshafts are arranged between the two sides of the conveying rack; conveying sheets and conveying plates are arranged at the two inner side walls of the conveying rack and are connected; a driving shaftis arranged at the end part of the conveying rack; a driving motor is arranged at the side wall position of the end part of the conveying rack; the front part of the driving motor is connected with the driving shaft; a temperature controller is arranged at the position of the outer-side part of the drying rack; a plurality of electric heating tubes are arranged at the inner bottom part of the drying rack and are electrically connected with the temperature controller; the electric heating tubes are arranged at the bottom part of the conveying rack. The drying device disclosed by the inventionhas the beneficial effects that by arrangement of the electric heating tubes, the aluminium-foil paper after film lamination can be conveniently heated and dried, so that the efficiency of drying treatment is greatly improved.

Owner:叶雨玲

Post-printing infrared light drying device used for silk screen printing

InactiveCN105799315AFacilitate transmissionControl rotationScreen printersPrinting press partsScreen printingDrive shaft

The invention relates to a post-printing infrared light drying device used for silk screen printing. The post-printing infrared light drying device comprises a rack. The rack is provided with a guide roller, a conveying roller and a transmission roller. The transmission roller is in butt joint with the conveying roller. A conveying belt is arranged between the guide roller and the conveying roller. The rack is provided with a material guiding plate, a driving roller and a driving motor. The driving motor is connected with the driving roller through a driving shaft. The driving roller is in butt joint with the transmission roller. The rack is provided with a supporting post. The driving motor is arranged on the supporting post. The rack is provided with a controller. The lower portion of the controller is provided with a plurality of infrared drying lamps. The end of the rack is provided with an infrared emitter which is connected with the infrared drying lamps through an optical fiber. According to the post-printing infrared light drying device used for silk screen printing, infrared light drying can be conducted on printed products through the infrared drying lamps, so that the drying treatment efficiency is greatly improved.

Owner:TAICANG XINHE PRINTING & PACKAGING

Calcining device

ActiveCN106440809AImprove pick-and-place efficiencyAvoid formingMaintainance of heating chambersCharge treatment typePre treatmentGraphite

The invention relates to a calcining device. The calcining device comprises a rack, a calcining furnace, a drying furnace, a drainage assembly, a heating assembly and a spraying device; a first sliding rail is arranged on the side wall inside the calcining furnace; a second sliding rail connected with the first sliding rail is arranged on the side wall inside the drying furnace; a drier is arranged at the bottom of the calcining furnace; the drainage assembly comprises a guide pipe and an exhaust fan; the heating assembly comprises a graphite plate, a heat conduction pipe, a heat conduction oil pump and a heat conduction oil heater; the spraying device is arranged outside the calcining furnace; the spraying device comprises an atomizer and a plurality of atomizing spray heads connected with the atomizer respectively; and the atomizing spray heads arranged at the top of the calcining furnace in a penetrating manner face the first sliding rail. According to the calcining device, powder raw materials after pretreatment are uniformly calcined on the surface during deep calcining, so that the calcining effect is outstanding, the product yield is high, and the product quality of the calcined powder raw materials is improved; and moreover, moist air at the upper end is prevented from being condensed after precooling to form condensate water, so that the drying treatment efficiency is improved.

Owner:DEMETER SUZHOU ELECTRONICS ENVIRONMENTAL MATERIALS CO LTD

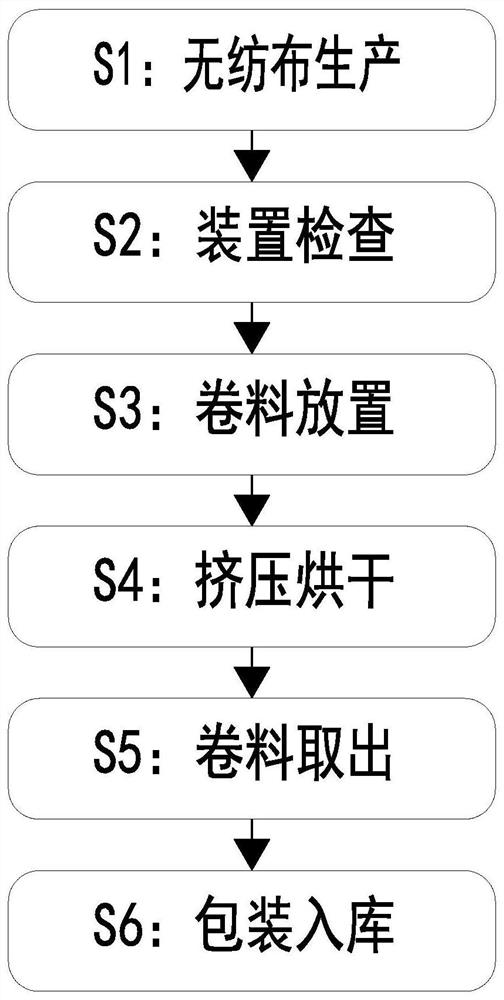

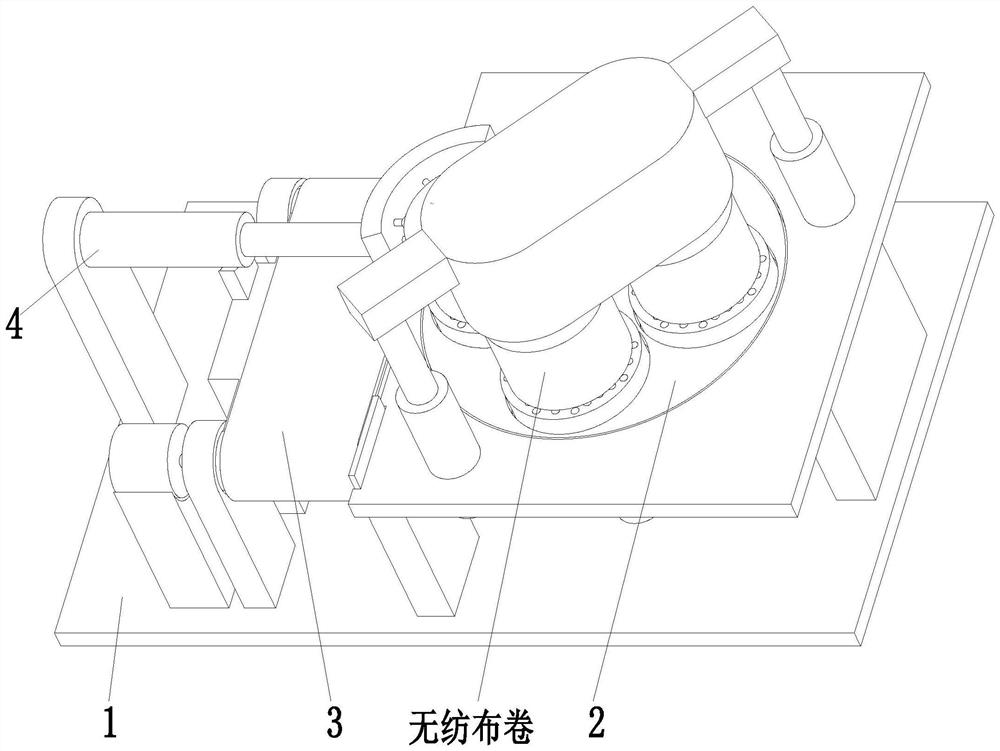

Spunlace non-woven fabric manufacturing process

ActiveCN112880317AReduce the efficiency of the dehydration processReduce drying efficiencyDrying solid materials without heatDrying chambers/containersProcess engineeringNonwoven fabric

The invention relates to a spunlace non-woven fabric manufacturing process which adopts a following spunlace non-woven fabric manufacturing device. The spunlace non-woven fabric manufacturing device comprises a base, a dewatering mechanism, a conveying mechanism, a material taking mechanism and inner clamping mechanisms, wherein the dewatering mechanism, the conveying mechanism and the material taking mechanism are sequentially arranged on the upper end face of the base from right to left, and the inner clamping mechanisms are uniformly arranged at the upper end of the dewatering mechanism. By means of the invention, the problems that in the process of dewatering and drying a coiled non-woven fabric, after the non-woven fabric in a non-woven fabric dewatering machine is dewatered for a certain time, the non-woven fabric is taken out, then a spunlace non-woven fabric roll can be dewatered again, and in the process, the dehydration treatment efficiency of the coiled spunlace non-woven fabric is reduced; and the spunlace non-woven fabric needs to be rolled into a drying room for turnover, but the efficiency of drying the rolled spunlace non-woven fabric is reduced in the process of turnover of the spunlace non-woven fabric can be solved.

Owner:江苏启宸新材料有限公司

Novel intelligent control running form chemical fertilizer drying device

InactiveCN106017037ACompact structureReasonable designManure dryingDrying solid materialsLiquid-crystal displayElectric machinery

The invention discloses a novel intelligent control running form chemical fertilizer drying device. The novel intelligent control running form chemical fertilizer drying device comprises a transmission control box, a supporting frame, a drying control box and a steam purification treatment box; the supporting frame is arranged on the transmission control box, the drying control box is arranged on the supporting frame, the steam purification treatment box is arranged on the drying control box, an exhaust pipeline is arranged on the steam purification treatment box, and an exhaust fan is arranged on the exhaust pipeline; a drive motor is arranged on the exhaust fan, an alarm indication lamp is arranged on the steam purification treatment box, a conveying belt is arranged on the transmission control box, an intelligent control box is arranged on the drying control box, a touch type liquid crystal display screen is arranged on the intelligent control box, and operation buttons are arranged on one side of the touch type liquid crystal display screen; and the novel intelligent control running form chemical fertilizer drying device has the beneficial effects of being compact in structure, reasonable in design and high in chemical fertilizer drying processing efficiency.

Owner:司美贞

Drying treatment method for ceramic blank drying process

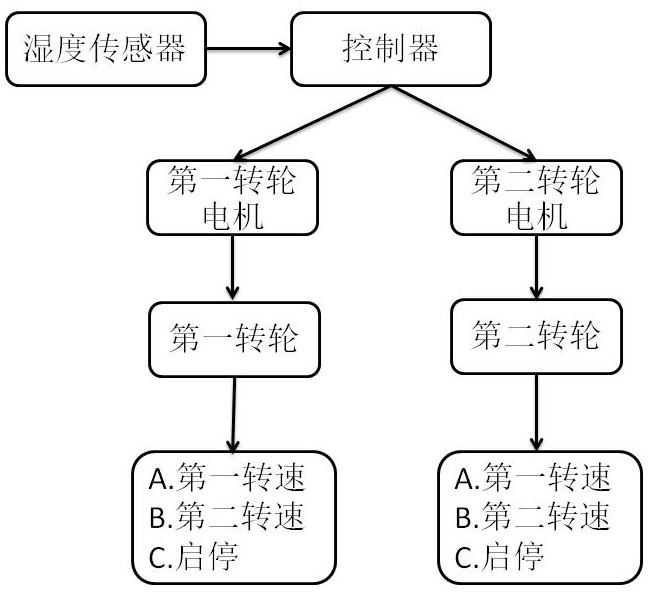

ActiveCN113048768AImprove drying process efficiencyLarge air volumeDrying gas arrangementsCeramic shaping apparatusManufacturing engineeringMoisture sensor

The invention discloses a drying treatment method for a ceramic blank drying process. The method involves a drying device and a controller. The drying device comprises a drying treatment chamber, a conveying mechanism, an air blower, a conical cover, a rectification grid and a heating mechanism. A ceramic blank is placed on the conveying mechanism, and the air blower comprises a volute, an air outlet pipe, a tongue part and a centrifugal impeller. The method is characterized in that the volute is provided with an arc-shaped part, a rotating wheel is arranged between the arc-shaped part and the centrifugal impeller, the rotating wheel is driven by a rotating wheel motor to rotate or start and stop, and the method comprises the following steps that (1) a humidity sensor collects the drying degree of the ceramic blank and transmits a signal to the controller; (2) the controller controls the actions of the rotating wheel motor according to the signal; and (3) the rotating wheel motor controls the starting, stopping and rotating speed of the rotating wheel. By arranging the first rotating wheel and the second rotating wheel and controlling the rotating speeds of the first rotating wheel and the second rotating wheel, the air outlet vortex wind power of the air blower can be increased / adjusted, air exhausting of the air blower has higher vortex wind power, and therefore the drying treatment efficiency of the ceramic blank is improved.

Owner:JIANGXI CIMIC CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com