Sizing device

A sizing device and technology for sizing, which are applied in the processing of textile material equipment configuration, liquid/gas/vapor yarn/filament processing, textile and papermaking, etc. problem, to achieve good sizing effect, strengthen the effect of stirring, and reduce the effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

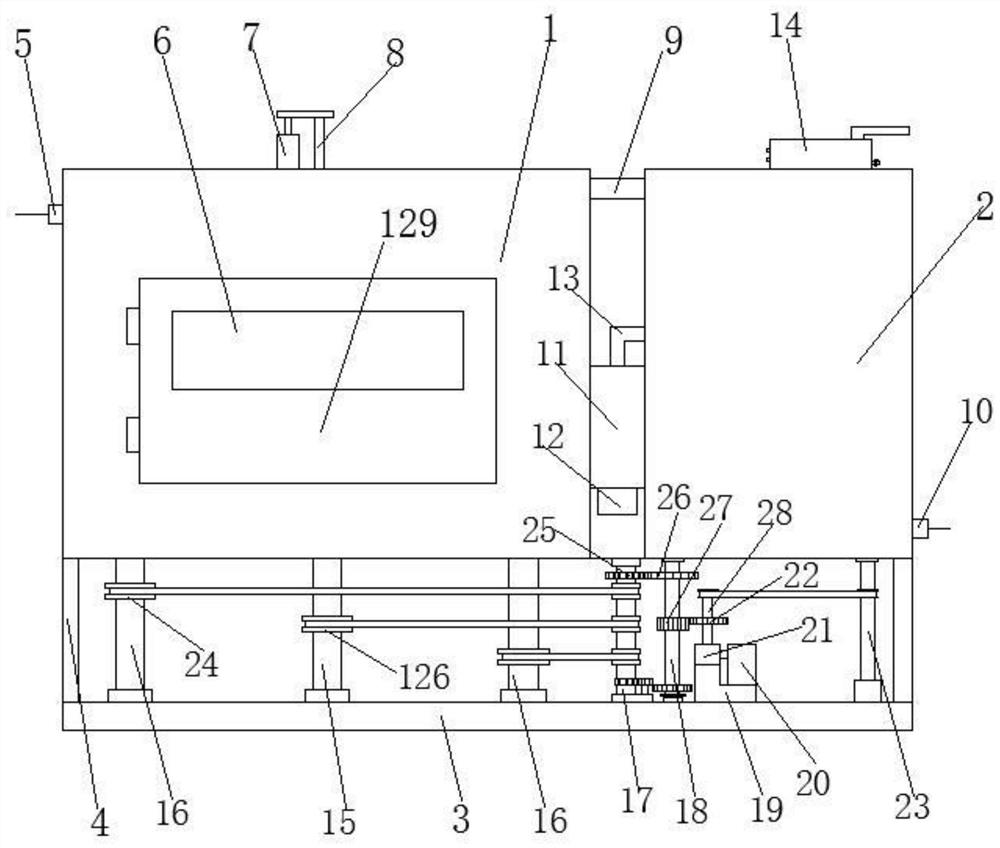

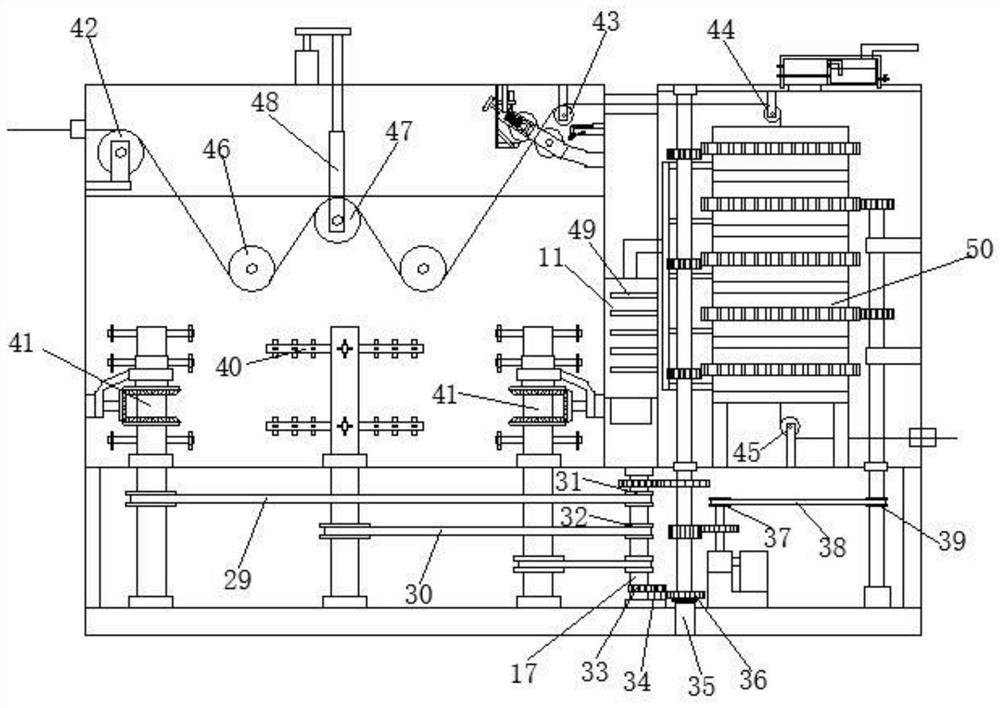

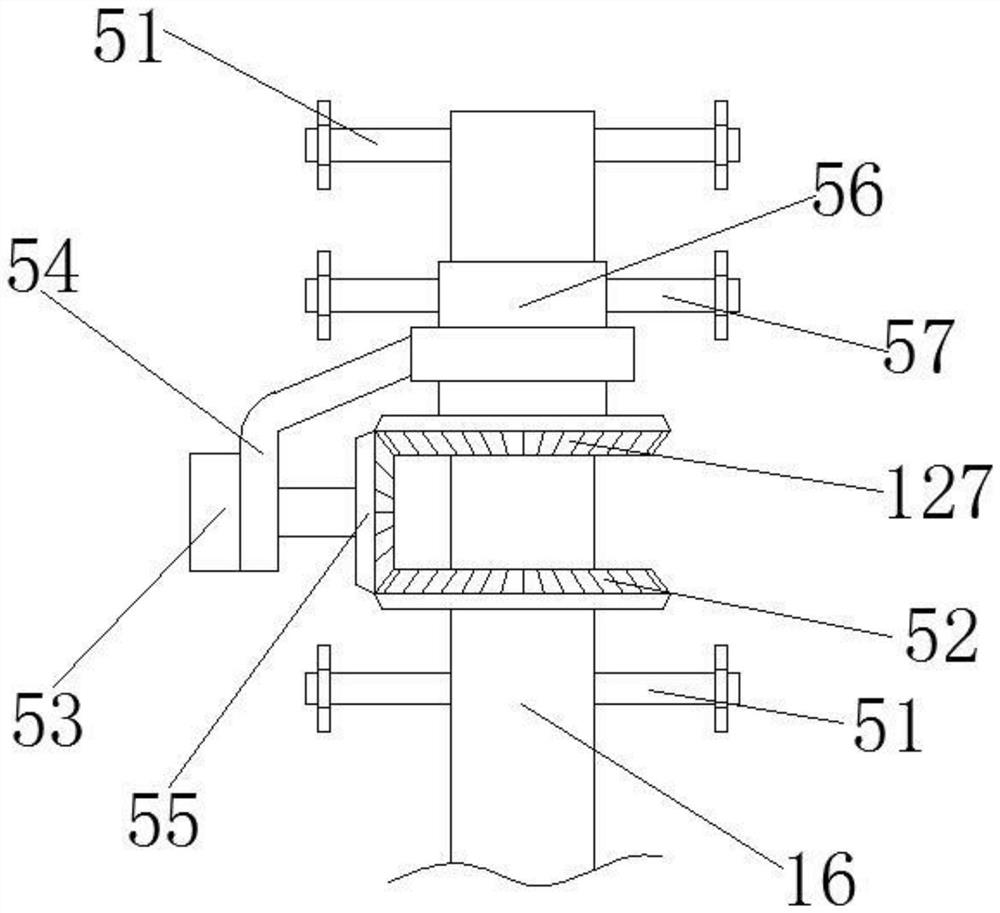

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-11 As shown, a sizing device includes a sizing box 1, a drying box 2, and a base 3, and support columns 4 are respectively connected between the sizing box 1, the drying box 2, and the base 3, and the left side of the sizing box 1 A feed port 5 is provided, a connecting pipe 9 is connected between the sizing box 1 and the drying box 2, and a discharge port 10 is provided on the right side of the drying box 2, and the yarn enters the sizing box 1 from the feeding port 5 After the sizing process, it enters the drying box 2 through the connecting pipe 9 for drying, and finally leaves through the discharge port 10 .

[0028] In the sizing box 1, the position on the right side of the feed inlet 5 is provided with an introduction roller 42; in the sizing box 1, the position on the left side of the connecting pipe 9 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com