Wood-plastic floor processing equipment

A technology of wood-plastic flooring and processing equipment, which is applied in the direction of lighting and heating equipment, heating devices, progressive dryers, etc., can solve the problems of insufficient positioning of wood-plastic flooring and affect the quality of wood-plastic flooring processing, and achieve flexible use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

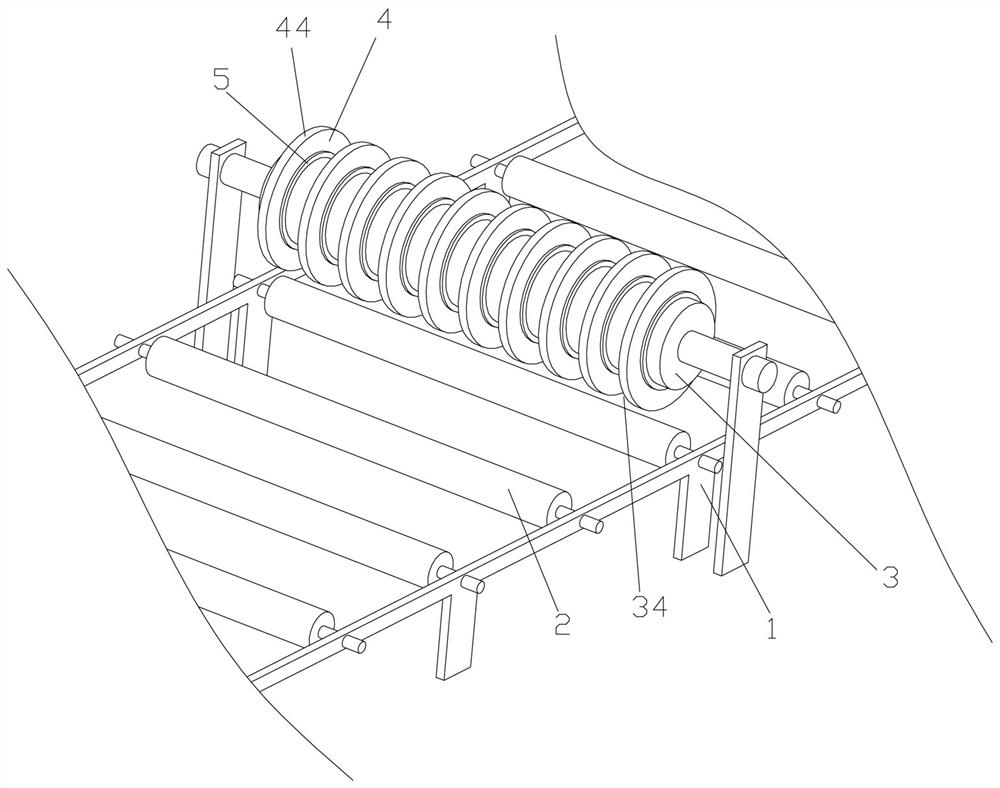

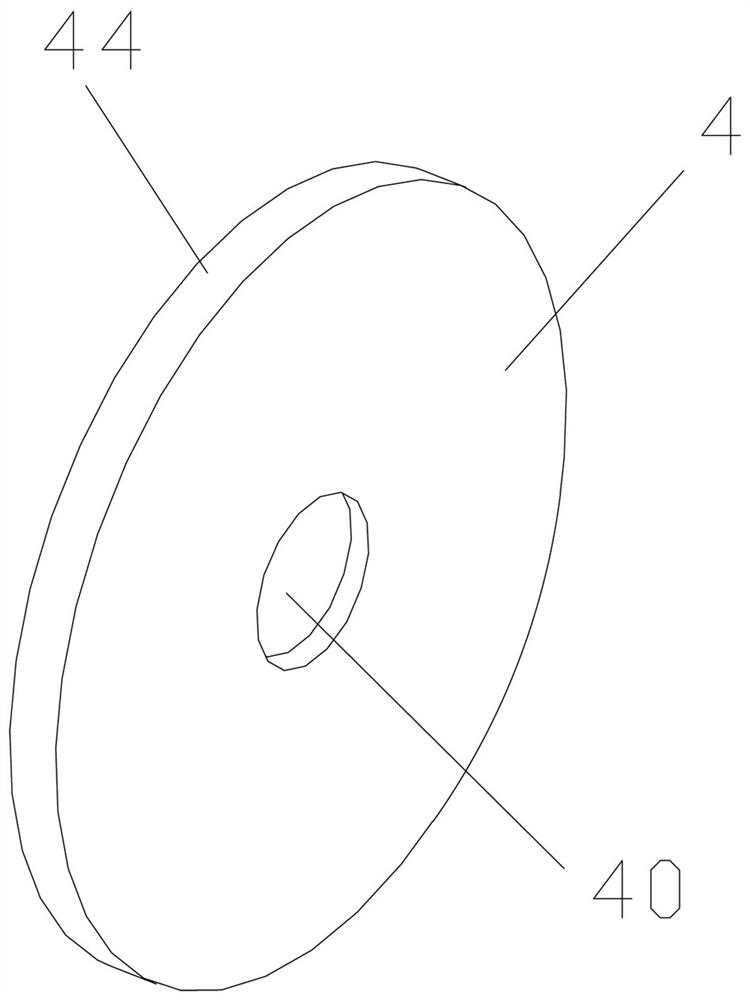

[0030] Example 1, such as Figure 1-10 As shown, a drying device for wood-plastic flooring includes a frame 1 and a conveying table 2 installed on the frame 1 for conveying wood-plastic flooring, and above the conveying table 2 is provided with a The heating body 3, the outer wall of the heating body 3 is sleeved with several heat dissipation and drying sets 4 distributed along the left and right directions of the heating body 3 and used to be close to the upper surface.

[0031] The direction of the conveying platform 2 is set as right rear and forward, that is, the rear end side of the conveying platform 2 is the upstream section, the front end side of the conveying platform 2 is the downstream end, and the two sides on the traveling path of the conveying platform 2 are used as the left and right sides. The heating body 3 can be installed and connected on the frame 1, and is set by the heat dissipation and drying sets 4 arranged at intervals, so that the heat of the heating ...

Embodiment 2

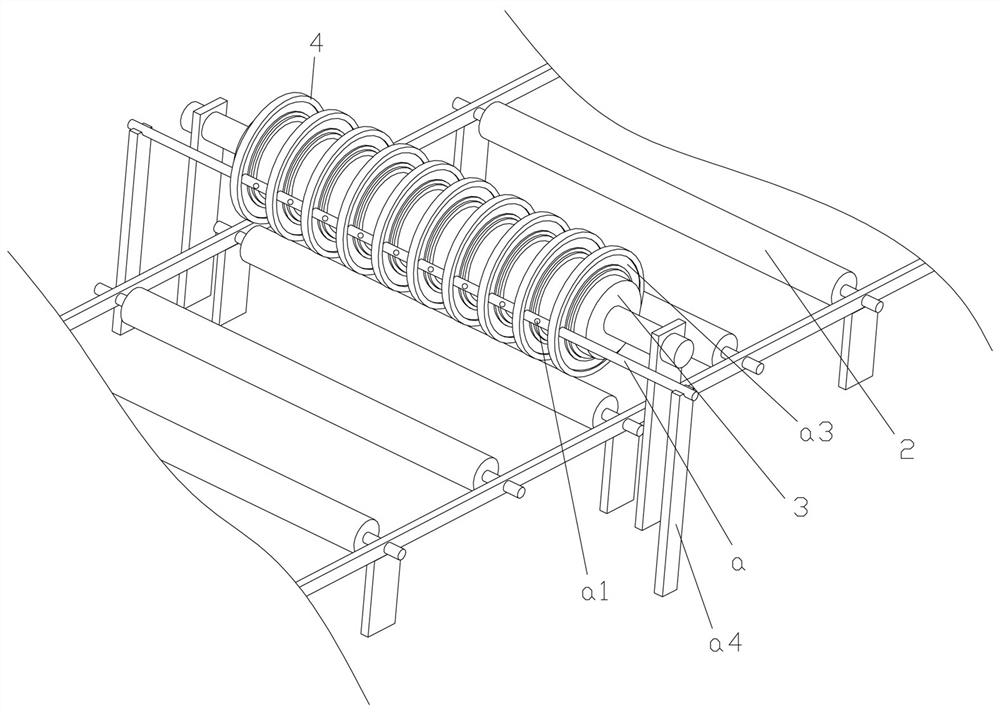

[0039] Embodiment 2, the drawings refer to Embodiment 1, a dust removal device for wood-plastic flooring, including a frame 1 and a heating body 3 installed on the frame 1, the heating body 3 is a heating roller, and the In the heating area of the outer wall of the heating body 3 is provided an air outlet pipe a consistent with the left and right axial direction of the heating body 3 , and the air outlet pipe a has air outlets a1 arranged at intervals along the axial direction of the heating body 3 . In this embodiment, the structure of the drying device in Embodiment 1 can be used to remove dust while heating, so that the quality of subsequent embossing or wire drawing operations is better, and the impact of dust and other impurities on the quality of wood-plastic flooring products is reduced. The outer wall of the heating body 3 forms a heating area due to the presence of air, and the hot air can be blown to the wood-plastic floor for drying and heating through the air outl...

Embodiment 3

[0045] Embodiment 3, the drawings refer to Embodiment 1, a wood-plastic floor processing equipment, including a frame 1 and a conveying device for conveying the wood-plastic floor, the conveying device includes a frame mounted on the frame 1 A conveying platform 2 for conveying wood-plastic flooring, the conveying platform 2 carries a rectangular limit frame b for limiting the surroundings of the wood-plastic floor, and the frame 1 is respectively provided with a A row of guiding and limiting wheels 6 for limiting and guiding the left side and the right side of the rectangular limiting frame b. The rectangular limiting frame b can better limit the wood-plastic floor, so that the wood-plastic floor is not easy to shift, and can perform better drying, dust removal, wire drawing, embossing and other operations. Of course, the height of the rectangular limiting frame b is less than For the wood-plastic floor, the rectangular limiting frame material can be made of high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com