Acid etching solution recycling regeneration system and method

A technology of regeneration system and etching waste liquid, which is applied in the direction of photographic process, diaphragm, instrument, etc., can solve the problems of inability to achieve recycling, waste liquid discharge, zero discharge, etc., to achieve clean production, reduce production cost, process High volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0040]An embodiment of the present invention provides a method for recycling and regenerating an acidic etching solution, comprising the following steps:

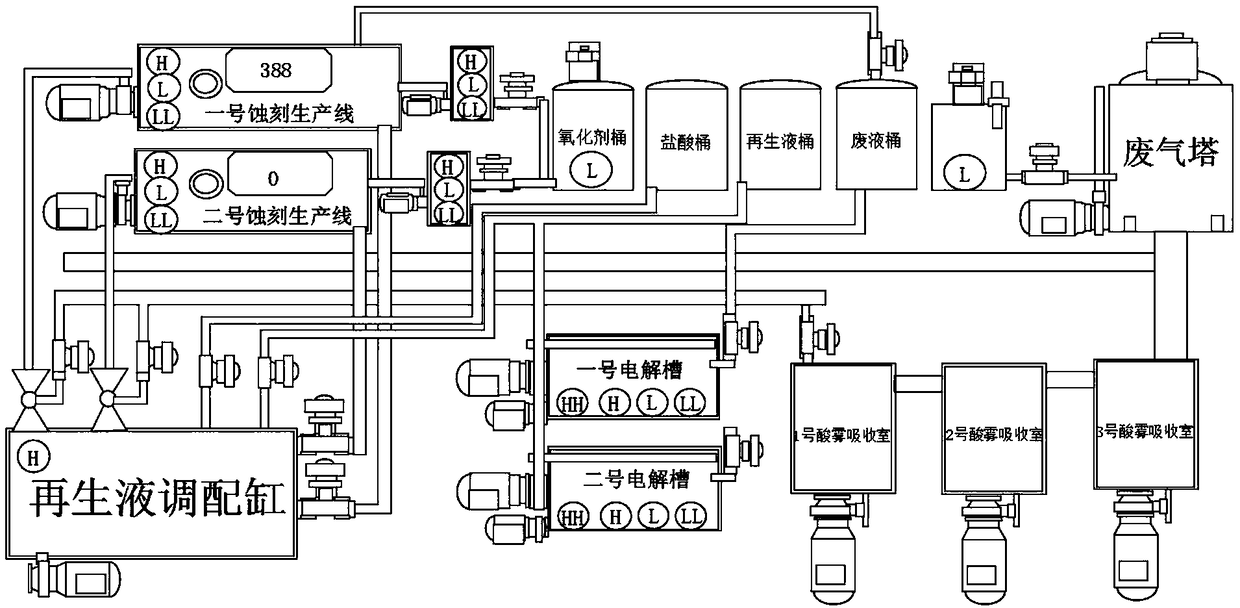

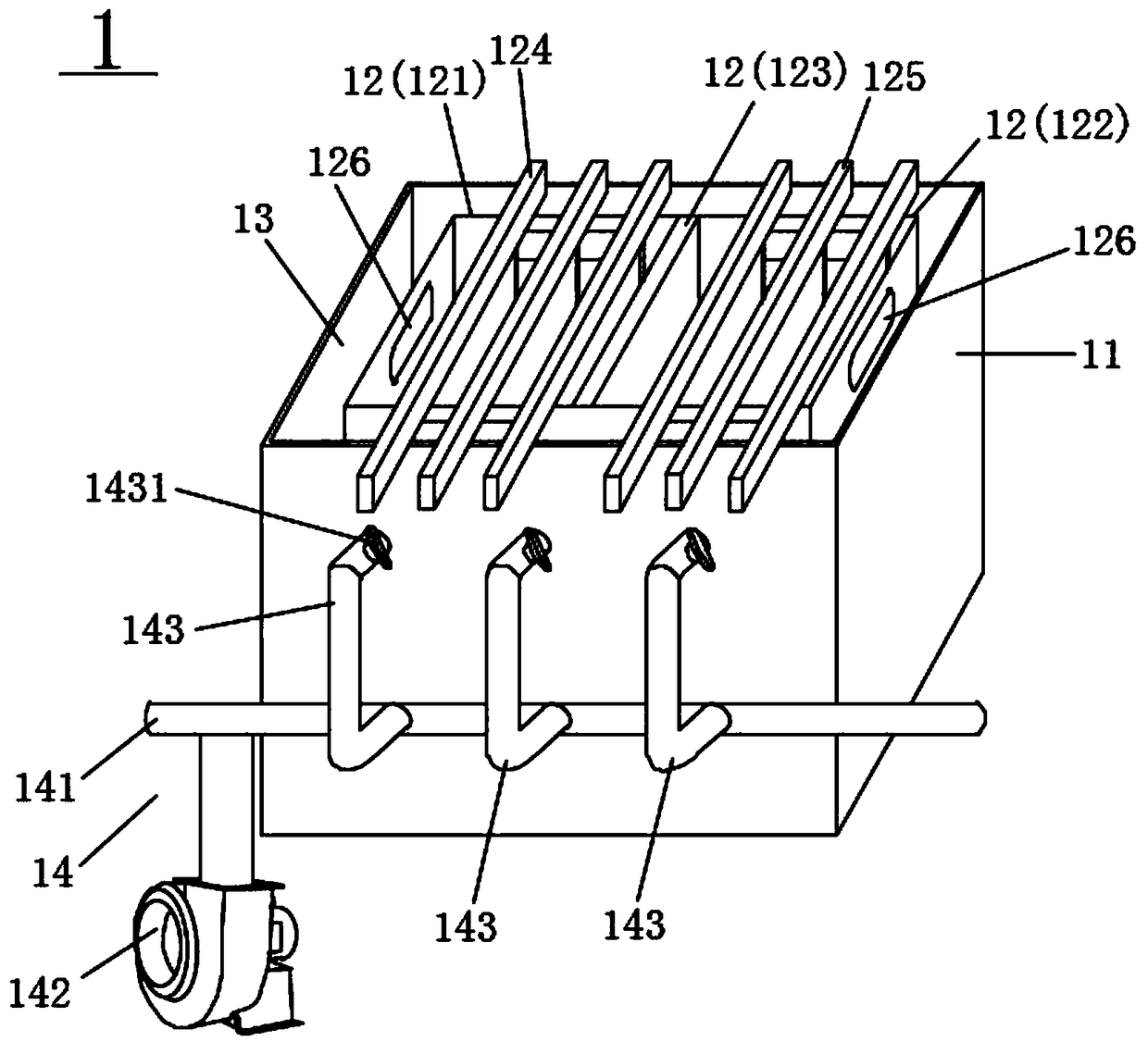

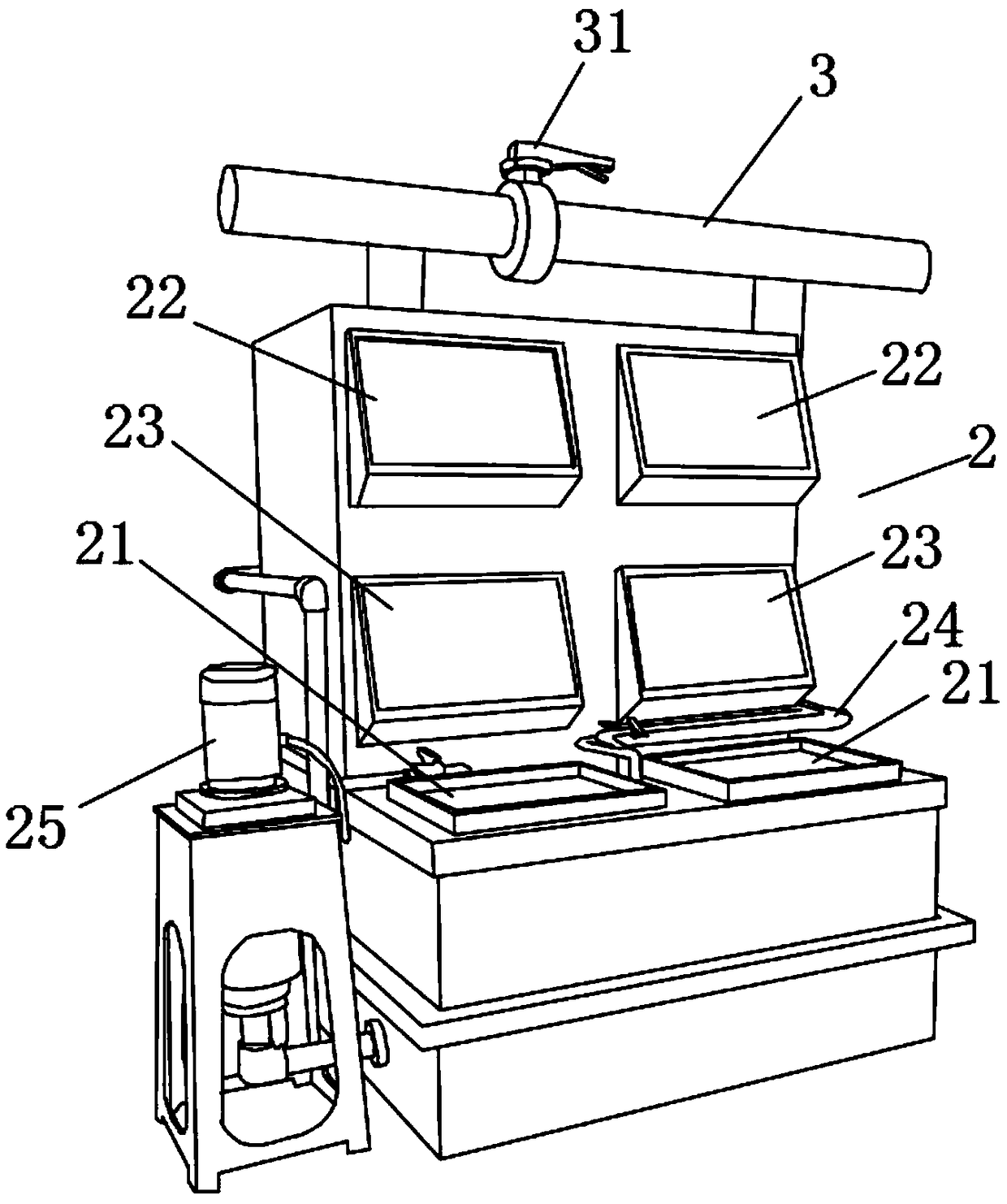

[0041] (1) Prefabricated an acid etching solution recycling system, please refer to figure 1 , which includes a waste liquid barrel, a regeneration liquid barrel, an ionic membrane electrolytic circulation device and a regeneration liquid deployment monitoring device, wherein the waste liquid barrel is respectively connected to the ion membrane electrolysis circulation device and at least one etching production line, and the regeneration liquid The barrels are respectively connected to the ionic membrane electrolytic circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com