Improved cooling tower

A cooling tower and main frame technology, applied in the field of cooling towers, can solve the problems of power consumption, poor cooling effect of cooling towers, low cooling efficiency, etc., achieve high cooling efficiency, improve efficiency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

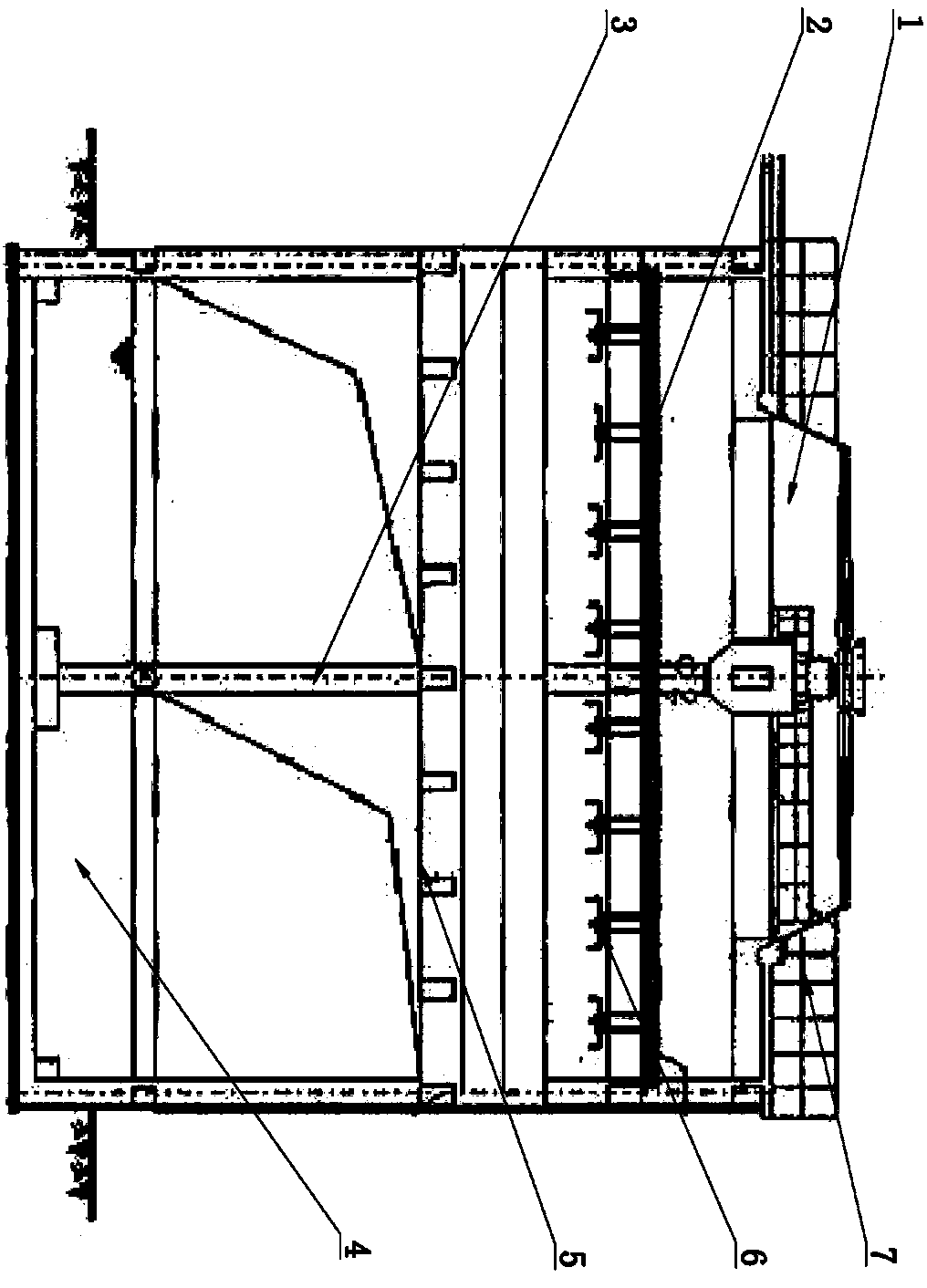

[0014] The purpose of the present invention is achieved as follows: an improved cooling tower, including a main frame, the main frame is arranged longitudinally, characterized in that the main frame is divided into an upper part, a middle part and a lower part, and the upper part is provided with a fan 1. The fan 1 is directly arranged at the top of the main frame, the fan 1 is driven by a driving device 7, and the driving device 7 is fixed on the top of the main frame, and the main frame is provided with a main shaft 3 from top to bottom; The middle part is provided with a cooling spray system. The cooling spray system includes several groups of spray pipes 2, and several groups of nozzles 6 are arranged on the spray pipes 2, and a cooling table is arranged below the spray system. , The cooling workbench is provided with several sets of baffles, the cooling workbench is directly fixed on the main frame, and the cooling workbench is supported by the main shaft 3; between the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com