Waste plastic recycling equipment

A technology for recycling equipment and waste plastics, applied in the field of waste plastic recycling equipment, can solve the problems affecting the mixing quality of mixed materials, discontinuous processing, time-consuming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

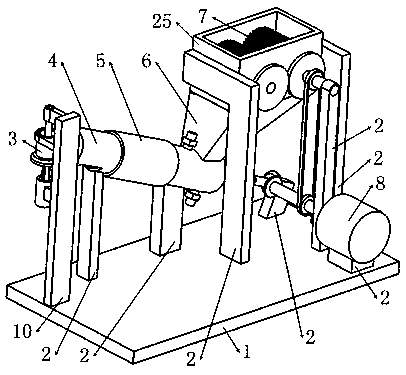

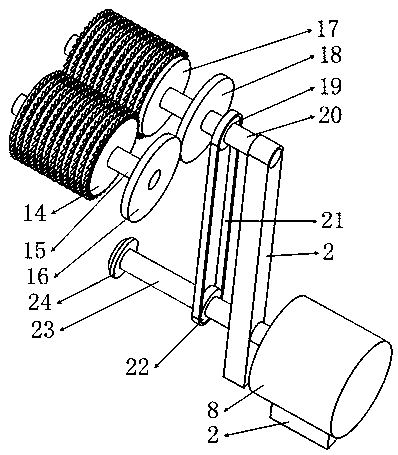

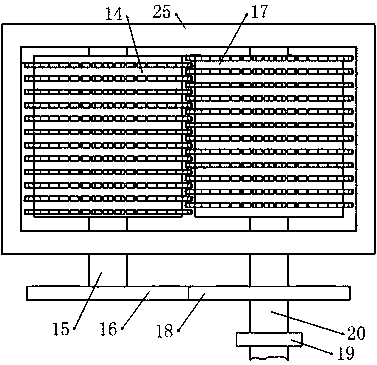

[0032] The structural proportions in the drawings are only schematic, and the structural proportions can be determined according to actual needs.

[0033] A waste plastic recycling equipment, which includes a base 1, a feeding mechanism 3, an electric drive 8, a conveying cylinder 4, a crushing mechanism 7, a telescopic shaft A 13, a screw sleeve 45, a sliding shaft 46, a spiral piece 48, and a telescopic shaft B 32. The water inlet pipe 26 and the drain pipe 27, wherein the base 1 is fixed on the ground; figure 1 , 2 , 10, the crushing mechanism 7, the electric drive 8, and the conveying cylinder 4 with the electric heating jacket 5 installed in the middle are all installed on the base 1 through the support 2 on itself; the conveying cylinder 4 with the discharge port 30 on the lower surface of the top is inclined On the base 1; the crushing mechanism 7 connected with the electric drive 8 transports the crushed plastic to the bottom of the conveying cylinder 4; the A telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com