Dryer waste heat reutilization device

A dryer and waste heat technology, applied in the direction of dryers, drying, drying gas arrangement, etc., can solve the problems of difficult secondary utilization, environmental impact, energy waste, etc., to reduce environmental impact and improve drying Effect, effect of exhaust gas temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

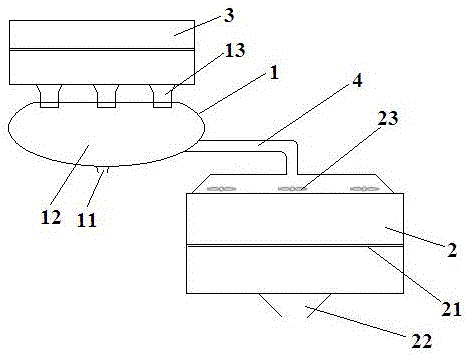

[0014] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 The dryer waste heat recycling device shown includes a fabric pre-dryer 3 and a dehumidification and impurity removal bin 1, one end of the dehumidification and impurity removal bin 1 is connected to the top of the cloth dryer 2 through a ventilation pipe 4, and the other One end is connected to the bottom of the cloth pre-dryer 3 through a plurality of blowing devices 13, and the cloth dryer 2 is discharged into the drying air from the drying air inlet 22 at the bottom, and the cloth conveying line 21 in the cloth dryer 2 is The cloth is dried, and the hot and humid exhaust gas discharged after drying is discharged into the dehumidification and impurity removal bin 1 through the air introduction device 23 at the top of the cloth dryer 2 and the ventilation pipe 4. The dehumidification and impurity removal bin 1 is a large space and low flow rate chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com