Patents

Literature

72results about How to "Easy to heat and dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

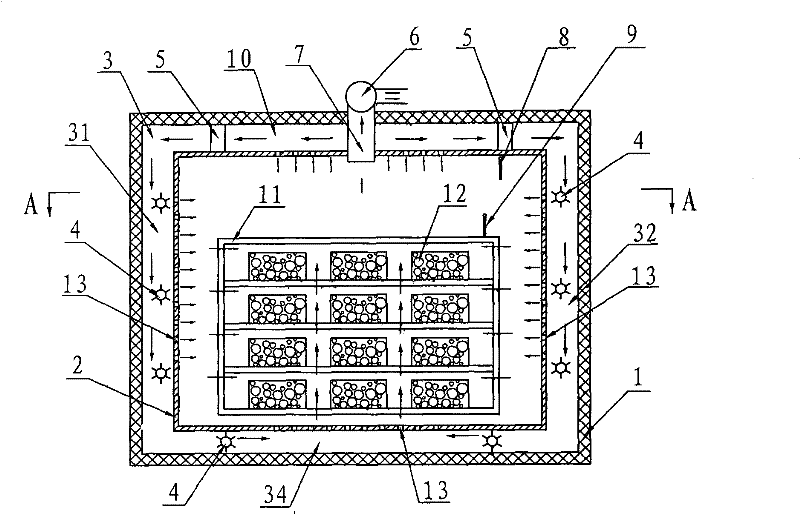

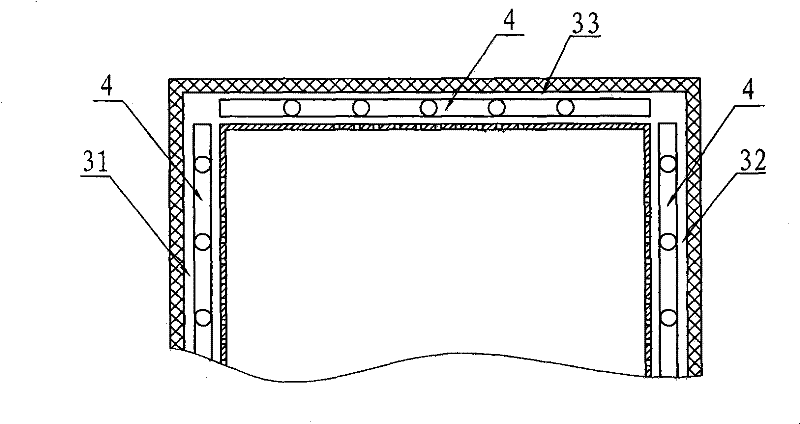

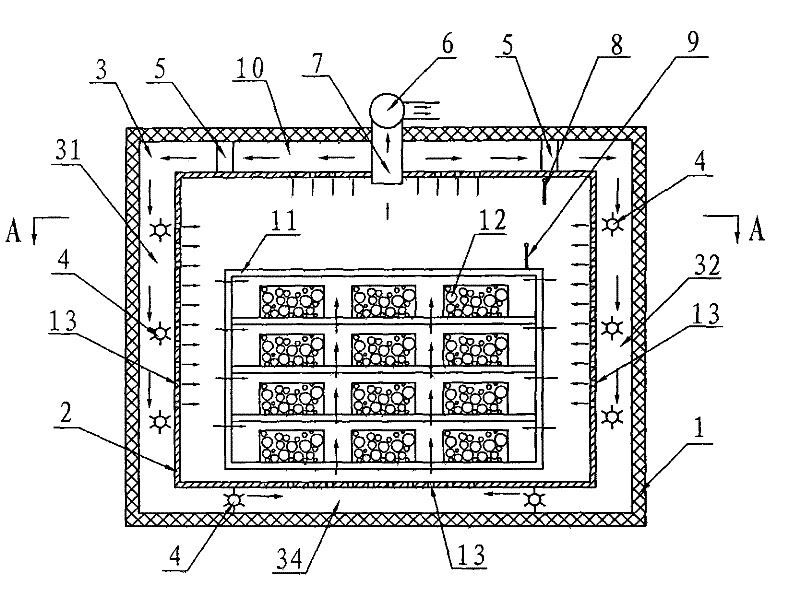

Special baking oven for silicon material

InactiveCN101749929AFully drawn outPulled out in timeDrying solid materials with heatDrying gas arrangementsCooking & bakingWater vapor

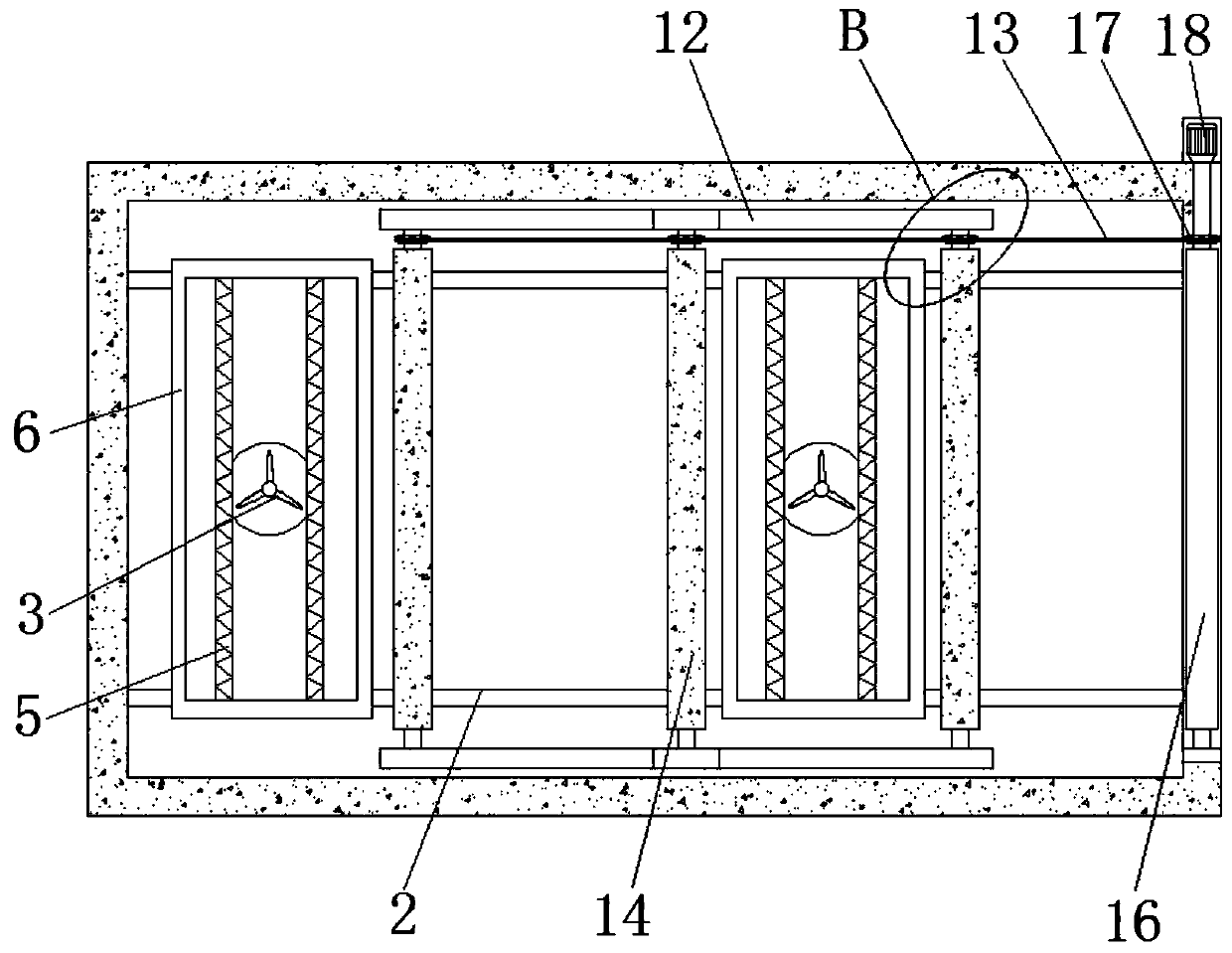

The invention relates to a special baking oven for a silicon material, comprising a thermal insulation shell, an inner container, a high temperature air cavity, a hot air duct, a heater, a circulating fan, a dehumidifier, a dehumidification pipe, a humidity sensor and a temperature sensor, wherein the high temperature air cavity is arranged on top of the inner container, the hot air duct is arranged around the inner container, the heater is arranged in the hot air duct, the circulating fan is arranged between the high temperature air cavity and the hot air duct, the dehumidifier is communicated with the inner chamber of the inner container, the humidity sensor and the temperature sensor are arranged to realize automation control of the baking oven, hot air in the baking oven can form backflow to facilitate full contact of hot air and silicon material, and the dehumidifier can discharge water vapor in the baking oven in time and form proper vacuum in the baking oven to reduce moisture vaporization temperature and improve baking speed. The invention has obvious energy-saving effect and can greatly reduce energy consumption and labor cost.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

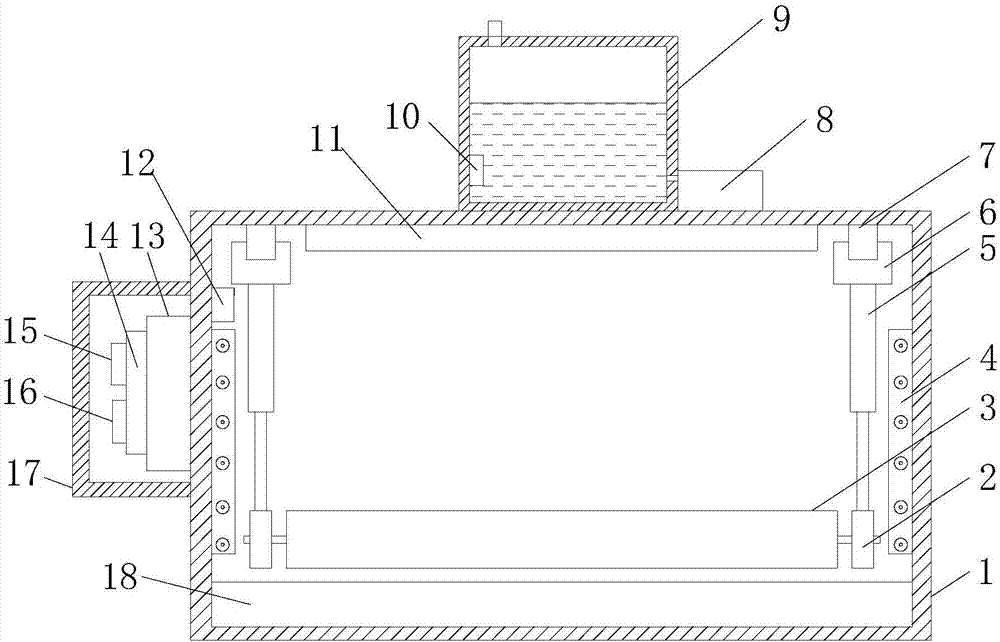

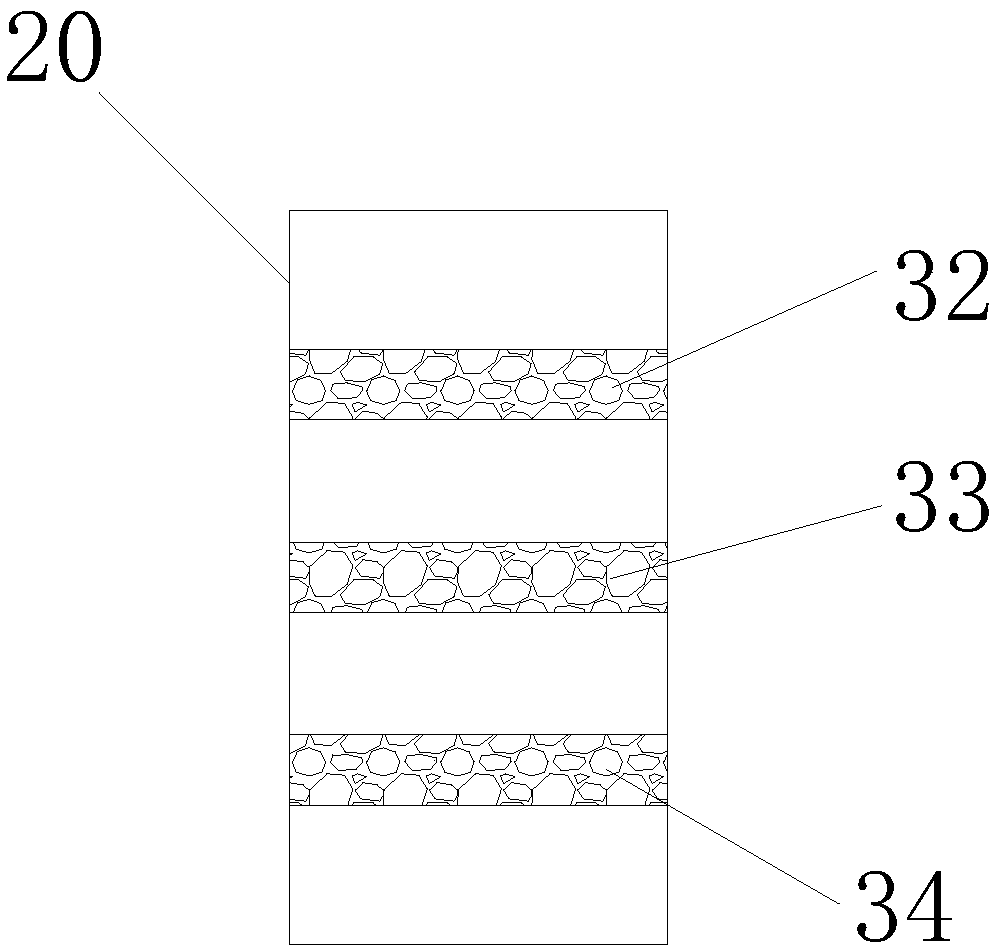

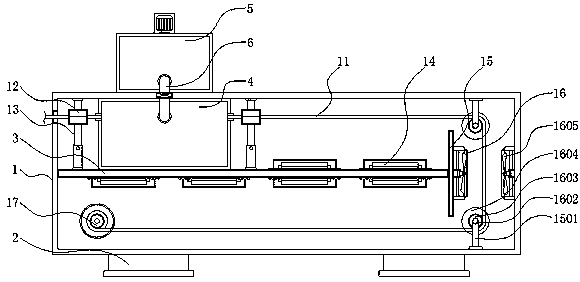

Medical dryer

InactiveCN103134274AWill not polluteAvoid pollutionDrying gas arrangementsDrying chambers/containersEngineeringContamination

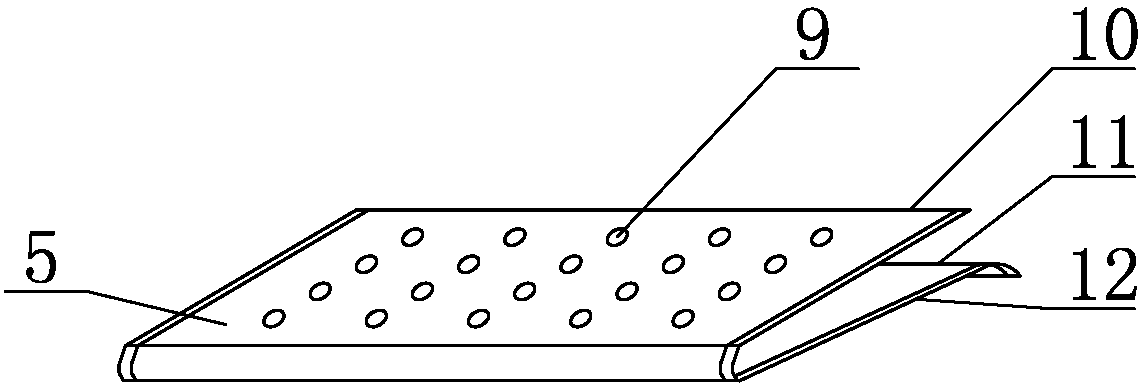

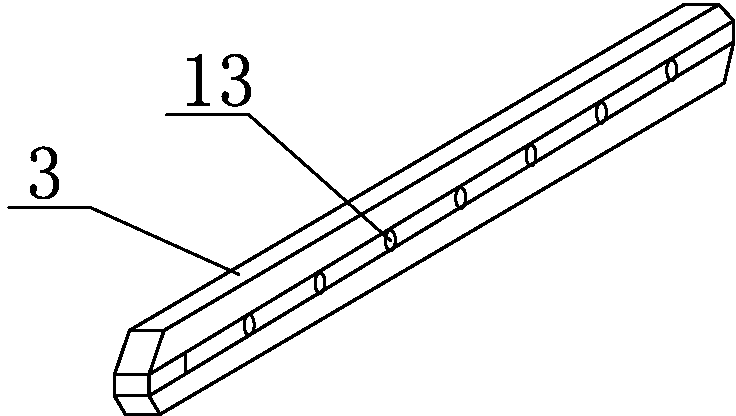

The invention belongs to the field of medical apparatus and particularly relates to a medical dryer. The medical dryer comprises an enclosure and is characterized in that bracket slide rails are arranged in the enclosure, brackets are installed on the bracket slide rails, the upper layer of each bracket is a leak screen layer, leak holes are formed in each leak screen layer, the lower layer of each bracket is a guide layer, the leak screen layers and the guide layers are connected together, one side of each guide layer tilts down, a gap is reserved between the one side of each guide layer and the inner wall of the enclosure, a liquid discharge groove is formed in the bottom of the enclosure and connected with a liquid discharge pipe, and damp pumping exhaust fans are installed on the enclosure. In the drying process, even if water drips down from the leak holes of the leak screen layers, the water can not contaminate substances on the lower layers, and the possibility of liquid contamination is avoided. Meanwhile, the guide layers are arranged to isolate to-be-dried substances on each two brackets, and water evaporated from to-be-dried substances on each lower bracket surges upward, condenses after encountering each guide layer, is guided along the lower surface of each guide layer and then drips into the liquid discharge groove. The medical dryer can dry a plurality of different substances at the same time, and cross contamination can not happen.

Owner:淄博金墨知识产权顾问有限公司

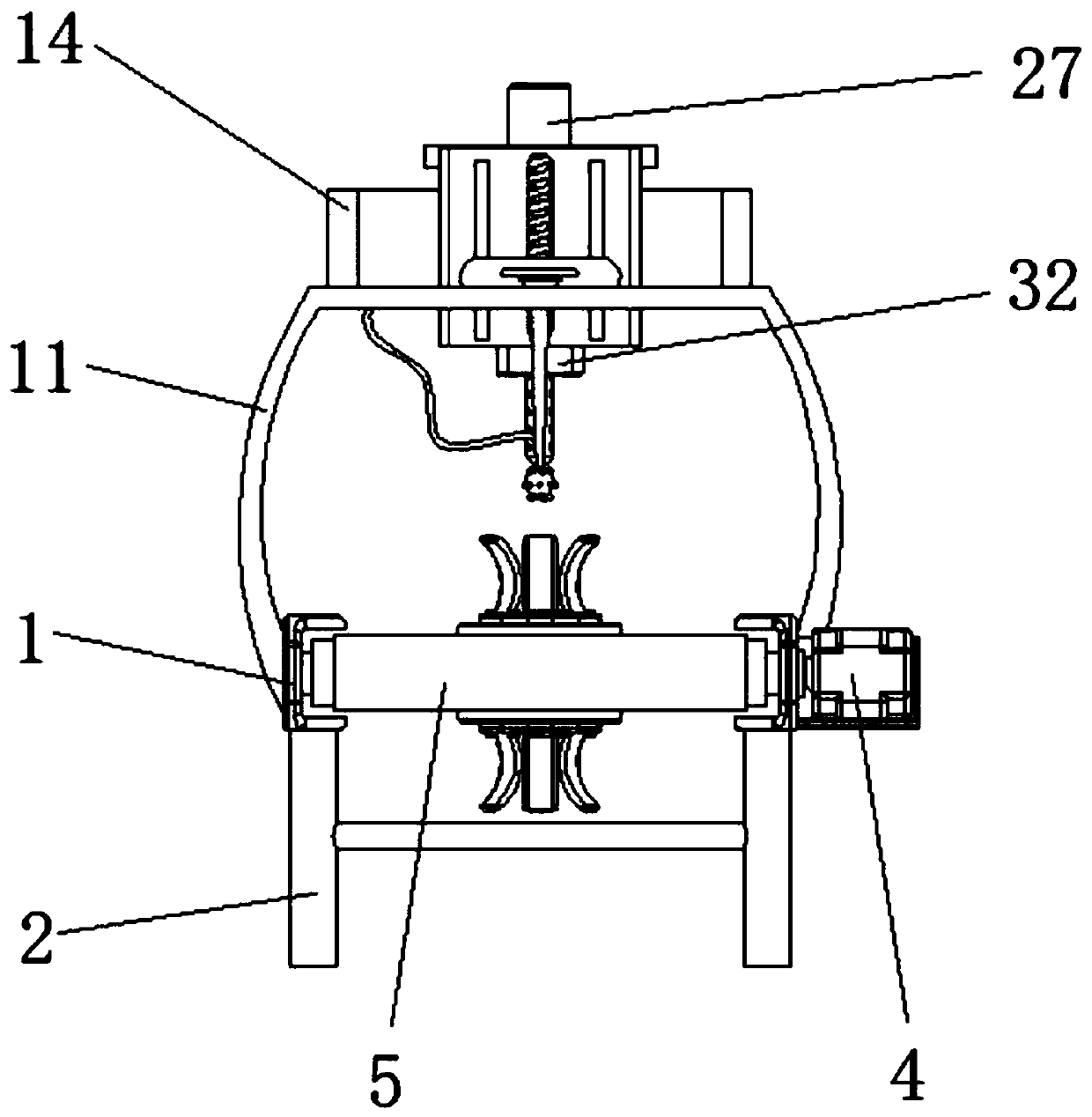

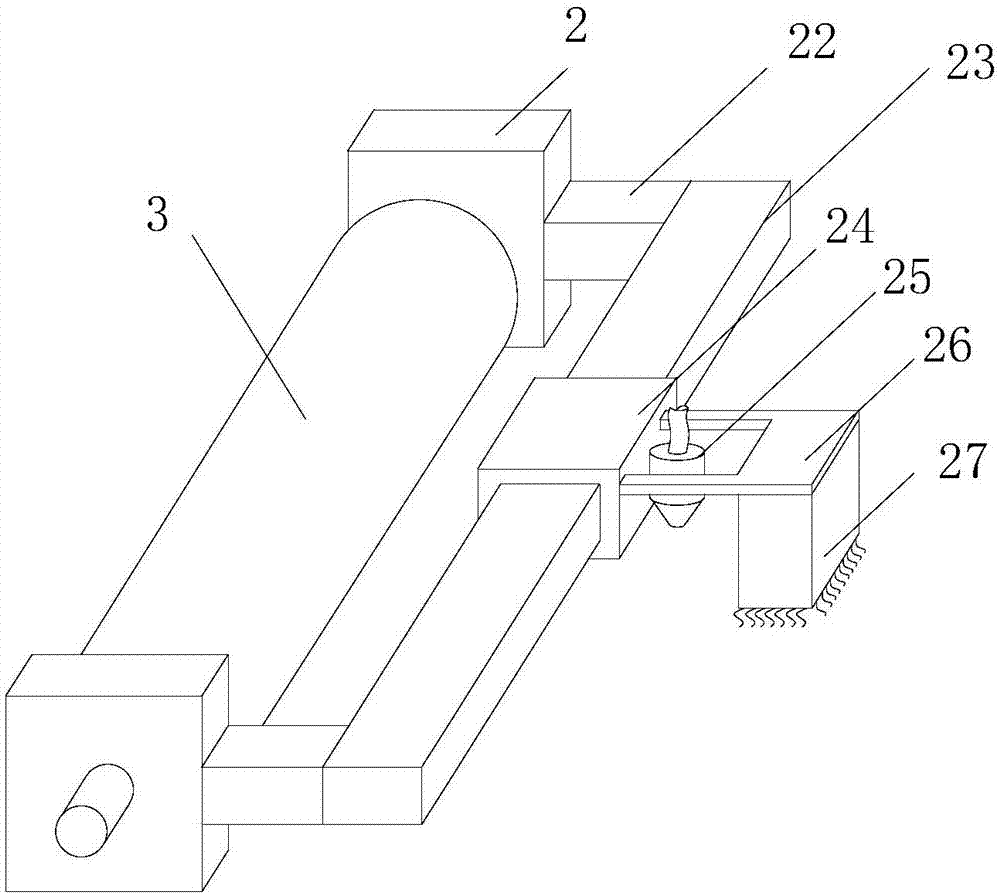

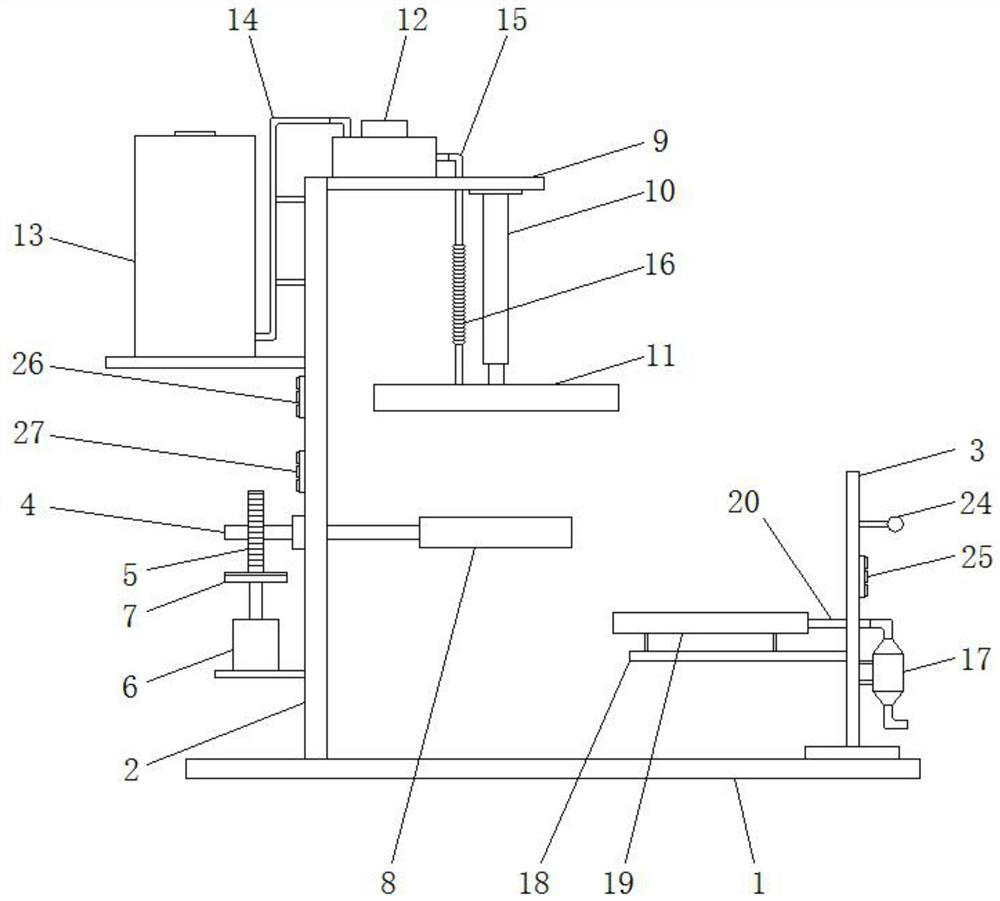

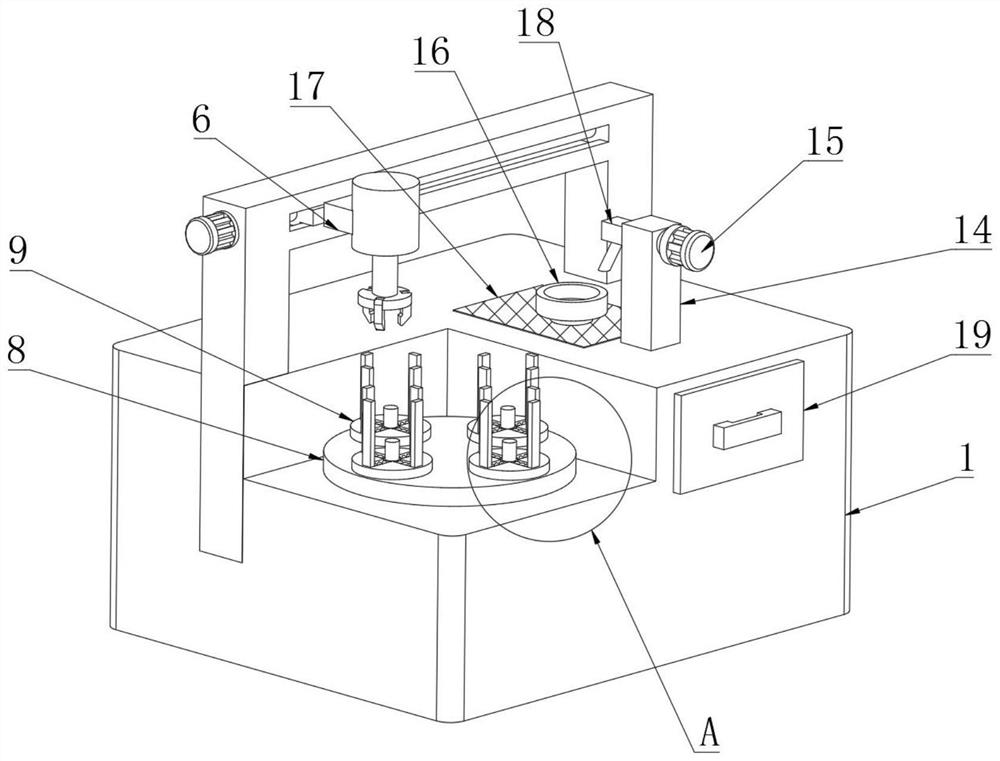

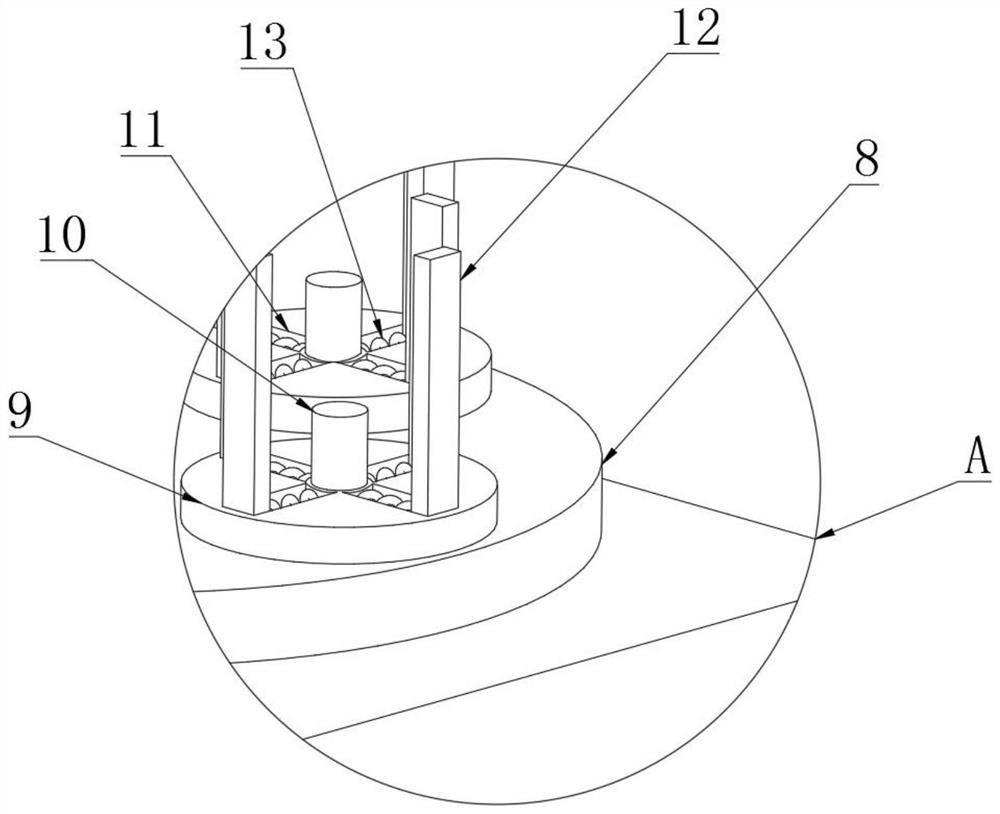

Ceramic bottle internal glaze spraying equipment for process ceramic production

ActiveCN111113649AAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

The invention belongs to the technical field of glaze spraying equipment, in particular to ceramic bottle internal glaze spraying equipment for process ceramic production. The ceramic bottle internalglaze spraying equipment comprises a protection support plate, wherein supporting legs are arranged at the bottom of the protection support plate, and an L-shaped supporting plate is arranged on one side of the protection support plate; a first motor is arranged at the top of the L-shaped supporting plate, and the output end of the first motor penetrates through the protection support plate. A ceramic bottle internal glaze spraying mechanism is arranged, on the one hand, storage and placement of glaze for glazing the surface of a ceramic bottle can be achieved through a material storage box, paint can be conveniently provided for glazing and spraying on the internal surface of the ceramic bottle, and meanwhile, the material storage box is used for storing the glaze so that the working amount of repeated adding of the glaze by an operator can be relieved; and on the other hand, a guide supporting cylinder can be conveniently inserted into the interior of the ceramic bottle through the mode that a transmission screw is adopted to move up and down for adjustment, and uniform glaze spraying treatment is carried out on the inner wall of the ceramic bottle by using a spherical glaze spraying joint.

Owner:广东金润源陶瓷股份有限公司

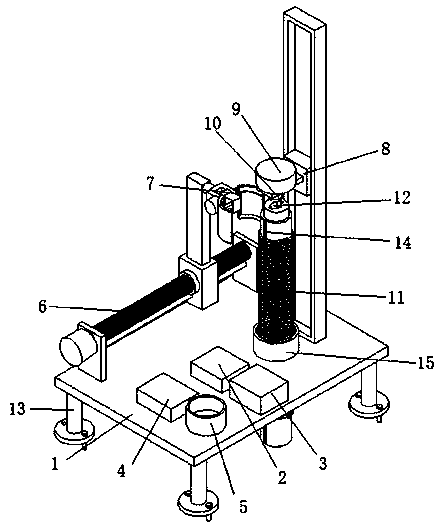

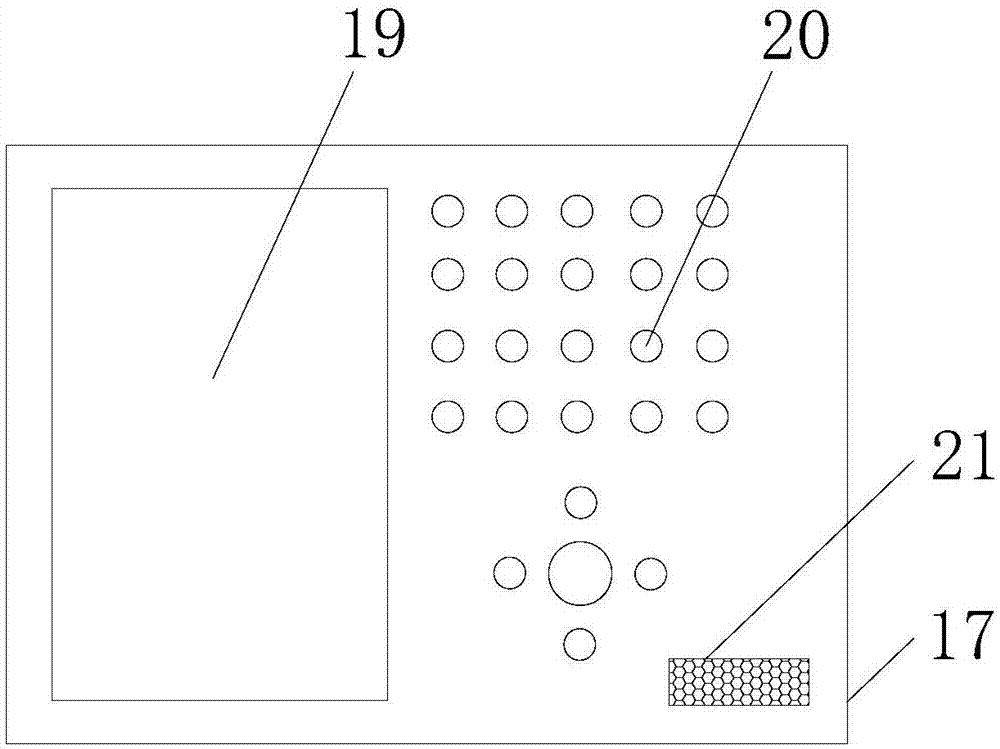

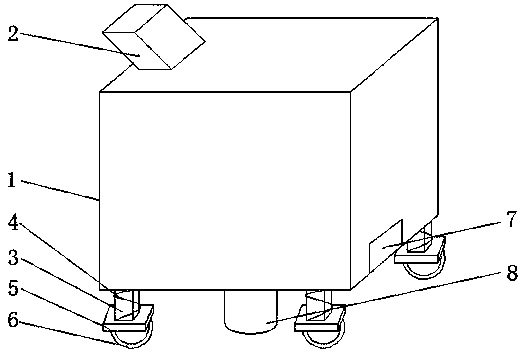

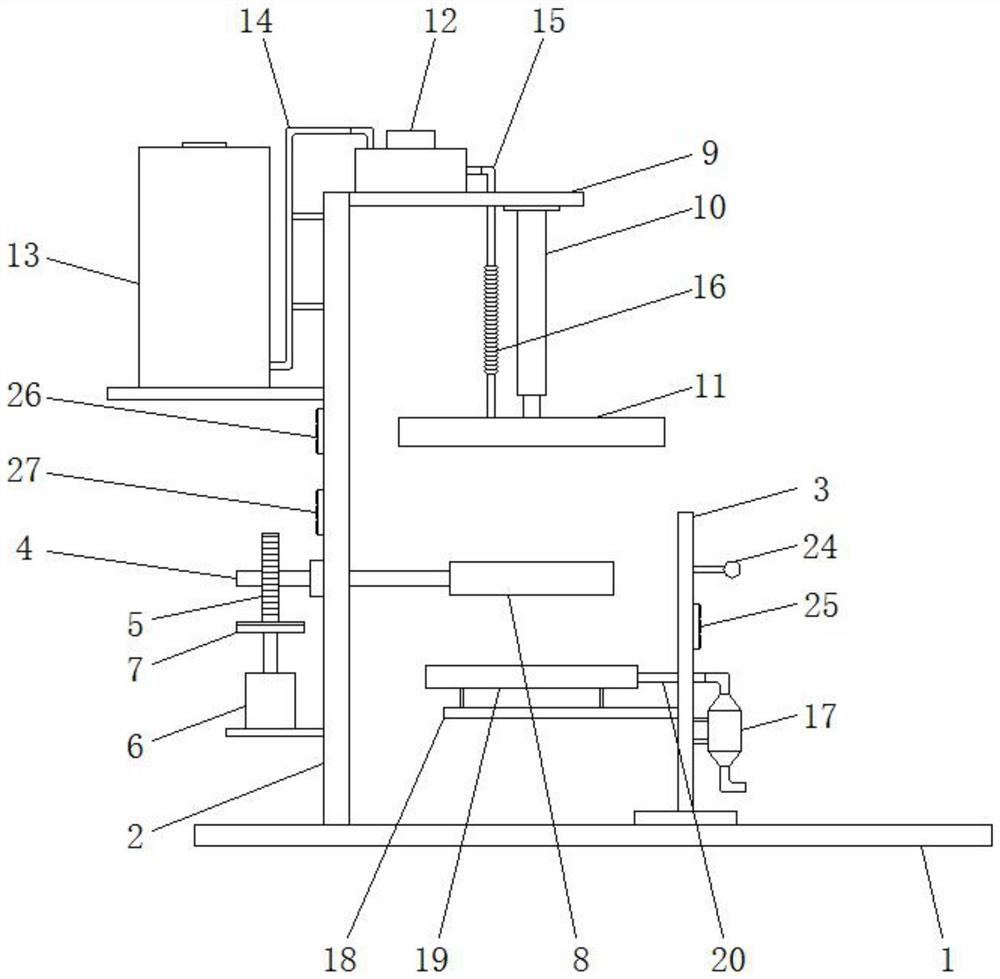

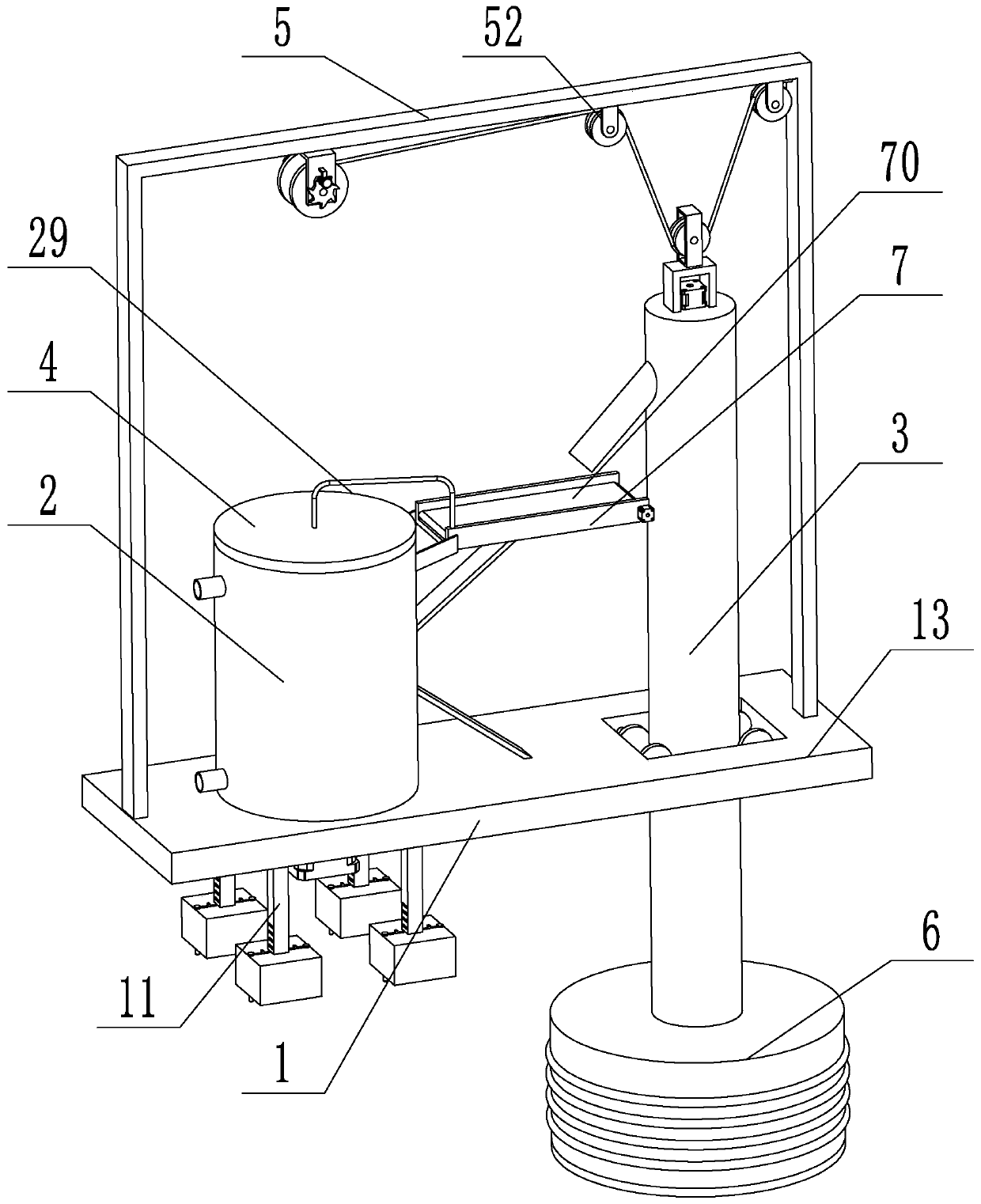

Soil detection device

PendingCN110672360AImprove work efficiencyIncrease frictionWithdrawing sample devicesSoil humidityBiology

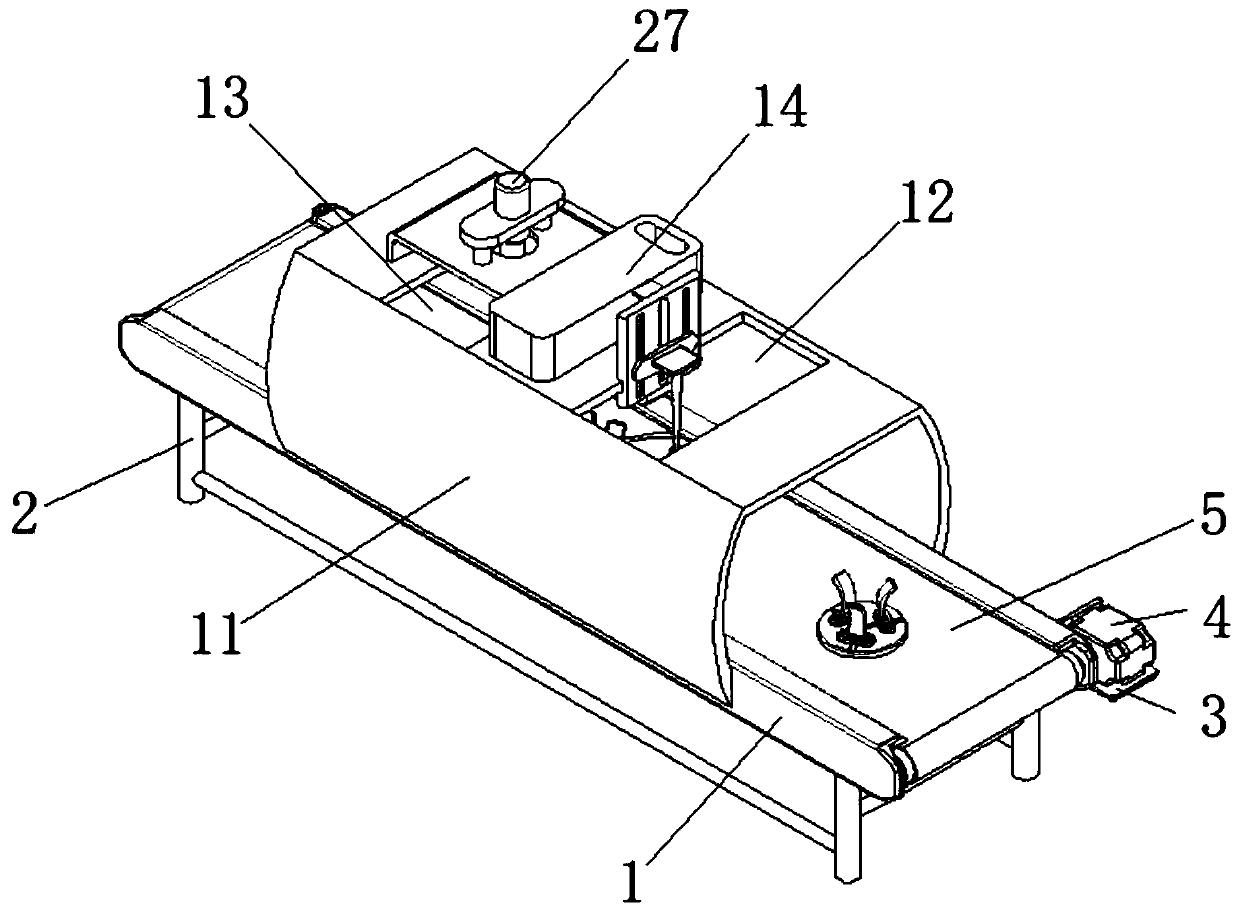

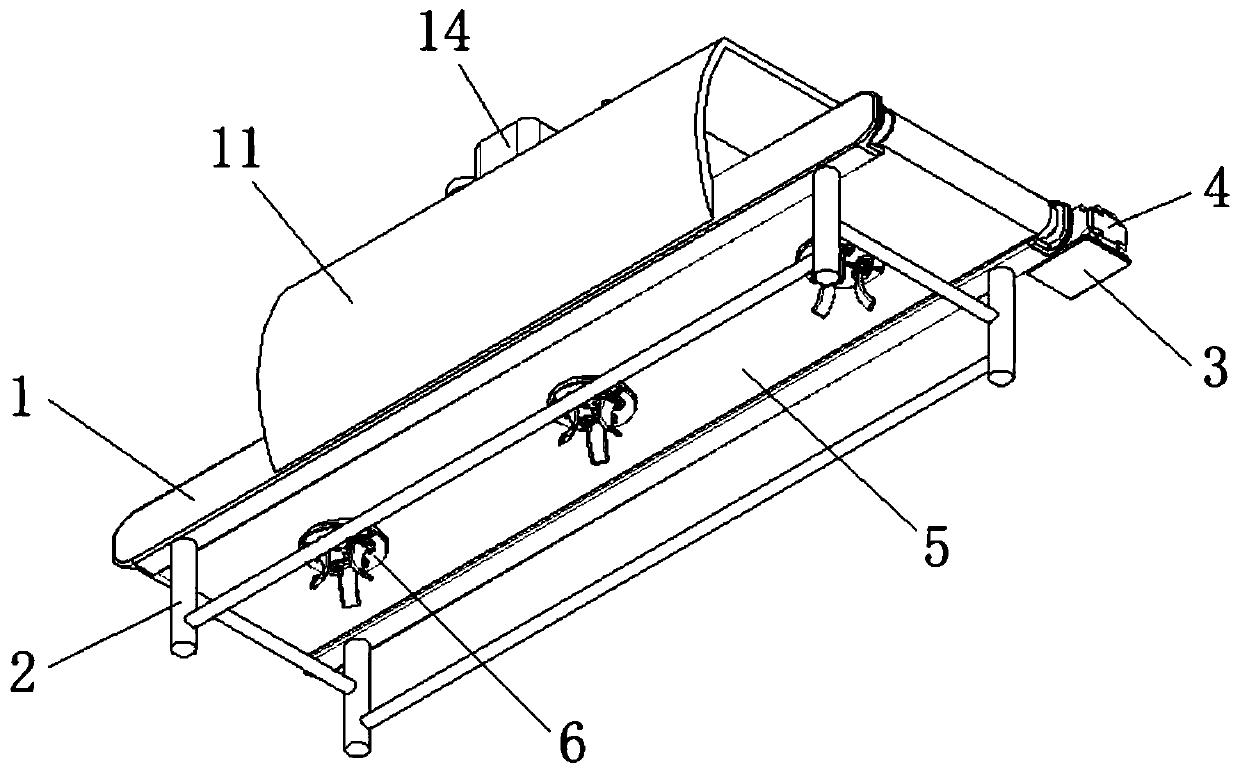

The invention discloses a soil detection device. The soil detection device comprises a console, a longitudinal regulation mechanism and a sampling mechanism; a fixed mechanism is mounted on the lowersurface of the console; a transverse regulation mechanism is mounted at the left part of the console; a clamping mechanism is mounted on the transverse regulation mechanism; and the sampling mechanismis arranged on the console. According to the soil detection device, the sampling mechanism is arranged, so that while accurate sampling is implemented, soil at different depths can be simultaneouslysampled, thereby facilitating carrying out detection of the soil at different depths by an experimenter; scale marks are set, so that a sampling depth can be observed; the clamping mechanism is arranged, so that the sampling mechanism can be clamped by the clamping mechanism after sampling, thereby facilitating sampling by an inspector without holding a sample with a hand by the inspector and preventing the hand of the inspector from being damaged by polluted soil; and a drying box is arranged, so that the sample can be dried, thereby preventing influence of soil humidity on a detection result.

Owner:ZHUHAI GAOLING INFORMATION TECH COLTD

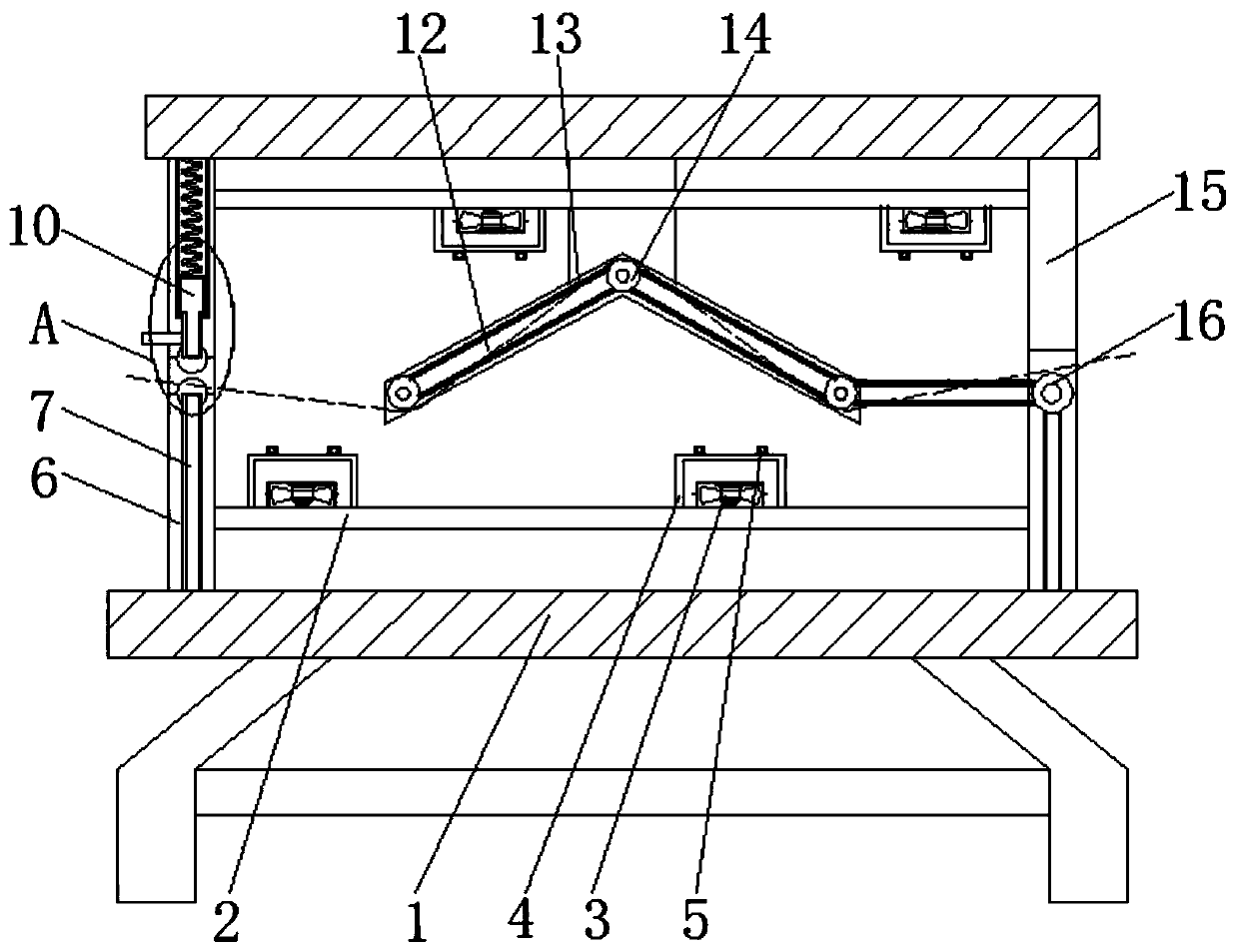

Household clothes drying rack

InactiveCN108660707AEasy to hangAvoid the Problem of Hanging on a Drying RackOther drying apparatusTextiles and paperEngineeringUltraviolet germicidal light

The invention relates to the technical field of household products, and discloses a household clothes drying rack. The rack comprises four mounting blocks, the bottoms of the four mounting blocks arefixedly connected with connecting rods, the bottoms of the connecting rods are fixedly connected with lifting devices, pulling ropes are disposed on the inside of the lifting devices, hooks are fixedly connected to the bottoms of the pulling ropes, hanging loops are attached to the bottoms of the hooks, moving devices are fixedly connected to the bottoms of the hanging loops, the interiors of themoving devices are fixedly connected with drying devices, two sides of the drying devices are fixedly connected with ultraviolet germicidal lamps, and suspension rods are fixedly connected to the bottoms of the moving devices. The household clothes drying rack makes the suspension rods rise or fall, facilitates the hanging of clothes, avoids the problem of manually hanging the clothes on a clothesdrying rack by a clothes picking rod, saves time and labor, is safe and reliable, can effectively conduct drying during air-drying, refuses to rely on whether to dry the clothes, and improves the speed of clothes drying.

Owner:杨秀龙

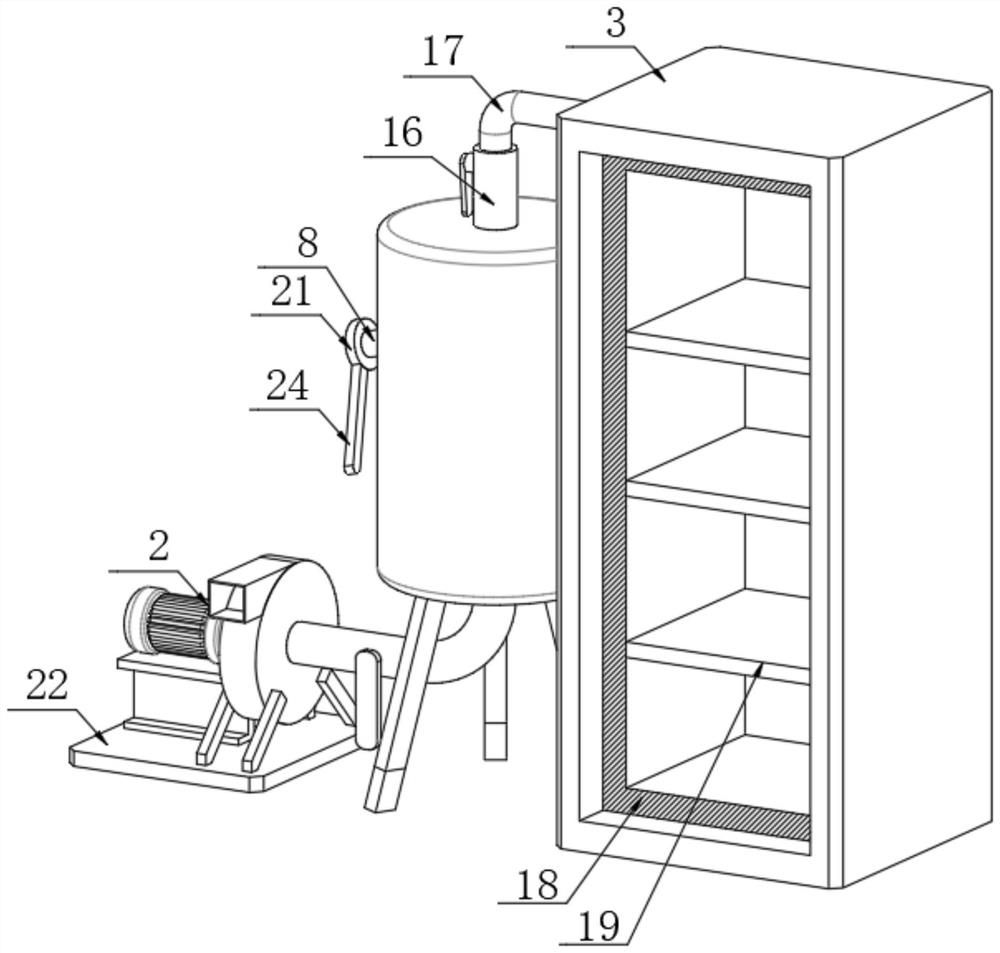

Environment-friendly flue gas waste heat drying device

ActiveCN112378182AEfficient use ofMake full use ofDispersed particle filtrationTransportation and packagingThermodynamicsFlue gas

The invention discloses an environment-friendly flue gas waste heat drying device in the technical field of flue gas treatment. The environment-friendly flue gas waste heat drying device comprises a tank body, the inner side of the tank body is coated with a heat insulation coating, a draught fan is arranged on one side of the tank body, a drying box is arranged on the other side of the tank body,a filtering assembly is arranged in the tank body, the filtering assembly comprises air guide pipes, a vertical rod, fan blades, heat conduction wires, a discharging pipe, a filtering cylinder and asealing plate, an air duct is fixedly connected to the bottom end of the interior of the tank body, the air guide pipes are rotationally connected to the top of the air duct, and the fan blades are fixedly connected to the outer side of the vertical rod. According to the environment-friendly flue gas waste heat drying device, air can be heated through heat of the heat conduction wires and the tankbody, so that the heated air is conveyed into a heat preservation interlayer through a connecting pipe, heating and drying of objects are facilitated, the structure is beneficial to full and reasonable utilization of heat in exhausted flue gas, and therefore, the environment-friendly flue gas waste heat drying device is more energy-saving, environmentally friendly and high in practicability.

Owner:SHANDONG DAIRONG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Disinfecting and drying plant for leather production

ActiveCN107130062AEasy to disinfectEasy to sterilize and dryLeather pressing/rollingLavatory sanitoryEngineeringLinear actuator

The invention discloses a disinfecting and drying plant for leather production. The disinfecting and drying plant comprises a disinfecting box, a heating plate is installed on the inner wall of the top of the disinfecting box, the two sides of the heating plate are each provided with a first linear guideway, a first linear guideway sliding block is installed at the bottom of each first linear guideway, a linear actuator is installed at the bottom end of each first linear guideway sliding block, a fixing plate is installed at the bottom end of each linear actuator, and a grinding roller is installed on one side of each fixing plate; a connecting rod is installed on one side of each fixing plate, a second linear guideway is installed at one end of each connecting rod, a second guideway sliding block is installed on each second linear guideway, an atomizing spray head and a support are installed on one side of each second guideway sliding block, and a cleaning brush is installed at the bottom end of each support; and ultraviolet radiators are installed on the inner walls of the two sides of the disinfecting box, a temperature sensor is installed on the inner wall of one side of the disinfecting box, a storage table is installed on the inner wall of the bottom of the disinfecting box, and a disinfectant storage box is installed at the top of the disinfecting box. By means of the plant, leather can be conveniently dried and disinfected.

Owner:安徽金鑫达皮业科技有限公司

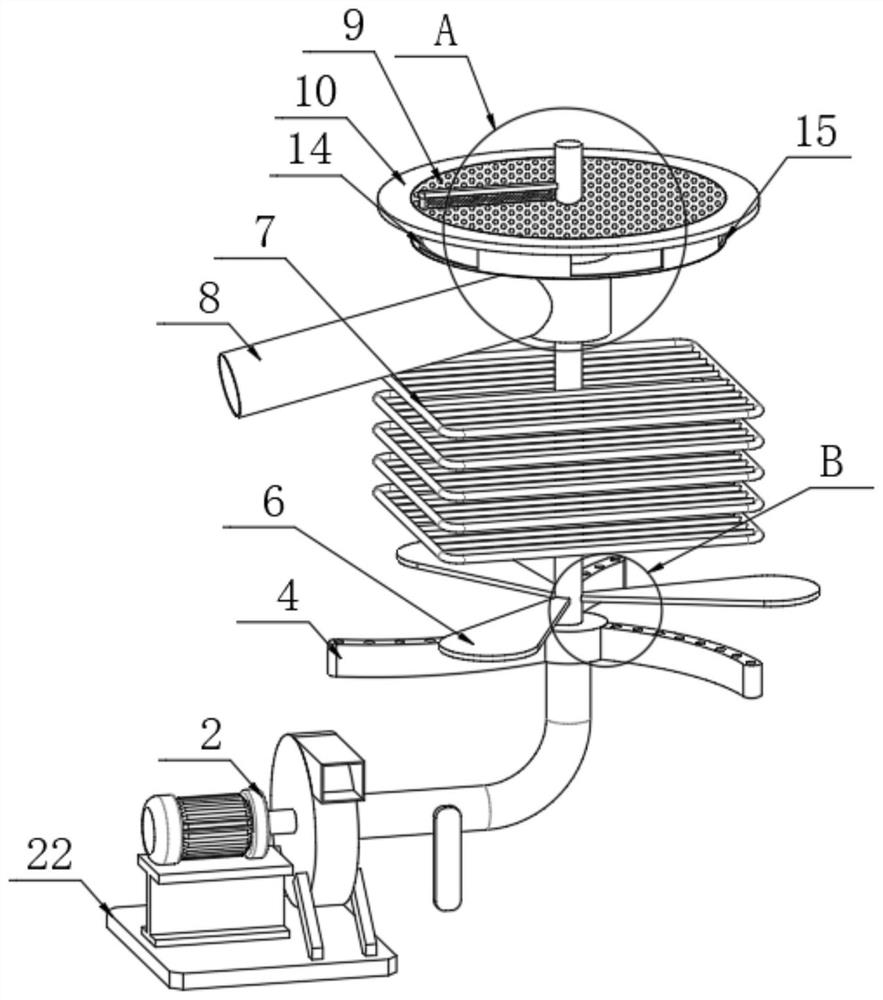

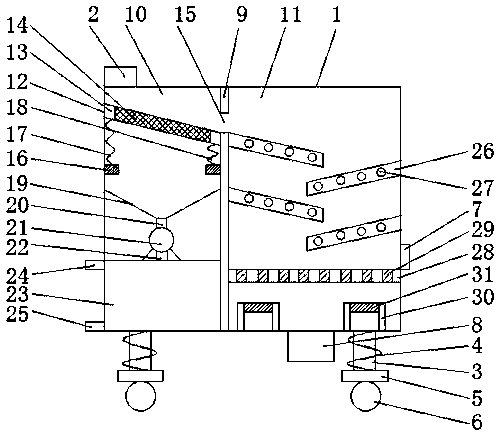

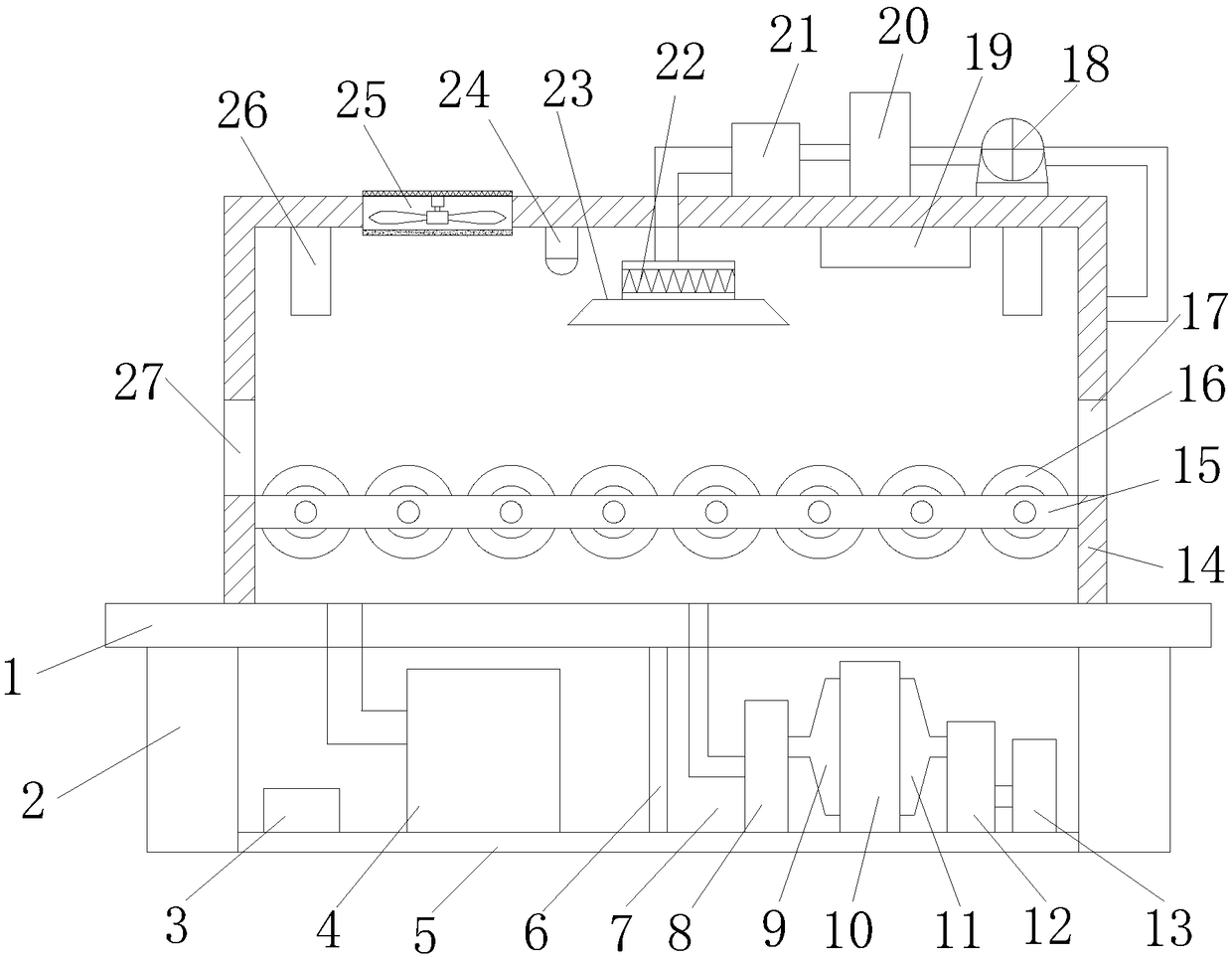

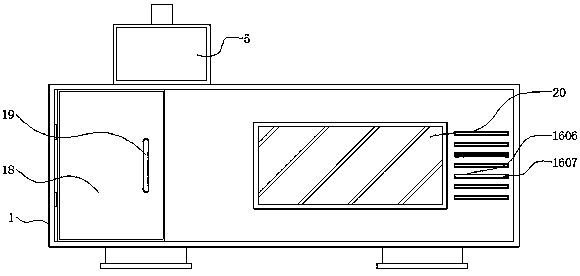

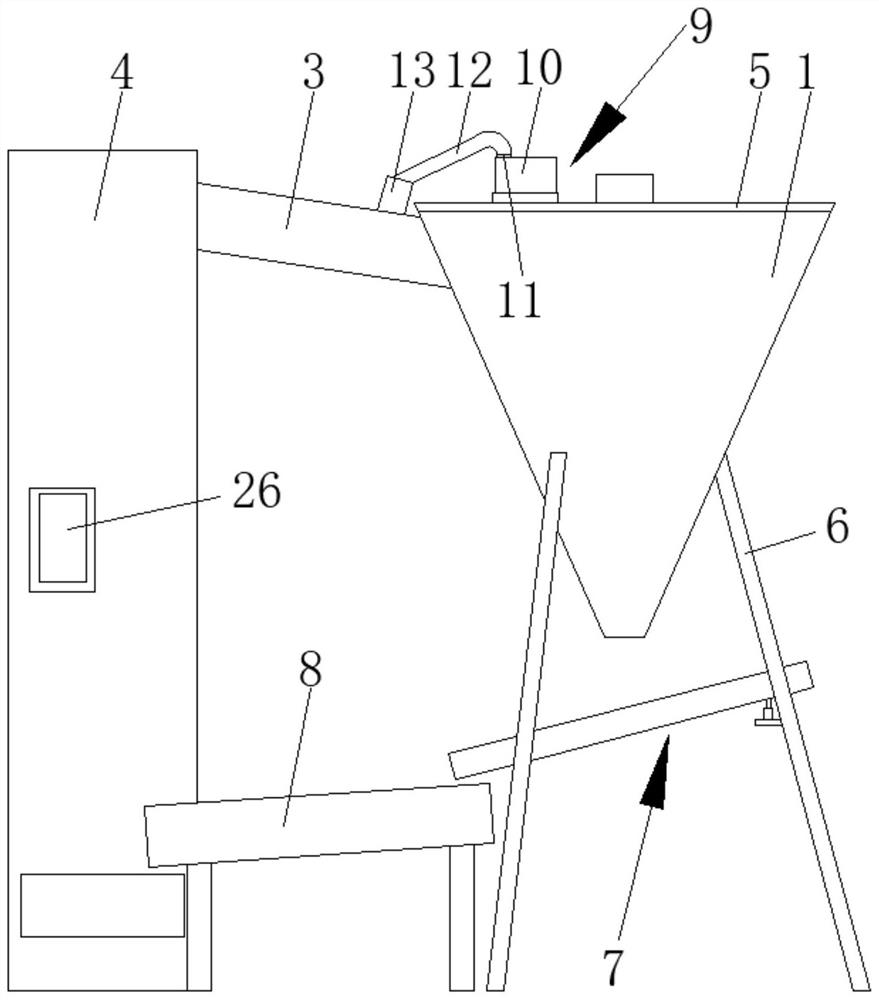

Rapid drying device for traditional Chinese medicinal materials

InactiveCN109764643AEasy to dryEasy to heat and dryDrying using combination processesDrying solid materials without heatWater storage tankEngineering

The invention discloses a rapid drying device for traditional Chinese medicinal materials. A separating plate is used for dividing a box body into a water removal chamber and a drying chamber, a vibration sieve is obliquely installed in the water removal chamber, a water collecting bucket, a first connecting pipe, a vacuum water pump, a second connecting pipe and a water storage tank are installedat the lower end of the vibration sieve, water attached to the traditional Chinese medicinal materials are pumped down from a separating net on the vibration sieve through the vacuum water pump, thewater attached to the traditional Chinese medicinal materials can be quickly removed, drying of the traditional Chinese medicinal materials is facilitated, and consumption of energy is reduced; a plurality of baffles are fixed on the side wall of the drying chamber in an inclined manner, a plurality of heating pipes are installed in the baffles, a mounting bracket is fixed to the bottom end of theinterior of the drying chamber, a hot air machine is mounted on the mounting bracket, heating drying of the traditional Chinese medicinal materials on the baffles is facilitated, air is heated through the hot air machine, the hot air is blown to the traditional Chinese medicinal materials on the baffles through vent holes in a bottom plate, quick drying of the traditional Chinese medicinal materials is facilitated, and the drying efficiency is high.

Owner:卢雪薇

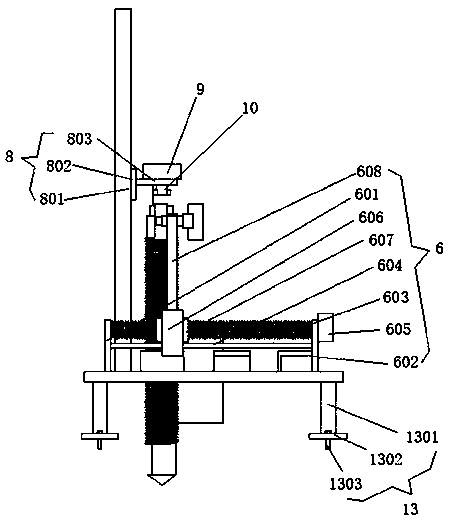

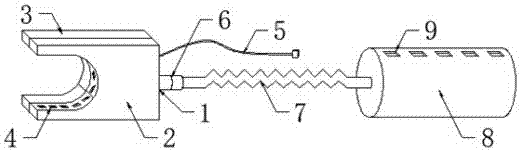

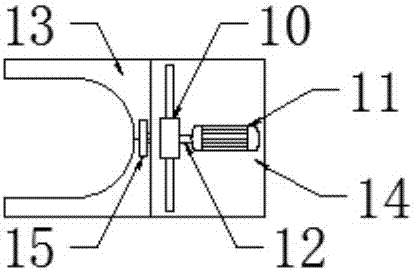

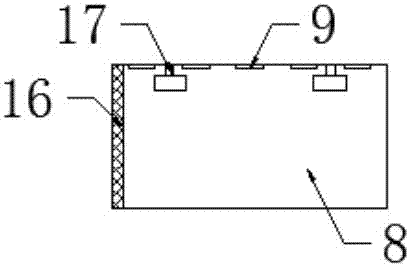

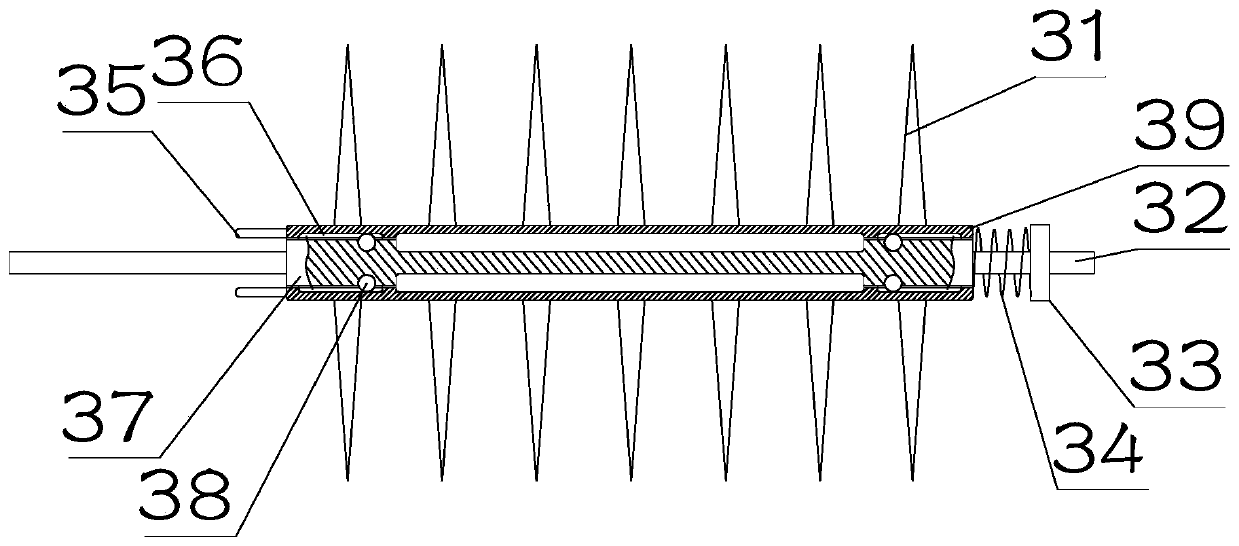

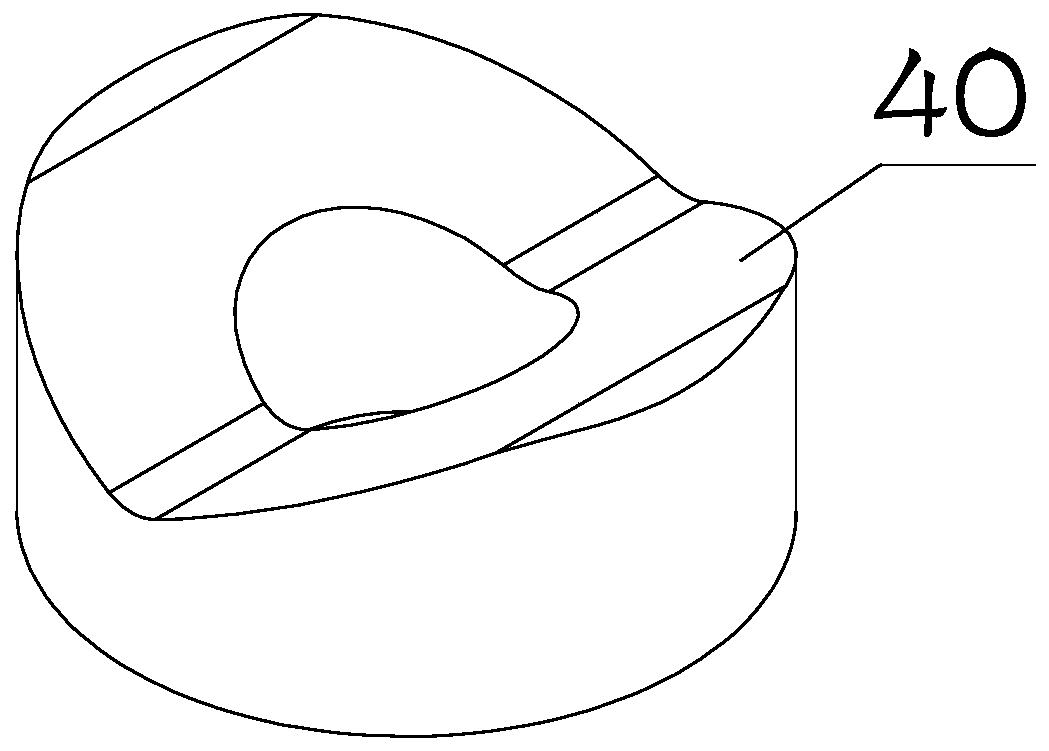

Water-cooled drilling machine slurry collecting device

InactiveCN107511937AStable absorptionImprove collection efficiencyWorking accessoriesStone-like material working toolsPulp and paper industrySlurry

The invention discloses a water-cooled drilling machine mud collecting device, comprising a device body, the device body is composed of a mud suction device arranged on the side of the device body, a telescopic conduit arranged on the side of the suction device, and an end portion of the telescopic conduit. This kind of water-cooled drilling machine mud collection device can effectively adjust the size of the mud suction by using the free opening and closing of the movable arc plate, and then fix the two movable arc plates to a suitable Therefore, it is suitable for drill bits of different sizes and is easy to use. At the same time, the suction cup can effectively fix the suction cup and keep the suction cup stable, so as to absorb the mud stably, avoid leakage, and greatly improve the collection efficiency of the mud. It can effectively heat and dry the mud and remove the moisture in the mud, so as to facilitate subsequent treatment, and it is very practical.

Owner:卢易达

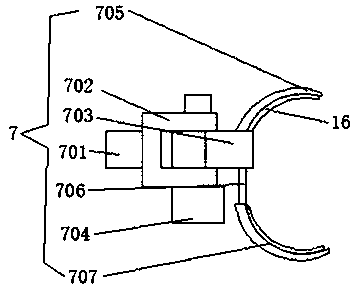

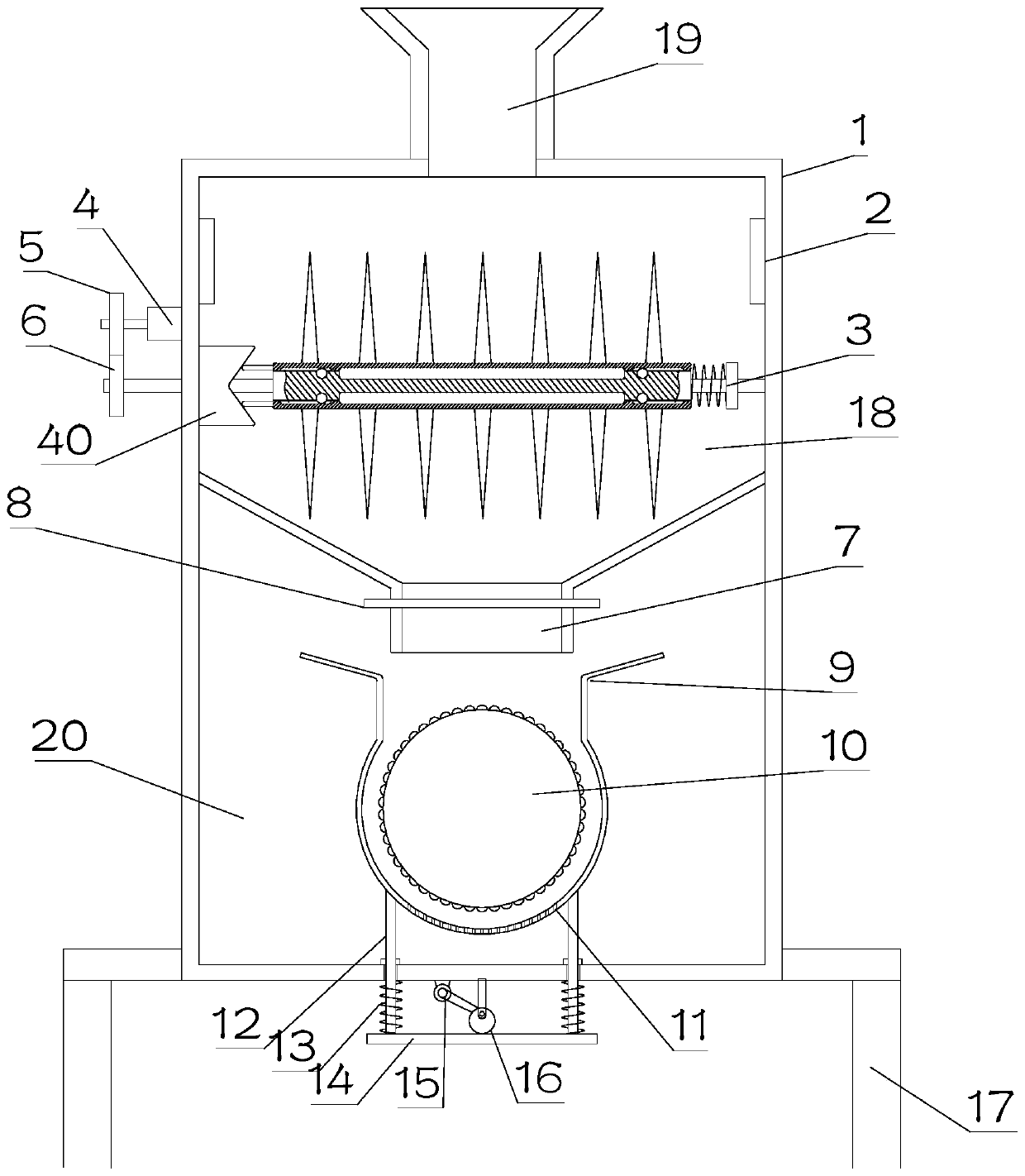

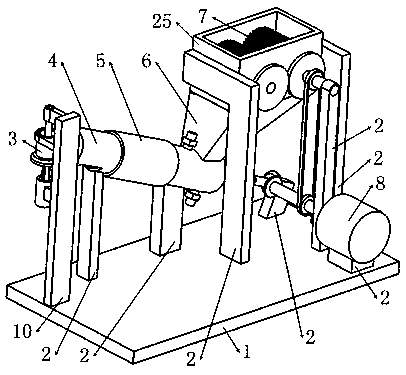

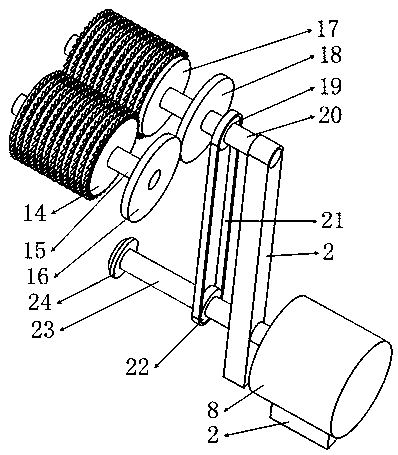

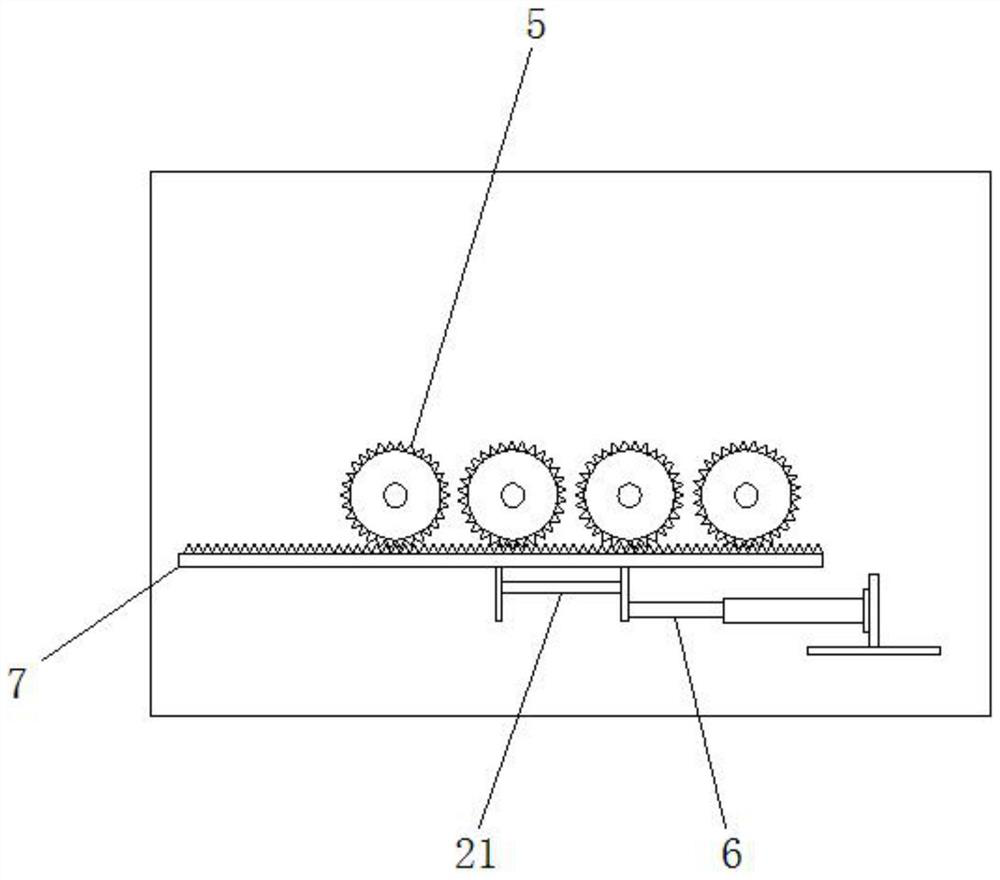

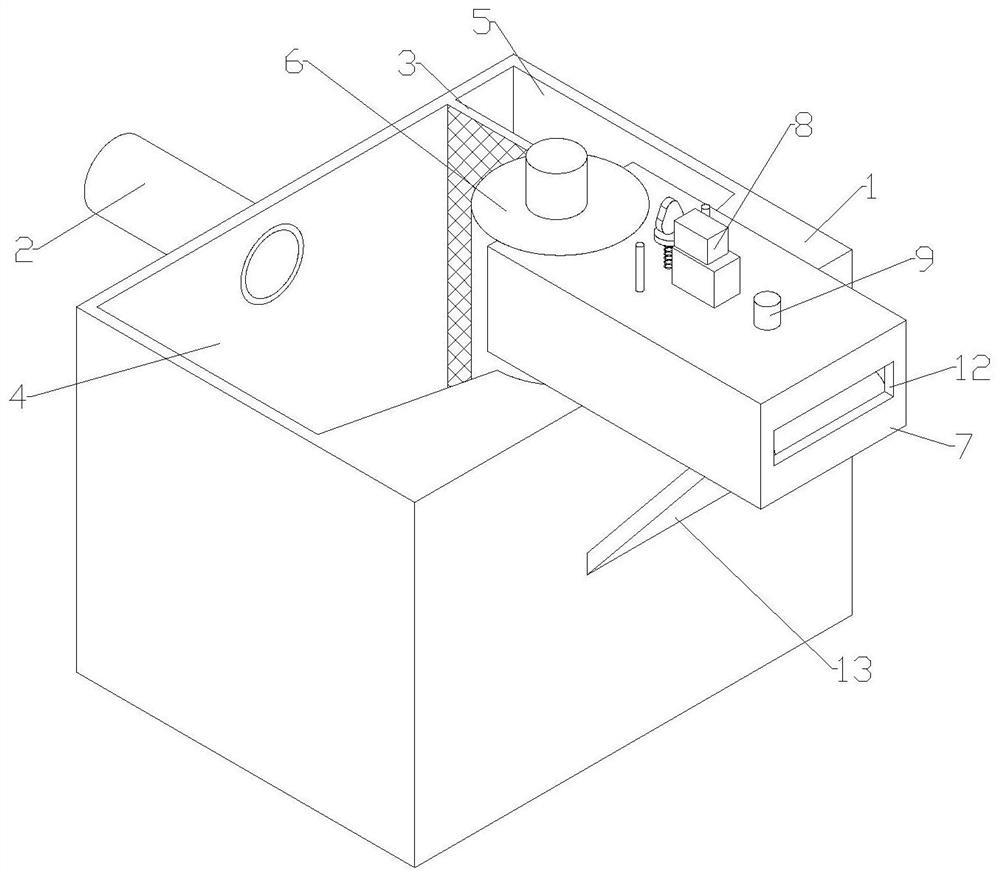

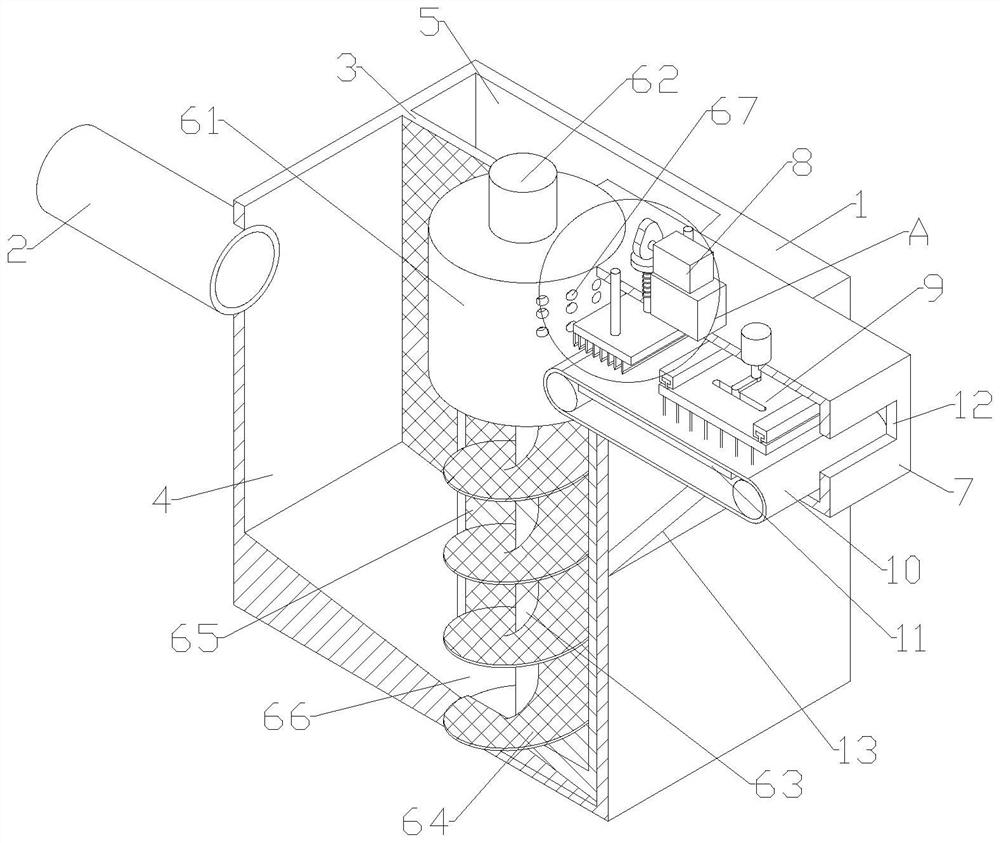

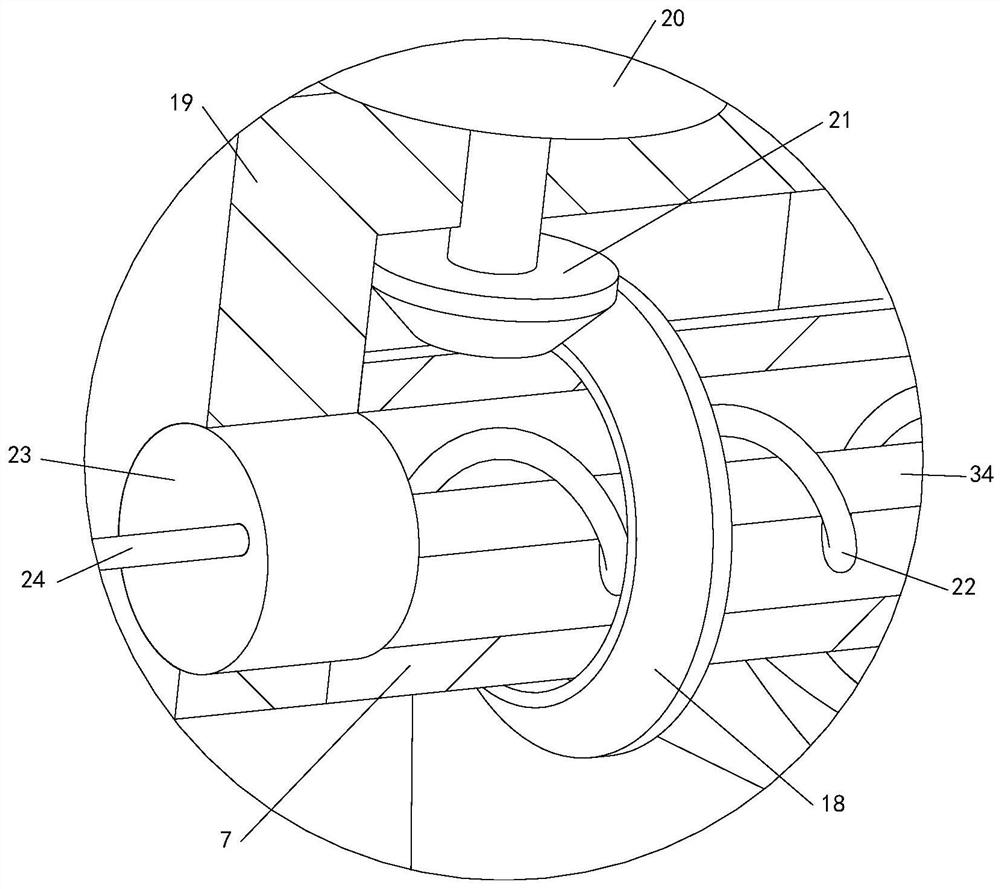

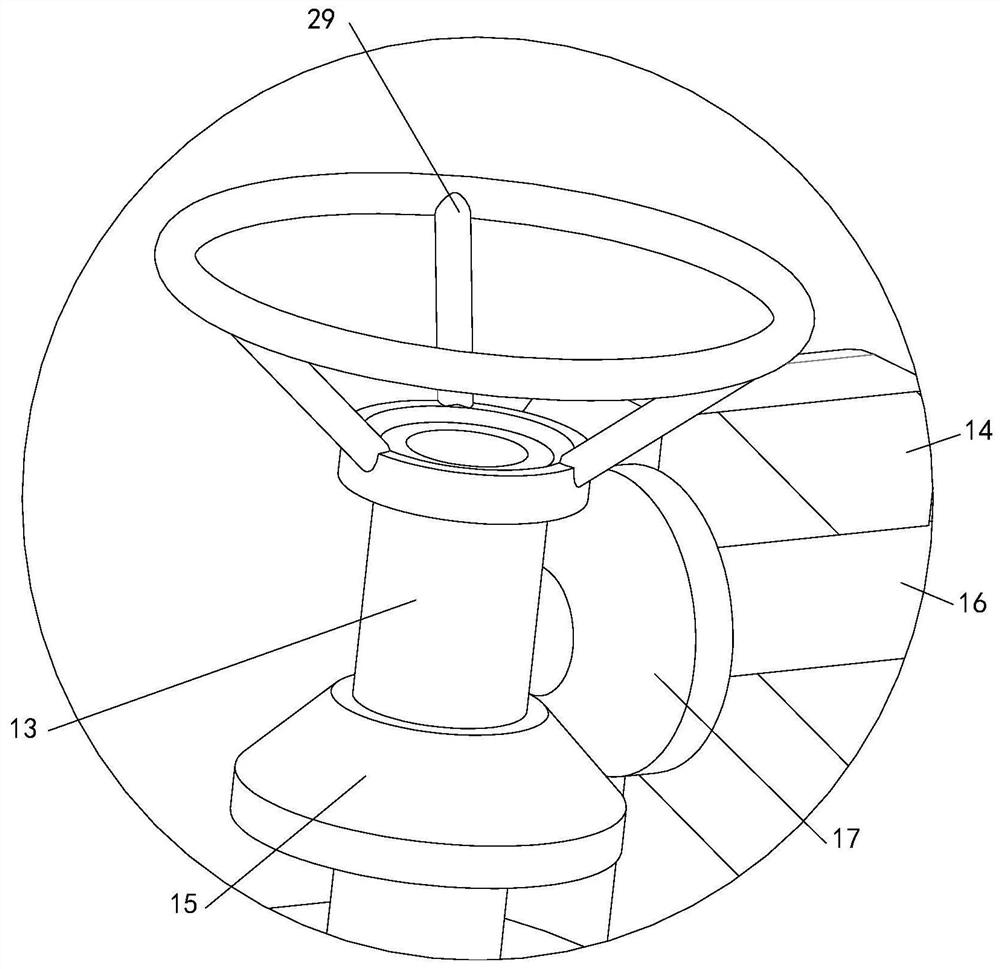

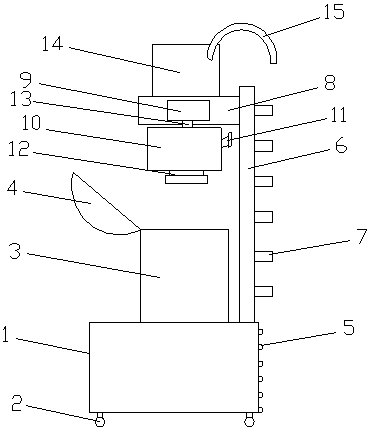

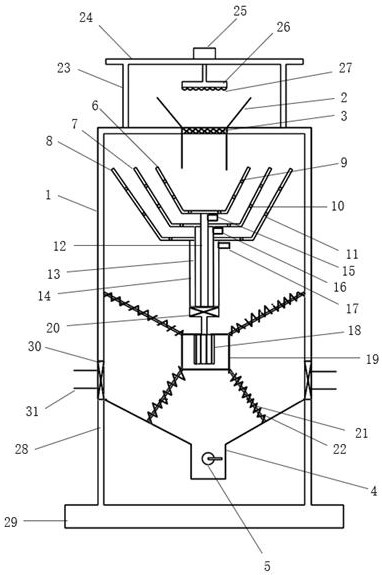

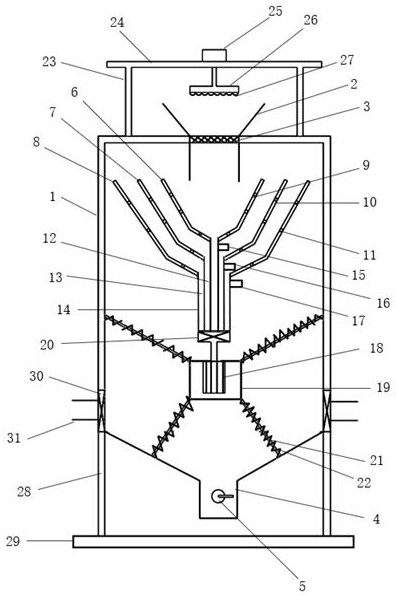

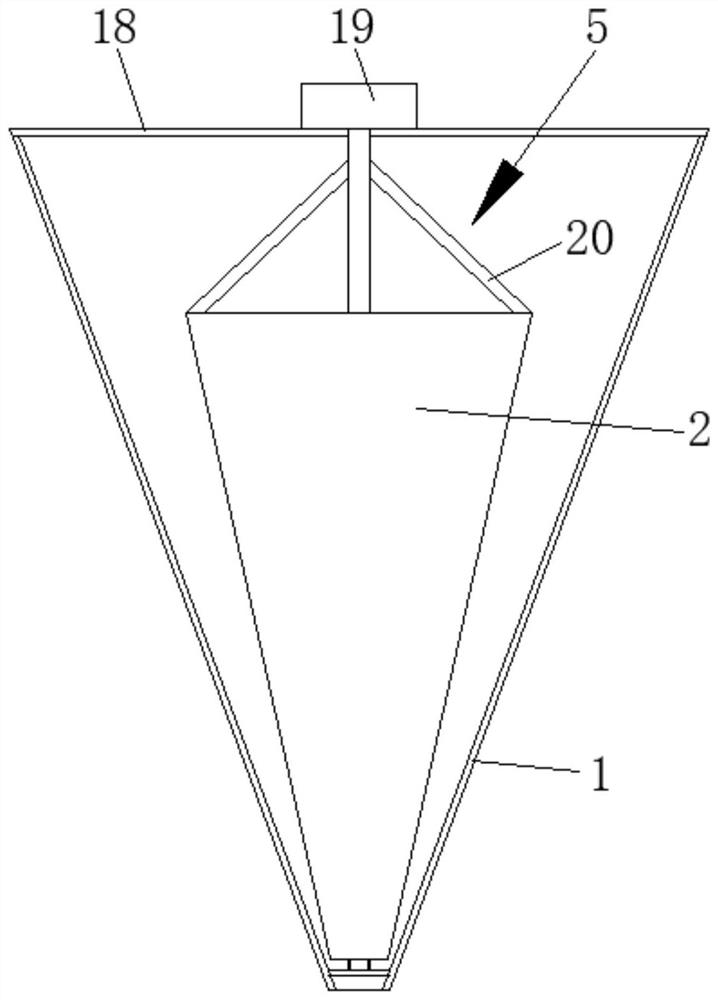

Medicinal material smashing and grinding device

ActiveCN110665621AEasy to heat and dryIncrease uncertaintySievingScreeningElectric machineryMedicinal herbs

The invention discloses a medicinal material smashing and grinding device, and relates to the technical field of medicinal material processing equipment. The medicinal material smashing and grinding device comprises a main body, wherein the main body is provided with a smashing cavity and a grinding cavity communicating with each other; a smashing assembly is self-rotatably arranged in the smashing cavity; a grinding hopper is arranged in the grinding cavity and is arranged right under a discharge hole of the smashing cavity; a grinding roller is rotatably arranged in the center in the grinding hopper; discharge holes are formed in the bottom part of the grinding hopper in an array way; connecting rods are fixedly arranged on two sides of the bottom part of the grinding hopper and penetrate through the bottom part of the main body; a reciprocating block is fixedly connected to one ends, far away from the grinding hopper, of the connecting rods; first elastic pieces sleeve the outer sides of the connecting rods; two ends of the first elastic pieces are fixedly arranged on the main body and the reciprocating block; an eccentric wheel is abutted against the upper end of the reciprocating bock in a rolling way and is in transmission connection with a motor B through a belt; and the motor B is fixedly arranged on the bottom part of the main body. The medicinal material smashing andgrinding device provided by the invention has better smashing and grinding effects and is convenient to discharge at the same time.

Owner:重庆化工职业学院

Waste plastic recycling equipment

InactiveCN111037877AImprove recycling efficiencyLow area costProcess engineeringEnvironmental engineering

The invention belongs to the field of waste recycling, and particularly relates to waste plastic recycling equipment. The waste plastic recycling equipment comprises a feeding mechanism, a conveying barrel, a crushing mechanism, a sliding shaft, spiral pieces and a telescopic shaft B, wherein the crushing mechanism installed on a base falls into the bottom of the conveying barrel filled with clearwater for cleaning after crushing water plastics, and the plastics can be cleaned by a forward spiral piece and a stirring piece on the spiral piece; then after a reversed spiral piece is utilized totransport and dry the plastics, the plastics are discharged, and in the process of discharging, the plastics are mixed with an assistant released by the feeding mechanism. According to the waste plastic recycling equipment, the waste plastics can be subjected to crushing, cleaning and assistant adding synchronously, and a large amount of liquid remaining in a water plastic bottle further can be separated; the whole equipment does not need to be equipped with multiple machining equipment synchronously, the floor area and input cost are reduced, the crushing, cleaning, drying and assistant adding processes all can be automatically matched to work, and the recycling efficiency of the plastics is greatly improved without manual transfer of the waste plastics.

Owner:杭州绿一环保技术有限公司

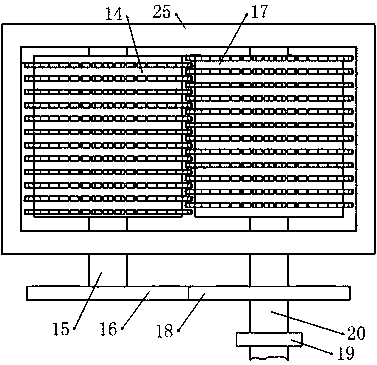

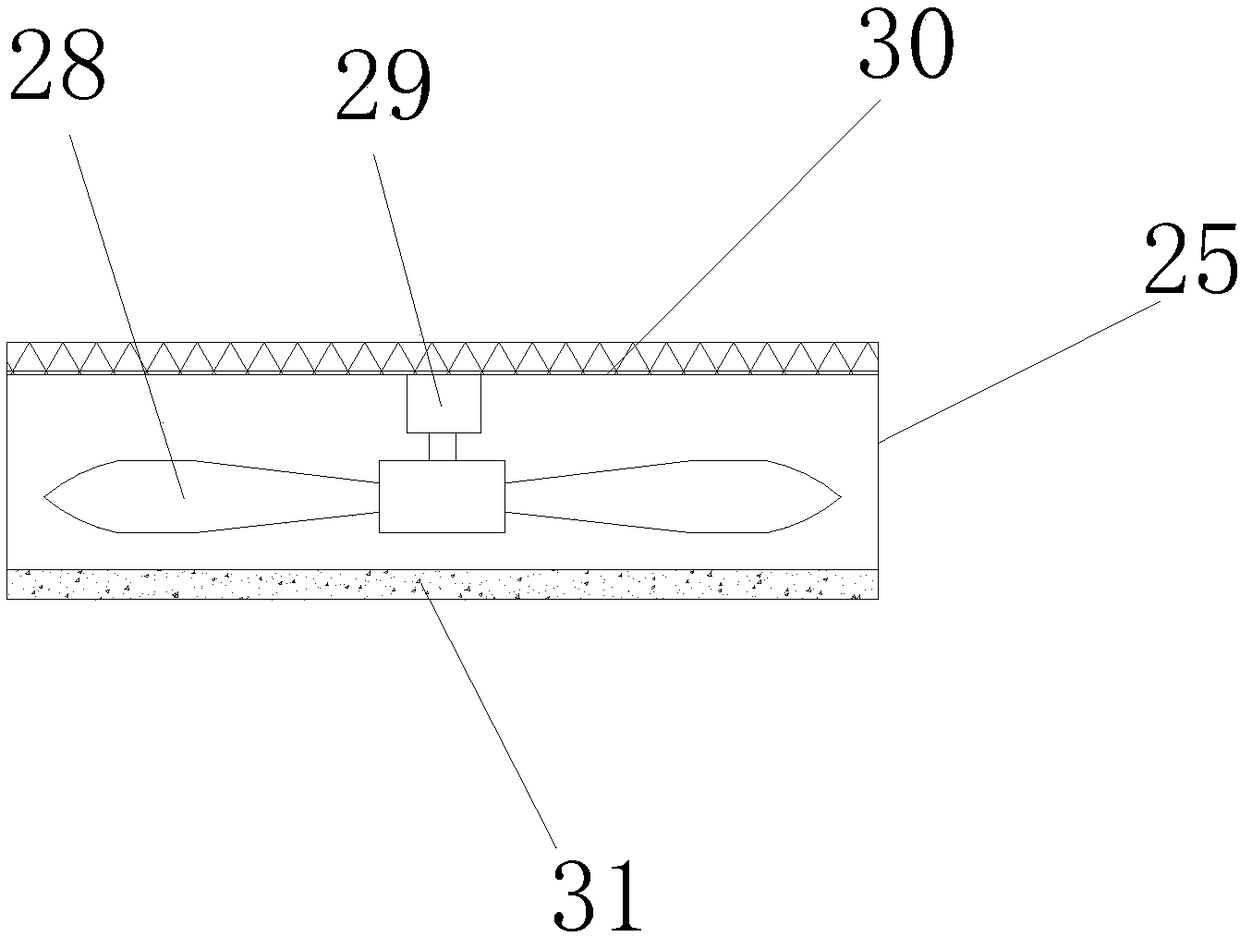

Bamboo strip drying device

InactiveCN108278875AGood drying effectReduce humidityDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringAir pump

The invention discloses a bamboo strip drying device. The bamboo strip drying device comprises a base plate and a drying chamber; the drying chamber is arranged above the middle part of the base plate; a plurality of transmission rollers are arranged at the internal lower portion of the drying chamber; the transmission rollers are connected through a bracket and are fixed to the internal left andright sides of the drying chamber; the left and right ends of the internal upper portion of the drying chamber are symmetrically provided with ultraviolet lamps; the left side of the internal upper portion of the drying chamber is provided with an exhaust fan component; the right side of the exhaust fan component is provided with a temperature sensor; the temperature sensor is positioned at the middle of the internal upper portion of the drying chamber; the right end of the temperature sensor is provided with an air blowing hood; the upper portion of the air blowing hood is connected with an air blower through a connecting pipe; the air blower is positioned at the middle of the external upper portion of the drying chamber; the right end of the air blower is connected with a water removingfilter; the right end of the water removing filter is connected with a circulating air pump; and the right end of the circulating air pump communicates with the middle of the right end of the drying chamber. The bamboo strip drying device disclosed by the invention is simple in structure, good in heating and drying effect, high in drying speed, good in drying effect and beneficial for popularization.

Owner:赵耀祥

Surface spraying device for anti-fog myopia correction glasses

The invention belongs to the field of myopic glasses processing, and relates to a surface spraying device for anti-fog myopic correction glasses. The device comprises a base, a first side plate, a second side plate, a rotating mechanism for conveniently spraying two surfaces of a lens surface, a spraying mechanism for spraying a lens and an air blowing mechanism for quickly drying; the first side plate is welded to one end of the upper surface of the base; the rotating mechanism and the spraying mechanism are arranged on the first side plate; the rotating mechanism is located below the spraying mechanism; the second side plate capable of sliding is arranged on the upper surface of the base; and the air blowing mechanism is arranged on the second side plate. According to the surface spraying device for the anti-fog myopia correction glasses, lenses on a rotating rod is driven by a gear disc to turn over, the multiple lenses can be turned over under the condition that the lenses are not moved, and the turning-over mode is simple and rapid; spraying on the two faces of each lens is facilitated, the spraying efficiency is greatly improved, rapid drying can be conducted after spraying is completed, the drying speed of a coating is accelerated, and the production efficiency and the product quality are greatly improved.

Owner:吉首市宏佳达科技有限公司

Drying device of spandex advertisement cloth, capable of eliminating wrinkles

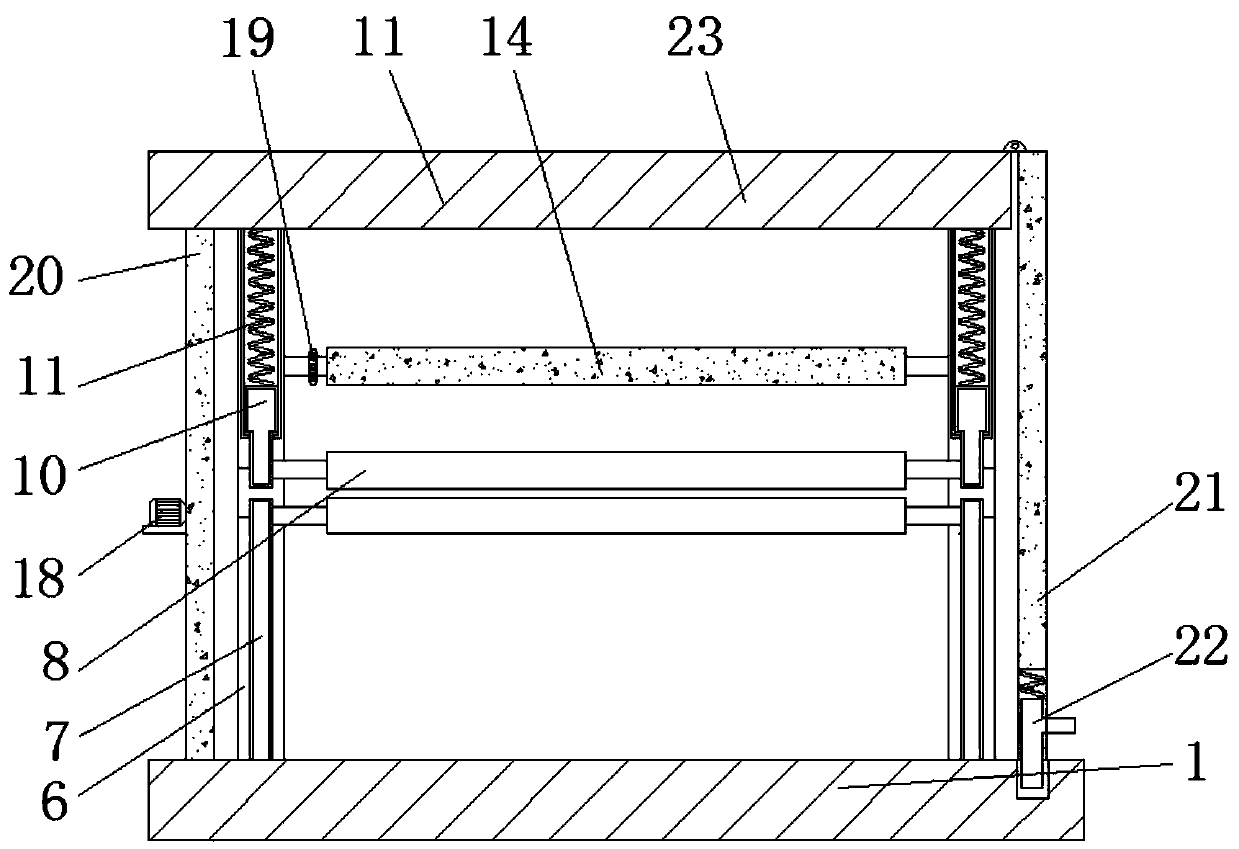

PendingCN111288776AEasy maintenanceImprove drying effectDrying gas arrangementsDrying machines with progressive movementsEngineeringMechanical engineering

The invention discloses a drying device of spandex advertisement cloth, capable of eliminating wrinkles. The drying device comprises a baseplate, a horizontal rod, a heating wire, a heating rod and atop plate, wherein the horizontal rod is fixed above the baseplate; a fan is installed above the horizontal rod; an installation frame is installed above the fan; a left supporting plate is fixedly connected to the left side of the installation frame, and an inner landing leg is connected inside the left supporting plate; a cylinder is installed above the inner landing leg; a first raised block isfixed on the left side of a second raised block; a fixation frame is installed on the right side of the left supporting plate; the heating rod is installed in front of the second gear; a right supporting plate is fixed on the left side of the heating rod; a first gear is connected behind a cloth guiding roller; and a front plate is installed in front of the right supporting plate. The drying device of spandex advertisement cloth, capable of eliminating wrinkles has the beneficial effects that anti-wrinkle processing is conducted on the cloth; the device can be repaired easily; and drying effects are better.

Owner:海宁市金茂经编有限公司

Sewage treatment device capable of reducing sludge discharge

PendingCN112279395AEasy dischargeDoes not affect processingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSewage treatment

The invention discloses a sewage treatment device capable of reducing sludge discharge, which comprises a treatment box, the treatment box is divided into a settling cavity and a water outlet cavity by a filter screen partition plate, a sewage pipe sleeves the treatment box on the side of the settling cavity, a sewage discharge mechanism is mounted on the other side of the settling cavity, a fixedbox is mounted at the top of the treatment box, and one end of the fixed box is connected with the sewage discharge mechanism; an outlet is formed in the other end of the fixed box; a conveying beltis installed at the bottom of an inner cavity of the fixed box, a heating plate is installed on the inner wall of the fixed box in the inner cavity of the conveying belt, a chopping mechanism is installed at one end of a fixed box top plate, and a rake rod mechanism is installed at the other end of the fixed box top plate. Sewage enters the settling cavity to be settled, sludge is gathered and increased and then is conveyed into the fixed box through the sewage discharging mechanism in a filter pressing mode, the sludge is extruded into strips through filter pressing and falls on the conveyingbelt, the sludge strips are cut up through the chopping mechanism, the sludge is flatly laid on the conveying belt through the rake rod mechanism, a heating plate can heat the sludge conveniently todry the sludge, and finally the sludge is discharged from the outlet. The purpose of synchronously discharging sludge in sewage treatment is achieved, and sludge discharge is reduced.

Owner:NANJING GONGCHENG RES INST OF ENERGY CONSERVATION & NEW MATERIALS TECH CO LTD

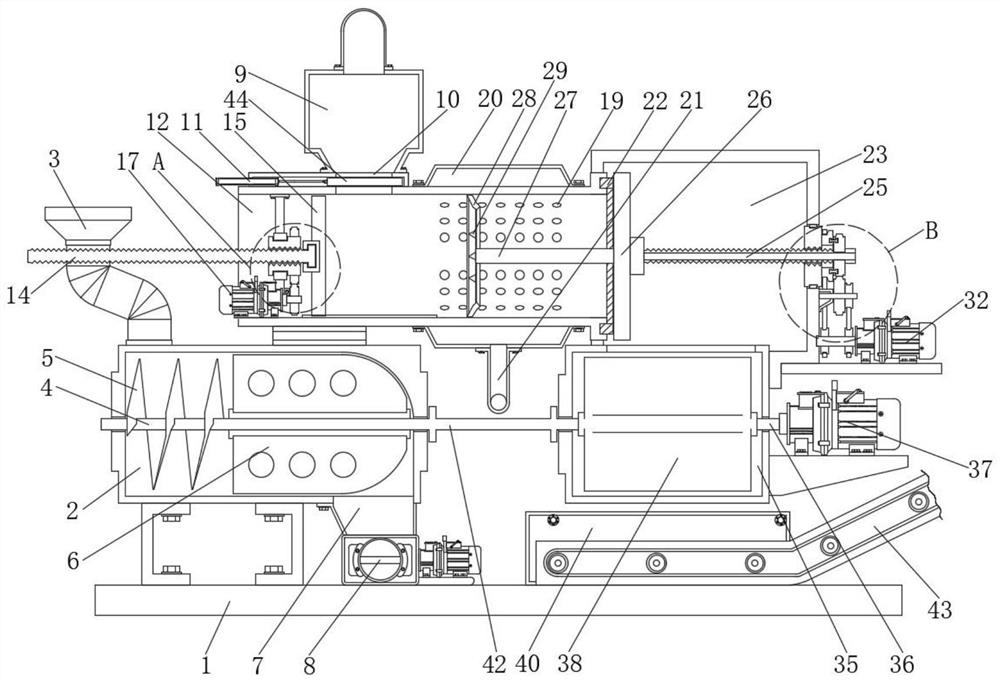

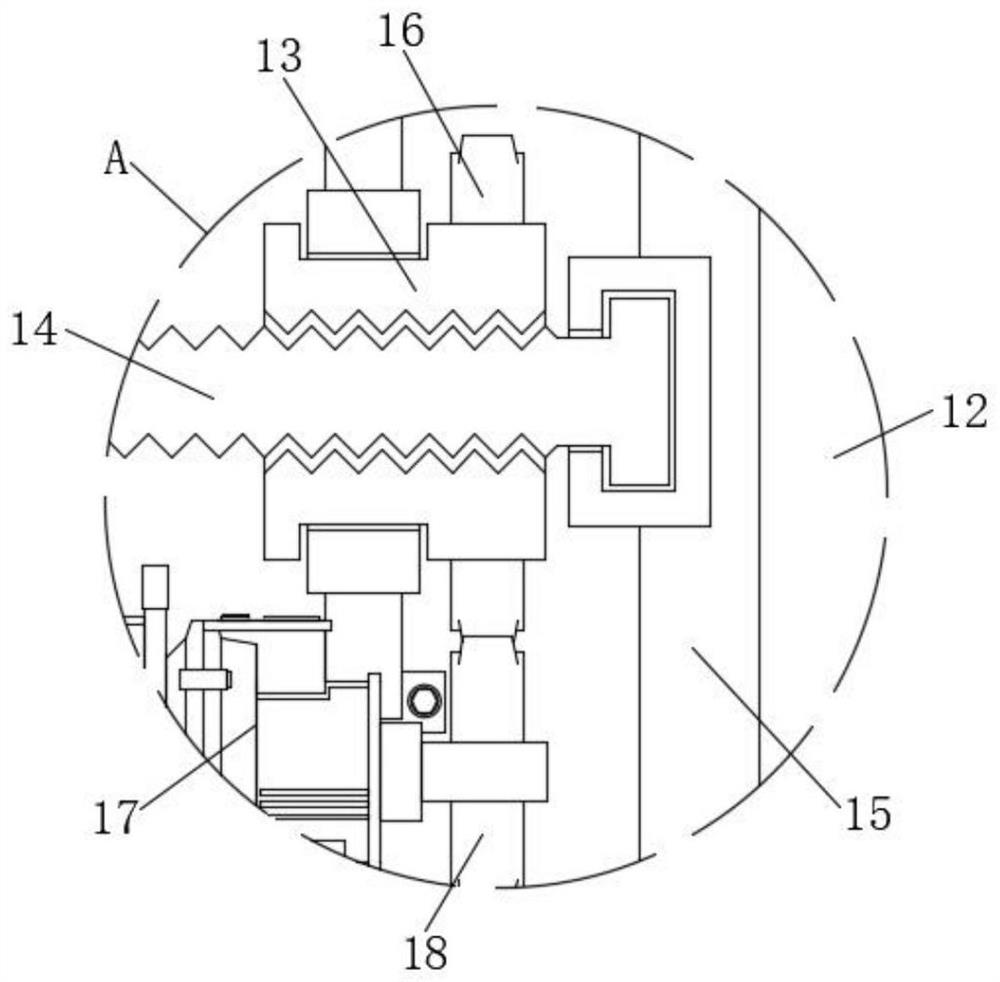

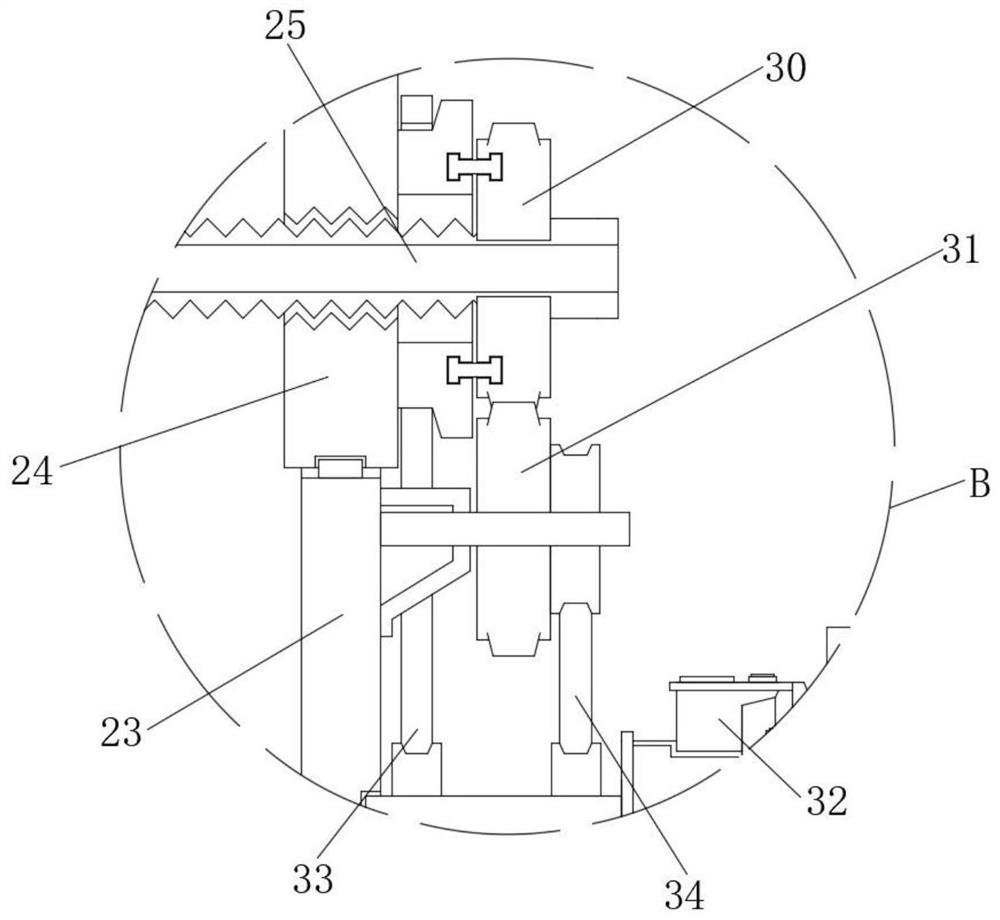

Coal gangue, ardealite and sludge ceramsite production equipment and production process thereof

ActiveCN111687989AReduce cost lossPromote sustainable developmentFeeding arrangmentsAuxillary shaping apparatusSludgeExpanded clay aggregate

The invention relates to the technical field of coal gangue ceramsite production equipment, in particular to coal gangue, ardealite and sludge ceramsite production equipment and a production process thereof. The equipment comprises a base, a sludge pump, an electric push rod, a first servo motor, a second servo motor, a third servo motor and a steam heater; a mixing tank is fixedly installed aboveone end of the base; a material transportation pipe fixedly communicates with the left side of the top of the mixing tank; a first rotary shaft is arranged at the central position inside the mixing tank in a horizontally inserting mode; and spiral vanes are fixedly installed on the left side outer wall of the first rotary shaft. Sludge, coal gangue and ardealite are organically combined as raw materials, are dehydrated after mixing, are subjected to drying processing, are then subjected to pelleting in a pelletizer, and are subjected to fire molding in a rotary kiln. The equipment and the process are beneficial to utilizing the sludge and coal gangue waste to generate beneficial values, is beneficial to lowering cost and consumption in environmental governance, and is convenient for realizing sustainable development of resources.

Owner:武汉绿发环能科技有限公司

Food additive production heating device

PendingCN113720101AGood for drying and crushingImprove use reliabilityDrying chambers/containersDrying machines with non-progressive movementsPhysicsElectric machinery

The invention relates to the technical field of production heating devices, and particularly relates to a food additive production heating device. The food additive production heating device comprises a mounting frame and a bracket, wherein the bracket is connected with the mounting frame; the bracket is connected with a left end frame and a right end frame; the left end frame communicates with a feeding hopper; a discharging opening is formed in the right end frame; a drying cylinder is connected between the left end frame and the right end frame; a rotating mechanism is mounted between the drying cylinder and the bracket; an adjusting frame mechanism and an adjusting block mechanism are separately mounted on the left end frame and the right end frame; the adjusting frame mechanism is connected with a roller; the roller is connected with the adjusting block mechanism; the adjusting frame mechanism is provided with a driving roller mechanism; the driving roller mechanism is provided with a heating mechanism; the driving roller mechanism comprises a gear ring and a driving frame; the gear ring is connected with the roller; the driving frame is connected with a sliding frame; the driving frame is provided with a speed adjusting motor; and the speed adjusting motor is connected with a conical wheel. The food additive production heating device is good in drying and crushing effect, reliable to use, high in production efficiency, flexible to use, simple to adjust and practical.

Owner:王静

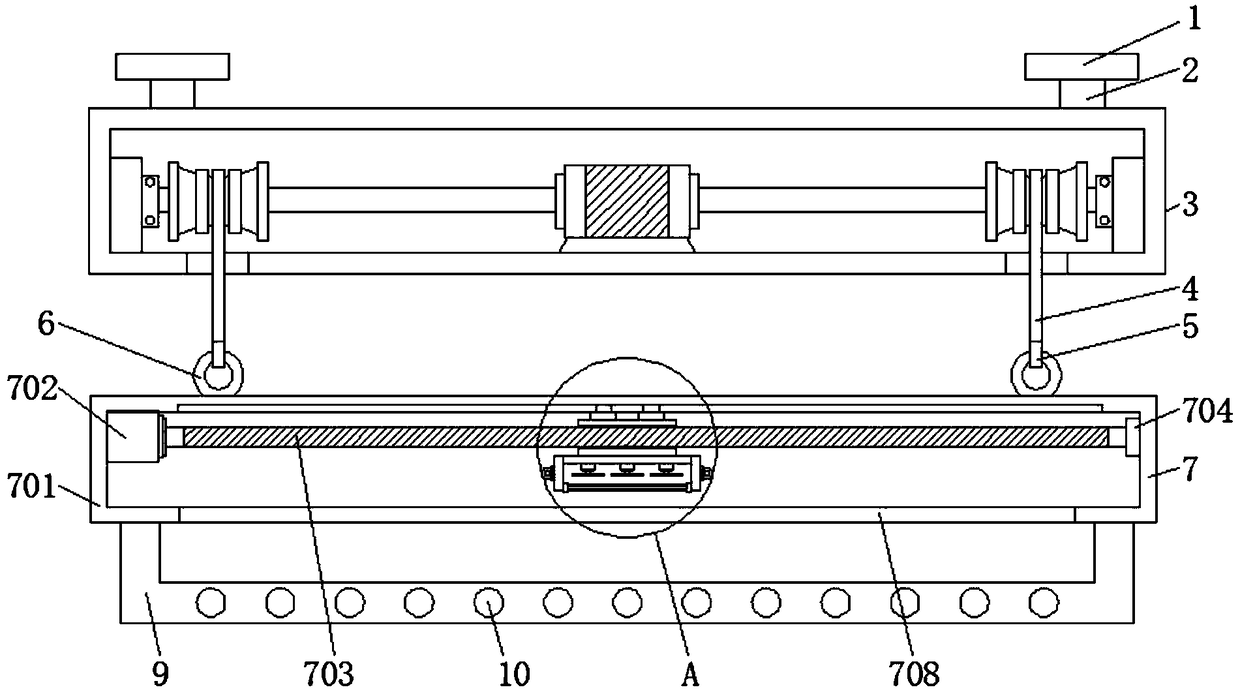

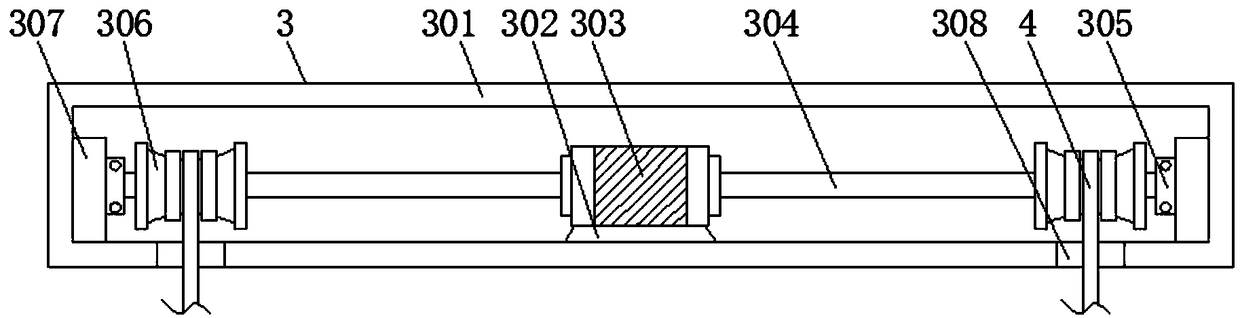

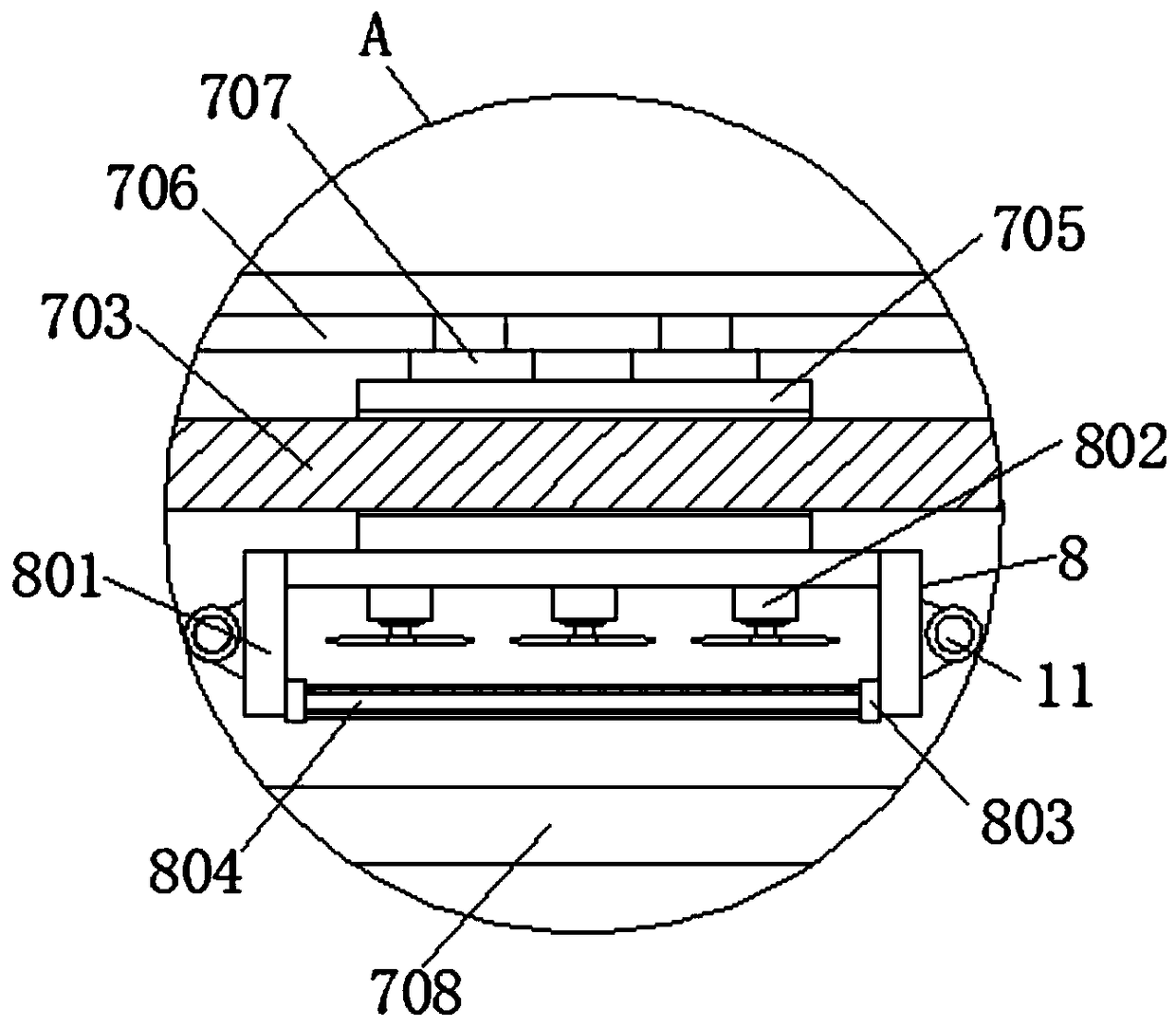

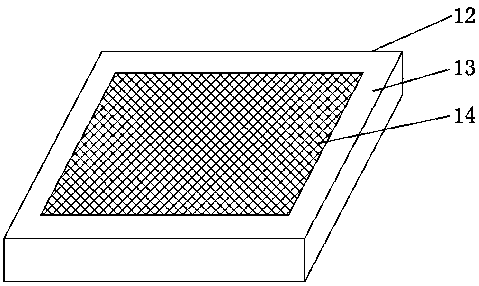

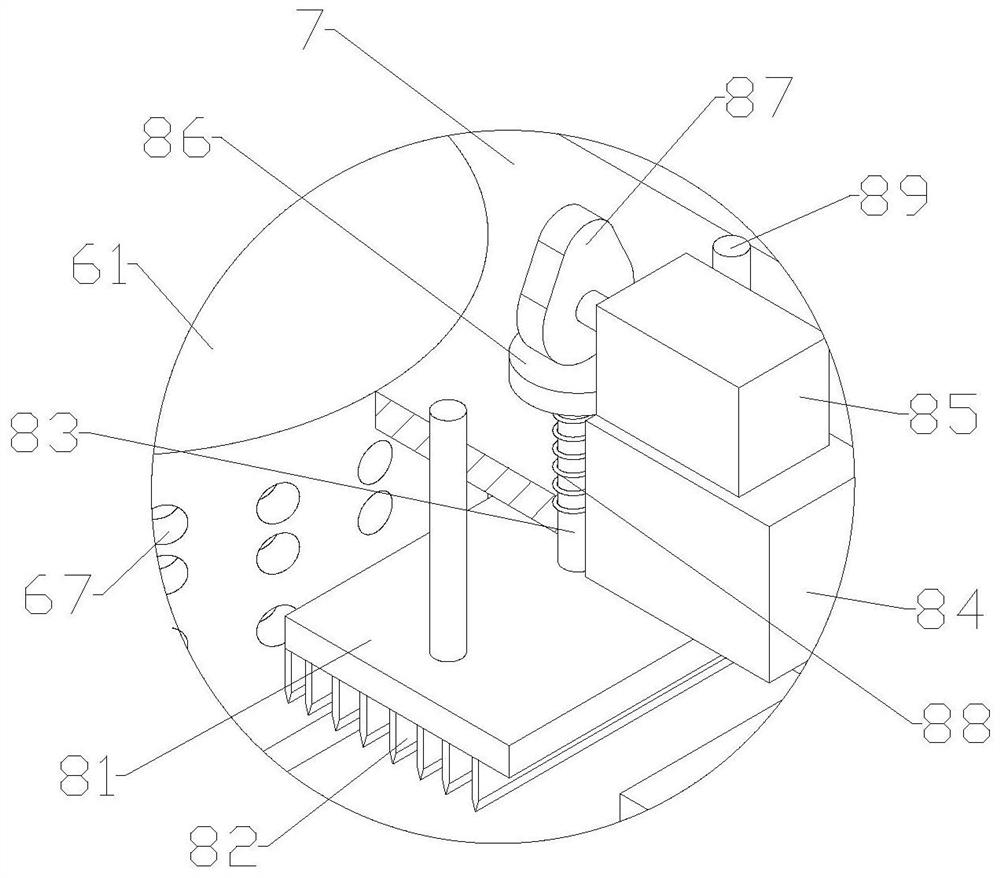

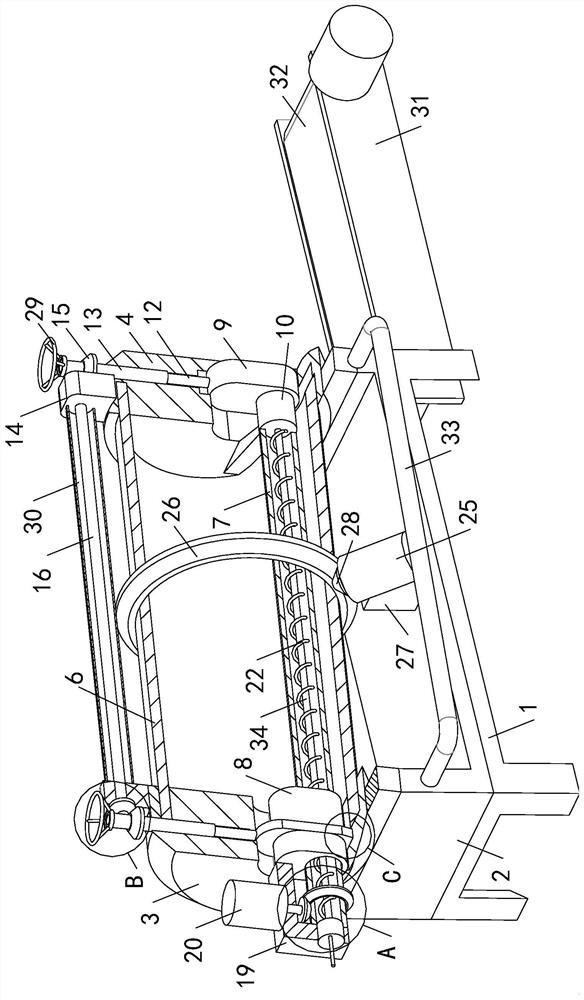

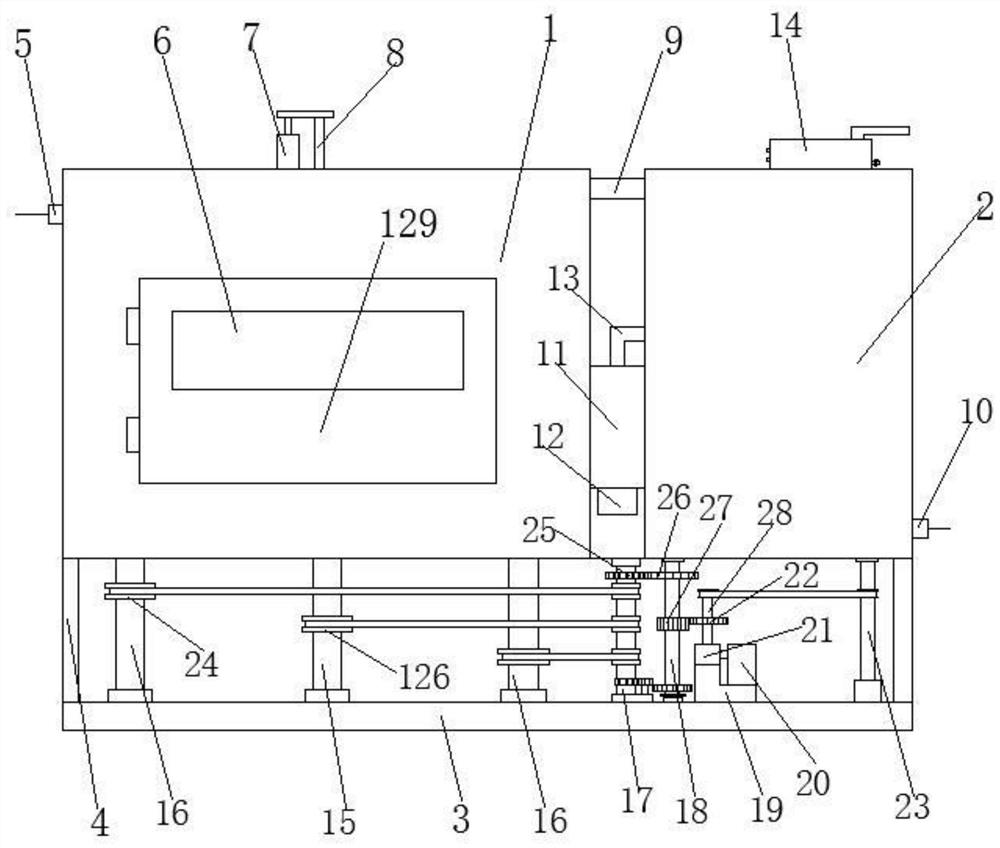

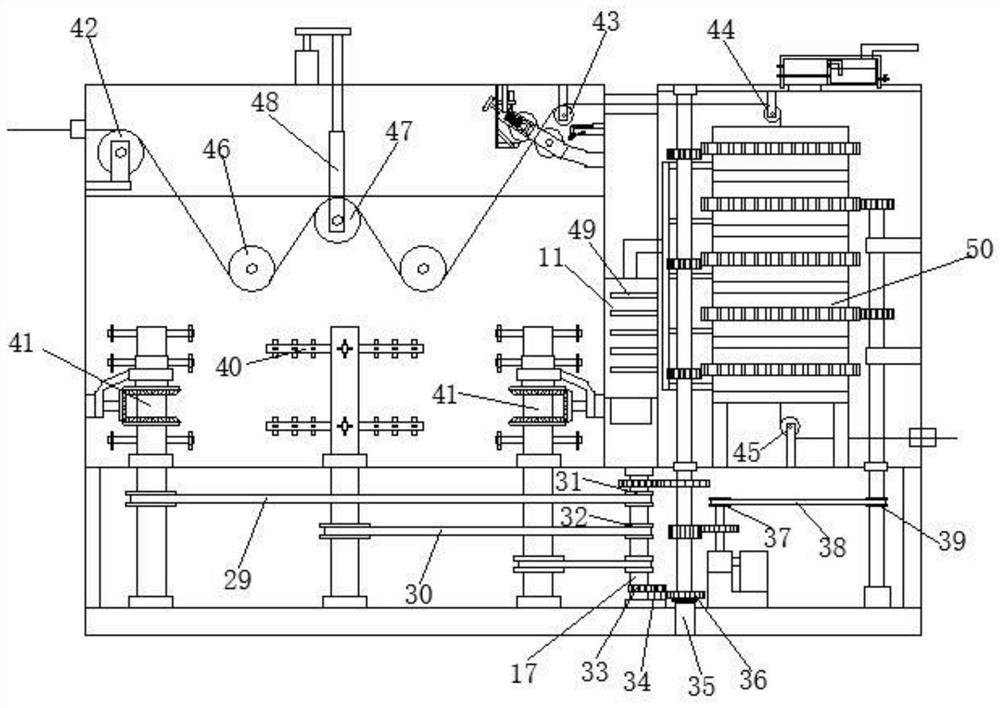

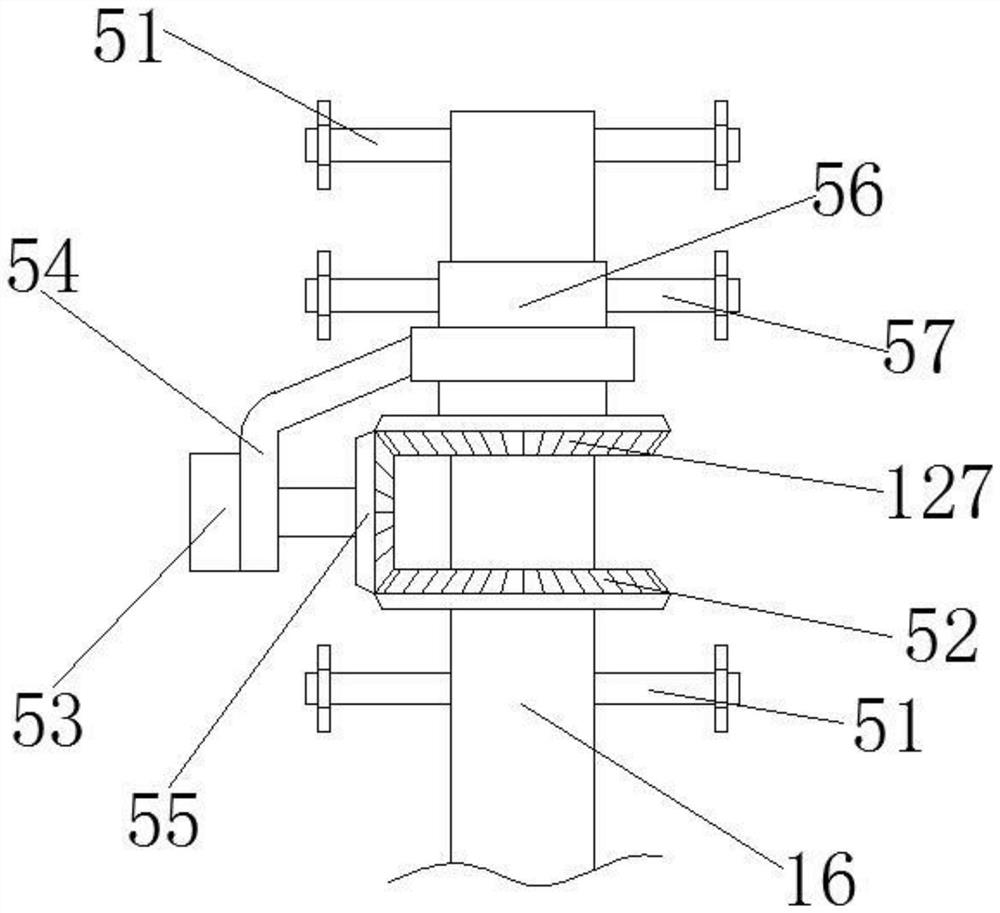

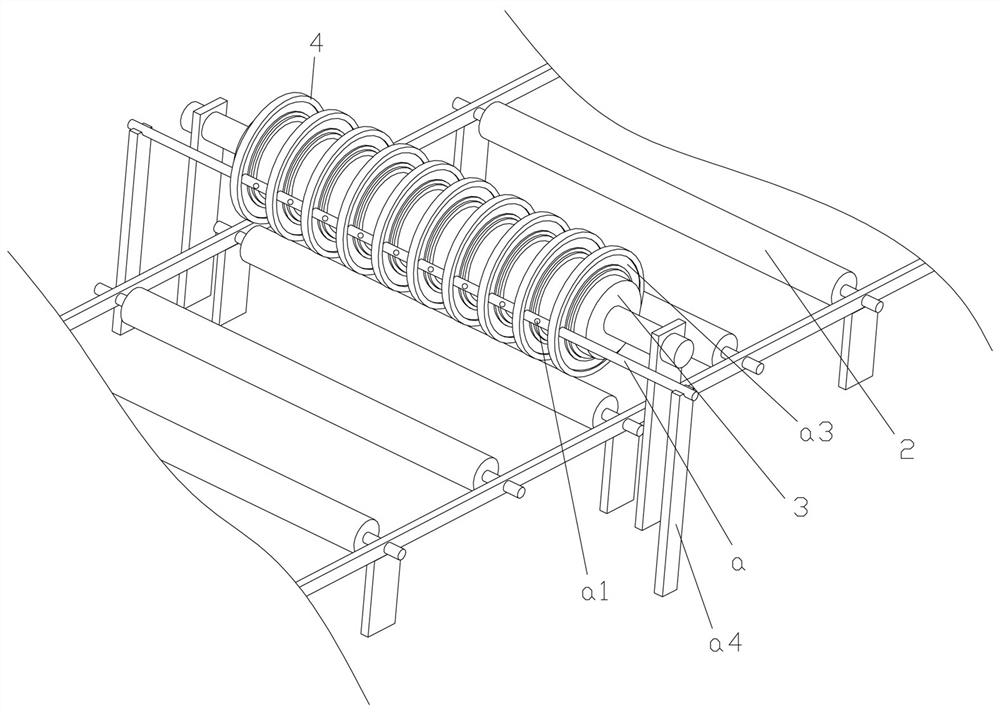

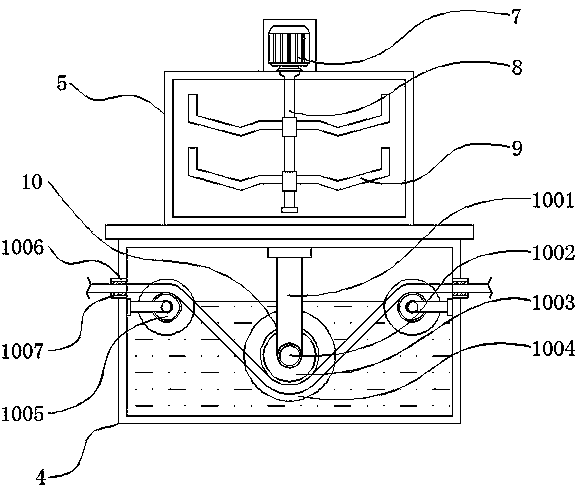

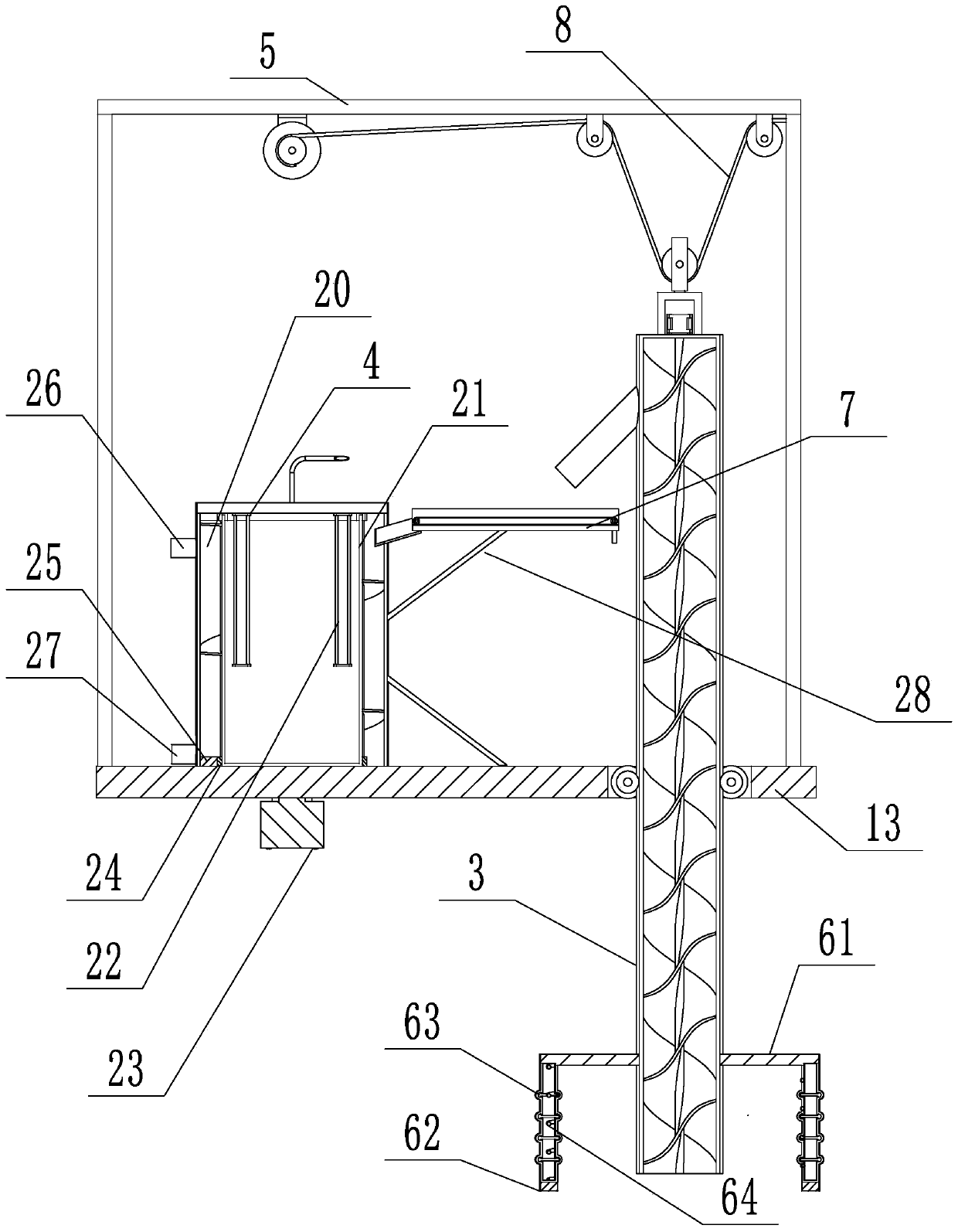

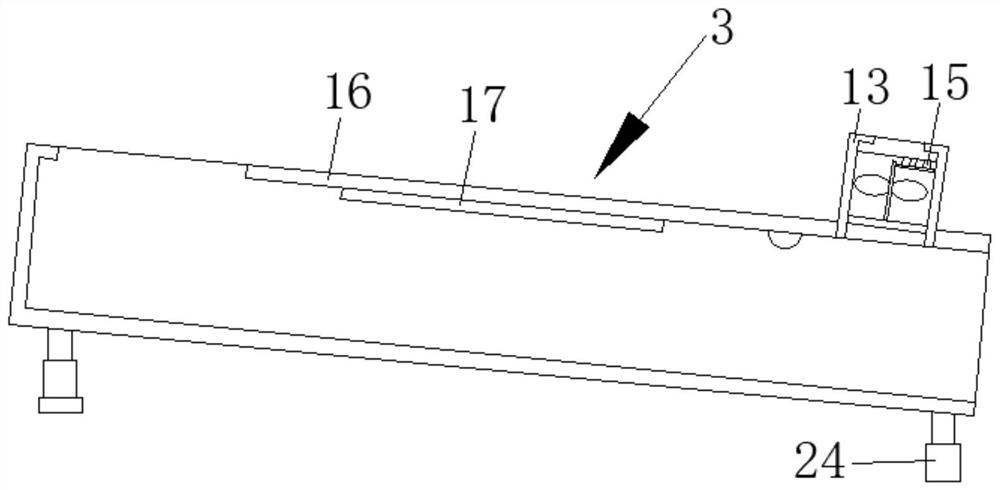

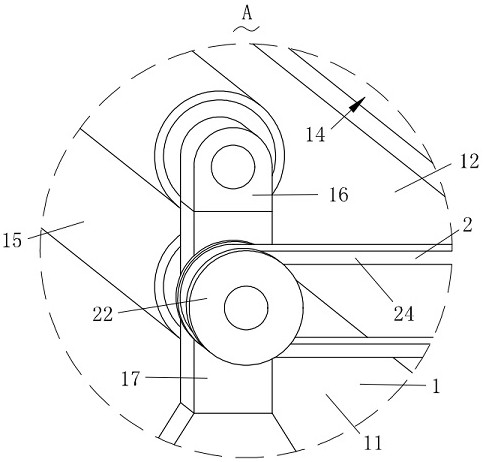

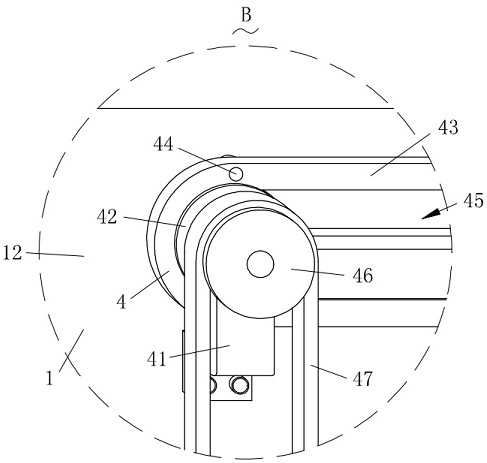

Movable-type drying equipment provided with even-mixing cylinder

InactiveCN107906845AEasy to heat and dryDrying chambers/containersDrying machines with local agitationElectric machineryStructural engineering

The invention discloses movable-type drying equipment provided with an even-mixing cylinder. The movable-type drying equipment comprises a movable rack body, and movable roller devices are mounted atthe two ends of the bottom of the movable rack body. A drying cylinder is fixedly mounted at the upper end of the movable rack body, and a cover-lifting-type seal head is mounted at the upper end of the drying cylinder. First ladder frame pedal rods are arranged on rack main bodies on the two sides of the movable rack body correspondingly, and a fence plate wall is vertically arranged on the tableface of one side of the movable frame body. Second ladder frame pedals are arranged on the end face of the outer side of the fence plate wall, and an even-mixing cylinder mounting seat is arranged atthe top end of the end face of the inner side of the fence plate wall. A rotary driving motor is fixedly arranged at the front end of the even-mixing cylinder mounting seat, and the even-mixing cylinder is connected to the lower end of the rotary driving motor. In this way, the movable-type drying equipment can dry materials, the even-mixing cylinder is arranged at the upper end of the drying cylinder, thus the materials can be stirred and evenly mixed before being dried, and the materials can be scattered and better heated and dried.

Owner:WUXI SHANGDE DRYING EQUIP CO LTD

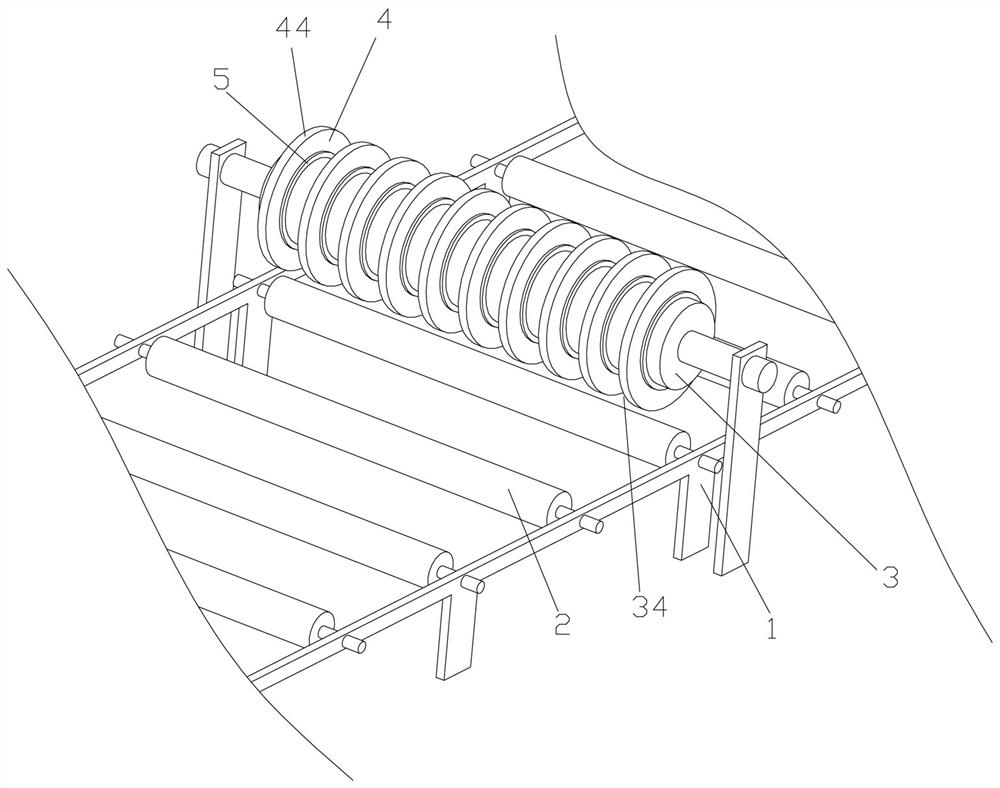

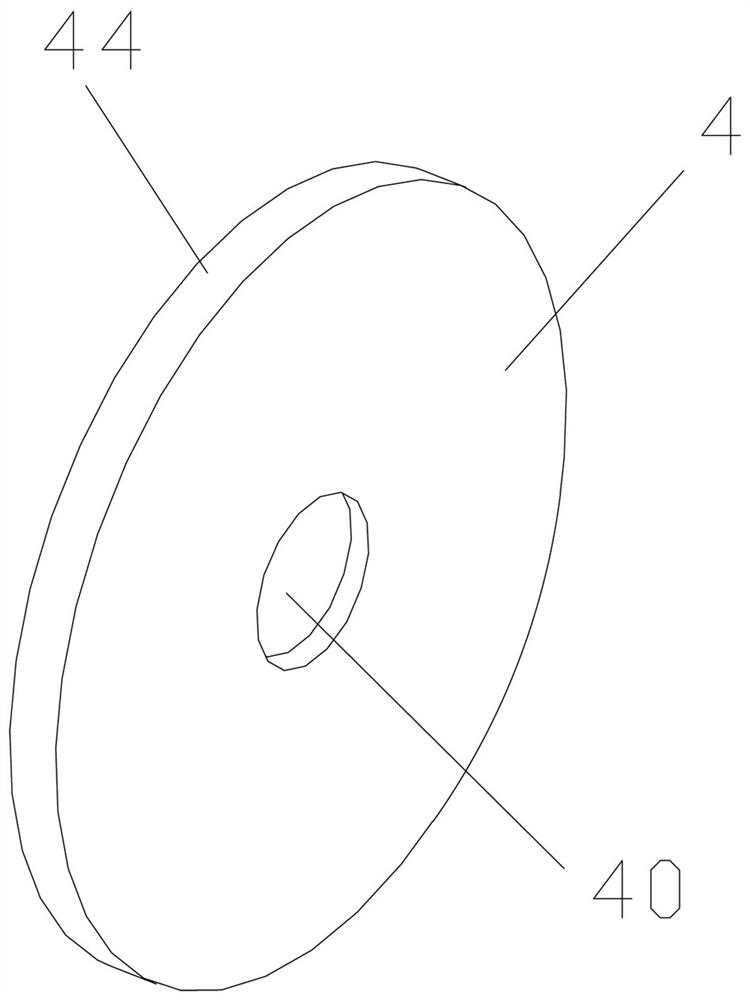

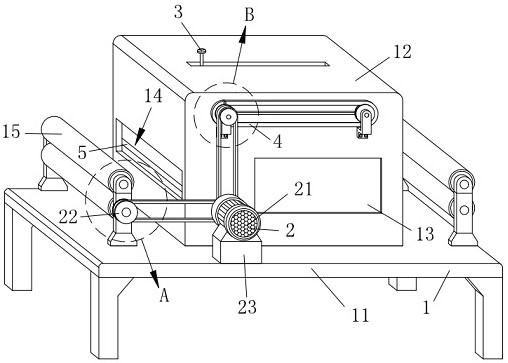

Sizing device

InactiveCN113005674AStir wellEasy to heat and dryTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsYarnElectric machinery

The invention discloses a sizing device. The sizing device is characterized by comprising a sizing box, a drying box and a base, wherein supporting columns are connected between the sizing box and the base and between the drying box and the base; a feeding port is formed in the left side of the sizing box; a communicating pipe is connected between the sizing box and the drying box; a discharging port is formed in the right side of the drying box; a guide-in roller is arranged at the position, located on the right side of the feeding port, in the sizing box; a first guide roller is arranged at the position, located on the left side of the communicating pipe, in the sizing box; a plurality of sizing rollers are arranged in the middle of the sizing box; a tensioning roller is arranged between every two adjacent sizing rollers; a first stirring shaft is rotationally arranged on the lower portion of the sizing box; and second stirring shafts are rotationally arranged at the positions, located on the two sides of the first stirring shaft, of the lower portion of the sizing box. According to the invention, one driving motor is adopted to stir a sizing agent and dry yarn, so that the number of driving mechanisms is reduced and the cost is reduced.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

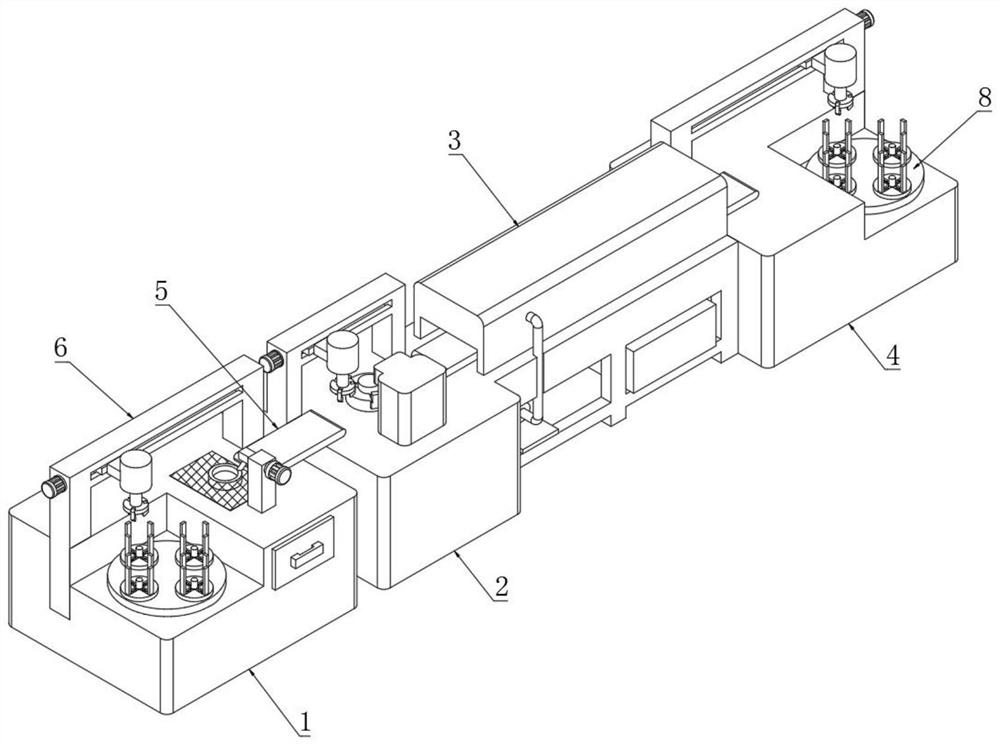

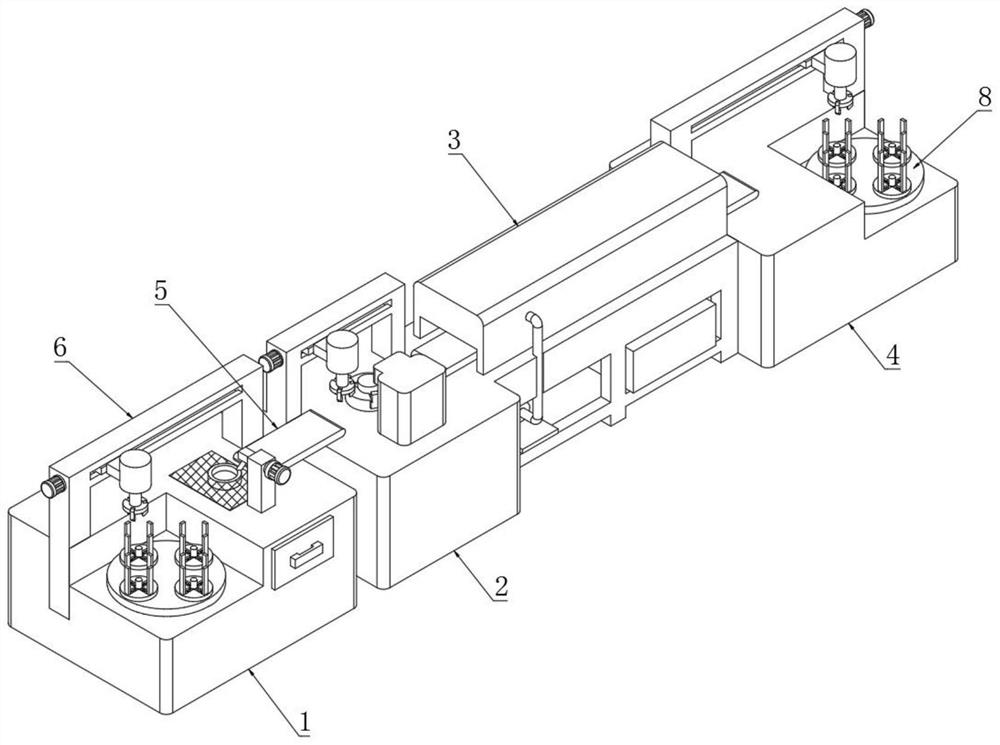

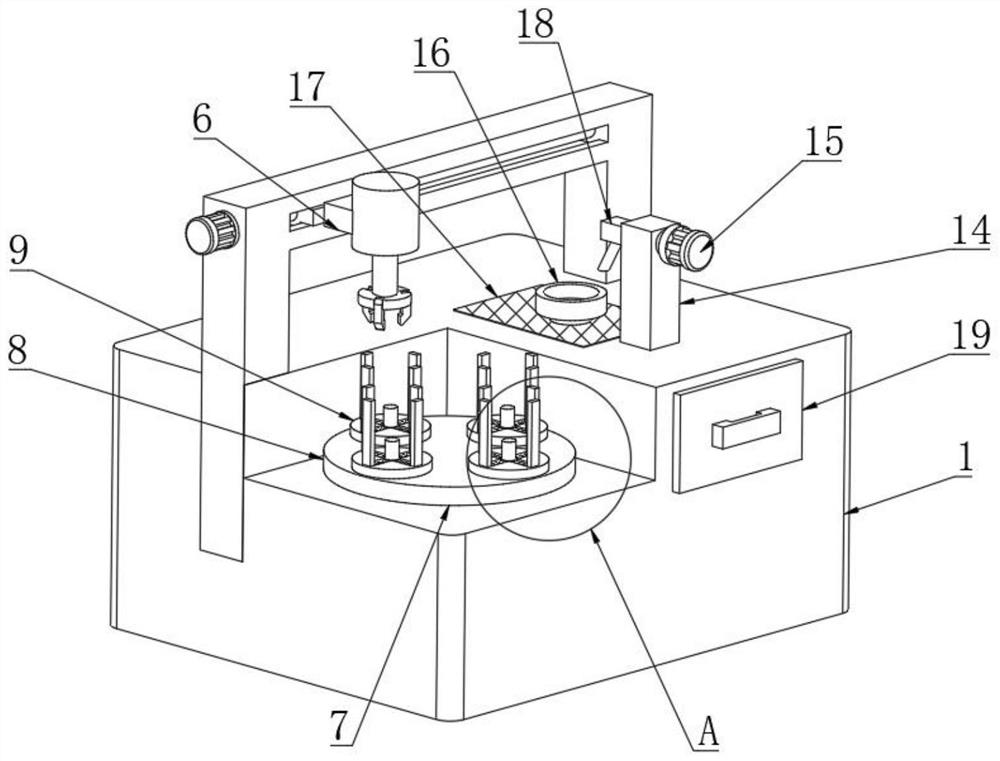

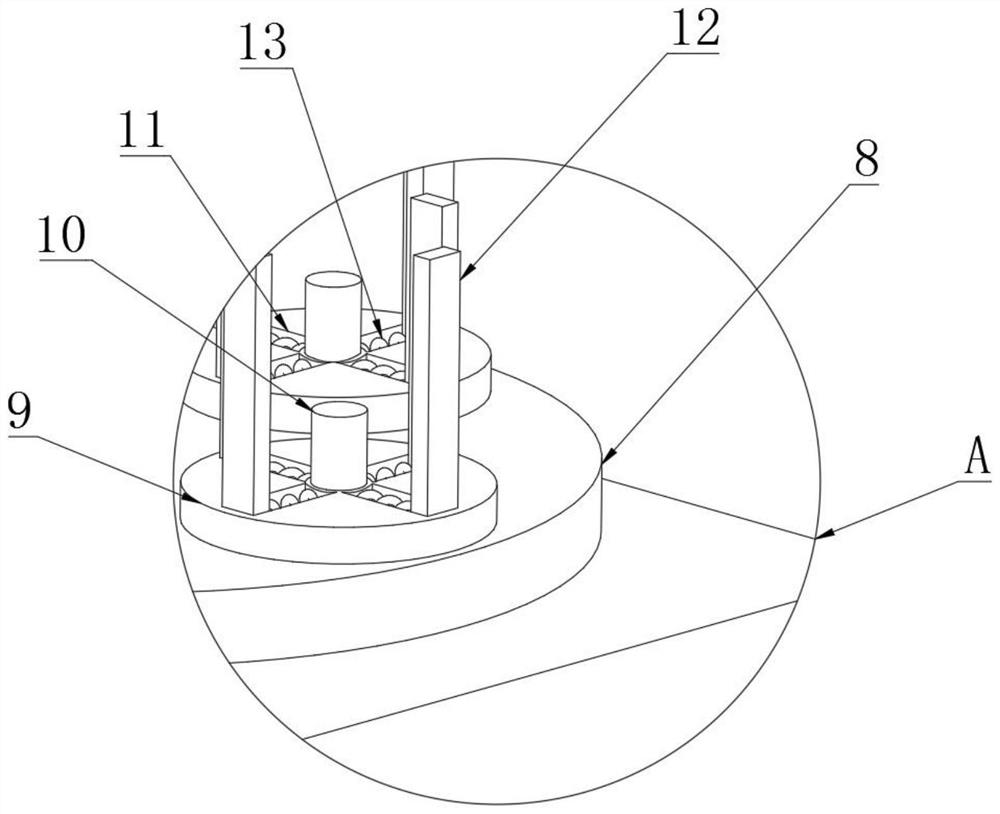

Equipment for spraying PTFE on framework oil seal lip and spraying method of spraying PTFE on framework oil seal lip

ActiveCN111715455AScientific and reasonable structureEasy to usePretreated surfacesCleaning using gasesEngineeringMechanical engineering

The invention discloses equipment for spraying PTFE on a framework oil seal lip and a spraying method of spraying the PTFE on the framework oil seal lip. The equipment comprises a feeding table, wherein a spraying table is fixedly connected to one end of the feeding table, a drying channel is fixedly connected to the other end of the spraying table, a discharging table is fixedly connected to theother end of the drying channel, and conveyors are fixedly connected to positions of adjacent sides of top end of the feeding table and the top end of the spraying table. The equipment is scientific and reasonable in structure and safe and convenient to use, station rotary discs, placement bases, fixing rods, clamping grooves, limiting rods and tension springs are arranged, and products are conveniently stacked in order through the station rotary discs on the feeding table and the discharging table, so that movable clamps conveniently grab the products, the product feeding and discharging speed is increased, the working efficiency is improved, and meanwhile, the limiting rods are pulled through the tension springs to drive the limiting rods to retract along the clamping grooves, and then the station rotary discs conveniently place the products with different specifications.

Owner:陕西奉航科技有限责任公司

Wood-plastic floor processing equipment

ActiveCN112431375AFlexible useEasy to useDrying machines with progressive movementsFlooringAgricultural engineeringStructural engineering

The invention relates to the technical field of wood-plastic floor production, in particular to wood-plastic floor processing equipment. The wood-plastic floor processing equipment comprises a machineframe and a conveying device used for conveying wood-plastic floors. The conveying device comprises a conveying table installed on the machine frame and used for conveying the wood-plastic floors. Arectangular limiting frame used for limiting the periphery of the wood-plastic floors is borne on the conveying table, the positions, located on the two sides of the conveying table, of the machine frame are each provided with a row of guide limiting wheels used for limiting and guiding the left side edge part and the right side edge part of the rectangular limiting frame, and the wood-plastic floors are effectively limited.

Owner:浙江天博生物新材料股份有限公司

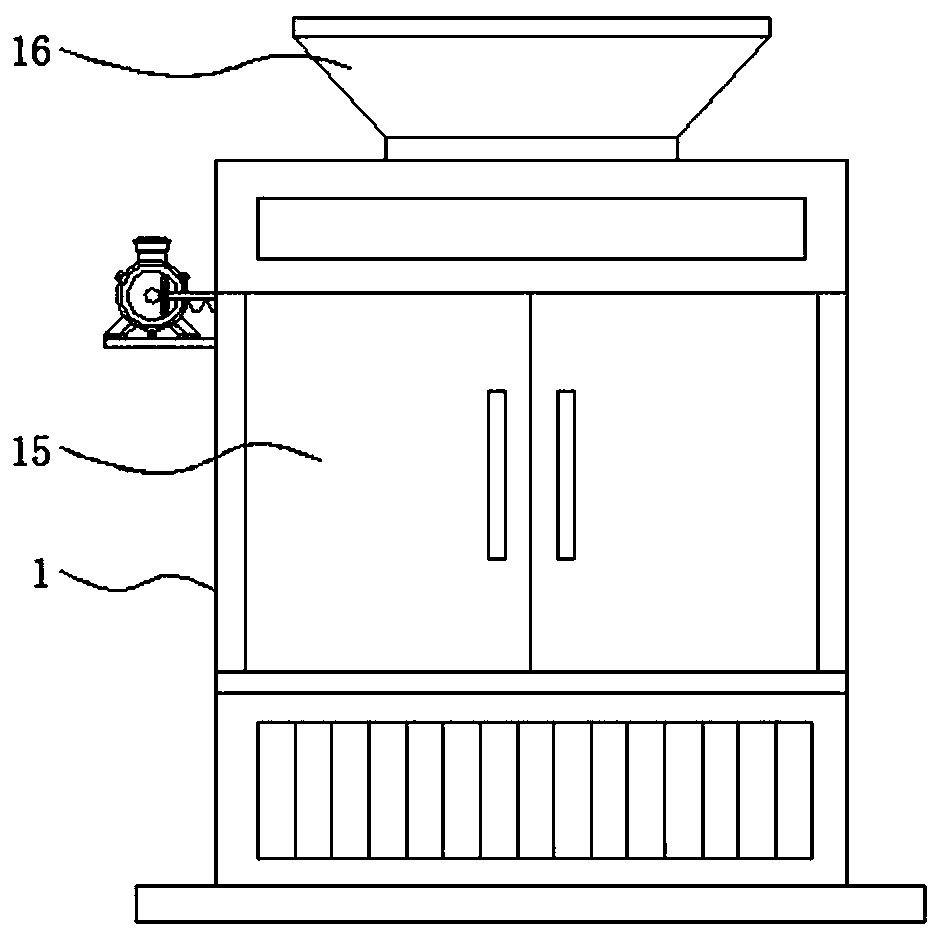

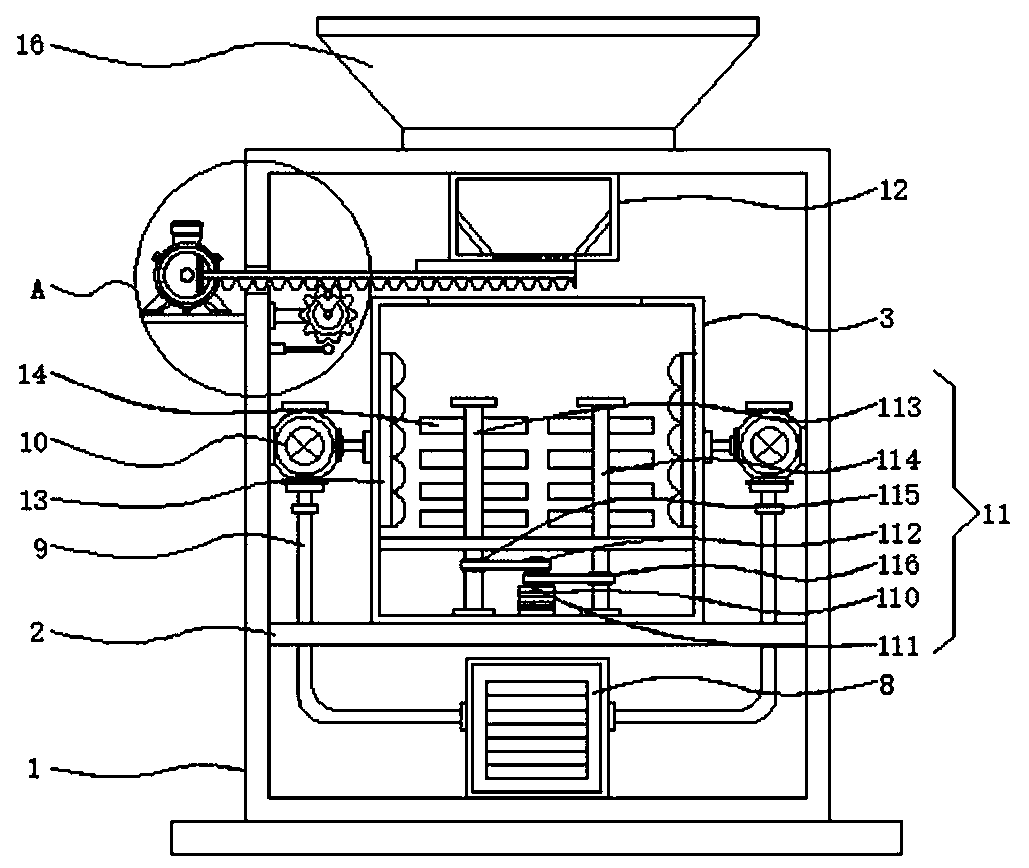

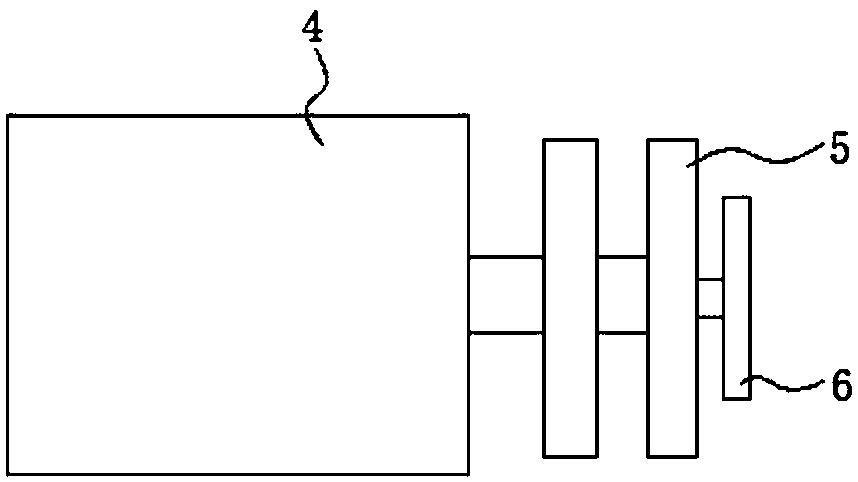

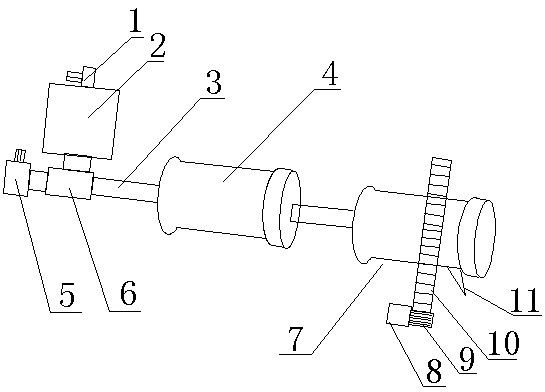

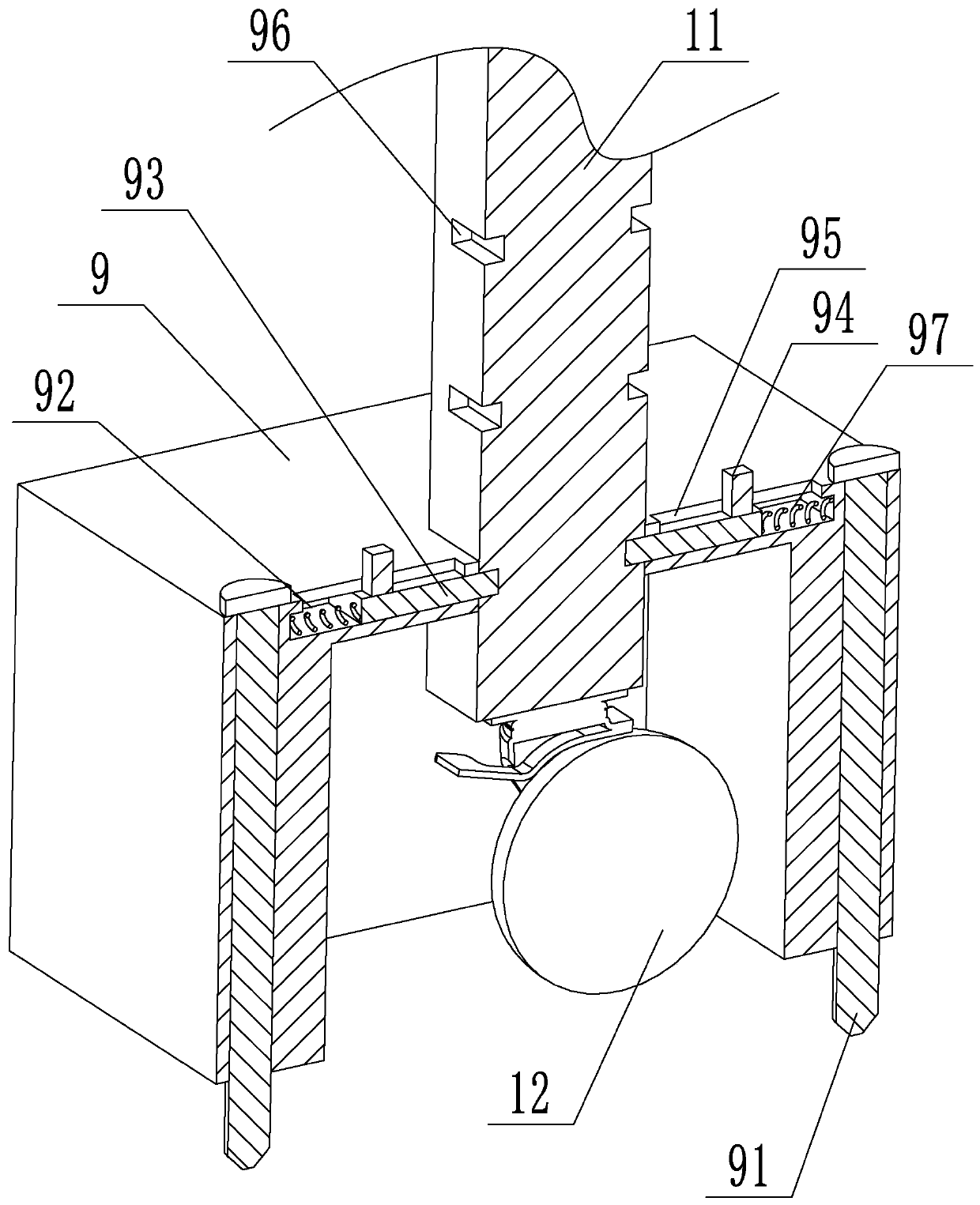

Metal silicon production equipment with automatic screening function

InactiveCN113369127AEasy to disassembleEasy to replaceSievingScreeningProcess engineeringMechanical engineering

The invention discloses metal silicon production equipment with an automatic screening function, and relates to the technical field of metallic silicon production. The metal silicon production equipment comprises a box body, a feeding hopper is arranged in the center of the top of the box body, a vibrating screen is installed in the feeding hopper, a discharging pipe is arranged at the bottom of the box body, a discharging valve is installed on the discharging pipe, a screening mechanism is arranged inside the box body, the screening mechanism is located under the feeding hopper, and a driving mechanism is connected to the lower end of the screening mechanism. According to the metal silicon production equipment, the structure is simple, the practicability is high, the automatic screening function can be achieved, silicon powder of different specifications can be screened out according to the requirements of customers, the screening efficiency is high, the precision is high, and the wide market prospect is achieved.

Owner:济南鹏程硅业有限公司

Environmentally-friendly sludge treatment device

InactiveCN110746080AQuantitativeControl the feeding speedSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusSludgeElectric machine

The invention provides an environmentally-friendly sludge treatment device. The environmentally-friendly sludge treatment device comprises: a box body; a connecting plate, wherein two sides of the connecting plate are fixed to two sides of the inner wall of the box body; a control box, wherein the bottom of the control box is fixed to the top of the connecting plate; and a first motor arranged atone side of the box body through a supporting plate. The environmentally-friendly sludge treatment device can well treat sludge; the first motor is turned on to drive a rotating disc, a straight toothed plate can move left and right, quantification can be well realized, the feeding speed is flexibly controlled, and normal drying of a control box is prevented from being blocked; and a second motoris turned on to make sludge evenly heated in the control box, so the effect of evenly mixing and drying the sludge is achieved, the drying time is greatly shortened, and the drying rate is increased,thereby the practicability of the device is improved.

Owner:榆林市榆阳区水点食品有限公司

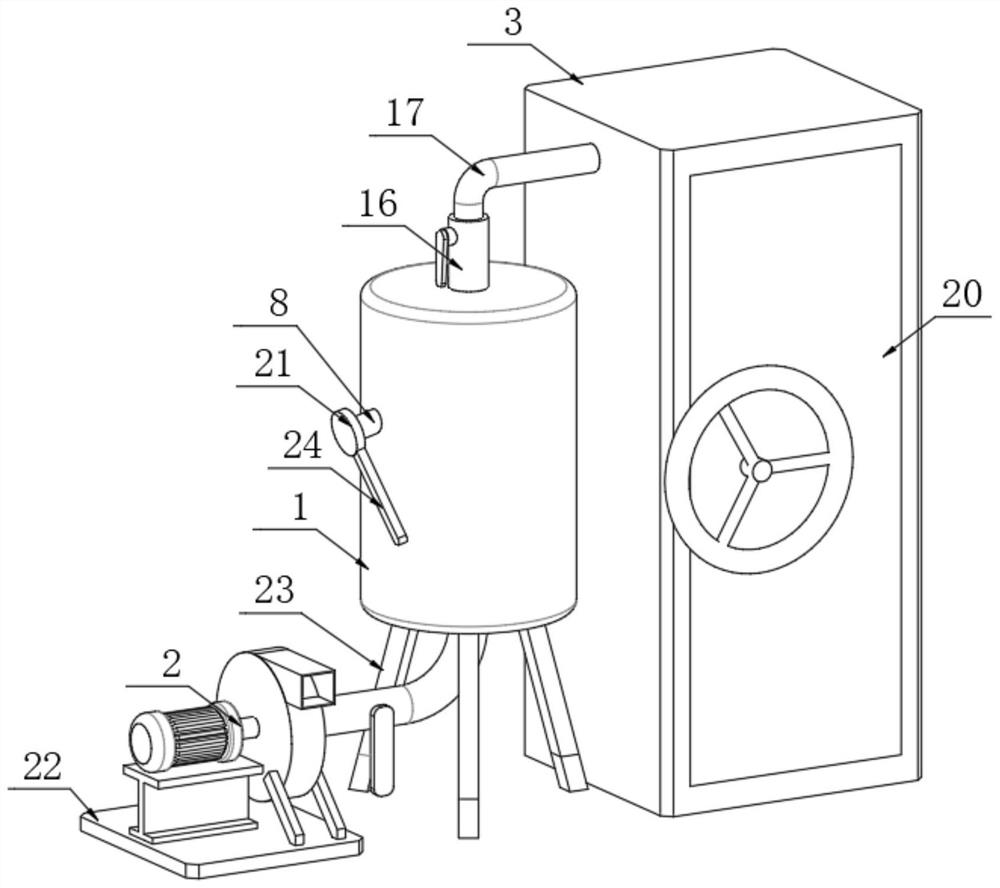

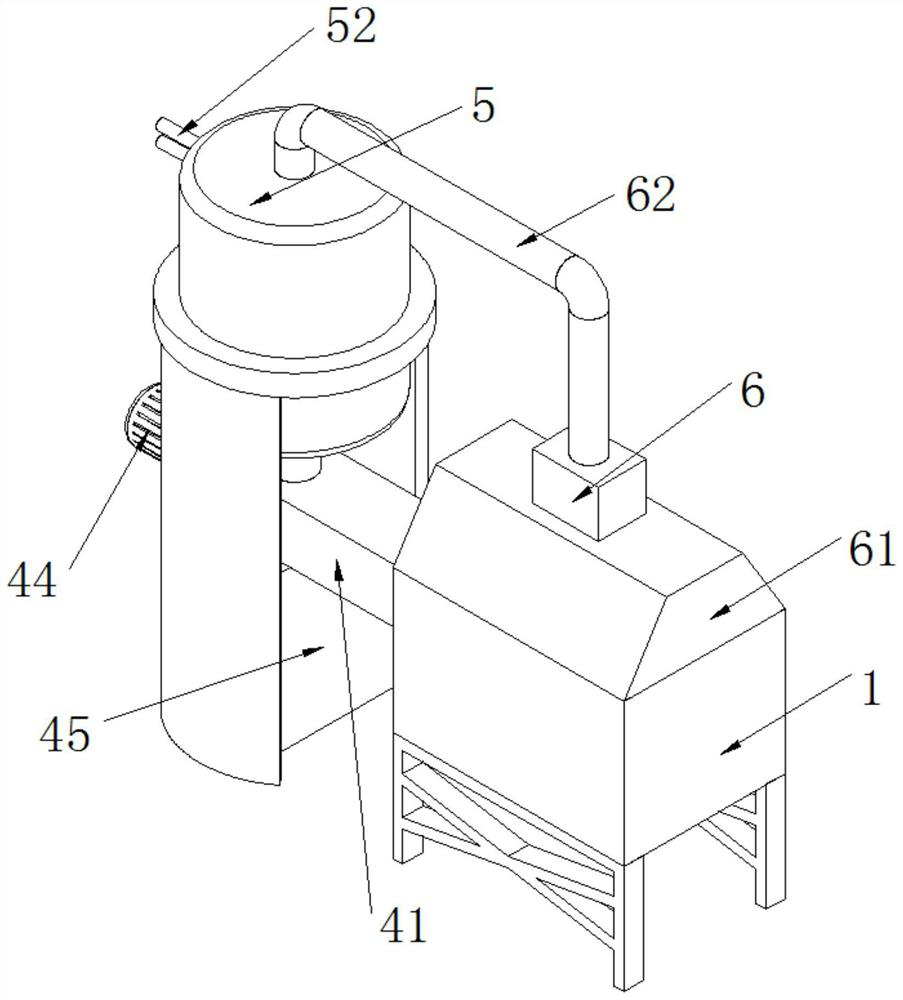

Fertilizer drying and cooling device

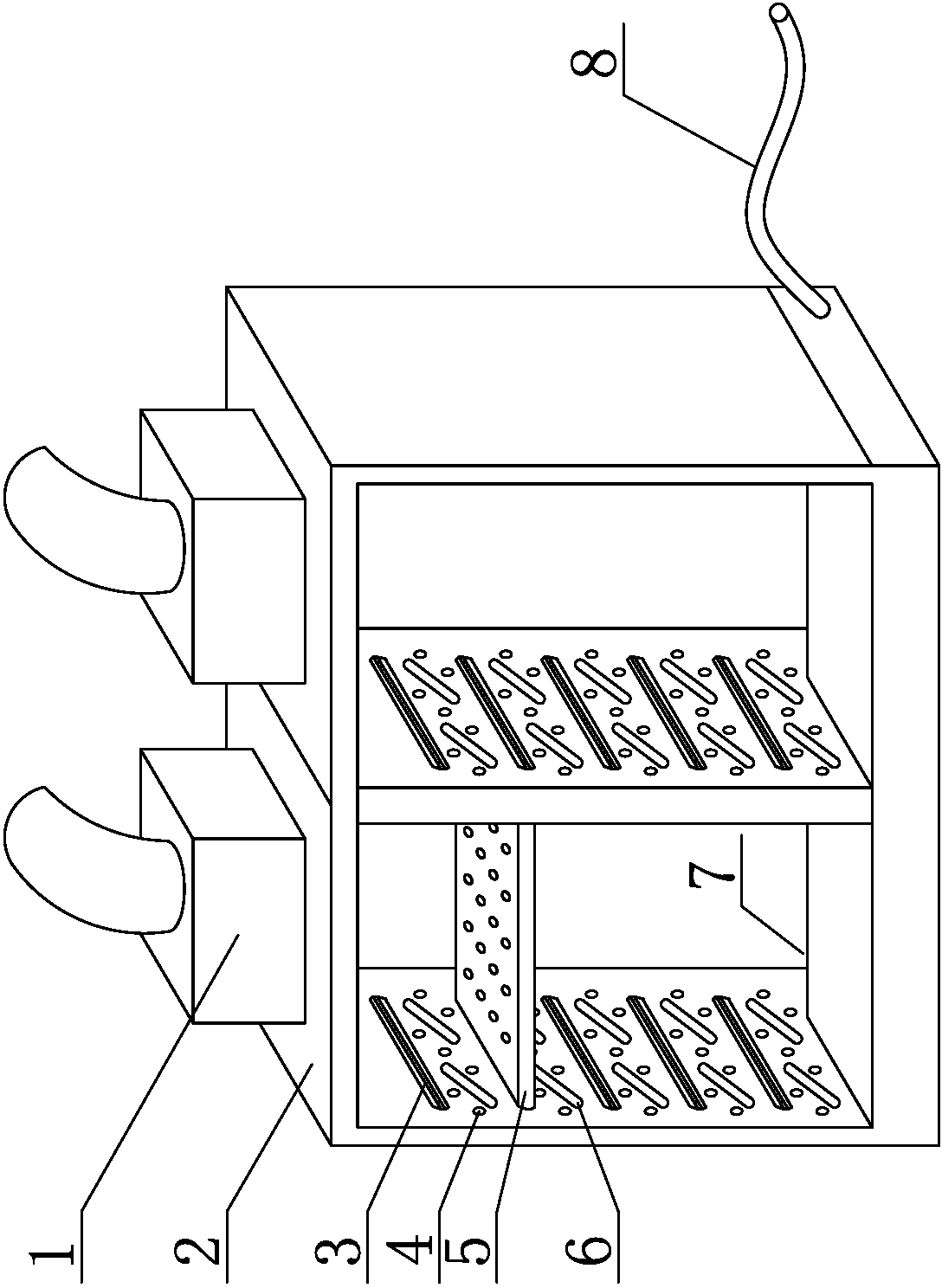

InactiveCN103994644ALarge wind capacityFully heated and driedDrying gas arrangementsDrying machines with non-progressive movementsCooling effectAir blower

The invention discloses a fertilizer drying and cooling device. The fertilizer drying and cooling device comprises a drying case (4) and a cooling case (7). The drying case (4) is connected with an injection induced-draft device (6) through a pipeline (3). The injection induced-draft device (6) is connected with a hot blast stove (2) and an injection induced-draft fan (5) respectively. The hot blast stove (2) is further connected with an air blower (1). The drying case (4) is connected with the cooling case (7) through the pipeline (3). The cooling case (7) is provided with a chain (10), and a motor (8) is arranged below the cooling case (7). A gear (9) is installed on one side of the motor (8). The drying case (4) and the cooling case (7) are placed aslant. The fertilizer drying and cooling device has the advantages that the injection induced-draft fan is adopted, the induced-draft capacity is high, the drying case and the cooling case can rotate, and the drying effect and the cooling effect are good.

Owner:成都市龙泉驿区齐盛机械厂

Disinfection device for infusion tube processing and having drying structure

InactiveCN111588882AEasy injectionWell mixedDrying gas arrangementsLavatory sanitoryElectric machinerySurgery

The invention discloses a disinfection device for infusion tube processing and having a drying structure, and relates to the technical field of infusion tube processing. The disinfection device comprises a machine body, a cleaning and disinfecting box and a traction drying mechanism; supporting columns are fixed below the machine body; furthermore, a supporting plate is fixed in the middle in themachine body; the cleaning and disinfecting box is installed at the left side above the supporting plate; a liquid mixing box is installed above the cleaning and disinfecting box; a liquid injection pipe is connected between the cleaning and disinfecting box and the liquid mixing box; furthermore, a motor is installed above the middle part of the liquid mixing box; a motor shaft is arranged at thelower side of the motor; and stirring blades are fixed outside the motor shaft. The disinfection device in the invention has the beneficial effects that: due to arrangement of a cleaning and disinfecting mechanism, cleaning and disinfecting of an infusion tube body are conveniently achieved; feeding rollers at the two sides of the interior of the cleaning and disinfecting box can conveniently pull the infusion tube body passing through the inlet and outlet positions; and the infusion tube body can be soaked in disinfectant water to be disinfected through pressing rollers.

Owner:东莞市奇趣机器人科技有限公司

Sludge treatment system and pumping device thereof

InactiveCN111472404ASimple structurePlay a protective effectSludge treatment by de-watering/drying/thickeningMechanical machines/dredgersThermodynamicsSludge

The invention relates to a sludge treatment system. The sludge treatment system comprises a base and a shell, wherein the base is connected with a suction device; a cavity is formed in the shell; a heating barrel is rotatably mounted in the cavity; spiral stirring blades are formed on the outer part of the heating barrel; a top cover is arranged on the top of the shell; a heating tube is arrangedon the bottom of the top cover and extends into the heating barrel; the top cover is rotatably connected with the heating barrel; a driving mechanism for driving the heating barrel to rotate is arranged on the bottom of the base; an exhaust tube which communicates with the outside is arranged on the top of the cavity; a discharge hole is formed in the bottom of the cavity; a conveying rack is arranged on the shell; and a conveyor belt is arranged on the conveying rack. The sludge treatment system has the effect of primarily drying pumped sludge.

Owner:BEIJING NO 2 MUNICIPAL CONSTR ENG LTD

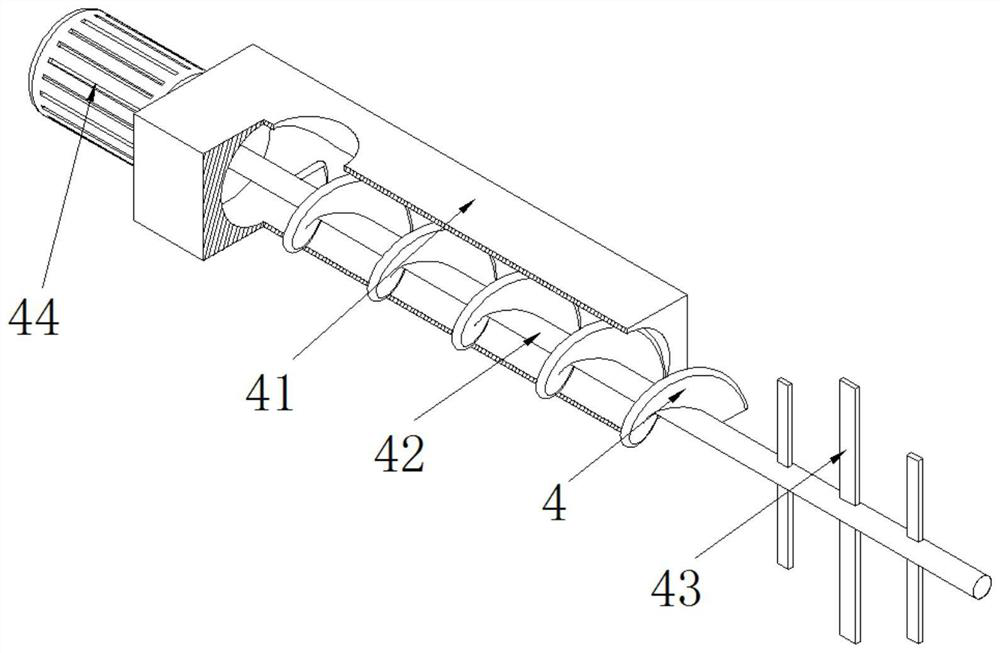

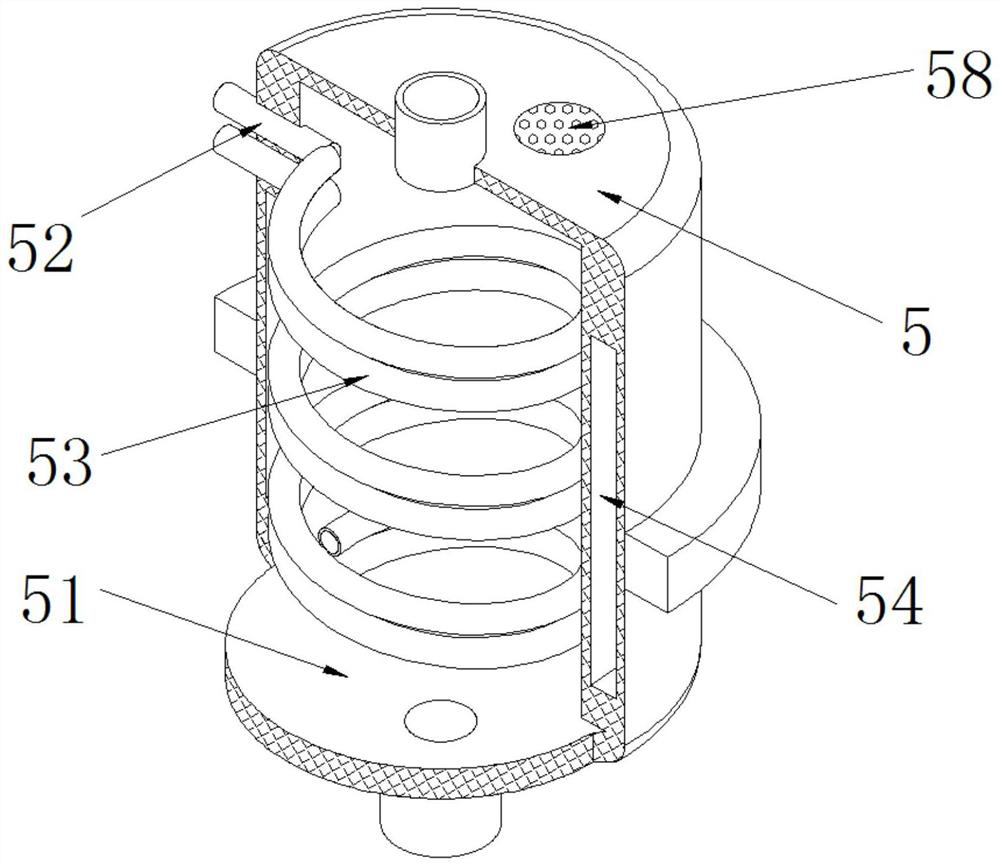

Dry powder premixed mortar production device

ActiveCN114030081ADry fastEasy to heat and dryDischarging apparatusMixing operation control apparatusProcess engineeringMechanical engineering

The invention belongs to the technical field of mortar production, and particularly relates to a dry powder premixed mortar production device which comprises a stirring tank, a stirring cavity is formed in the stirring tank, a discharging opening is formed in the lower end of the stirring tank, a feeding device is installed on the surface of one end of the stirring tank, the feeding device comprises a spiral piece, and the feeding device feeds materials into the stirring tank through the spiral piece; and a drying device is installed on the surface of one end of the feeding device. According to the dry powder premixed mortar production device, raw materials are heated and dried through the drying device, after the raw materials are injected into the heating tank, the storage time of the raw materials in the heating tank is prolonged through the spiral pipe, meanwhile, the heater is started to heat the interior of the heating cavity, the temperature in the heating cavity is increased, and then drying of the raw materials is promoted; and the outer surface of the heating tank is covered with a heat preservation layer, the heat loss rate in the heating tank is reduced through the heat preservation layer, then the use efficiency of the heater is improved, and therefore the raw material heating and drying device has the advantage of facilitating heating and drying of raw materials.

Owner:广西益生宜居建材科技有限公司

A kind of equipment and method for spraying PTFE on lip of skeleton oil seal

ActiveCN111715455BScientific and reasonable structureEasy to usePretreated surfacesCleaning using gasesMechanical engineeringIndustrial engineering

The invention discloses a device for spraying PTFE on the lip of a skeleton oil seal and a spraying method thereof. It includes a feeding table, one end of the feeding table is fixedly connected with a spraying table, and the other end of the spraying table is fixedly connected with a drying channel. The other end of the drying channel is fixedly connected with a blanking table, and the top of the feeding table and the adjacent side of the top of the spraying table are fixedly connected with a conveyor. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. Position turntable, placement seat, fixed rod, card slot, limit rod and tension spring, through the station turntable on the loading table and unloading table, it is convenient to stack the products neatly, so as to facilitate the mobile fixture to grab the products and improve the The speed of product loading and unloading is improved, and the efficiency of work is increased. At the same time, the limit rod is pulled by the tension spring, which drives the limit rod to shrink along the card slot, thereby facilitating the placement of products of different specifications on the station turntable.

Owner:陕西奉航科技有限责任公司

Repeated grinding and filtering equipment for chemical raw material production

InactiveCN111790482APrevent fallingAvoid cloggingSievingScreeningStructural engineeringAnnular array

The invention discloses repeated grinding and filtering equipment for chemical raw material production. The repeated grinding and filtering equipment for the chemical raw material production comprisesa grinding hopper, a grinding roller and a lifting machine, wherein the grinding roller in a circular truncated cone shape is arranged in an inner cavity of the grinding hopper, the distance betweenthe grinding hopper and the upper half portion of the grinding roller is larger than that between the grinding hopper and the lower half portion of the grinding roller, the top end of the grinding roller is connected with a rotating device, a round rod is welded to the inner wall of the grinding hopper, the grinding roller is rotationally connected with the round rod through a bearing block, threesets of inclined supporting rods arranged in an annular array mode are welded to the periphery of the grinding hopper, a vibration filtering device is connected among the three sets of inclined supporting rods, a material passing channel is formed in the side face of the grinding hopper, a heating and drying device is arranged in the material passing channel, the side face of the heating and drying device is connected with the lifting machine, and a belt conveyor is arranged below a discharging opening of the vibration filtering device. The repeated grinding and filtering equipment for the chemical raw material production not only can be used for heating and drying, but also can be used for grinding, filtering and repeated treatment.

Owner:习子林

Cloth drying device for novel textile machine

ActiveCN113587610AEasy to hold and transferQuality improvementDrying chambers/containersDrying machines with progressive movementsProcess engineeringTextile

The invention relates to the technical field of cloth drying, in particular to a cloth drying device for a novel textile machine. The cloth drying device comprises a conveying mechanism, two symmetrical guide mechanisms are mounted in the conveying mechanism, a driving mechanism is mounted on the conveying mechanism, and a drying mechanism is connected in the conveying mechanism; two sliding mechanisms are arranged on the conveying mechanism; cloth with different thicknesses can be conveniently conveyed and flattened through power transmission of the driving mechanism to the conveying mechanism, the cloth in the conveying process can be guided and supported under the action of the guide mechanisms, the cloth is made to have flexibility, and pulling damage is prevented; and the cloth in the conveying process can be dried under the action of the drying mechanism, fine adjustment is facilitated, the drying efficiency is improved, and the sliding mechanisms can work under the action of the driving mechanism, so that the drying mechanism repeatedly moves back and forth in the conveying mechanism, and the drying efficiency is improved.

Owner:响水县嘉亿纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com