A kind of equipment and method for spraying PTFE on lip of skeleton oil seal

A technology of lip spraying and skeleton oil seal, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve problems such as not suitable for mass production, unguaranteed quality, waste of labor, etc., and achieve increase The effect of spraying, safe and convenient to use, and the effect of convenient spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

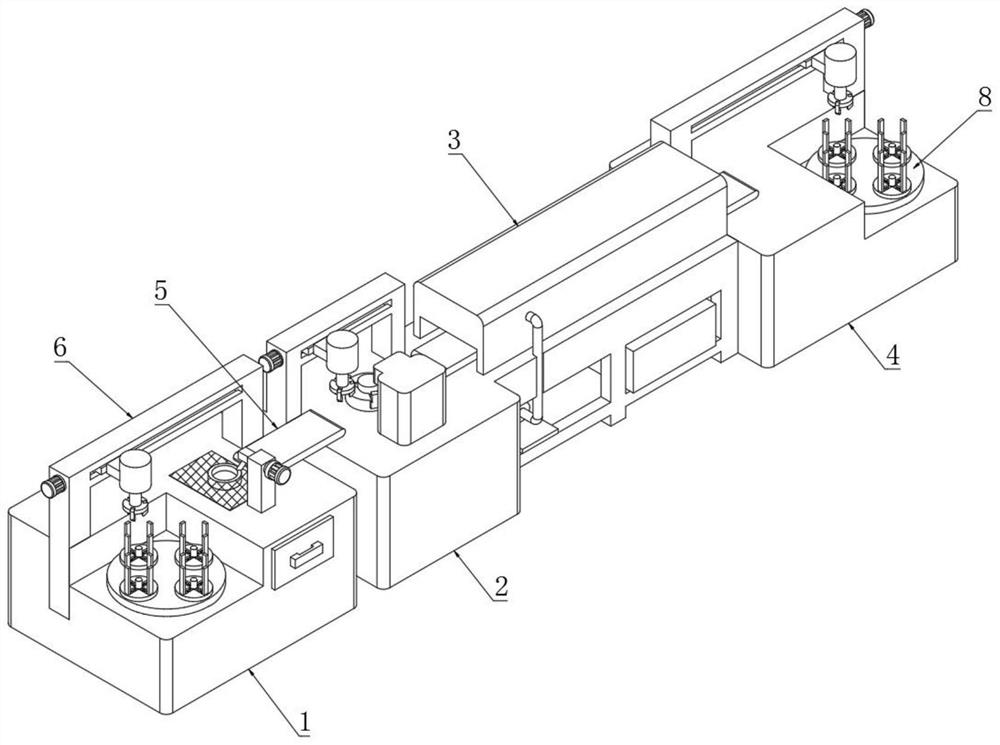

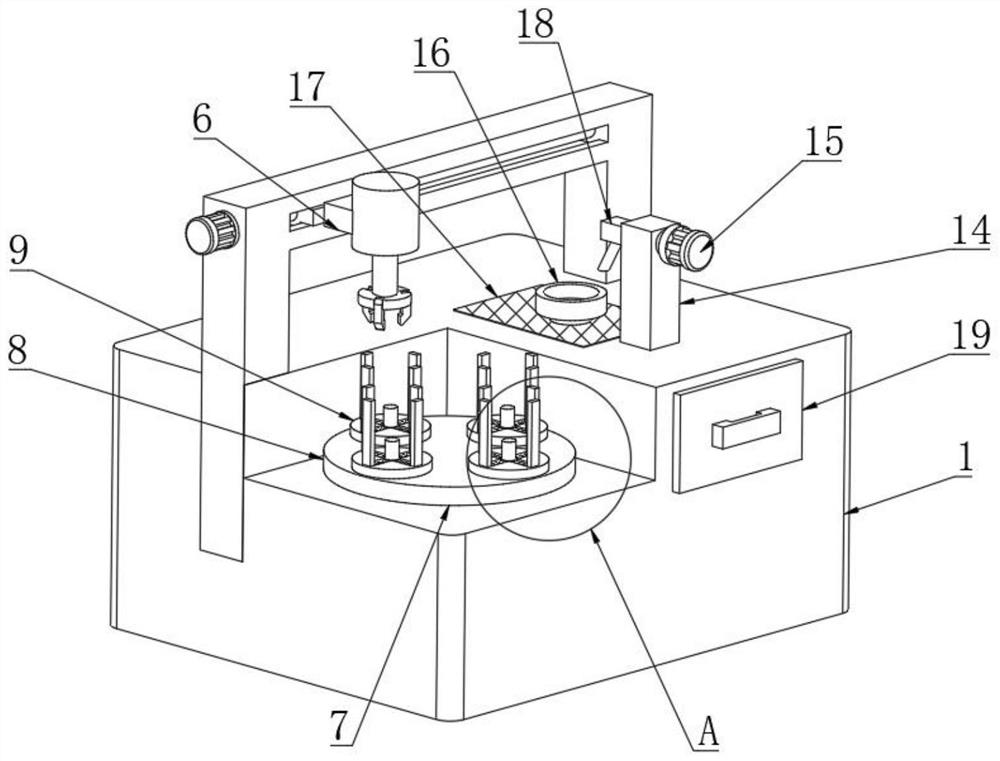

[0045] Example 1: as Figure 1-8 As shown, the present invention provides a technical solution, a device for spraying PTFE on the oil seal lip of a skeleton, comprising a feeding table 1, one end of the feeding table 1 is fixedly connected with a spraying table 2, and the other end of the spraying table 2 is fixedly connected with a drying Dry channel 3, the other end of the drying channel 3 is fixedly connected with the unloading table 4, the top of the loading table 1 and the adjacent side of the top of the spraying table 2 are fixedly connected with the conveyor 5, and the top of the spraying table 2 and the unloading table are fixedly connected 4. The conveyor 5 is fixedly connected to the adjacent side of the top, and the conveyor 5 runs through the drying channel 3;

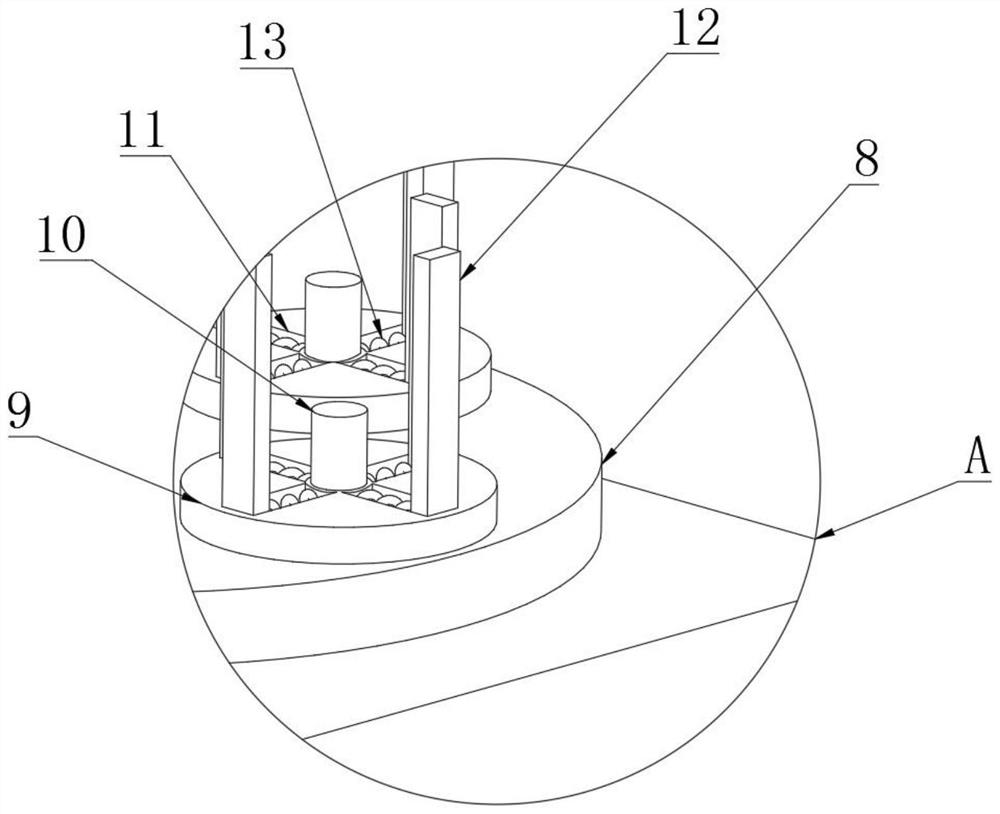

[0046] There is a slot 7 at the top corner of the loading table 1, and the top of the slot 7 is rotatably connected with a station turntable 8. In order to facilitate loading and unloading, the top of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com