Drying processing technology and drying processing device for thunberg fritillary bulb

A technology of processing technology and processing device, which is applied in the field of drying processing technology and drying processing device of fritillary fritillaria, can solve the problems of long drying time and low drying processing efficiency, and achieve low cost and high drying processing efficiency. The effect of high efficiency and high selling price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

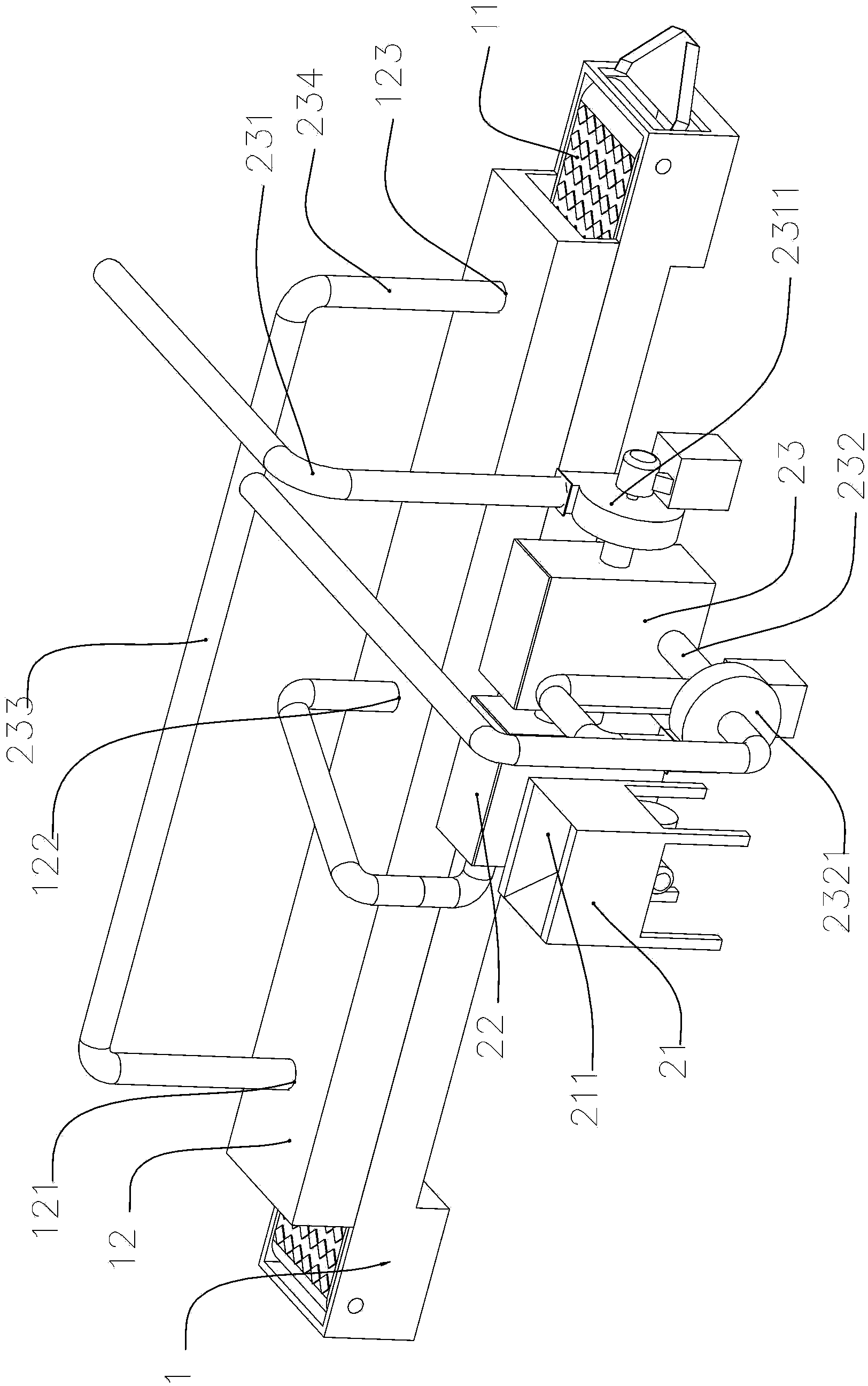

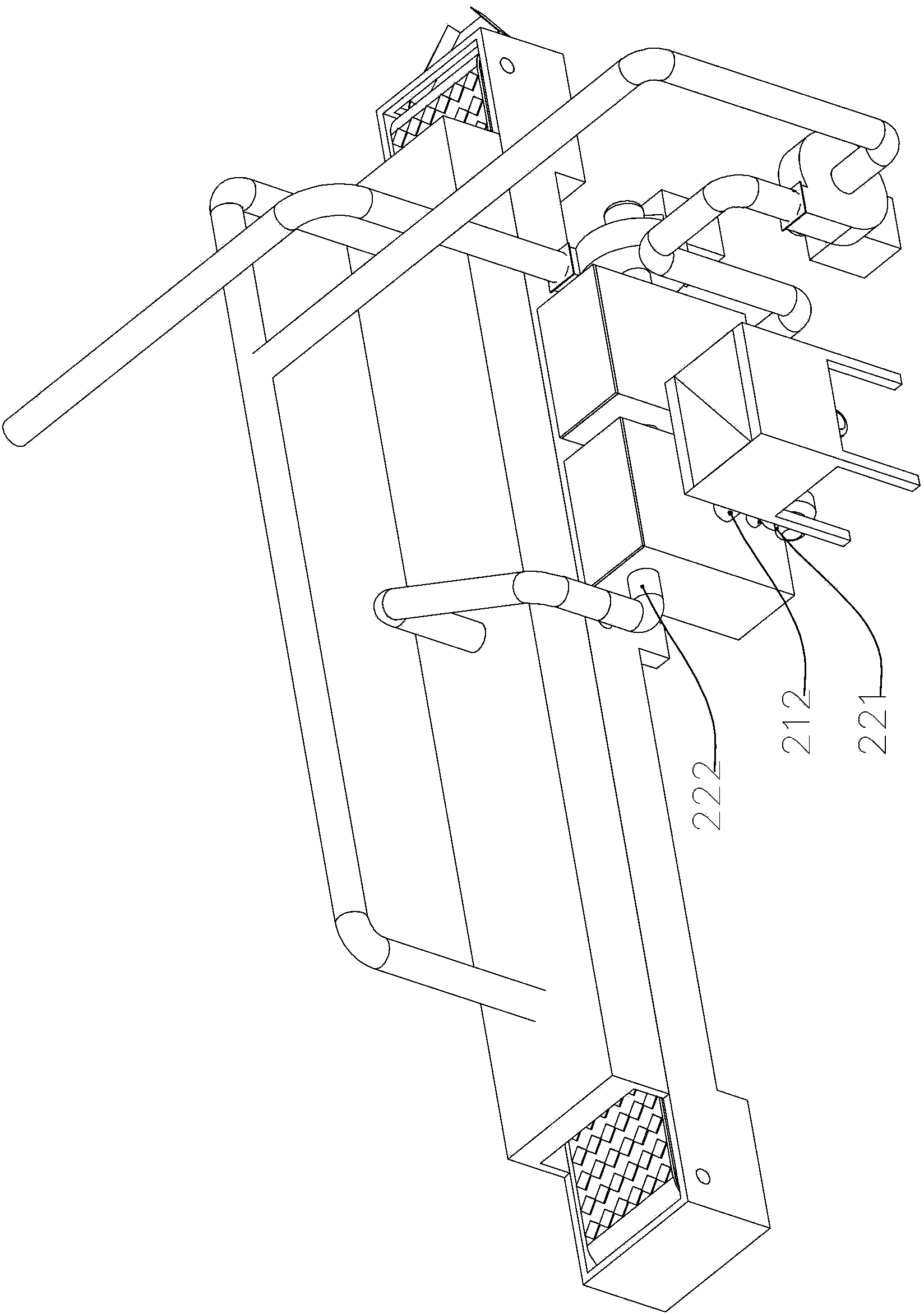

Image

Examples

Embodiment 1

[0034] (1) Rinse the fresh fritillaria, and drain on the bamboo raft;

[0035] (2) Slice Fritillaria fritillata, the slice thickness is 3mm;

[0036] (3) Put the Fritillaria slices on the feed port of the conveyor belt of the tunnel hot air dryer, control the transmission speed of the conveyor belt to 56.5cm / min, and the conveyor belt along the 0-- The hot air temperature of the 3.5m tunnel is controlled at 80°C, the hot air temperature of the 3.5-6.5m tunnel is controlled at 70°C, the hot air temperature of the 6.5m-8.5m tunnel is controlled at 60°C, and the entire drying time is controlled at 15 minutes

[0037] (4) Spread the dried Fritillaria flakes on the row of wood chips in a dry and ventilated clean room to cool to room temperature. The moisture content of the finished Fritillary Fritillaria slices is controlled below 5%, which is flat and oval, white or light yellow in color, with Dried fritillaria has a normal smell. Store and sell in large packaging in airtight pl...

Embodiment 2

[0039] (1) Rinse the fresh fritillaria, and drain on the bamboo raft;

[0040] (2) Slice Fritillaria fritillata with a thickness of 4mm;

[0041](3) Put the Fritillaria slices on the feed port of the conveyor belt of the tunnel hot air dryer, control the transmission speed of the conveyor belt to 42.5cm / min, and the conveyor belt along the 0-- The hot air temperature of the 3.5m tunnel is controlled at 100°C, the hot air temperature of the 3.5-6.5m tunnel is controlled at 80°C, the hot air temperature of the tunnel after 6.5m-8.5m is controlled at 70°C, and the entire drying time is controlled at 20 minutes

[0042] (4) Spread the dried Fritillaria flakes on the row of wood chips in a dry and ventilated clean room to cool to room temperature. The moisture content of the finished Fritillary Fritillaria slices is controlled below 5%, which is flat and oval, white or light yellow in color, with Dried fritillaria has a normal smell. Store and sell in large packaging in airtight ...

Embodiment 3

[0044] (1) Rinse the fresh fritillaria, and drain on the bamboo raft;

[0045] (2) Slice Fritillaria fritillata with a thickness of 3.5mm;

[0046] (3) Put the Fritillaria slices on the feed port of the conveyor belt of the tunnel hot air dryer, control the transmission speed of the conveyor belt to 50cm / min, and the conveyor belt along the conveying direction of the conveyor belt is 0--3.5 The temperature of the hot air in the m tunnel is controlled at 90°C, the temperature of the hot air in the 3.5-6.5m tunnel is controlled at 75°C, the temperature of the hot air in the 6.5m-8.5m tunnel is controlled at 65°C, and the entire drying time is controlled at 20 minutes

[0047] (4) Spread the dried Fritillaria flakes on the row of wood chips in a dry and ventilated clean room to cool to room temperature. The moisture content of the finished Fritillary Fritillaria slices is controlled below 5%, which is flat and oval, white or light yellow in color, with Dried fritillaria has a no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com