Anti-overbaking multifunctional on-line measurement and control system of textile printing and dyeing fabrics

A measurement and control system, textile printing and dyeing technology, applied in textile and papermaking, textile material processing, removal of liquid/gas/vapor, etc. Labor cost, increase selling price, and the effect of saving steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

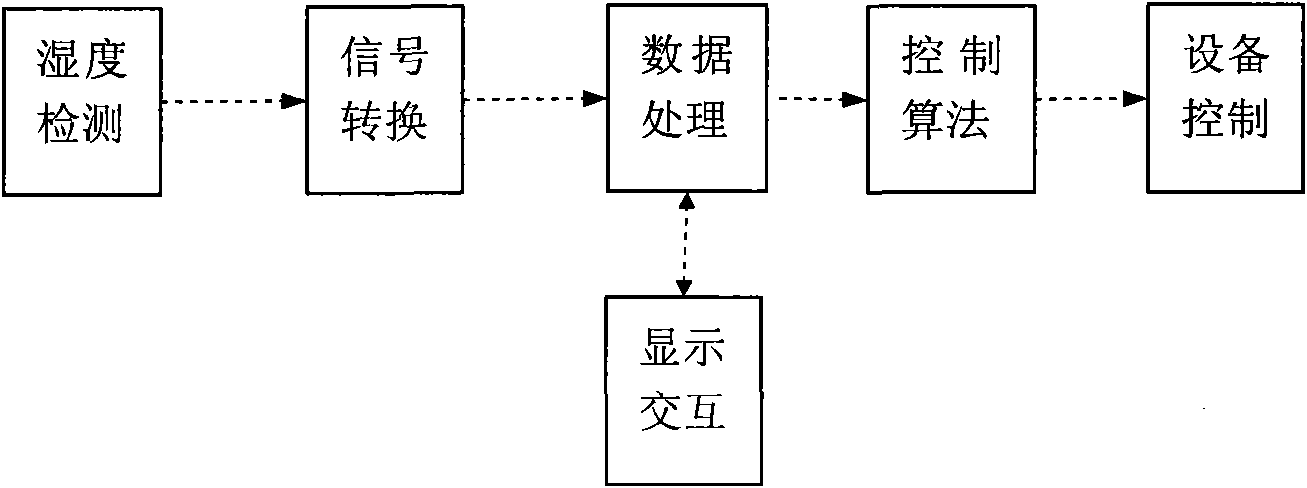

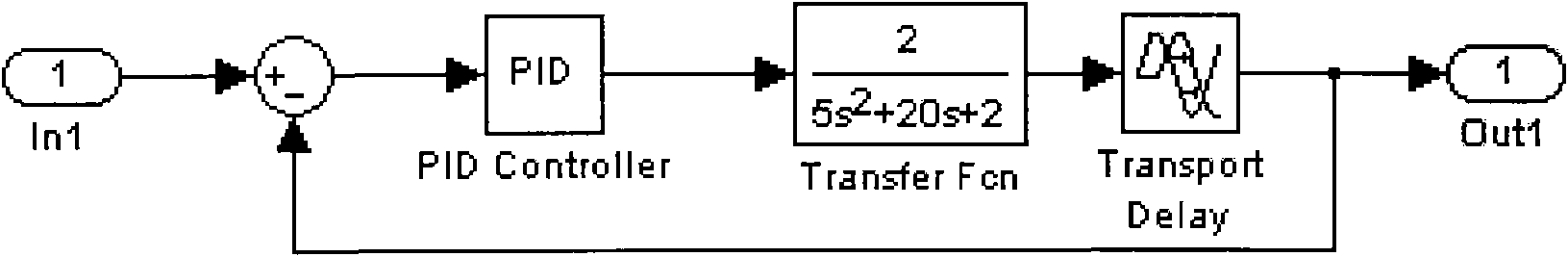

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

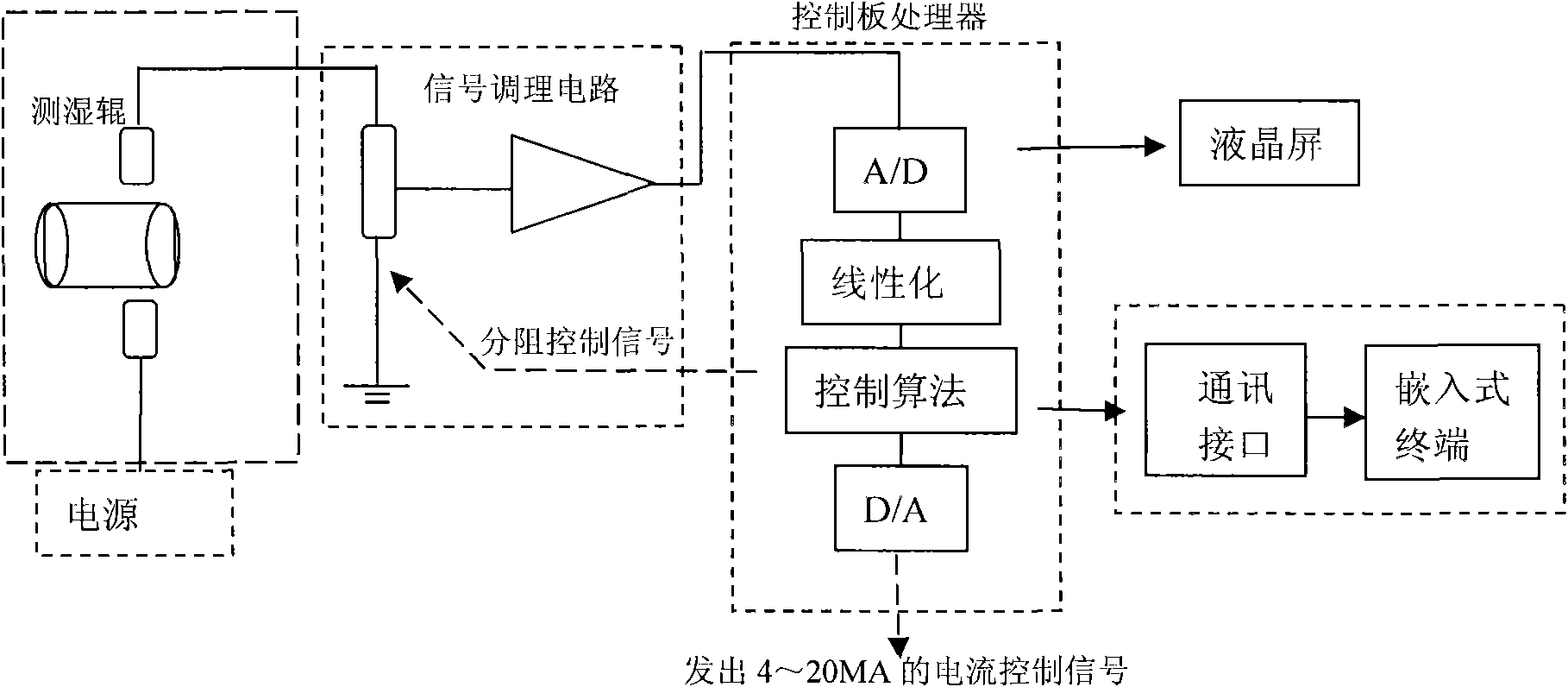

[0023] The multifunctional online measurement and control system for preventing overdrying of textile printing and dyeing fabrics in this embodiment includes a humidity measuring roller for humidity detection, the humidity measuring roller is connected to a signal conditioning circuit through a signal line, and the signal conditioning circuit is connected to the control board processor ; The control board processor is also connected to the electric control device of the steam valve through the signal line, and the steam valve is located on the steam supply pipeline of the drying steam.

[0024] In this embodiment, the control board processor selects TI company Provides a range of Cortex TM - M3's LM3S1138 control board processor. The board processor features powerful on-chip memory, enhanced power managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com