Special baking oven for silicon material

A technology of oven and silicon material, which is applied in drying, drying machine, drying solid materials, etc., can solve the problems of silicon material drying and other problems, and achieve the effects of accelerated drying speed, smooth running path of hot gas, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

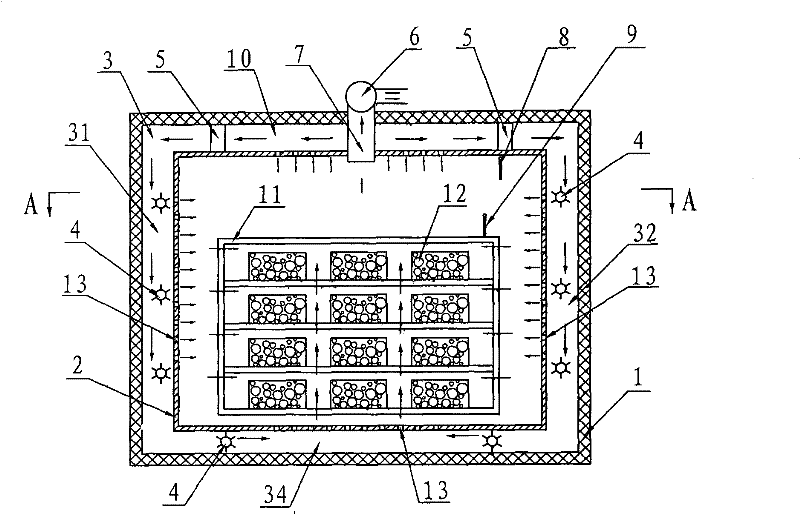

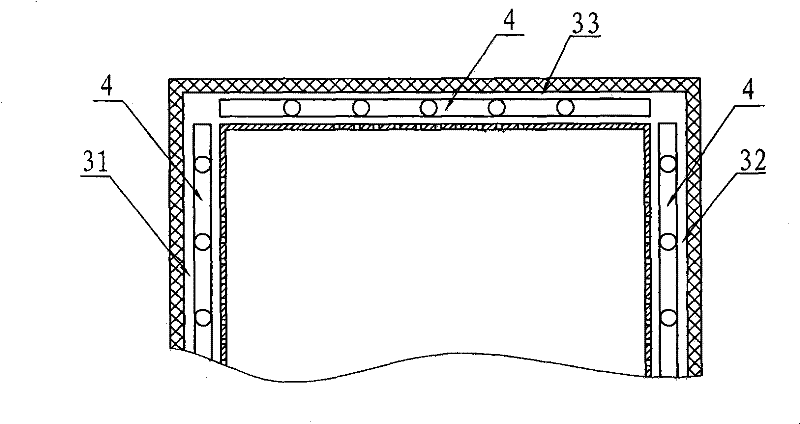

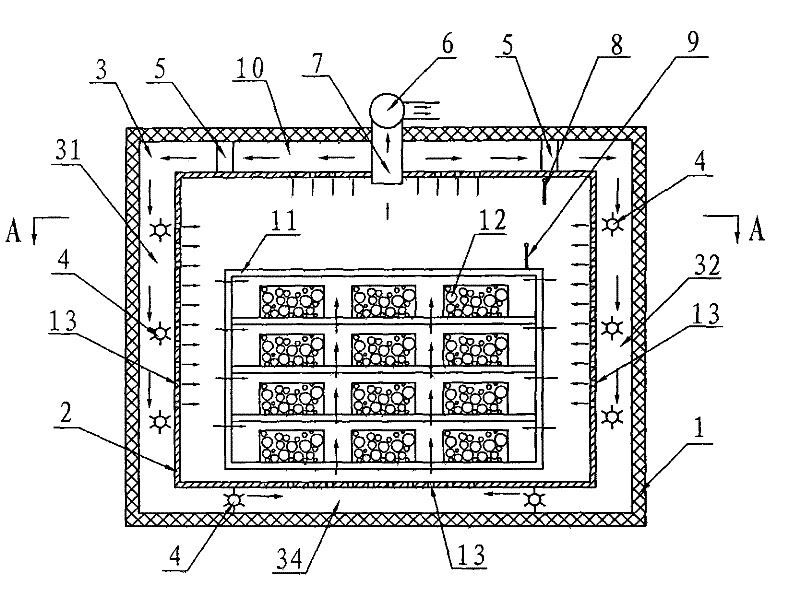

[0010] as attached figure 1 , figure 2 As shown, the special oven for silicon material of the present invention includes a thermal insulation shell 1, an inner tank 2, a heat passage 3, a heater 4, a circulation fan 5, a dehumidification fan 6, a dehumidification pipe 7, a humidity sensor 8 and a temperature Sensor 9, high-temperature air cavity 10, material rack 11, silicon material 12, liner 2 is placed in the heat preservation shell 1, and the top of the liner 2 is provided with a high-temperature air cavity 10, and the high-temperature air cavity 10 is formed by the top of the liner 2 It is combined with the top of the inner cavity of the thermal insulation shell 1, and the thermal air passage 3 is formed between the inner cavity of the thermal insulation shell 1 and the side of the inner tank 2. 32. The rear air duct 33 and the lower air duct 34 are composed of heaters 4 in the left air duct 31, right air duct 32, rear air duct 33 and lower air duct 34, and two circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com