Indirect heating type dryer

A drying device and heating technology, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of low filling rate, large heat loss, high filling rate, etc., and achieve effective reverse conveying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

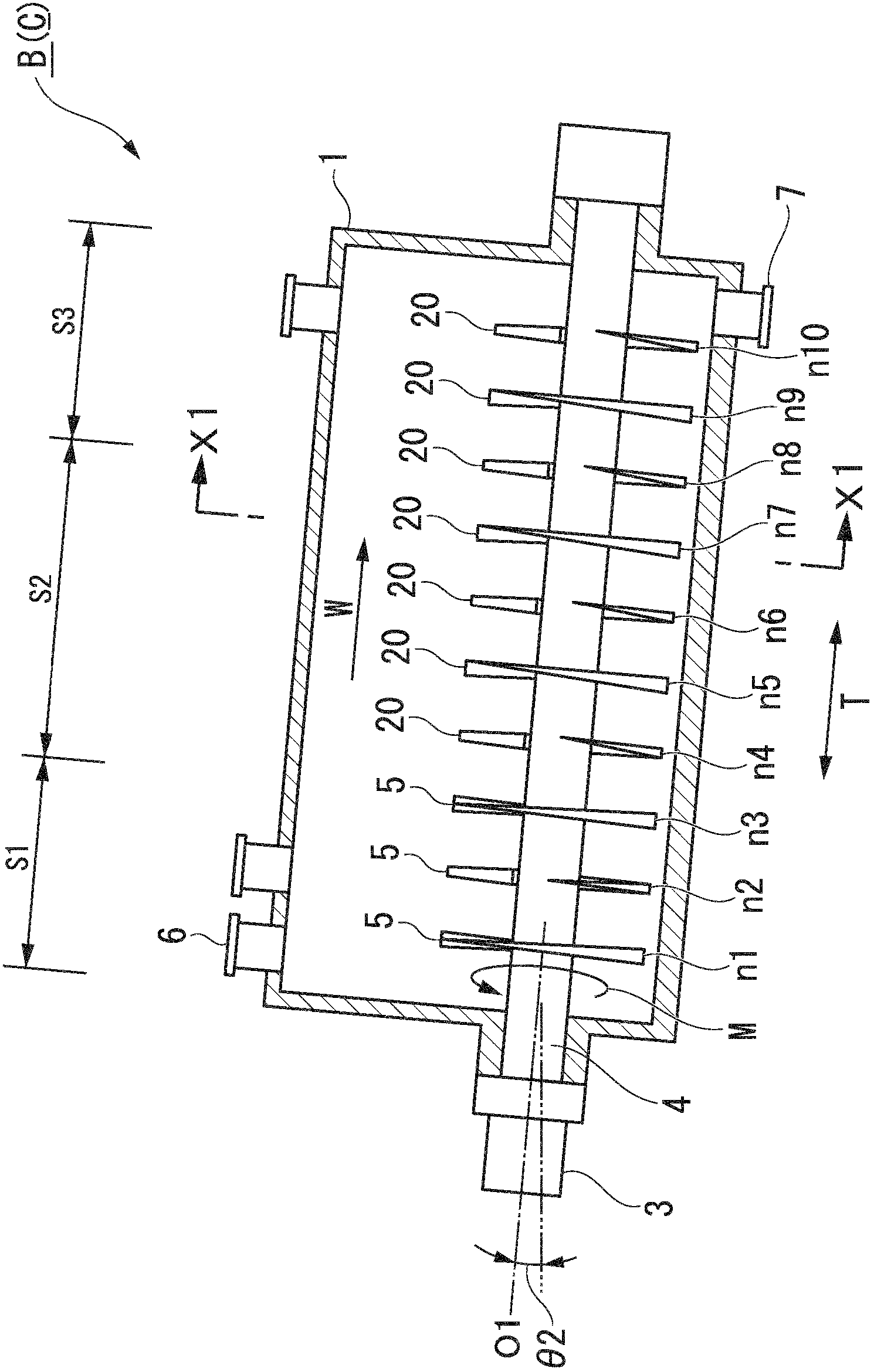

[0111] Below, refer to Figure 1 to Figure 5 The indirect heating drying device according to the first embodiment of the present invention will be described. Here, the present embodiment relates to a method for drying waste such as various biomass, sewage sludge, factory drainage sludge, food waste / kitchen waste, fecal sludge, livestock excrement, plant juice residue, etc. An indirect heating drying device for drying (moisture reduction) treatment.

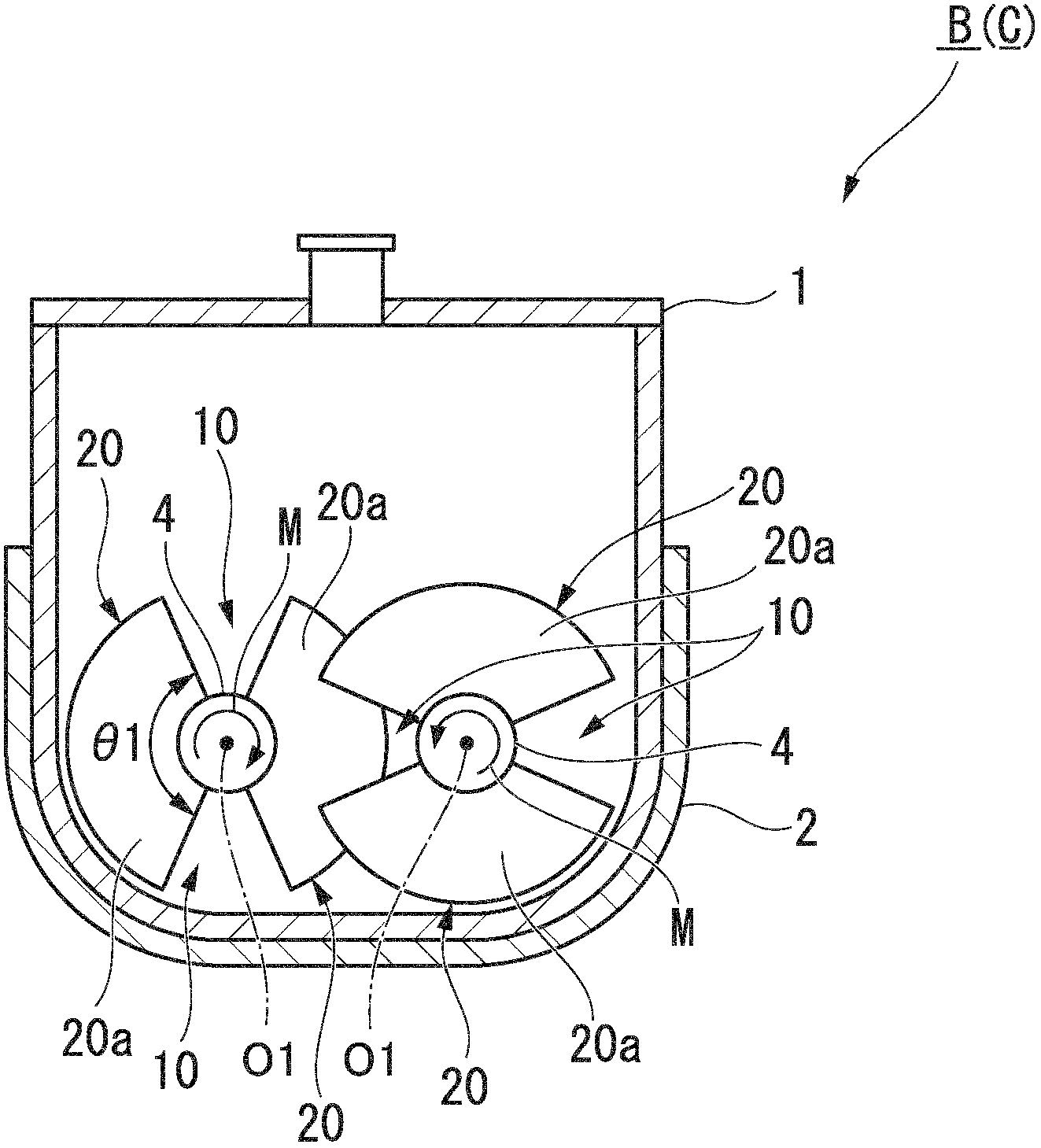

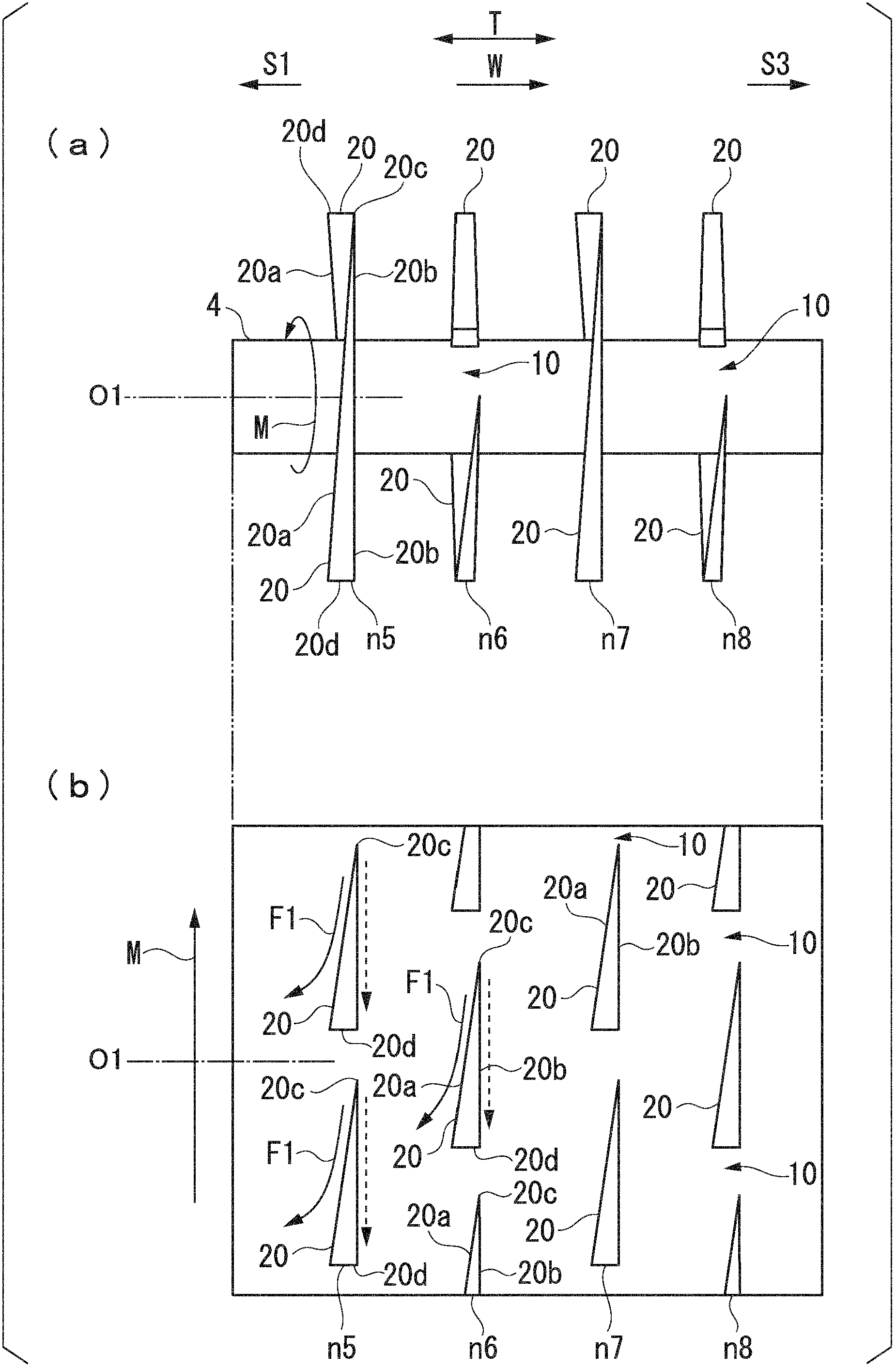

[0112] The indirect heating drying device B of this embodiment is as figure 1 as well as figure 2 As shown, similar to the conventional indirect heating drying device A, it includes a housing 1, an outer cover 2, a rotating shaft 4, and a plurality of stirring blades 5, 20, wherein the housing 1 has a bottom with a substantially U-shaped cross section. The container and the cover 2 heat the casing 1 (and further heat the object P), and the rotating shaft 4 penetrates from the front side S1 of the casing 1 in the front-rear di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com