Patents

Literature

46results about How to "High selling price" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High yield and high quality cultivation method for cross-fertilization No.1 dwarf banana

ActiveCN103947497AModerate harvest periodIncrease productionCultivating equipmentsHarvest timePest control

The invention discloses a high yield and high quality cultivation method for cross-fertilization No.1 dwarf banana. The high yield and high quality cultivation method comprises the steps of selection and preparation of land, planting, bud reserving, water and fertilizer management, planted management, pest prevention and cure, and the like. According to the cultivation method disclosed by the invention, the cross-fertilization No.1 dwarf banana can be moderate in harvest time, the fruit yield is high, the quality is good, and the selling price is high, thus the economic performance is improved.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Apple cultivation method

InactiveCN105875310AGreat tasteRegular shapeCultivating equipmentsHorticulture methodsFruit treeSugar

The invention relates to an apple cultivation method, in particular to an apple cultivation method. The apple cultivation method comprises cultivation methods in a germination stage, a flowering stage, a young fruit stage, an expanding stage of young fruits, an expanding stage of fruit trees, and a fruit picking period. Apples cultivated by the apple cultivation method provided by the invention are good in mouthfeel, regular in fruit shape, fast in fruit expanding, good in color, and good in surface gloss, and the sugar degree and the selling price are greatly improved.

Owner:董金锋

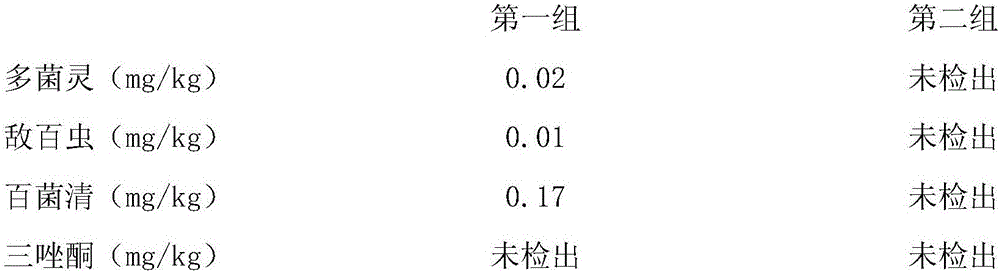

Green and ecological breeding method for pale butterfly chickens

InactiveCN103098757AReduce usageImprove the living environmentAnimal feeding stuffBird housingsDiseaseVeterinary Drugs

The invention relates to the technical field of animal husbandry breeding, in particular to a green and ecological breeding method for pale butterfly chickens. The method specifically includes that breeding under a forest is carried out by choosing a sandiness earth slope with forests, by adding safe and original ecology Chinese medicine herbs including pale butterfly flowers, caesalpinia minax hance, and liquorice poached liquid, and preventing and curing of disease of the chickens are carried out. Due to the fact that feed additives are refused, and antibiotics and veterinary drugs are avoided, the situation that the chickens bred are green products are guaranteed, besides, chicken has slight pale butterfly flowery flavor and quality is greatly improved. At the same time, land sources are furthest protected, and the purpose of green and ecological breeding is achieved.

Owner:谢建福

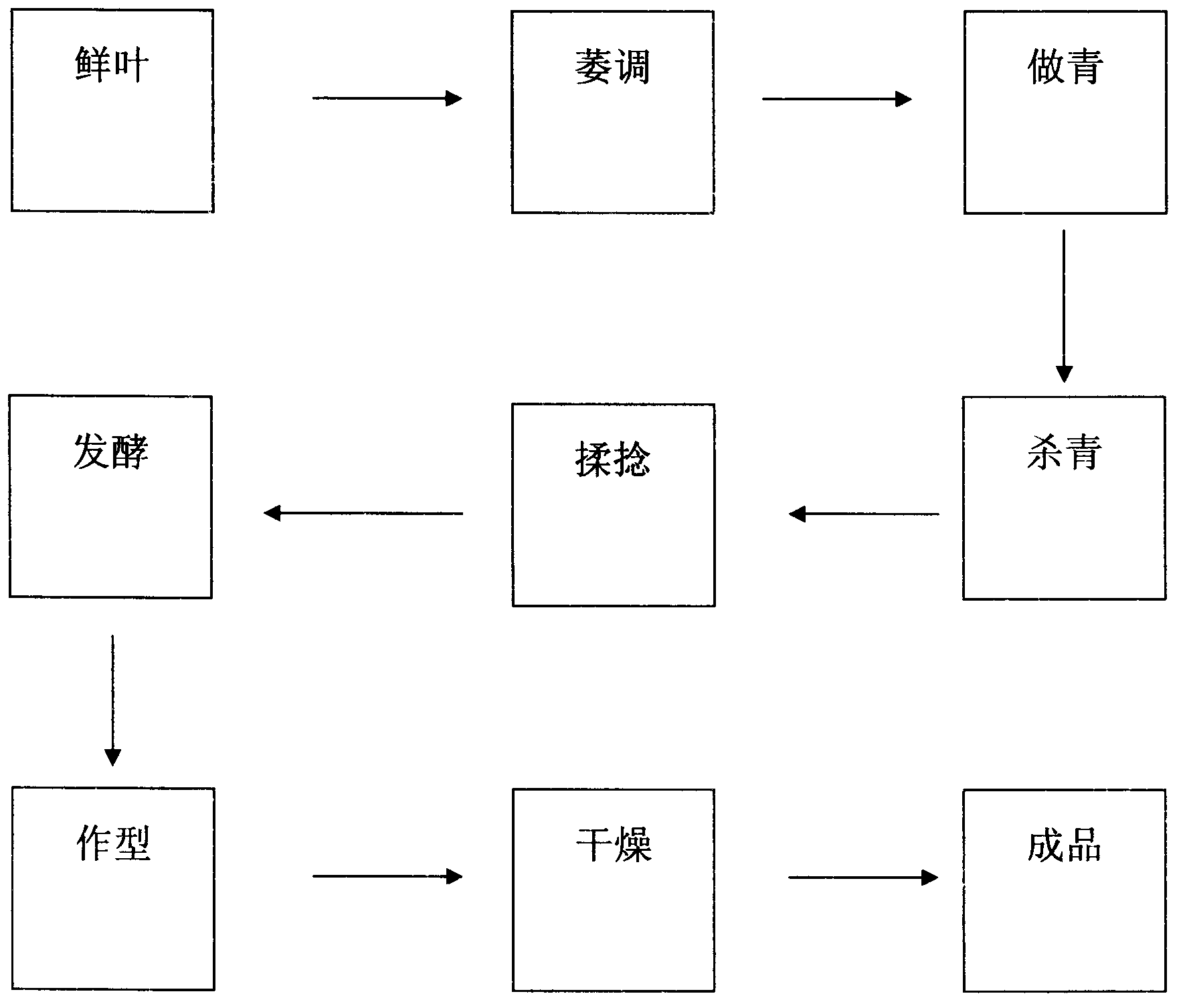

Method for processing purple-bud tea

The invention relates to the technical field of tea processing, and in particular relates to a method for processing purple-bud tea. Ordinary fresh pekoe tea is used as a raw material, and the method specifically comprises the procedures of sunning, withering, green making, water removing, rolling, fermentation, shaping and the like, wherein a main technical measure of organically combining a green tea processing process and a black tea processing process is adopted in an implementation process, and the ordinary pekoe tea is finally processed into distinctive and alternative purple tea. According to the purple tea and the processing method thereof, the technical measure is unique, and the process is simple and easy to implement; the new processed purple tea variety has the quality characteristics of both black tea and green tea so as to be unique in the market; the value of the ordinary pekoe tea is greatly improved; the tea processed by the process is high in quality and price, and has significant benefits.

Owner:GUANGXI PINGGUO LANGFU ORGANIC TEA IND CO LTD

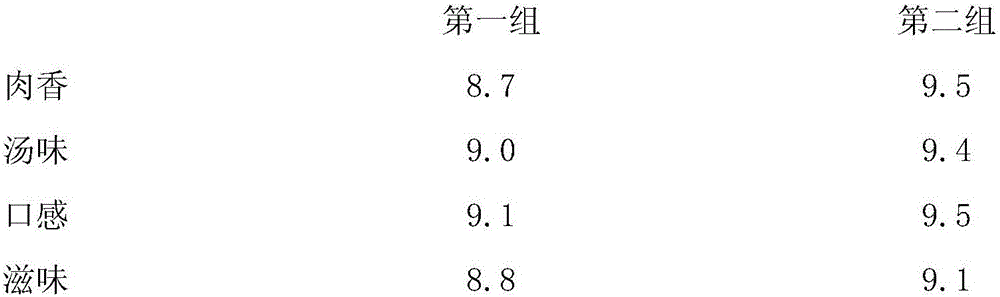

Green ecological breeding method for silky fowls

InactiveCN103931555AProtect the ecologyImprove qualityFood processingAnimal feeding stuffFowlLand resources

The invention relates to the technical field of livestock breeding, in particular to a green ecological breeding method for silky fowls. The method specifically includes the steps of selecting a sandy soil slope with woods for breeding under the woods, and adding decoction of safe and original ecological Chinese herbal medicine including buddleia officinalis, caesalpinia minax and licorice into pollution-free feed to prevent and cure diseases of silky fowl groups. Due to the fact that no feed additive is used, antibiotics and veterinary medicine are avoided, it is guaranteed that produced silky fowls are green products, a light buddleia officinali fragrance rises from silky fowl meat, and the quality is greatly improved. Meanwhile, the land resources are protected to the maximum degree, and green ecological breeding is achieved.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

Method for cultivating tender ginger in deep furrows through deep ploughing

InactiveCN104285635AImprove commodityHigh selling priceSeed and root treatmentVegetative propogationSoil preparationPest control

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

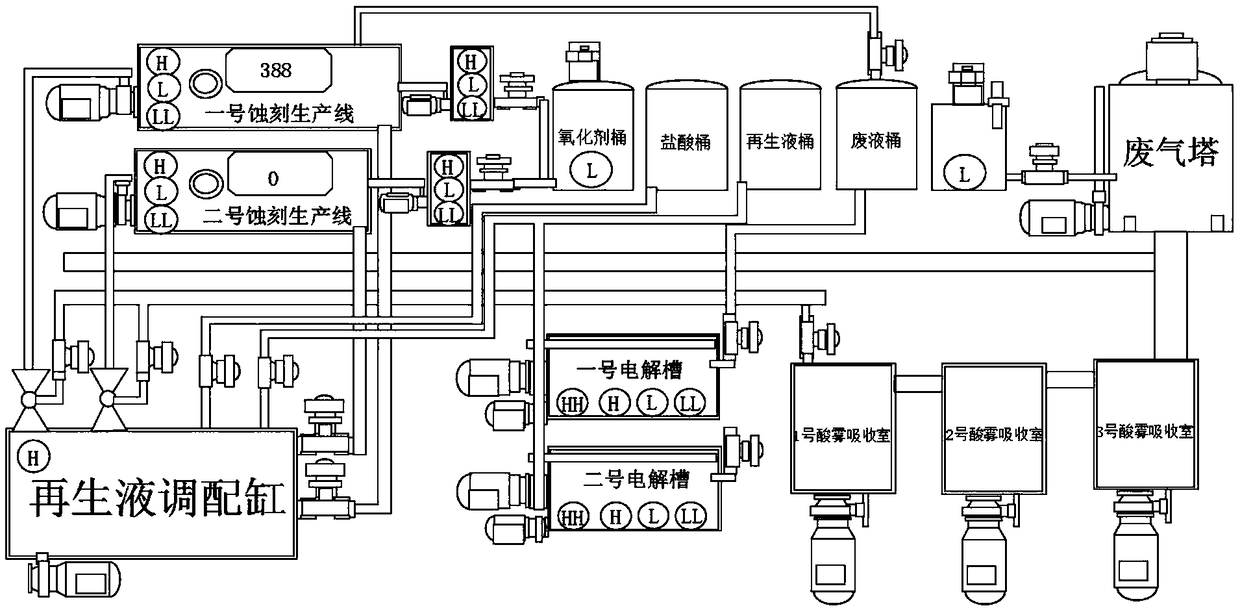

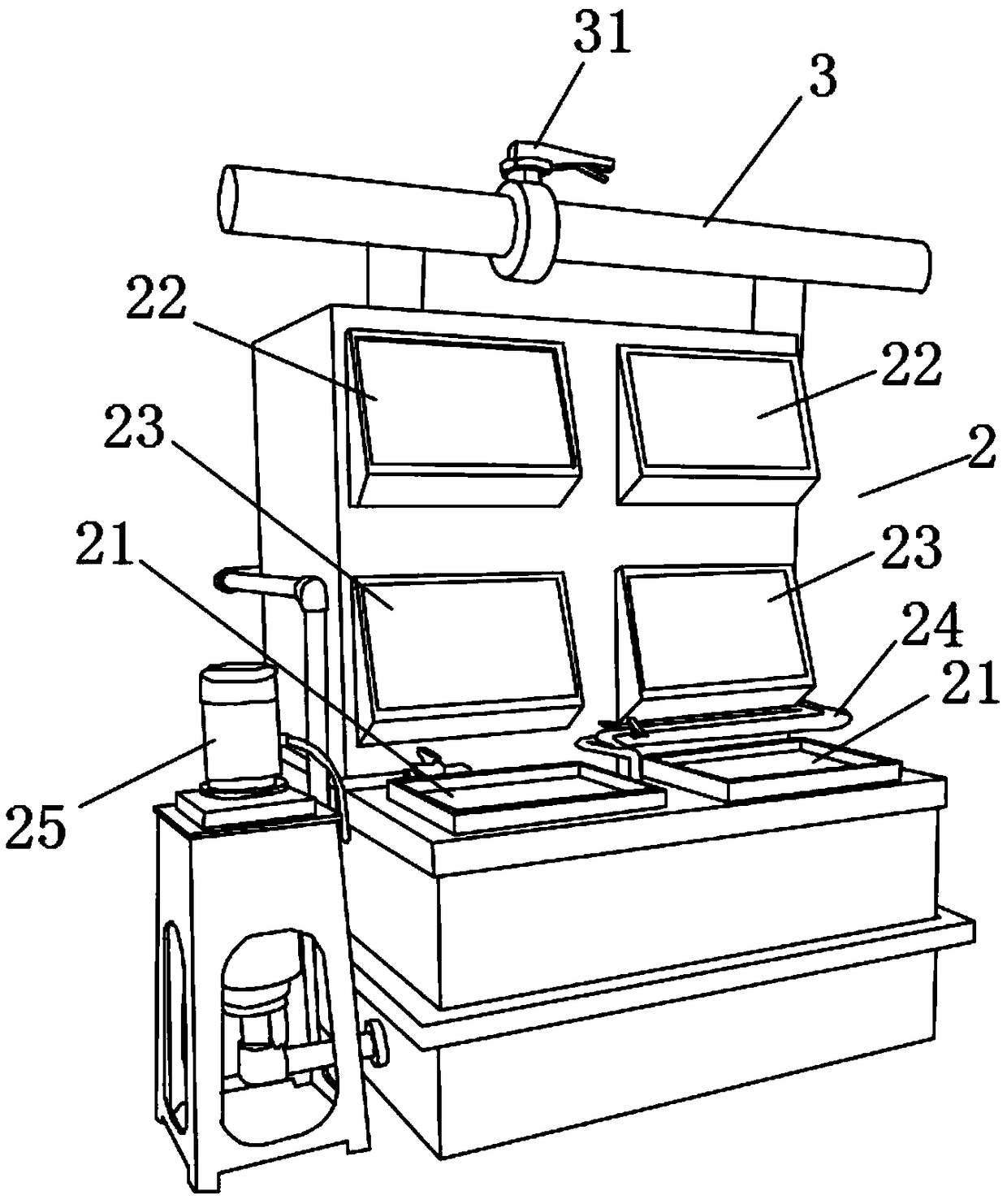

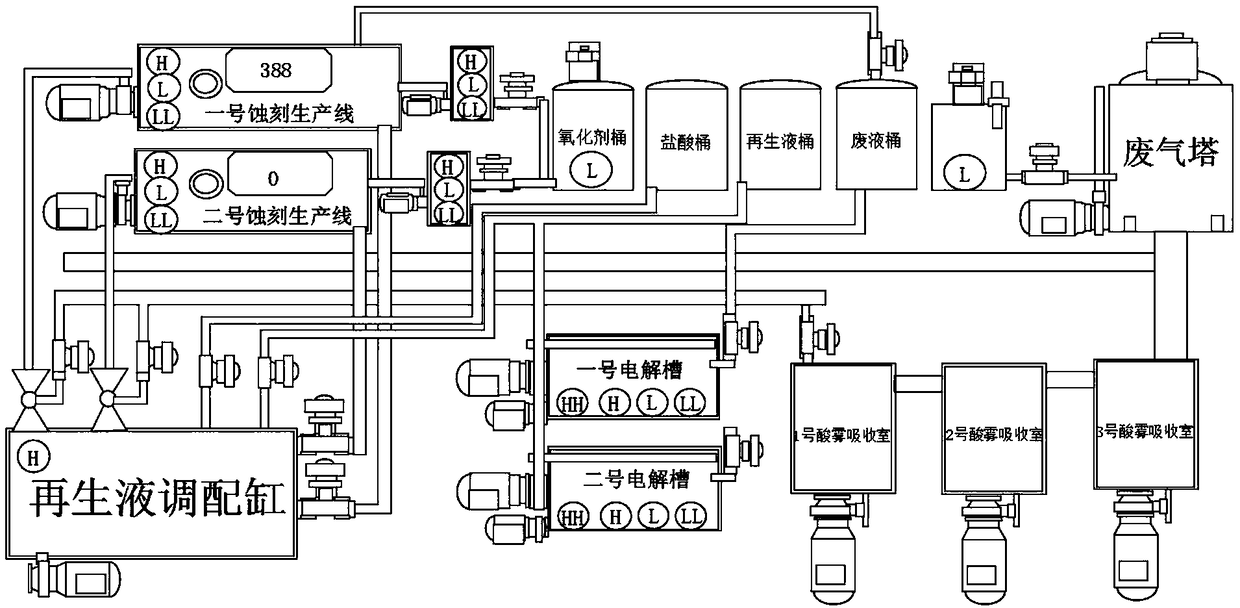

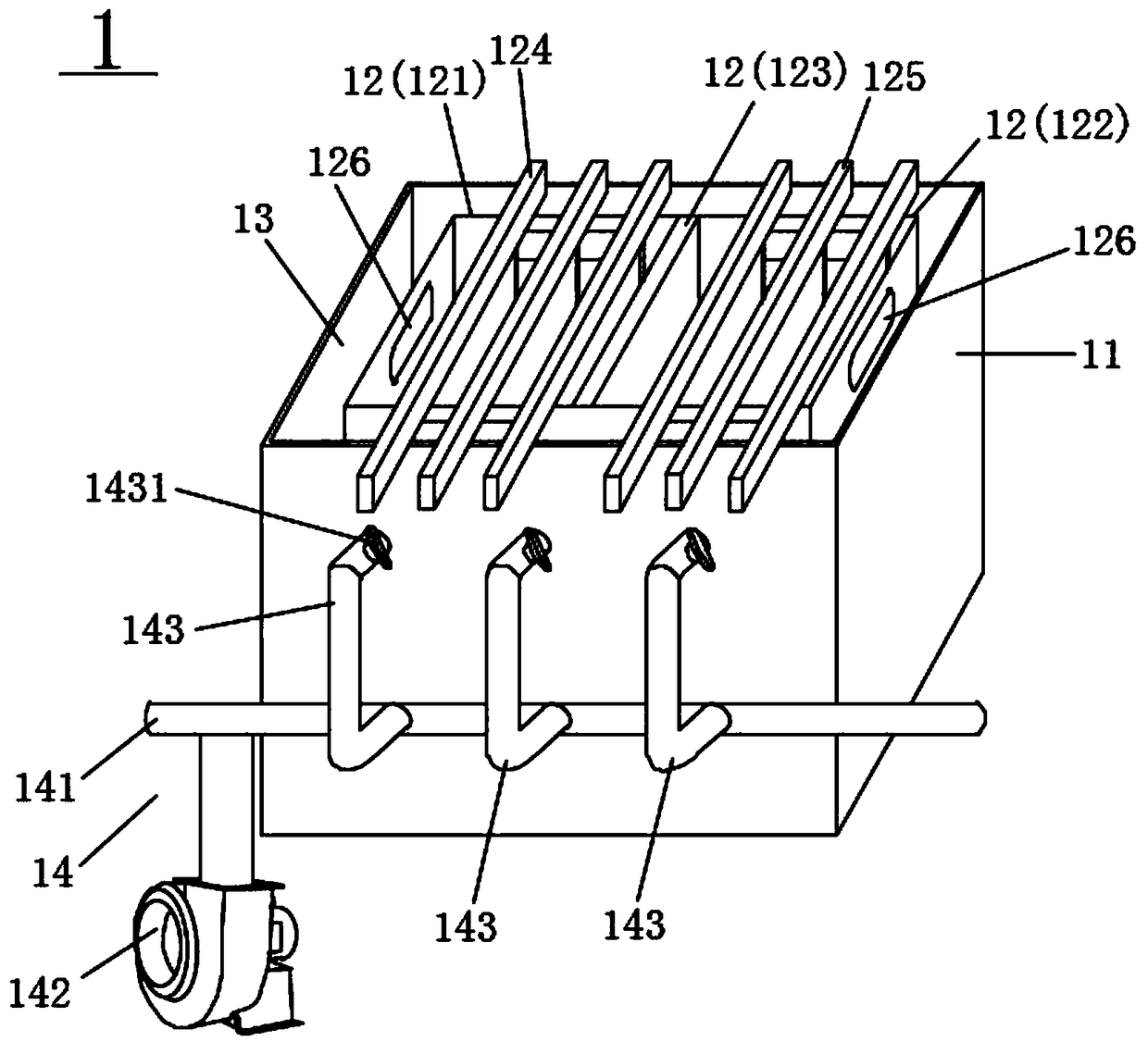

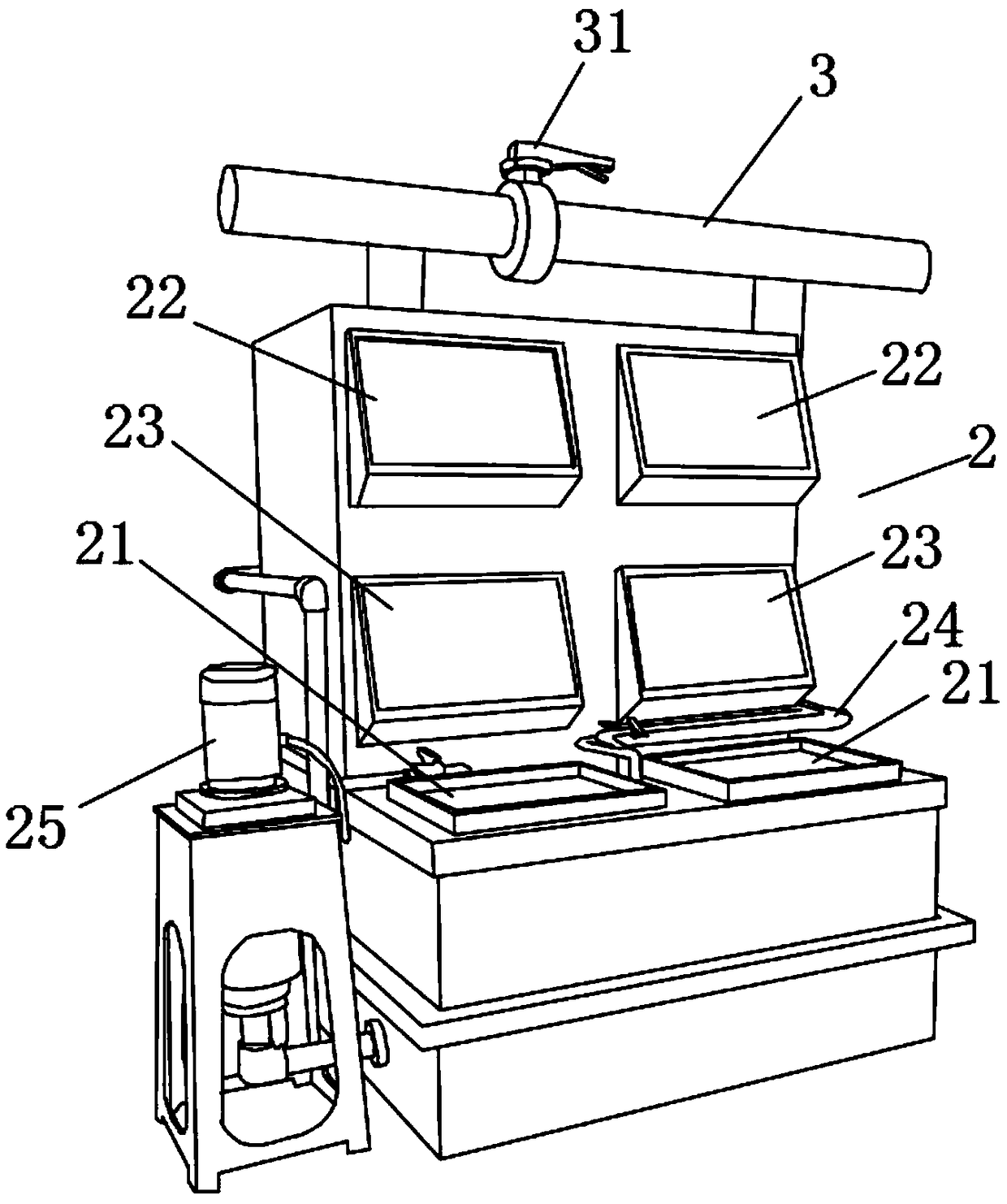

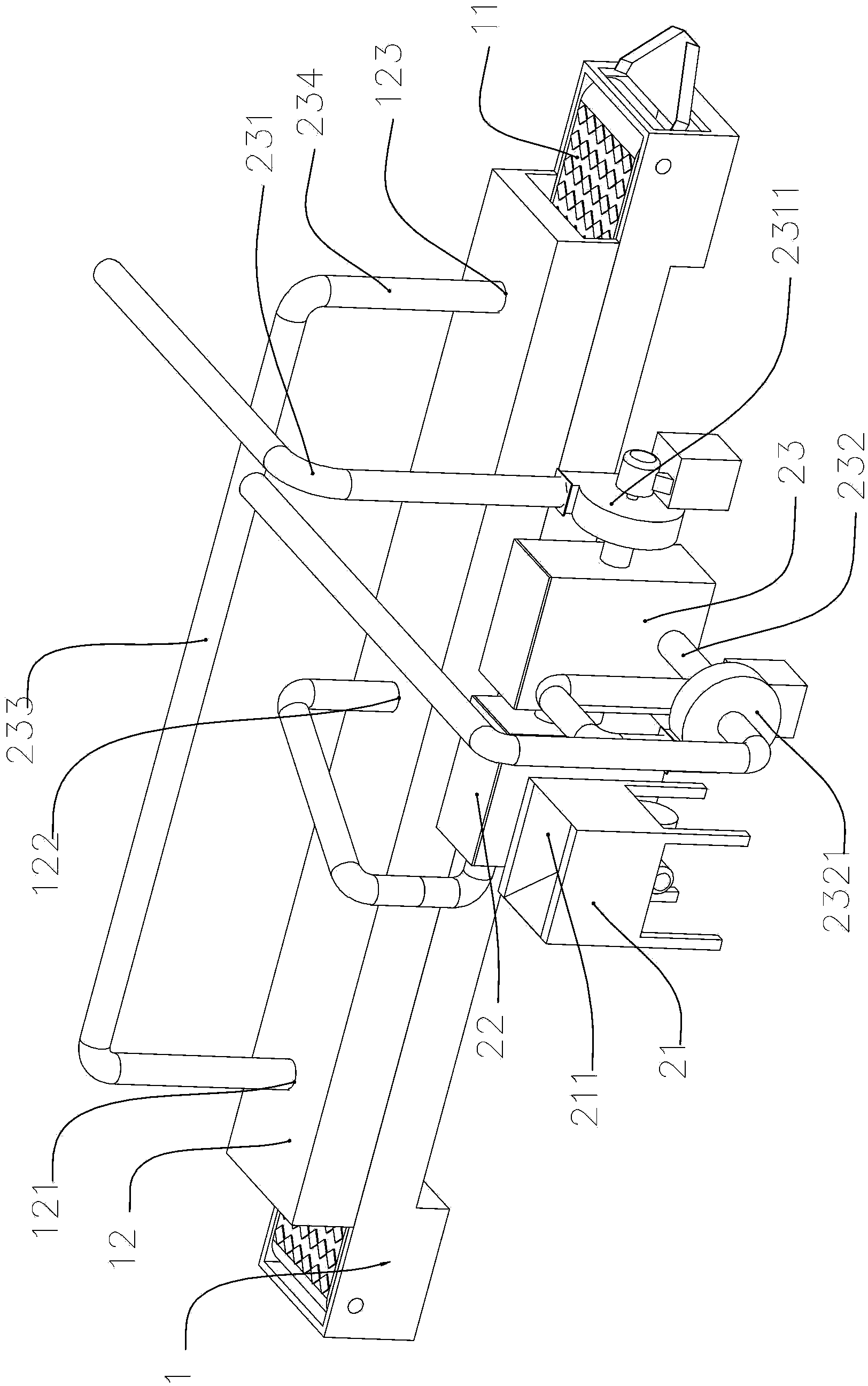

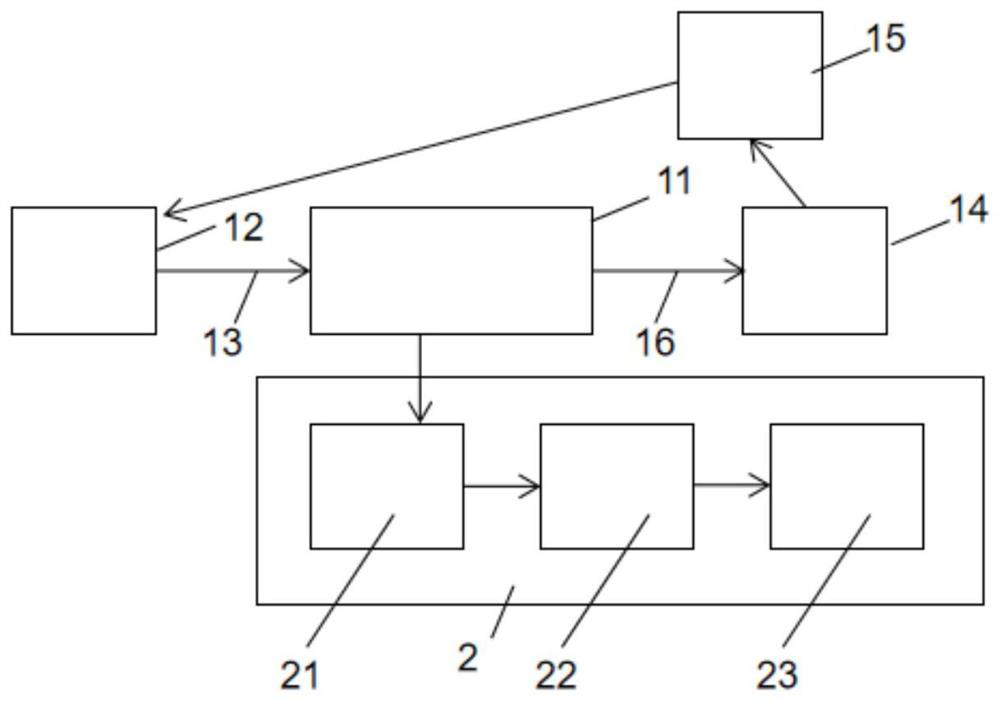

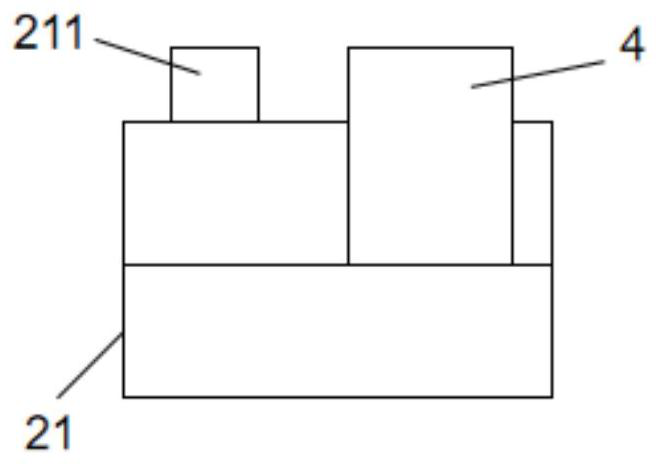

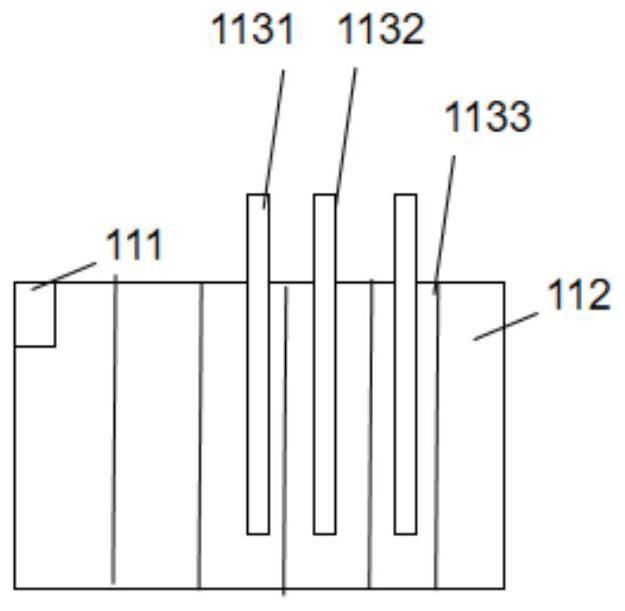

Acid etching liquid recycling system and method thereof

InactiveCN109023374ASave production materialsReduce manufacturing costPhotography auxillary processesProcess efficiency improvementIon-exchange membranesChemistry

The invention discloses an acid etching liquid recycling method which comprises the following steps of (1) prefabricating an acid etching liquid recycling system; (2) storing a waste etching liquor produced by an etching production line in a waste liquor barrel, and adding the waste etching liquor in the waste liquor barrel into an ion-exchange membrane electrolysis circulating device through an automatic-detection adding method; (3) electrolyzing the waste etching liquor through the ion-exchange membrane electrolysis circulating device so as to produce recycled liquid and elemental copper, storing the recycled liquid in a recycled liquid barrel, and moving out the elemental copper as a copper plate; and (4) adding an oxidizing agent, hydrochloric acid and the recycled liquid stored in therecycled liquid barrel into a recycled liquid blending monitoring device, detecting and blending the recycled liquid through multiple detectors in the recycled liquid blending monitoring device, enabling the oxidation reduction potential range of the recycled liquid to range from 480 to 520mv, enabling the copper concentration to range from 30 to 60g / L, and reflowing the recycled liquid into an etching production line so as to use. The invention further discloses an acid etching liquid recycling system applying the method.

Owner:德雅(深圳)环境科技有限公司

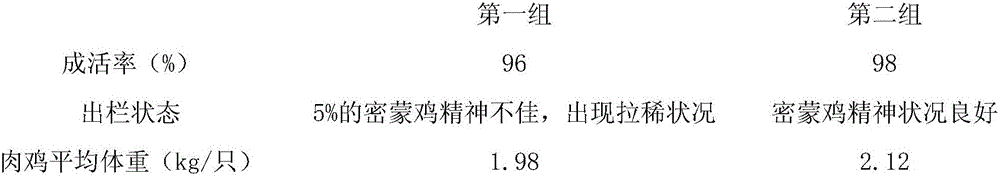

Chicken breeding method utilizing tomatoes

The invention relates to the technical field of poultry farming, in particular to a chicken breeding method utilizing tomatoes. Specifically, the chicken breeding method includes using mature tomato fruits as main foodstuff to feed broiler chicken. The main foodstuff, namely tomatoes, used in the chicken breeding method has extensive sources and is easy to get and low in cost; not only breeding cost of the broiler chicken is reduced, but also meat quality of the broiler chicken can be improved and is distinctive; and the commercial broiler chicken has good marketing prospect, high selling price and quite large development potentiality, and a feeder can make a profit.

Owner:何寒

Acid etching solution recycling regeneration system and method

PendingCN109440112AGeneration of controlRealize closed loopPhotography auxillary processesProcess efficiency improvementAcid etchingLiquid waste

The invention discloses an acid etching solution recycling regeneration method. The acid etching solution recycling regeneration method comprises following steps that (1) an acid etching solution recycling regeneration system is prefabricated; (2) an etching waste solution produced by an etching production line is stored in a waste solution barrel, and the etching waste solution in the waste solution barrel is added into an ionic membrane electrolysis circulation device in an automatic detection adding mode; (3) a regenerated solution and elemental copper are produced in the mode that the etching waste solution is electrolyzed by the ionic membrane electrolysis circulating device, the regenerated solution is stored in a regenerated solution barrel, and the elemental copper is removed out in the form of a copper plate; and (4) an oxidant, hydrochloric acid and the regenerated solution stored in the regenerated solution barrel are correspondingly added into a regenerated solution dispensing monitoring device, the regenerated solution is tested and dispensed by a plurality of detectors in the regenerated solution dispensing monitoring device, the redox potential range of the regenerated solution is between 480 mv and 520 mv, the copper concentration is within the range of 30-60 g / L, and then the regenerated solution flows back into the etching production line to be used. The invention further discloses an acid etching solution recycling regeneration system for implementing the method.

Owner:广州德雅新环境科技有限公司

Method for feeding pork pig with sugarcane

The invention belongs to the field of poultry farming, and particularly relates to a method for feeding pork pig with sugarcane. The method specifically comprises the following steps of: at the beginning of feeding the pork pig, obtaining 6-7 months sugarcane when the pork pig grows to 90-100 jin; feeding the pork pig with a fresh whole sugarcane plant; and adjusting the dosage of sugarcane to 50% of the total daily ration based on the future daily ratio of the pork pig. Through the feeding mode, the pork pig grows quickly, the weight of the pork pig obviously increases, the pork is delicious, and the pork pig is upgraded to high-end food. Through the invention, the pig eating sugarcane is similar to the boar taking grass as the major foodstuff in the wild, and the feeding mode adopts ecological feed to the original nature, thus the cost is reduced, and the pork of the produced pork pig has sweet and delicious mouthfeel. Meanwhile, the quality of the pork pig is remarkably improved almost without increasing the cost, the pork pig is unique on the market, the selling price of the pork product is high, and the economic benefits are obvious.

Owner:卢柳

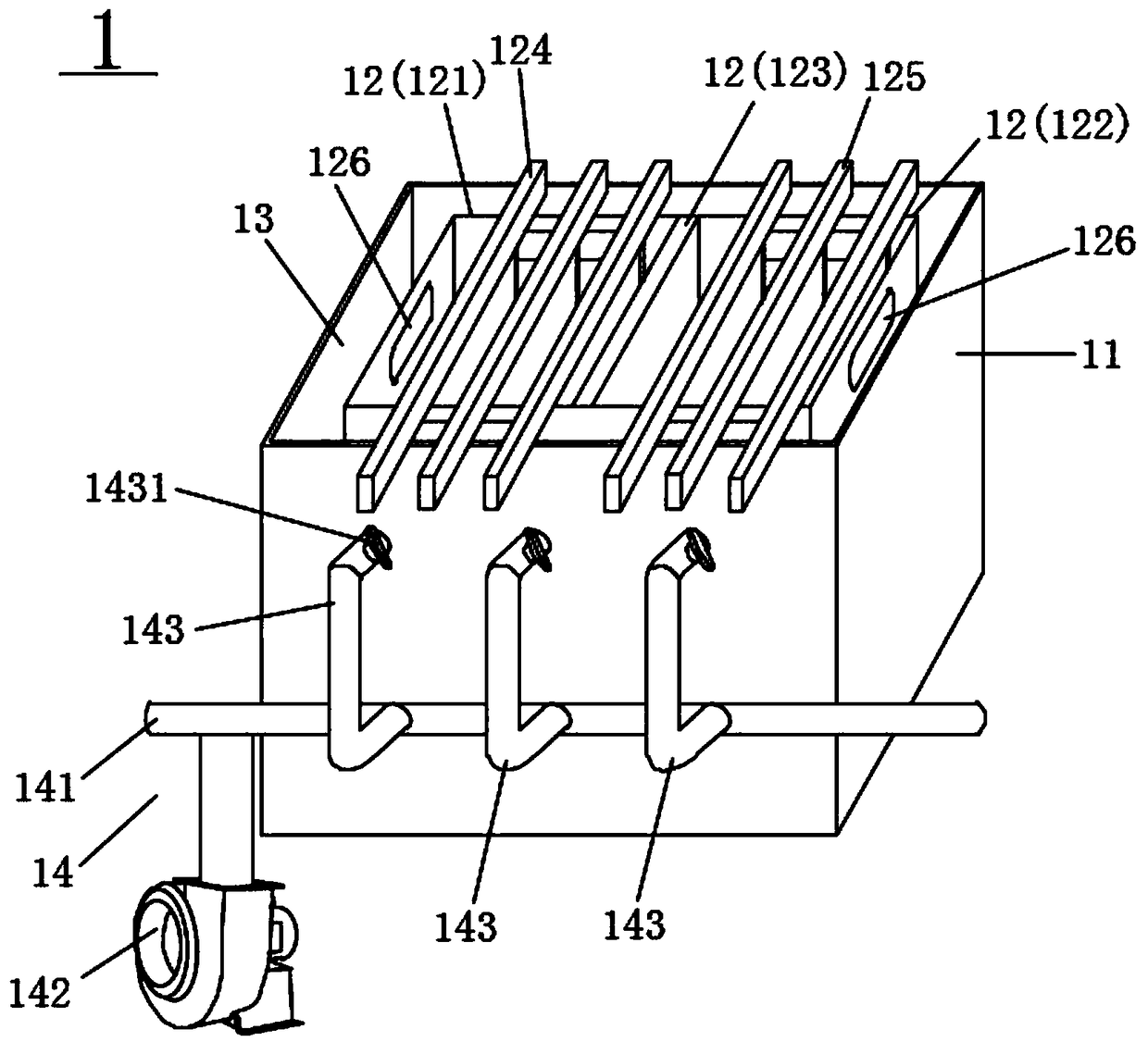

Drying processing technology and drying processing device for thunberg fritillary bulb

The invention discloses a drying processing technology and a drying processing device for thunberg fritillary bulb. The drying processing technology comprises the following steps of: rinsing fresh thunberg fritillary bulb clean and draining off moisture; slicing the thunberg fritillary bulb, wherein the slicing thickness is 3 to 4mm; placing thunberg fritillary bulb slices on a feed inlet of a conveying belt of a tunnel-type hot air dryer, controlling a conveying speed of a conveying belt into the range of 42.5cm per minute to 56.5cm per minute, controlling a 0-3.5m tunnel hot air temperature of the conveying belt along a conveying direction of the conveying belt into the range of 100 to 110 DEG C, controlling a 3.5-6.5m tunnel hot air temperature of the conveying belt along the conveying direction of the conveying belt into the range of 80 to 85 DEG C, controlling an over-6.5m tunnel hot air temperature of the conveying belt along the conveying direction of the conveying belt into the range of 70 to 75 DEG C and controlling whole drying time in the range of 15 to 20 minutes; spreading out the dried thunberg fritillary bulb slices, cooling to the room temperature and then packaging the thunberg fritillary bulb slices. The drying processing technology and the drying processing device for the thunberg fritillary bulb has the advantages of high drying processing efficiency, good shapes of the processed thunberg fritillary bulb slices and high selling price.

Owner:文成县华兴药材种植有限公司

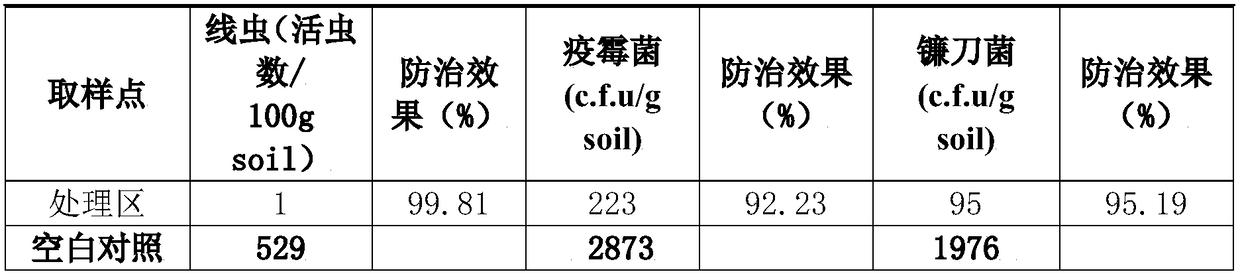

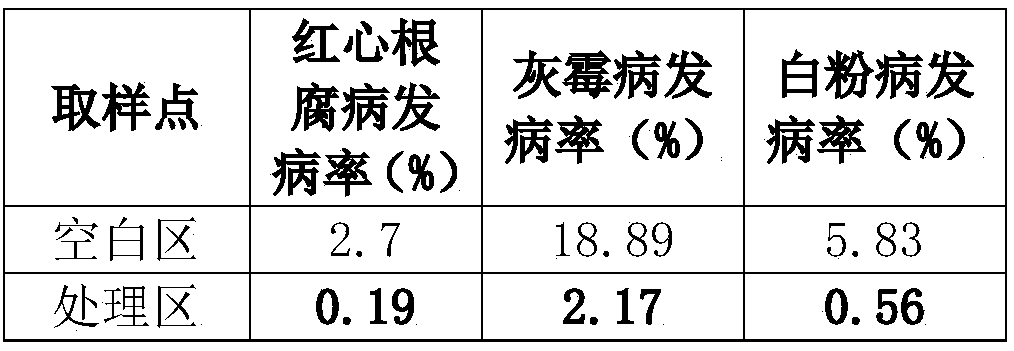

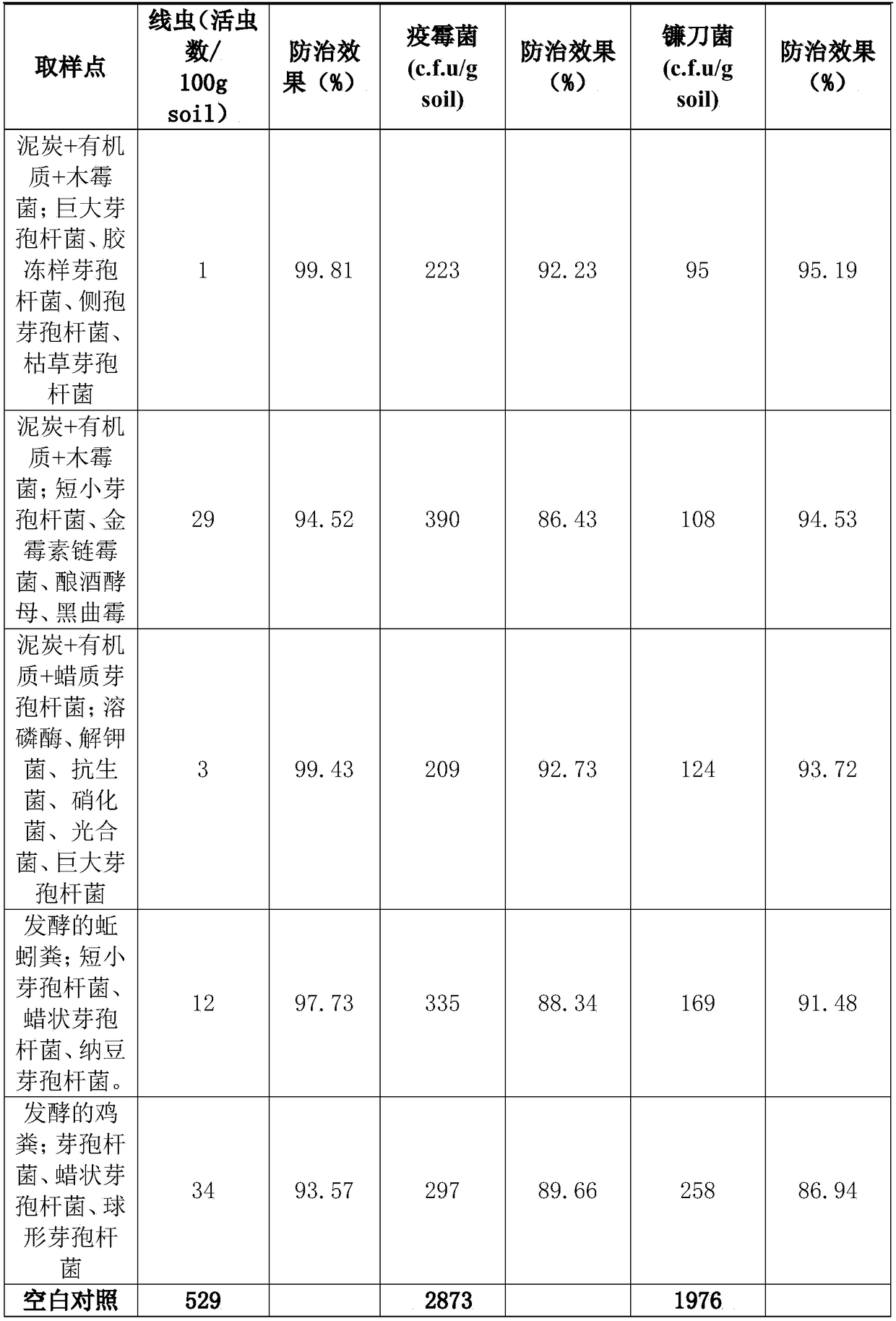

Repair method for semi-soil and semi-matrix cultivating soil

InactiveCN109174953AEasy to operatePromote growthContaminated soil reclamationSoil-working methodsDisinfectantReducer

The invention provides a repair method for semi-soil and semi-matrix cultivating soil. The method comprises the following steps: filling the lower part of a cultivating groove with nutritional soil; filling the upper part with a matrix; adding a disinfectant into the cultivating groove uniformly; adding a film to cover the cultivating groove for 7-10 days; uncovering the film to ventilate; detecting residues by means of a germination test; adding a soil reducer and the like to prepare the semi-soil and semi-matrix cultivating soil. The method can repair the matrix effectively, optimizes the physical and chemical characteristics of the matrix, balances nutrients in the matrix and solves the problems of secondary salinization and massive accumulation of soil-borne pathogenic bacteria and thelike. The method can reduce the incidence rate of the soil-borne diseases effectively and promote growth of plants positively.

Owner:北京市昌平区植保植检站 +1

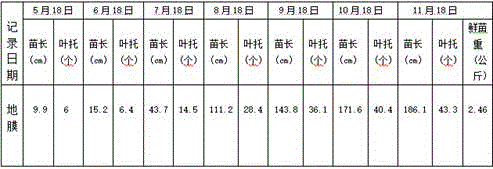

Radix millettiae speciosae plastic membrane mulching cultivation technology method

InactiveCN106717892AGood effectHigh selling priceClimate change adaptationCultivating equipmentsPesticidePest control

The invention discloses a radix millettiae speciosae plastic membrane mulching cultivation technology method. The radix millettiae speciosae plastic membrane mulching cultivation technology method is characterized by comprising the following steps of: selecting seeds, soaking the seeds, growing seedlings, transplanting the seedlings, carrying out soil preparation and furrowing, applying fertilizer, maintaining breeding, sprinkling root fixing water, applying compound fertilizer after five stipules grow on the plant, and timely spraying insecticide for pest control. Compared with radix millettiae speciosae free of plastic membrane mulching, the radix millettiae speciosae harvested by adopting the method are large and long in shape and bear heavy fruit. The radix millettiae speciosae plastic membrane mulching cultivation technology method has the advantages of good seed selection, good plant management, fine water replenishing, sufficient fertilizer application, complete pest control, breeding maintenance, good harvesting guarantee, a good pesticide effect, high selling price and maximized profit.

Owner:陈培党

Acidic etching solution cyclic regeneration system and method

InactiveCN112458463AGeneration of controlRestoring etch abilityPhotography auxillary processesProcess efficiency improvementEtchingElectrolysis

The invention discloses an acidic etching solution cyclic regeneration system. The system comprises an ionic membrane electrolysis circulating system, a chlorine absorption system and a regeneration solution blending monitoring system. The ionic membrane electrolysis circulating system is constructed into a solution circulating loop and comprises an electrolysis system. The chlorine absorption system comprises a chlorine treatment cylinder, an alkali liquor pool and a chlorine treatment tower secondary absorption system. The chlorine treatment cylinder and the alkali liquor pool respectively suck chlorine through negative pressure generated by an ejector and introduce the chlorine into low ORP etching liquor and an alkaline solution. An ORP monitor is used for controlling generation of chlorine by controlling the ORP value of the electrolytic etching solution. By controlling the ORP value of the electrolytic etching solution, generation of chlorine is effectively controlled, monovalentcopper ions are changed into divalent copper ions, the etching capability is recovered, operation completely returns to production, oxidants used in production are reduced or even canceled, production materials are saved, and the production cost is reduced.

Owner:江苏净拓环保科技有限公司

Method for using pitaya to feed broilers

InactiveCN103535324ANo pollution in the processTimely disinfectionFood processingAnimal feeding stuffWeight gainingBroiler

Disclosed is a method for using pitaya to feed broilers. The method includes: starting to feed the broilers with ripe pitaya fruits two months before the broilers fed conventionally come into the market; controlling and reducing regular feed amount of the broilers, and increasing pitaya fruit amount to feed the broilers; feeding the pitaya fruits for at least two months; wherein the pitaya fruits account for 70-80% of the feed of the broilers. The method has the advantages that the pitaya fruits are quite good in palatability, rich in nutrition, unique in function, few in disease and pest, and can grow normally basically without any chemicals; the broilers like to eat the pitaya fruits very much; the peels of the pitaya fruits contains anthocyanin which is quite precious nutrient substance; when the broilers eat the pitaya fruits having multiple functions, weight gaining effect is evident, and meat quality is improved greatly; the broilers fed by the pitaya fruits is delicious in meat quality and fragrant and sweet in taste.

Owner:凌爱秋

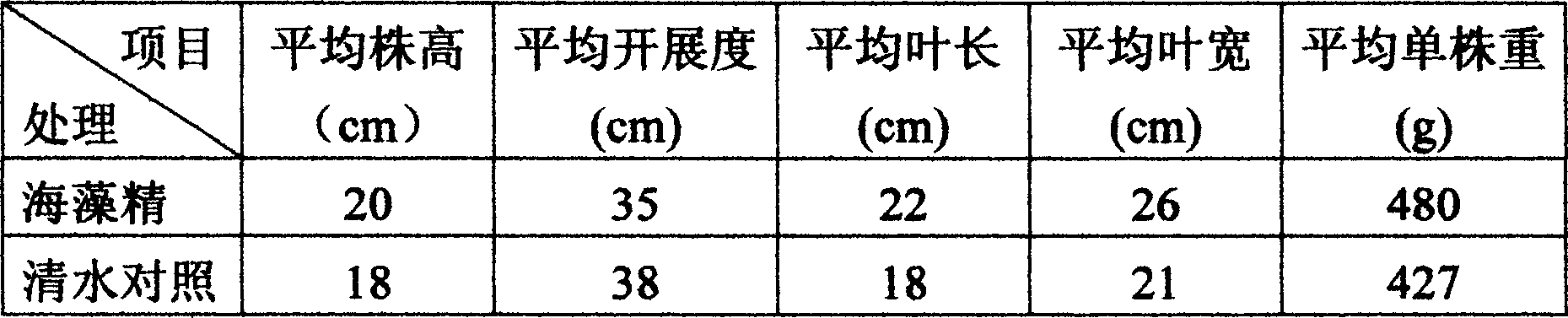

Marine algae extract plant immunity yield increase opsone and preparing method thereof

InactiveCN1524834APromote plant nutrition balanceImprove nutritional qualityBiocideAnimal repellantsWeedFertilizer

A sea weed extract plant immunization production increase opsone and process of making it which relates to the ocean biological pesticide, bio-fertilizer formula and method for making same, wherein detergent, nitrogen, phosphor, potassium and microelement are mixed for making solution A by the proportion of 1000 : (13-60) : (6-25) : (20-70) : (3-9), and water, potassium iodide and iodine are mixed for making solution B by the proportion of 1000 : (10-30) : (5-15), ethanol and 4-iodophenoxyacetic acid are mixed by the proportion of 1000 : (50-100) with the added neutralizing sodium-hydroxide for making solution C. The sea weed extract C solution and B solution are added into solution an in sequence by the proportion of 10 : (8-12) : (5-20) for producing synergism.

Owner:刘福京

Green and ecological buddleia officinalis chicken breeding method

ActiveCN105850888AImprove immunityImprove meaty aromaAnimal feeding stuffAccessory food factorsOfficinalisLicorice roots

The invention relates to the technical field of animal breeding, in particular to a green and ecological buddleia officinalis chicken breeding method. The green and ecological buddleia officinalis chicken breeding method specifically comprises the steps of selecting a sandy soil slope with woods for breeding under woods, and applying disease preventing and treating pesticides in buddleia officinalis chicken flocks by adding safe and originally ecological Chinese herbal medicines including buddleia officinalis flowers, caesalpinia minax Hance, licorice roots, spora lygodii, talcum powder and wrinkled gianthyssop herb decoction liquid to a pollution-free feed. Due to the fact that any feed additive is not used and antibiotics and veterinary medicines are not used, it is ensured that bred buddleia officinalis chickens are green products, chicken can also contain light fragrance of the buddleia officinalis flowers, and the quality is improved remarkably.

Owner:台州中知英健机械自动化有限公司

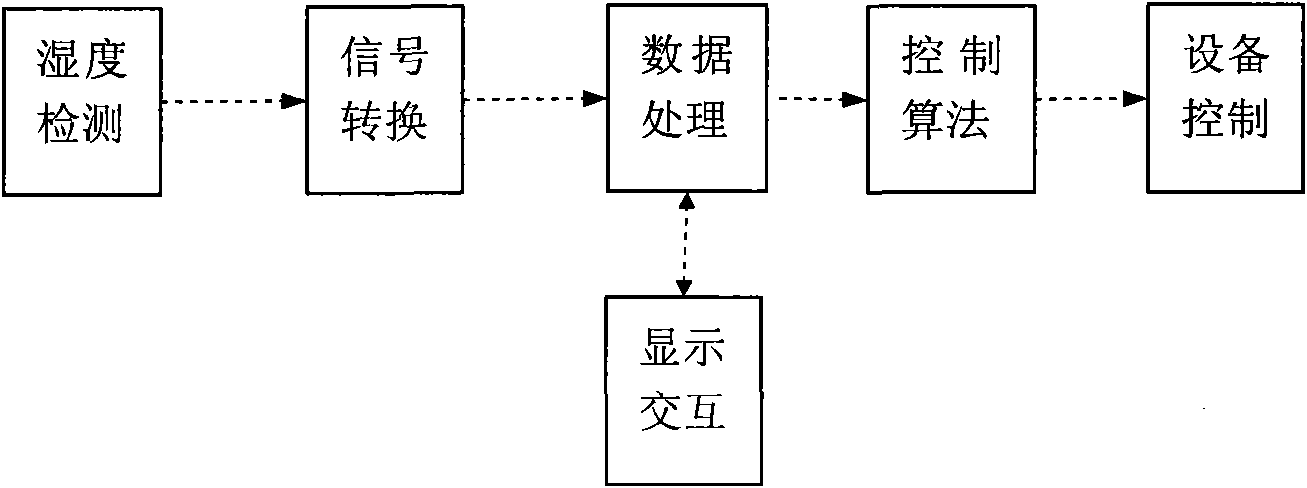

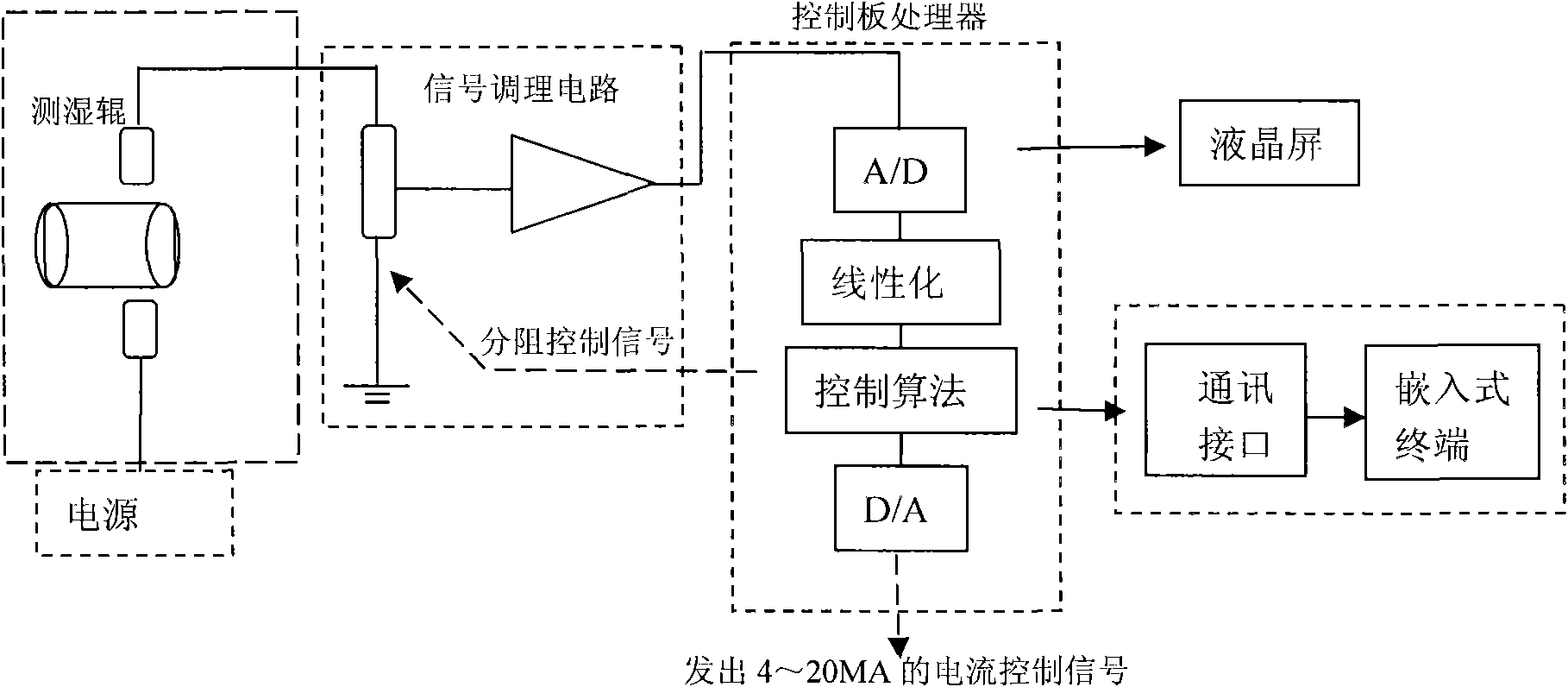

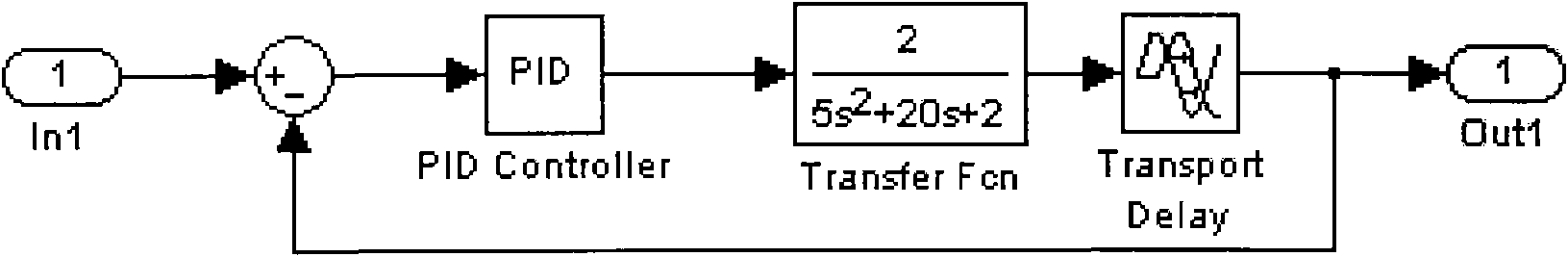

Anti-overbaking multifunctional on-line measurement and control system of textile printing and dyeing fabrics

InactiveCN101845733AQuality improvementReduce sizeLiquid/gas/vapor removalSignal conditioning circuitsTextile printer

The invention relates to a textile production control technology and aims to provide an anti-overbaking multifunctional on-line measurement and control system of textile printing and dyeing fabrics. The system comprises a humidity measurement roller used for humidity detection, wherein the humidity measurement roller is connected to a signal conditioning circuit through a signal wire, and the signal conditioning circuit is connected with a control plate processor; the control plate processor is connected to an electronic control device of a steam valve through a signal wire; and the steam valve is positioned on a steam supply pipeline for drying steam. Due to the effective use of the system, the purposes of accuracy control and automatic regulation are achieved, and finally, an ideal humidity of the fabrics is obtained. Overbaking cannot be caused, thereby the steam and energy are effectively saved, which directly and most benefits printing and dyeing mills by using the system.

Owner:杭州晨星电力科技有限公司

Cultivating method for ziyun high-yield apples

InactiveCN109089689AIncrease productionImprove result rateFertilising methodsCultivating equipmentsFruit treeSugar

The invention relates to a cultivating method for ziyun high-yield apples. The method comprises the steps of a germination stage, a flowering stage, a fruitlet stage, a fruited expanding stage, a fruit tree expanding stage and a fruit picking stage. Apples cultivated through the cultivating method for ziyun high-yield apples are good in taste, regular in shape, rapid in expansion, good in color, good in surface color and capable of greatly increase the sugar degree and selling price.

Owner:紫云自治县浩石立体农业开发有限公司

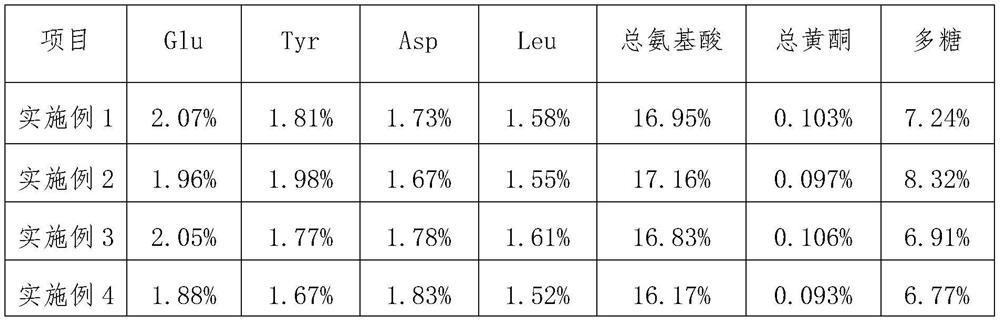

Wild-imitating cultivation method for increasing amino acid content of phallus impudicus

ActiveCN112154857AAchieve connectionShorten cultivation timeCultivating equipmentsMushroom cultivationBiotechnologyFirewood

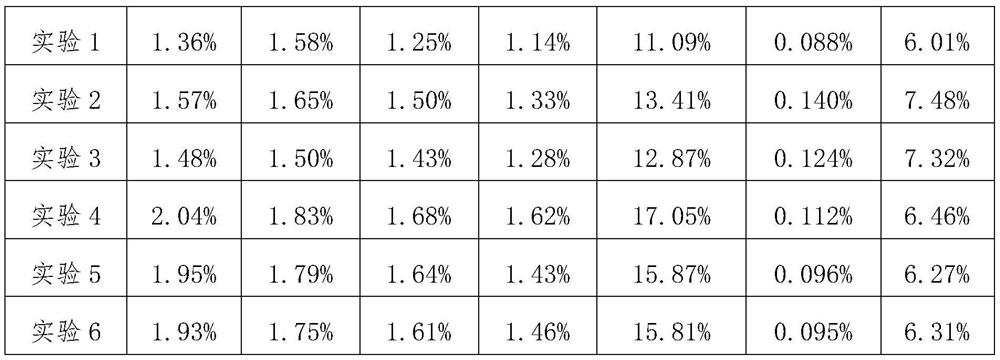

The invention belongs to the field of edible fungus cultivation, and particularly relates to a wild-imitating cultivation method for increasing an amino acid content of phallus impudicus. Gastrodia elata waste bacteria firewood is used as a main material for preparing a cultivation material, so that the gastrodia elata industry and the phallus impudicus industry are connected, and the economic benefits are increased; wood and bamboo branches in auxiliary materials of the cultivation material are respectively treated, so that the phallus impudicus can fully absorb the nutrition of the cultivation material, the content of inclusions is increased, and the amino acid content of the produced phallus impudicus reaches 16.95%, wherein the content of glutamic acid (Glu) reaches 2.07%; and meanwhile, management parameters are adjusted according to different growth stages of the phallus impudicus, the cultivation time of the phallus impudicus is shortened, the phallus impudicus comes into the market in advance, and the economic benefits are maximized.

Owner:毕节市林业科学研究所

Randia cochinchinensis broiler and breeding method thereof

The invention relates to a randia cochinchinensis broiler and a breeding method thereof, and particularly randia cochinchinensis fruits and randia cochinchinensis leaves are taken as a feed additive to feed the broiler. Through the implementation of the randia cochinchinensis broiler and the breeding method thereof, due to the fact that the raw materials of the randia cochinchinensis fruits and the randia cochinchinensis leaves are extremely wide in sources and low in cost, the cost of the prepared randia cochinchinensis feed additive is low. In addition, through the implementation of the randia cochinchinensis broiler and the breeding method thereof, the foodstuff mixed with the randia cochinchinensis feed additive is strong in fragrance excellent in palatability, and the broiler is very popular; the randia cochinchinensis fruits and the randia cochinchinensis leaves are of various functions and effects, the weight gaining effect of the broiler eating the foodstuff is obvious, and the meat quality is greatly improved. The meat quality of the breeding broiler is delicious, the aroma is unique, and the taste is sweet. Meanwhile, the production cost of the bred broiler is very low, but the bred broiler is high in quality and strong in identity. The market prospect of commercial broilers is good, the price is high, and raisers can get large profits.

Owner:许超群

Cultivation method for making grape plants lean to one side

InactiveCN108703005AGood for getting richGreat tasteCultivating equipmentsHorticulture methodsMain stemSingle plant

The invention discloses a cultivation method for making grape plants lean to one side. Single-plant fan-shaped growth in a traditional mode is changed into a single-main-stem one-sided mode, the product is good in taste and good in color, early appears on the market, and is high in selling price, popularization is facilitated, massive farmers are led to become rich, manpower is reduced, the yieldis greatly increased, the economic effects are improved, and the cost is reduced.

Owner:孟令波

Rough processing method of fragrant and sweet gastrodia elata

InactiveCN103845627AConsistent colorHigh selling priceFood preparationPlant ingredientsBiotechnologyGastrodia

The invention discloses a rough processing method of fragrant and sweet gastrodia elata. The method comprises the following steps: grading fresh gastrodia elata, and selecting damaged, incomplete and rotten gastrodia elata; soaking the graded fresh gastrodia elata by clean water, and repeatedly cleaning to remove silver sands till the fresh gastrodia is clean; placing the cleaned fresh gastrodia elata into boiled water, fishing out and draining off when the water is reboiled, and naturally cooling to room temperature; and after all gastrodia elata turns to brown, steaming for 10-25 minutes till the gastrodia elata is fully steamed, and conventionally drying. The gastrodia elata obtained is consistent in color, high in selling price and good in taste.

Owner:贵州乌蒙腾菌业有限公司

Production technology of feed capable of promoting rapid growth of black goats

InactiveCN107801848AEasy to manufactureEasy to operateFood processingAnimal feeding stuffHydrogen phosphateTechnology/technique

The invention discloses a production technology of a feed capable of promoting rapid growth of black goats. The production technology consists of the following raw materials of corn, soybean meal, full fat puffed beans, whey powder, fish meal, 1 part by mass of calcium hydrogen phosphate, stone powder and table salt. The production technology comprises the following technology techniques of crushing the raw materials, performing puffing, performing extruding, performing granulation and the like. When the obtained feed is fed to the black goats, nutrient component requirements of the black goats can be met, the black goats are bright in hair color, are powerful in running, leap and jump in mountains and roads, are strong and powerful, are delicately fragrant in meat quality, are fat in waist, and thick in meat, and have the effects of nourishing bodies and refreshing the mind. The feed is easy to make, the technology is simple, the cost is low, and the benefits are good.

Owner:陈培党

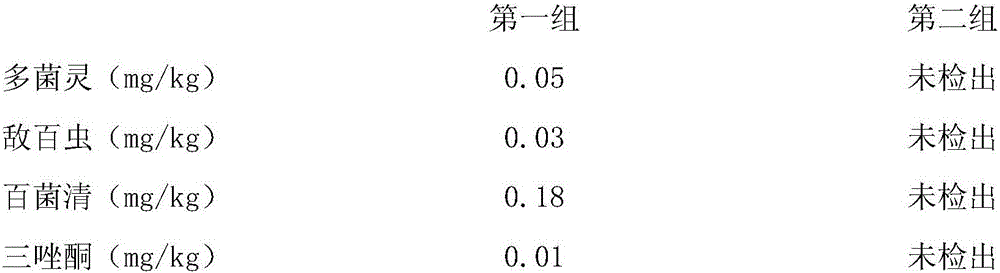

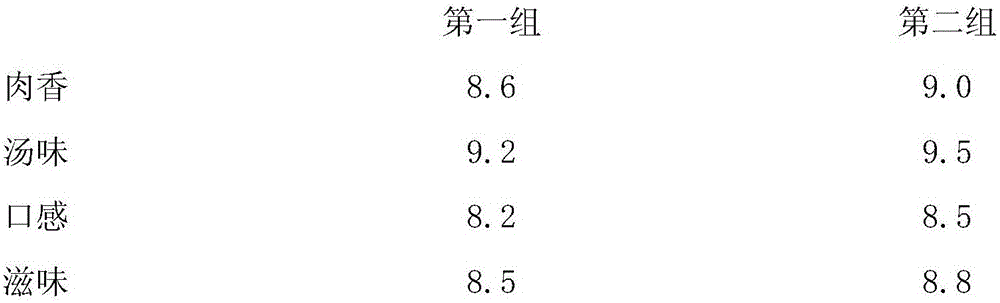

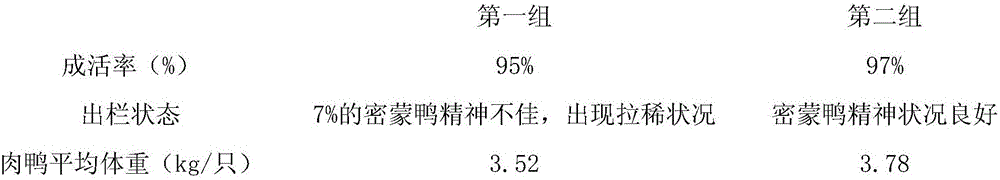

Green ecological breeding method for ducks fed with pale butterflybush flowers

The invention relates to the technical field of livestock breeding, in particular to a green ecological breeding method for ducks fed with pale butterflybush flowers. The method comprises specific steps as follows: a duck-fish vertically-integrated breeding platform is constructed on water surface, and ducks fed with the pale butterflybush flowers are subjected to disease prevention and treatment and pesticide elimination by adding safe and originally ecological Chinese herbal medicines including the pale butterflybush flowers, Caesalpinia minax, liquorice, mints, lygodium spores, talcum powder and a Rabdosia rubescens decoction to pollution-free feedstuff. Due to rejection of any feed additives as well as antibiotics and veterinary drugs, the raised ducks fed with the pale butterflybush flowers are green products, duck meat has light pale butterflybush flower fragrance, and the quality is greatly improved.

Owner:南丹县天赈牧业有限公司

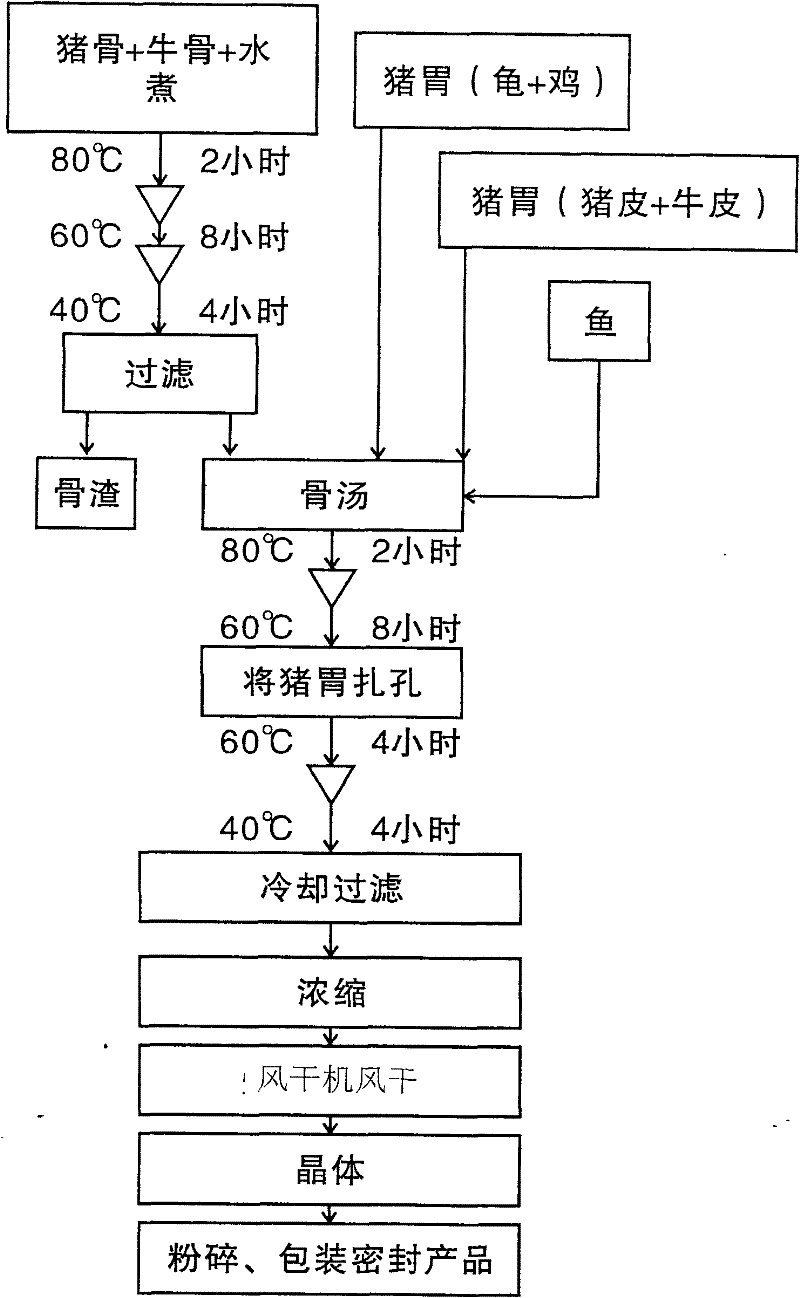

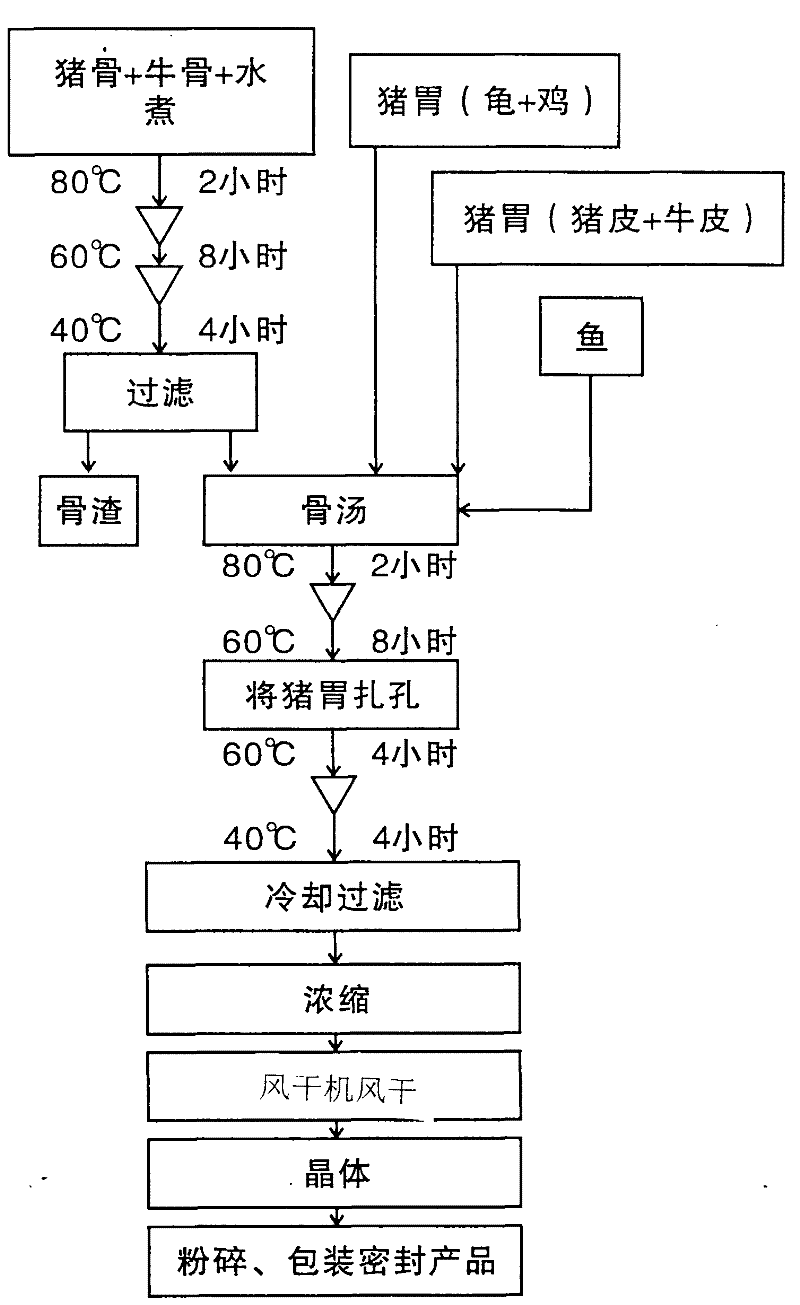

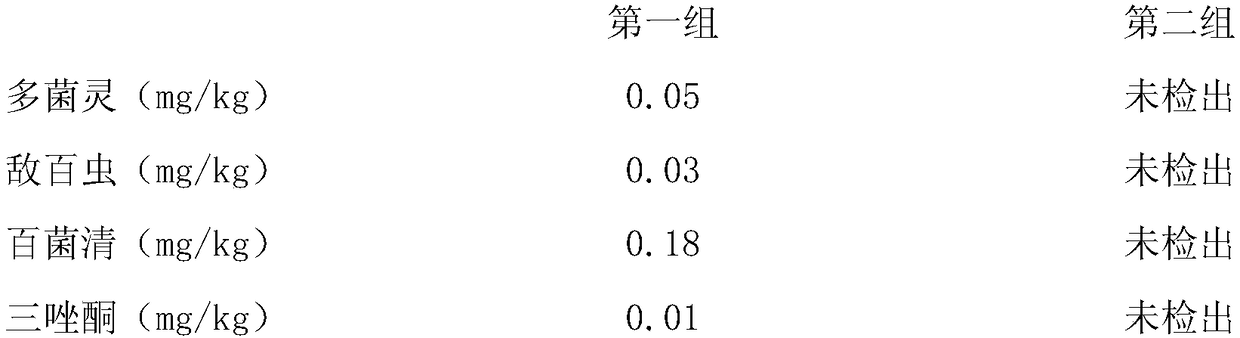

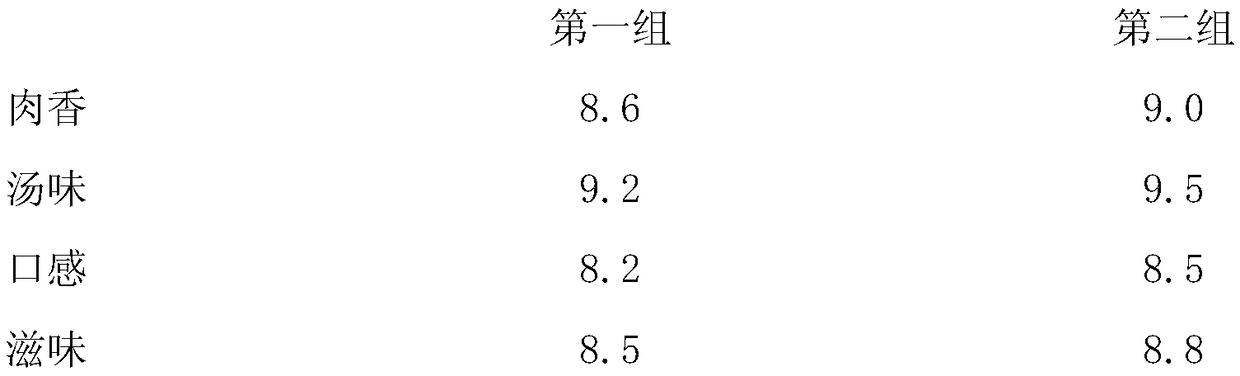

Production method for selenium-containing collagen

InactiveCN101849604BHas the value of development and promotionSimple production processProtein composition from fishProtein composition from meatFiltrationEngineering

The invention relates to a production method for selenium-containing collagen. The method adopts bones to make soup, turtles and chicken are contained in one pig stomach, pig skins and cow skins are contained in another pig stomach, the processed pig stomachs and fish are put together into a casserole filled with bone soup, and repetitive boiling, filtration, concentration, air drying, crushing and packaging are conducted to obtain the collagen product. The production technology of the invention is simple and unique, the expensive instruments and equipment are not required, the production period is short, the cost is very low, the produced product not only has the advantages and the application values of domestic and foreign similar products but also contains organic selenium, the contentof the organic selenium reaches 6.1mg / kg high and cannot be found in the existing literature, the collagen is a special collagen product, the application value and the development and popularization value of the collagen are very high, especially the selenium has great function on cancer fighting and thereby the development prospect is very high.

Owner:袁抗美 +1

Breeding method of yellow pear broiler chicken

The invention relates to a breeding method of a yellow pear broiler chicken. The breeding method specifically comprises the following steps: feeding the broiler chicken with mature yellow pear fruits as a main food. Yellow pear fruit sources are wide, the price is low and the cost for feeding the broiler chicken with the yellow pear fruits is low. Yellow pears are mellow in taste, fragrant in flavor, palatable in sweetness, and excellent in palatability, and are popular with the broiler chicken; yellow pear fruits contain various vitamins and high mineral content, so that the weight gain of the broiler chicken after eating the yellow pears is obvious, and the meat quality of the broiler chicken after eating the yellow pears is greatly improved. The bred broiler chicken is delicious in quality, unique in taste, and sweet in mouth feeling. In addition, the yellow pear juice contains enzymes similar to gastric juice, the enzyme can degrade protein and help digestion, and the broiler chicken has no fat after being eaten. The production cost of the bred broiler chicken is extremely low, high-quality and featured boiler chicken can be bred, and the commercial broiler chicken has good market prospects, is sold with high price and the benefit of breeders is high.

Owner:黄金利

Chicken breeding method utilizing tomatoes

The invention relates to the technical field of poultry farming, in particular to a chicken breeding method utilizing tomatoes. Specifically, the chicken breeding method includes using mature tomato fruits as main foodstuff to feed broiler chicken. The main foodstuff, namely tomatoes, used in the chicken breeding method has extensive sources and is easy to get and low in cost; not only breeding cost of the broiler chicken is reduced, but also meat quality of the broiler chicken can be improved and is distinctive; and the commercial broiler chicken has good marketing prospect, high selling price and quite large development potentiality, and a feeder can make a profit.

Owner:中科康源(唐山)生物技术有限公司

A method for improving the appearance of japonica japonica rice

The invention discloses a method for improving condition of Sophora buds from golden Sophora japonica. The method comprises the following steps: (1) water is added into an enzyme deactivating apparatus, alkali lye is added, and heating is carried out; (2) water and alkali lye are added into the enzyme deactivating apparatus every two hours in the heating process of the step (1), in order to guarantee alkali lye in a pot is kept at a certain concentration, heating is carried out till water is boiled, Sophora buds are added into the enzyme deactivating apparatus for carrying out enzyme deactivation, boiling state is kept and enzyme deactivation is carried out for 12-15 minutes, and the product is obtained. The method has obvious effects, processed Sophora buds from golden Sophora japonica have golden yellow color, good condition, and high price.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

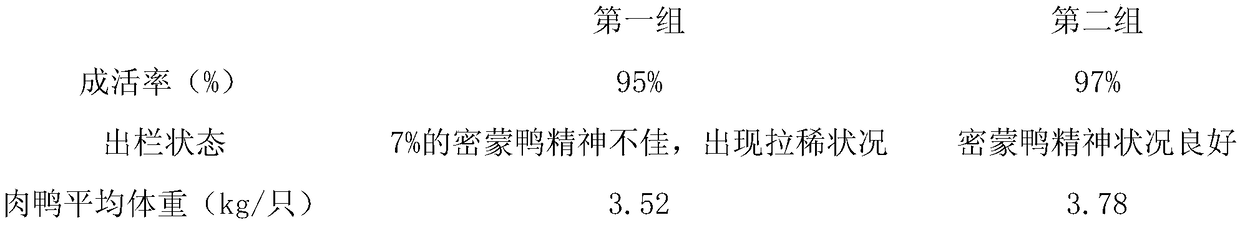

Green ecological breeding method of Mimeng duck

The invention relates to the technical field of livestock breeding, in particular to a green ecological breeding method for ducks fed with pale butterflybush flowers. The method comprises specific steps as follows: a duck-fish vertically-integrated breeding platform is constructed on water surface, and ducks fed with the pale butterflybush flowers are subjected to disease prevention and treatment and pesticide elimination by adding safe and originally ecological Chinese herbal medicines including the pale butterflybush flowers, Caesalpinia minax, liquorice, mints, lygodium spores, talcum powder and a Rabdosia rubescens decoction to pollution-free feedstuff. Due to rejection of any feed additives as well as antibiotics and veterinary drugs, the raised ducks fed with the pale butterflybush flowers are green products, duck meat has light pale butterflybush flower fragrance, and the quality is greatly improved.

Owner:南丹县天赈牧业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com