Metal silicon production equipment with automatic screening function

A technology of production equipment and functions, which is applied in the field of metal silicon production equipment with automatic screening function, and can solve the problems of low screening efficiency, complex structure of screening device, large floor space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

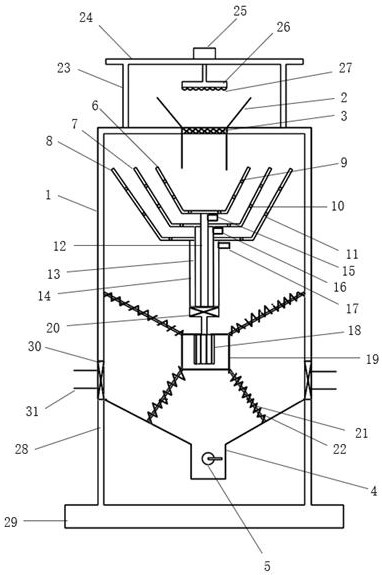

[0029] Such as figure 1 , as shown in 3, a metal silicon production equipment with automatic screening function, comprising a box body 1, a feed hopper 2 is arranged at the center of the top of the box body 1, a vibrating screen 3 is installed in the feed hopper 2, The bottom of the box body 1 is provided with a discharge pipe 4, the discharge pipe 4 is equipped with a discharge valve 5, the inside of the box body 1 is provided with a screening mechanism, and the screening mechanism is located at the bottom of the feed hopper 2. Directly below, the lower end of the screening mechanism is connected with a driving mechanism.

[0030] Further, in the above-mentioned technical scheme, metal silicon enters the box body 1 from the feed hopper 2, and the bulk silicon contained in the silicon is screened out through the vibrating screen 3, and the rest of the silicon powder falls into the screening mechanism for multiple processing. Stage screening, the driving mechanism provides pow...

Embodiment 2

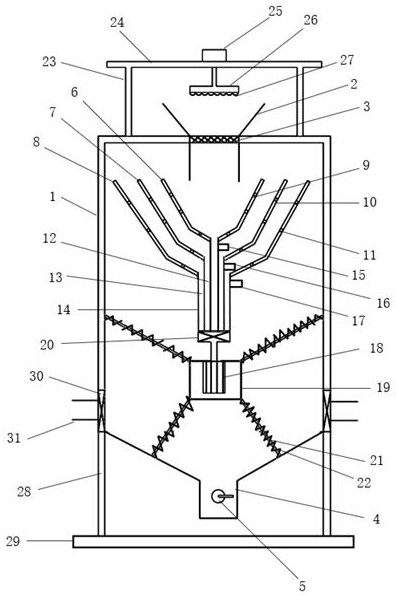

[0046] Such as figure 2 As shown, the bottom of the sieving tank is inclined, with the horizontal line as the reference, the angle of inclination is 45°.

[0047] Further, in the above technical solution, by setting the bottom of the screening tank inclined, it is convenient to increase the feeding speed, thereby improving the production efficiency.

[0048] Working principle: first close the first solenoid valve 15, the second solenoid valve 16, the third solenoid valve 17 and the discharge valve 5, turn on the hot air blower 30, and heat the airflow entering the box body 1 through the air inlet pipe 31, so that the box body The inside of the body 1 maintains a certain temperature. The metal silicon enters from the feed hopper 2, and under the action of the vibrating screen 3, the bulk silicon is screened out and stays on the screen of the vibrating screen 3, and the small particle powder enters the screening mechanism in the box 1 after passing through the vibrating screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com