High-efficiency dyed cloth drying device

A drying device and high-efficiency technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as large spacing, easy fading of pigments, and affecting product quality, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

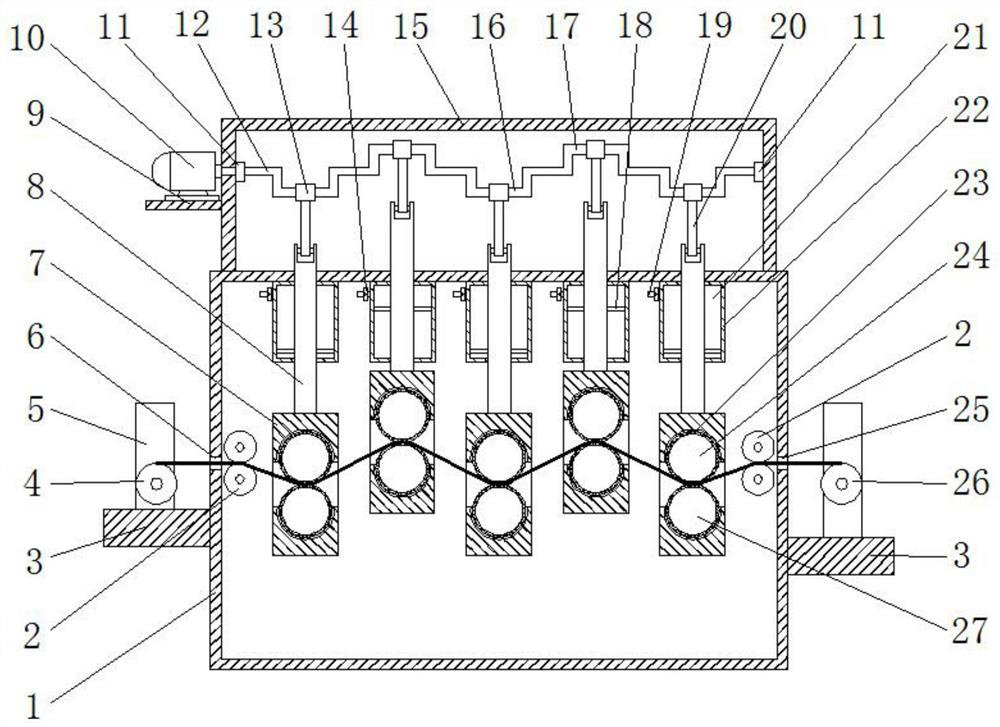

[0029] Such as figure 1 The shown high-efficiency dyeing cloth drying device includes a box body 1 with an electric heating element (not shown in the figure) inside, and two opposite sides of the box body 1 are provided with mutually aligned cloth inlets 6 and Cloth outlet 25, the side of the box body 1 corresponding to the cloth outlet 25 outlet end is provided with a winding roller 26, and the opposite side of the cloth inlet 6 and the cloth outlet 25 in the box body 1 is respectively provided with a group for conveying cloth. Conveyor roller group 2, be provided with at least two lifting frames 7 (five lifting frames 7 are shown in the accompanying drawing) equally spaced between two groups of conveying roller groups 2, described lifting frame 7 is provided with for clamping The upper roller 24 and the lower roller 27 holding the cloth, the upper roller 24 and the lower roller 27 are all parallel to the conveying roller group 2;

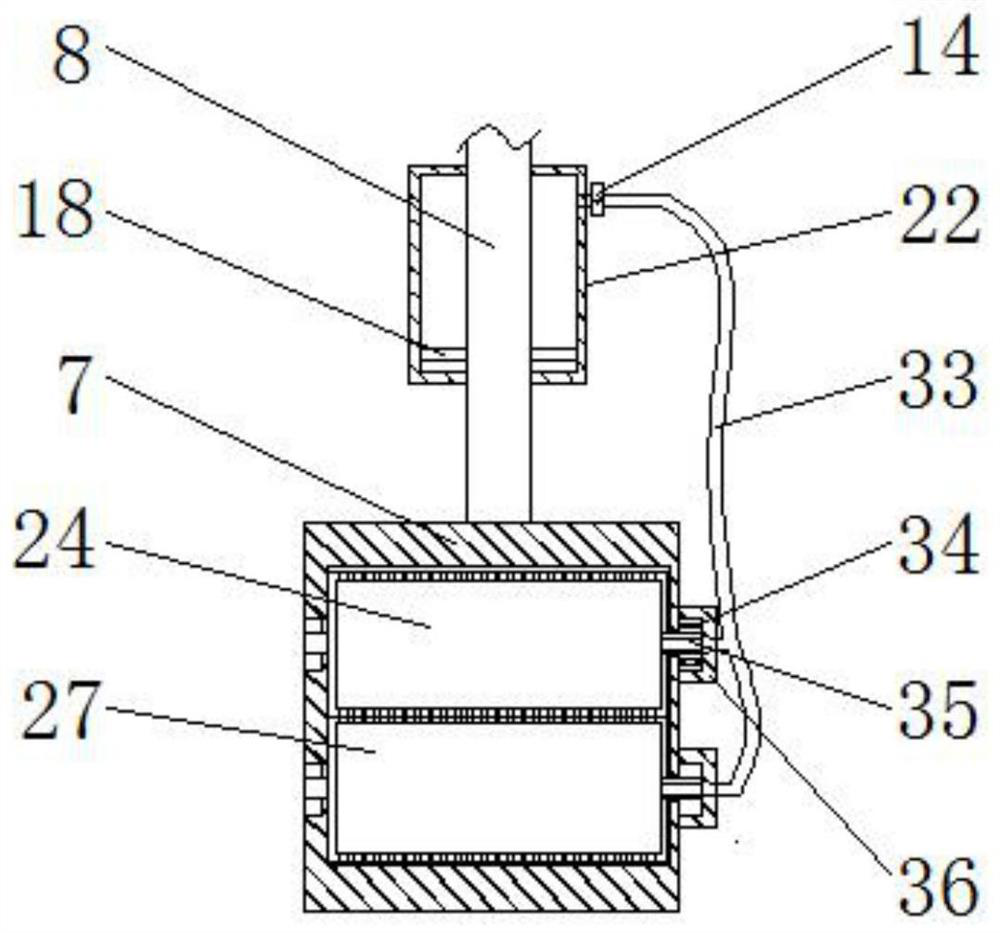

[0030] The top of each lifting frame 7 is ...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

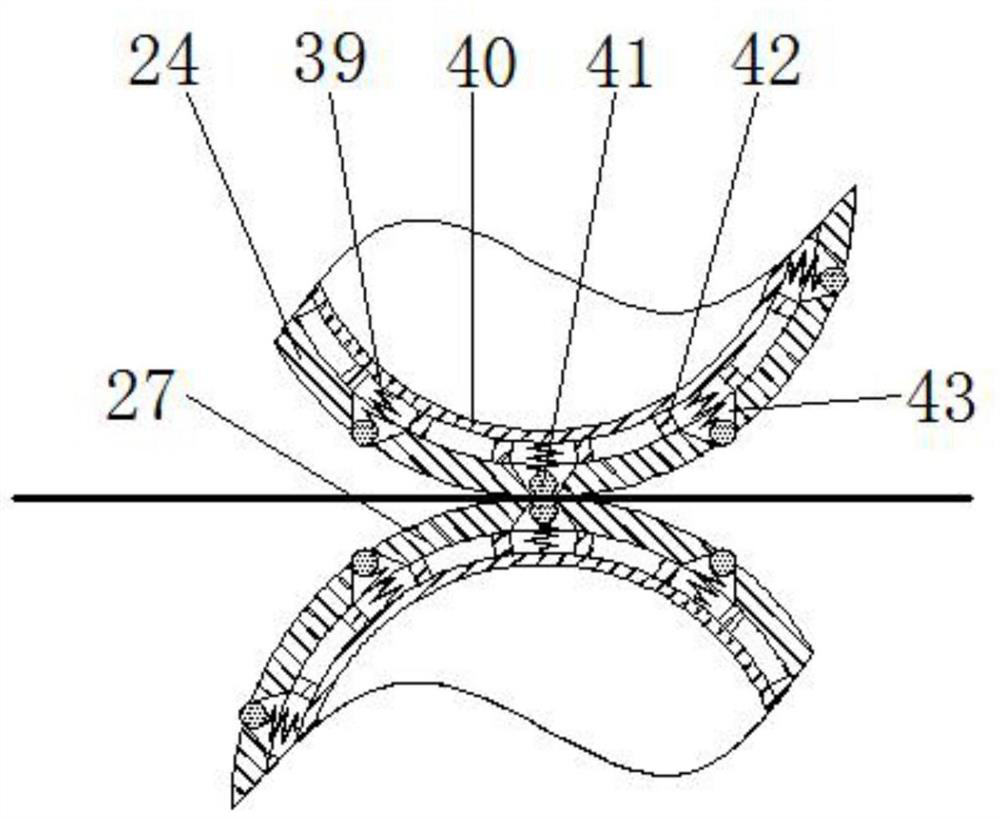

[0037] In this example, if Figure 5 and Figure 6 As shown, the first exhaust pipe 33 is only in communication with the inner cavity of the upper drum 24, not with the inner cavity of the lower drum 27, only the through hole 43 of the upper drum 24 is provided with a blocking assembly, and the lower drum No plugging assembly is provided in the through hole 43 of 27; Figure 4 As shown, a second cylinder 38 fixed to the inner bottom of the box body 1 is provided under each lifting frame 7, and a piston 31 whose periphery is attached to its inner wall is provided in the second cylinder 38. , and the rod-shaped part of the piston 31 runs through the top of the second cylinder 38 and is fixedly connected to the bottom of the lifting frame 7; the two sides of the lower end of the second cylinder 38 are respectively connected with a second air intake pipe 37 communicating with its inner cavity and the second ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com